Preparation method of degradable straw raw material PLA (polylactic acid)

A raw material, polylactic acid technology, applied in the field of preparation of degradable straw raw material PLA polylactic acid, can solve the problems of easily mistaken raw material ratio, complicated steps, weighing of various raw materials, etc., to achieve accurate ratio, scientific and reasonable structure, and use Safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

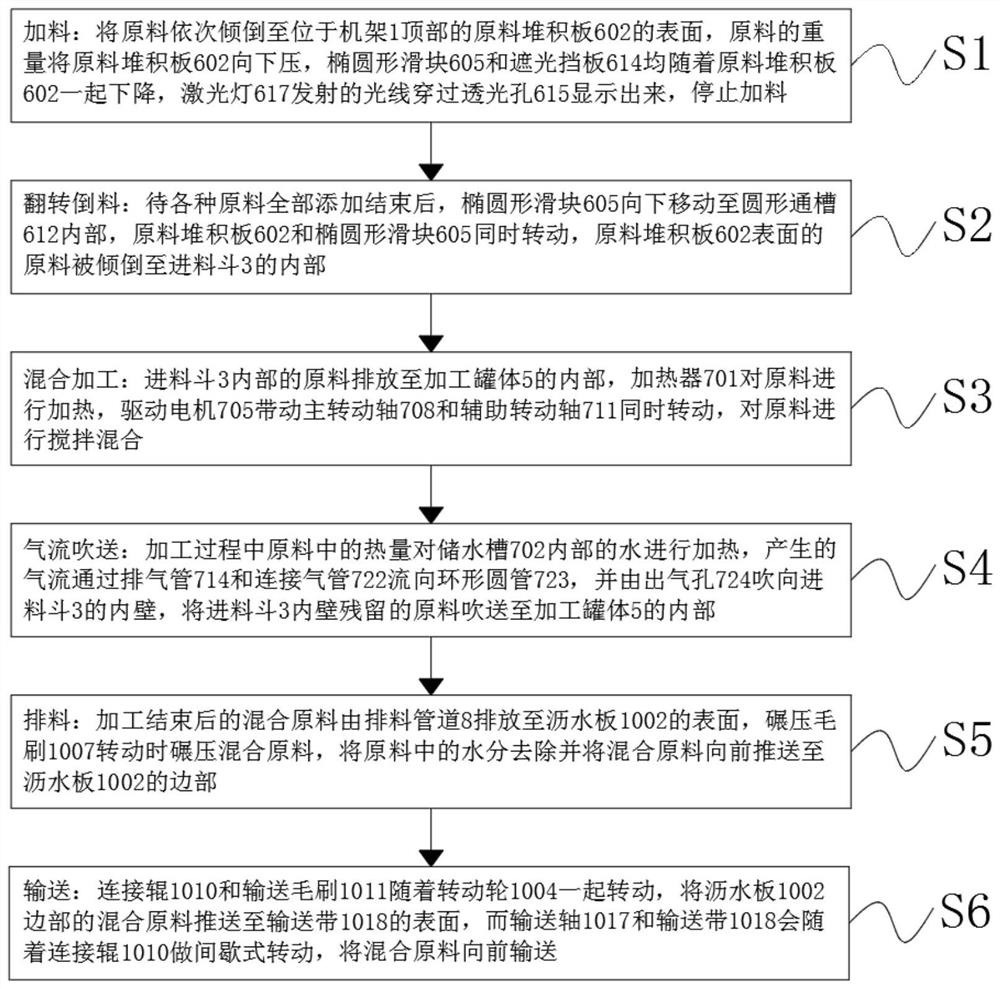

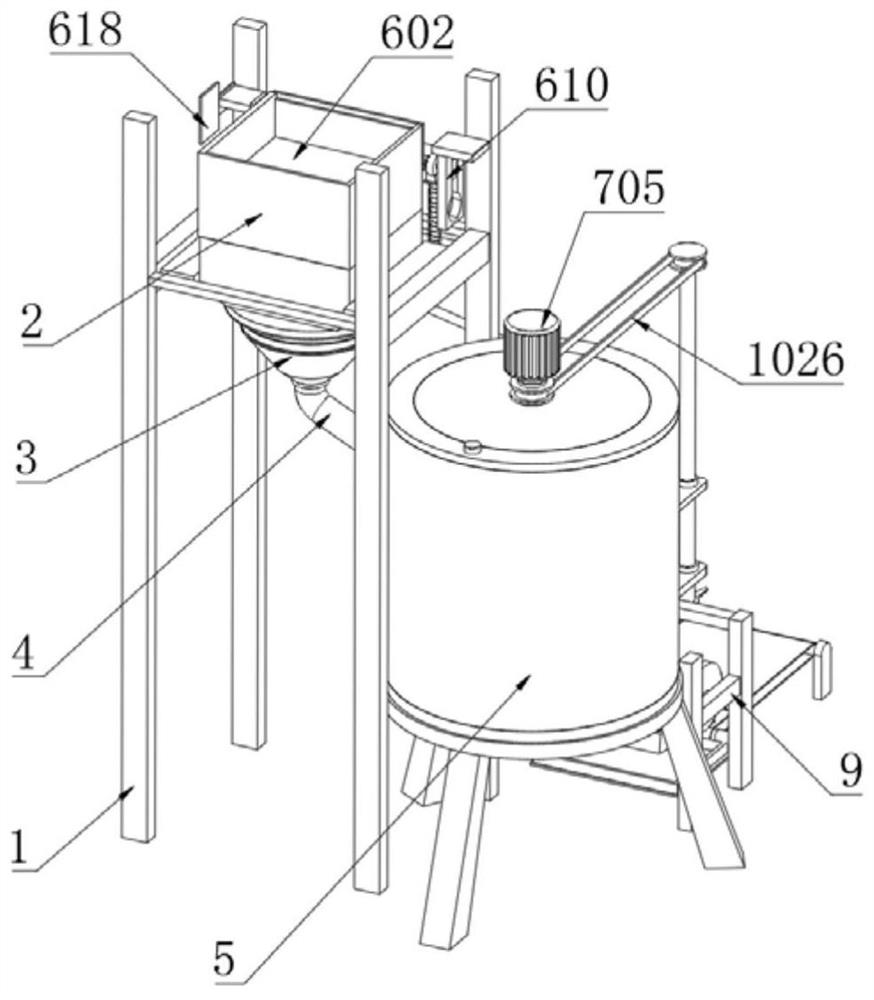

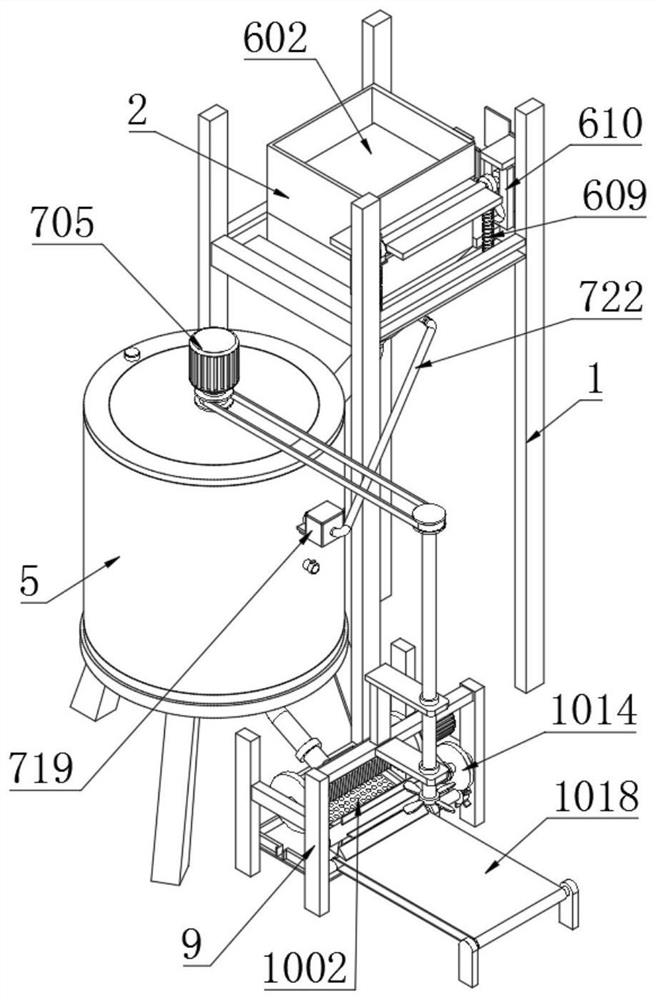

[0040] Example: such as Figure 1-10 As shown, the present invention provides a kind of technical scheme, a kind of preparation method of PLA polylactic acid of degradable straw raw material, comprises the steps:

[0041] S1: Feeding: Pour the raw materials sequentially onto the surface of the raw material stacking plate 602 located on the top of the frame 1, the weight of the raw materials will press the raw material stacking plate 602 downward, and the oval slider 605 and the shading baffle 614 will follow the raw material stacking plate 602 descend together, the light emitted by the laser lamp 617 is displayed through the light-transmitting hole 615, and the feeding is stopped;

[0042] S2: Overturning and unloading: After all the raw materials are added, the oval slider 605 moves down to the inside of the circular channel 612, the raw material accumulation plate 602 and the oval slider 605 rotate at the same time, and the surface of the raw material accumulation plate 602 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com