Glutinous rice drying device

A drying device and glutinous rice technology, applied in the direction of drying and preserving seeds, etc., can solve the problems of inability to dry glutinous rice, waste of fuel, long drying time, etc., and achieve the effect of speeding up the drying of glutinous rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

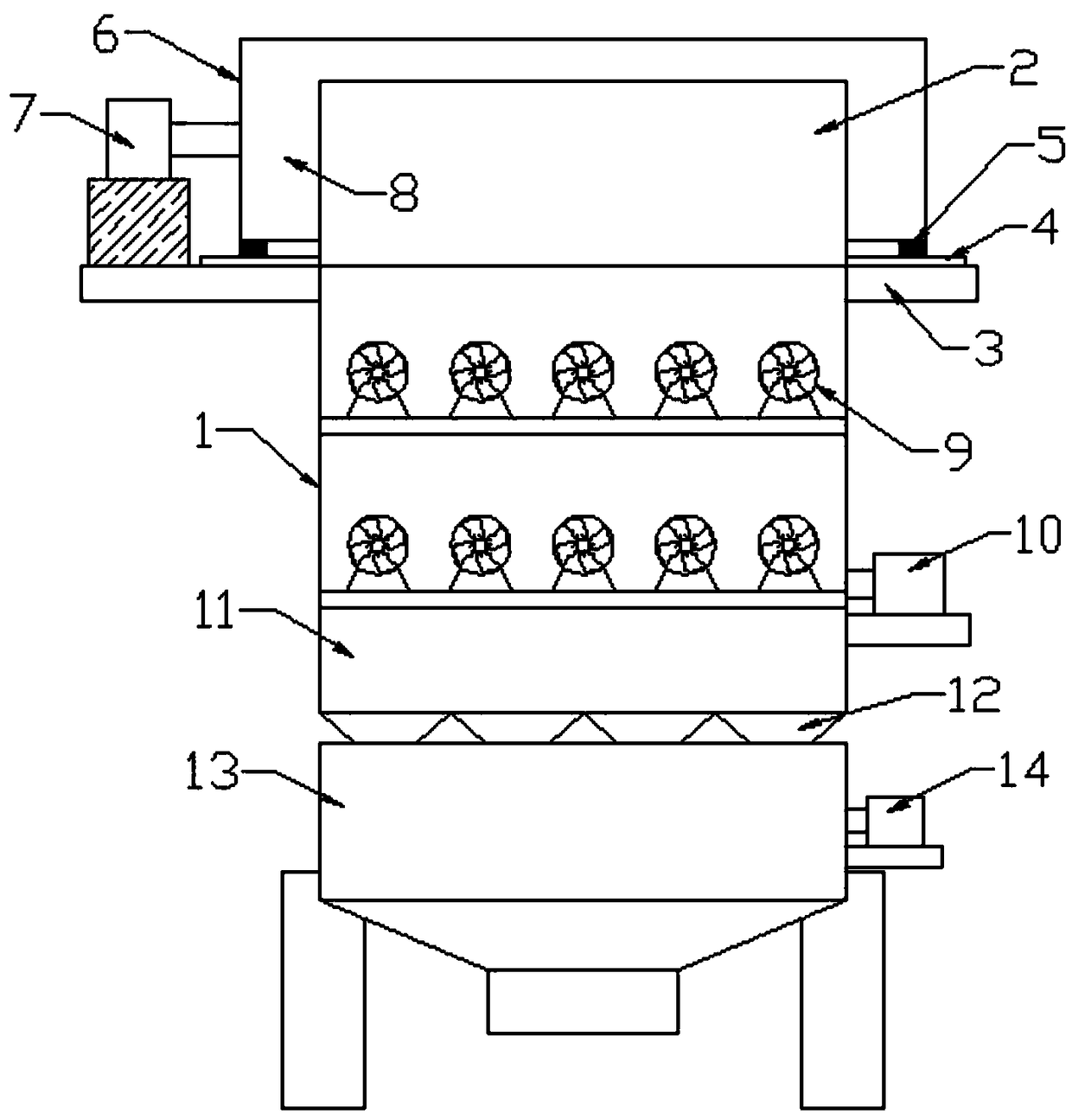

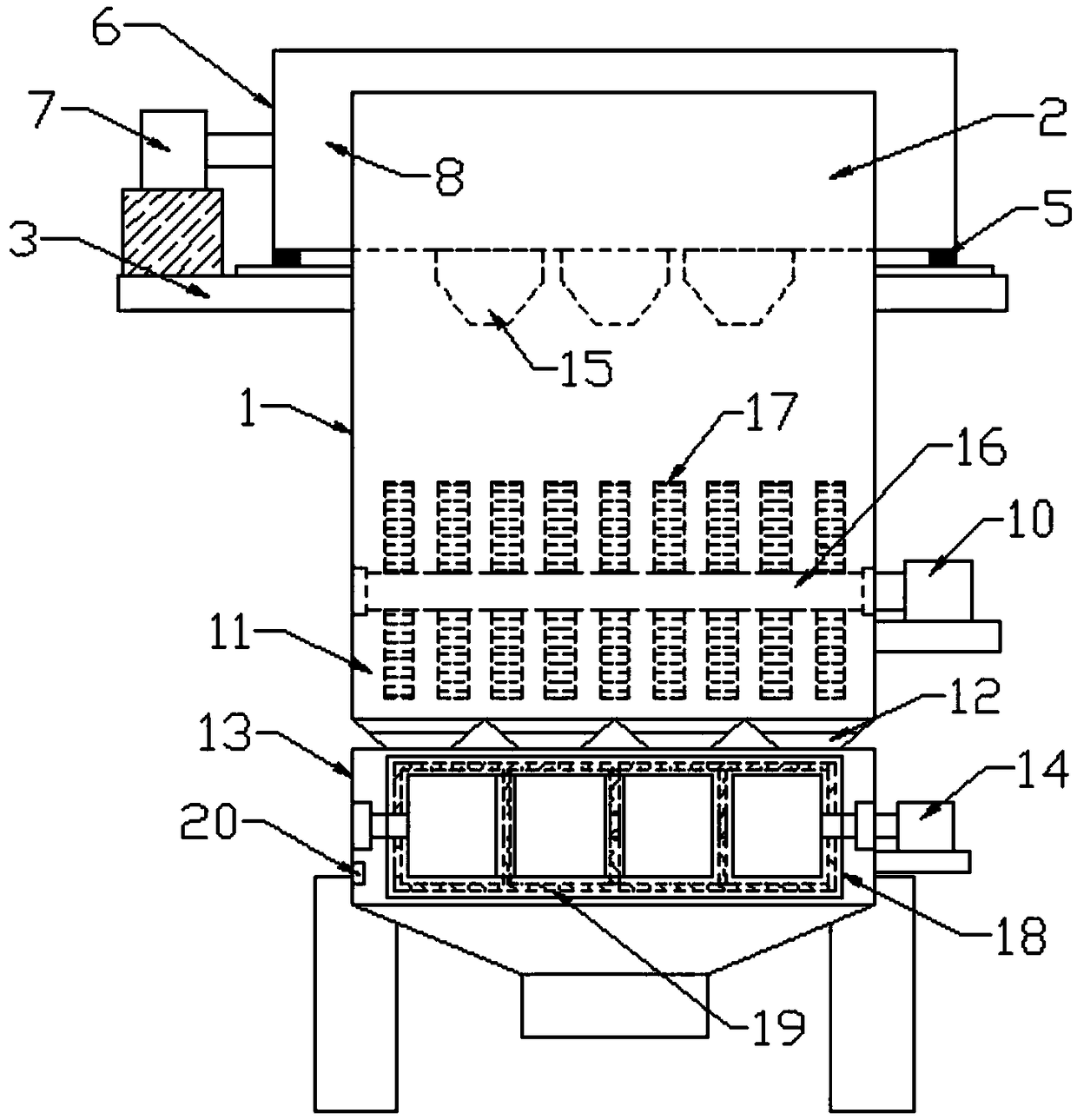

[0026] Such as figure 1 , figure 2 , Figure 4 with Figure 5 As shown, a glutinous rice drying device includes a dryer 1. The inside of the dryer 1 includes a No. 1 drying bin 11 and a No. 2 drying bin 13, and the top of the No. 1 drying bin 11 is provided with a glutinous rice inlet. A movable feeding mechanism 6 is provided above the entrance of the glutinous rice. The movable feeding mechanism 6 includes a storage bin 8 and a plurality of feeding nozzles 15 welded to the lower end of the storage bin 8. The plate of the feeding nozzle 15 A heating cavity 23 is opened inside the heating cavity 23. Several sets of heating resistance wires 19 are arranged in the heating cavity 23. The two ends of the lower end of the storage bin 8 are equipped with sliders 5, and both ends of the glutinous rice inlet of the dryer 1 are welded. The support plate 3 and the upper end surface of the support plate 3 are equipped with a slide rail 4, the movable feeding mechanism 6 is moved along the...

