A kind of sludge-coal gangue co-landfilling process

A technology of coal gangue and technology, applied in the field of sludge-coal gangue co-landfill technology, can solve the problems of occupying land and affecting the ecological environment, and achieve the effects of promoting contribution, improving environmental quality, and accelerating drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A sludge-coal gangue co-filling process test was carried out at a dewatered sludge landfill in Jincheng City, Shanxi Province.

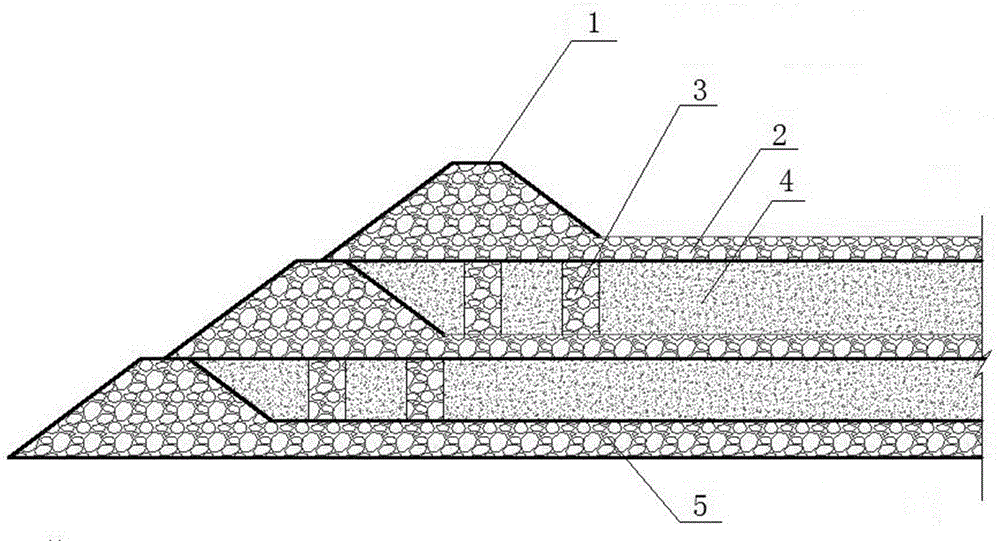

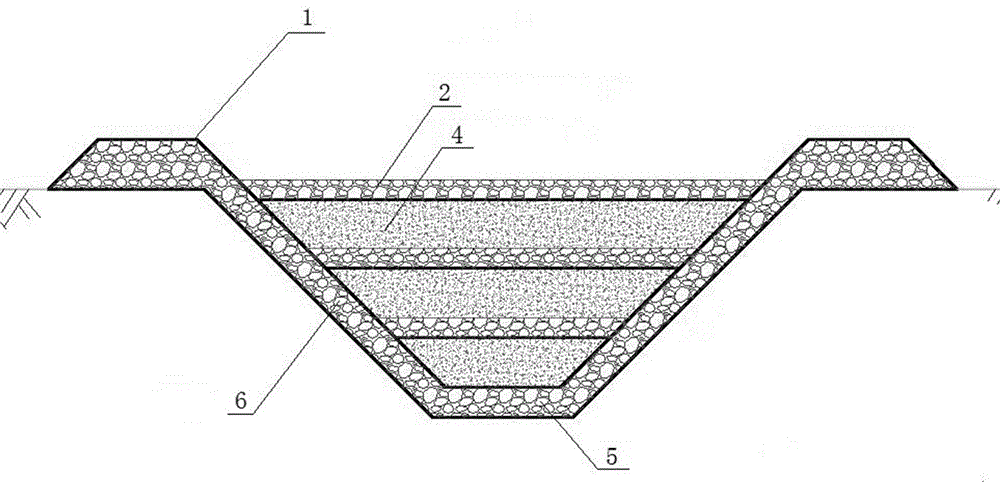

[0026] A kind of dewatered sludge-coal gangue landfill process comprises the following steps:

[0027] Step 1: Pour dewatered sludge with a water content of 85% from Jincheng Sewage Treatment Plant into the mixer, and then add a desiccant to the mixer. The desiccant is a mixture of fly ash and quicklime. When adding, follow the Dewatered sludge: fly ash: quicklime=80:15:5 volume ratio, turn on the mixer, adjust the speed of the mixer to medium speed, 60-100r / min, stir for 20min, and put the stirred dewatered sludge mixture from the mixer Unloaded in the middle, and dried naturally for 30 minutes, so that the moisture content of the dewatered sludge was reduced to 70%.

[0028] Step 2: The coal gangue pulled by Shanxi Jincheng Anthracite Mining Group Co., Ltd. is crushed by a crusher and screened, so that the coal gangue becomes uniform partic...

Embodiment 2

[0032] A sludge-coal gangue co-filling process test was carried out at a dewatered sludge landfill in Jincheng City, Shanxi Province.

[0033] A kind of dewatered sludge-coal gangue landfill process comprises the following steps:

[0034] Step 1: Pour the dewatered sludge with a water content of 75% from Jincheng Sewage Treatment Plant into the mixer, and then add a desiccant to the mixer. The desiccant is a mixture of fly ash and quicklime. When adding, follow the Dewatered sludge: fly ash: quicklime=80:15:5 volume ratio, turn on the mixer, adjust the speed of the mixer to medium speed, 60-100r / min, stir for 20min, and put the stirred dewatered sludge mixture from the mixer Unloaded in the middle, and dried naturally for 30 minutes, so that the moisture content of the dewatered sludge was reduced to 65%.

[0035] Step 2: The coal gangue pulled by Shanxi Jincheng Anthracite Mining Group Co., Ltd. is crushed by a crusher and screened, so that the coal gangue becomes uniform pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com