Embodiment 2

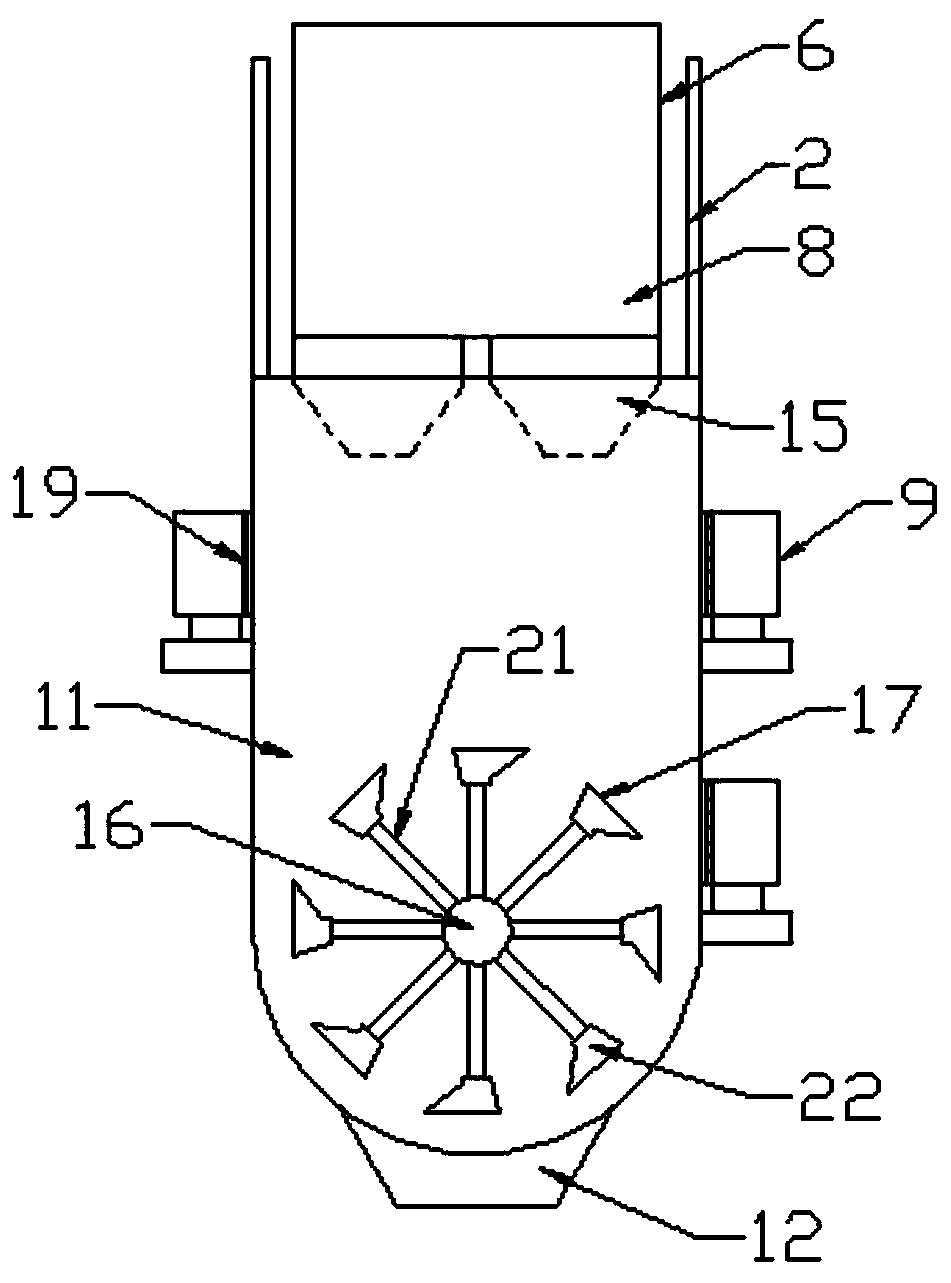

[0029] Such as Figure 1-3 with Figure 7 As shown, the outer wall of the No. 1 drying bin 11 is provided with a No. 1 servo motor, the output shaft of the No. 1 servo motor 10 penetrates the wall of the No. 1 drying bin 11, and the output shaft is connected to the No. 1 through a coupling. The inner connecting shaft 16 of the drying bin 11 is equidistantly arranged on the periphery of the connecting shaft 16 with several groups of No. 1 drying mechanism 17 which includes a number of connecting rods 21 which are welded at equal distances. On the shaft 16, the ends of all the connecting rods 21 far away from the connecting shaft 16 are welded with a material container 22; on both outer walls of the upper part of the No. 1 drying bin 11 are installed several fans 9, all of the fans 9 The air outlets are all set toward the inside of the No. 1 drying chamber 11, and all the air outlets of the fans 9 are installed with heating resistance wires 19; the lower outer wall of the No. 1 dr...

Embodiment 3

[0032] Such as Figure 1-7 As shown, in a glutinous rice drying device, a number of guide tubes 12 are equidistantly opened at the bottom end of the No. 1 drying bin 11, and all the guide tubes 12 are equipped with solenoid valves. The outlet ends are all connected to the inlet end of the No. 2 drying chamber 13. One end of the No. 2 drying chamber 13 is equipped with a No. 2 servo motor 14, and the output shaft of the No. 2 servo motor 14 runs through the wall of the No. 2 drying chamber 13. And the output shaft end is welded with the No. 2 drying mechanism 18, the inside of the No. 2 drying mechanism 18 is provided with a heating cavity 23, and the inside of the heating cavity 23 is provided with a heating resistance wire 19, and the No. 2 drying mechanism 18 is far away from the No. 2 servo One end of the motor 14 is welded with a bottom bracket, which is mounted on the inner wall of the second drying bin 13 through a bearing; a humidity sensor 20 is installed on the wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com