Adjustable positioning conveying table for plastic extruding plate machining device

A technology of processing device and conveying table, which is applied to conveyor objects, transportation and packaging, general parts of printing machinery, etc., can solve problems such as affecting processing operations, unstable shaking of extruded boards, and inability to position and fix extruded boards. Achieve better and smoother conveying, easy promotion and application, and reduce frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

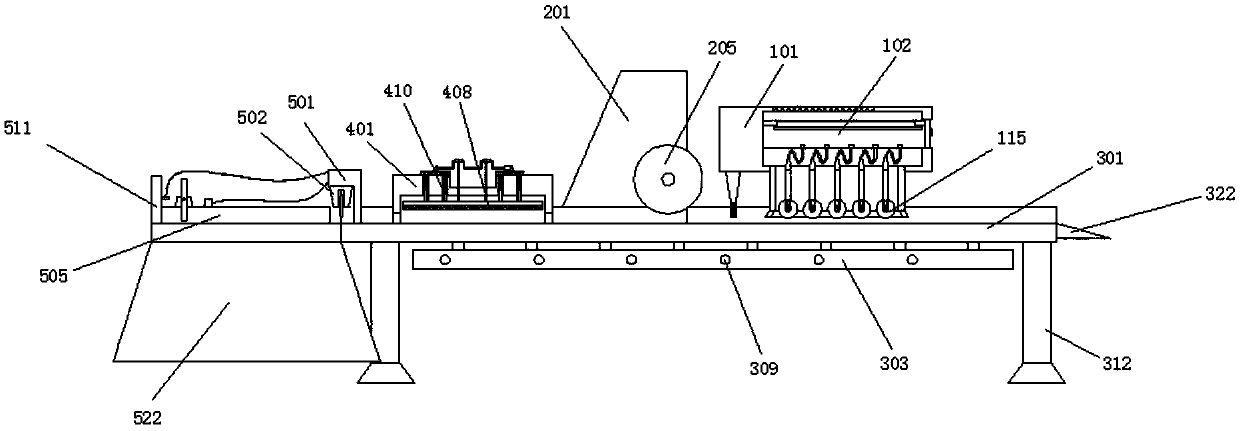

[0049] Embodiment 1: as Figure 1-22 As shown, an adjustable positioning conveyor table for extruded board processing equipment includes a conveyor table 301, and the top side of the conveyor table 301 is fixedly installed with a dust removal chamber 101, a printing table 201, and a drying chamber 401 in sequence from right to left. And beam frame 501.

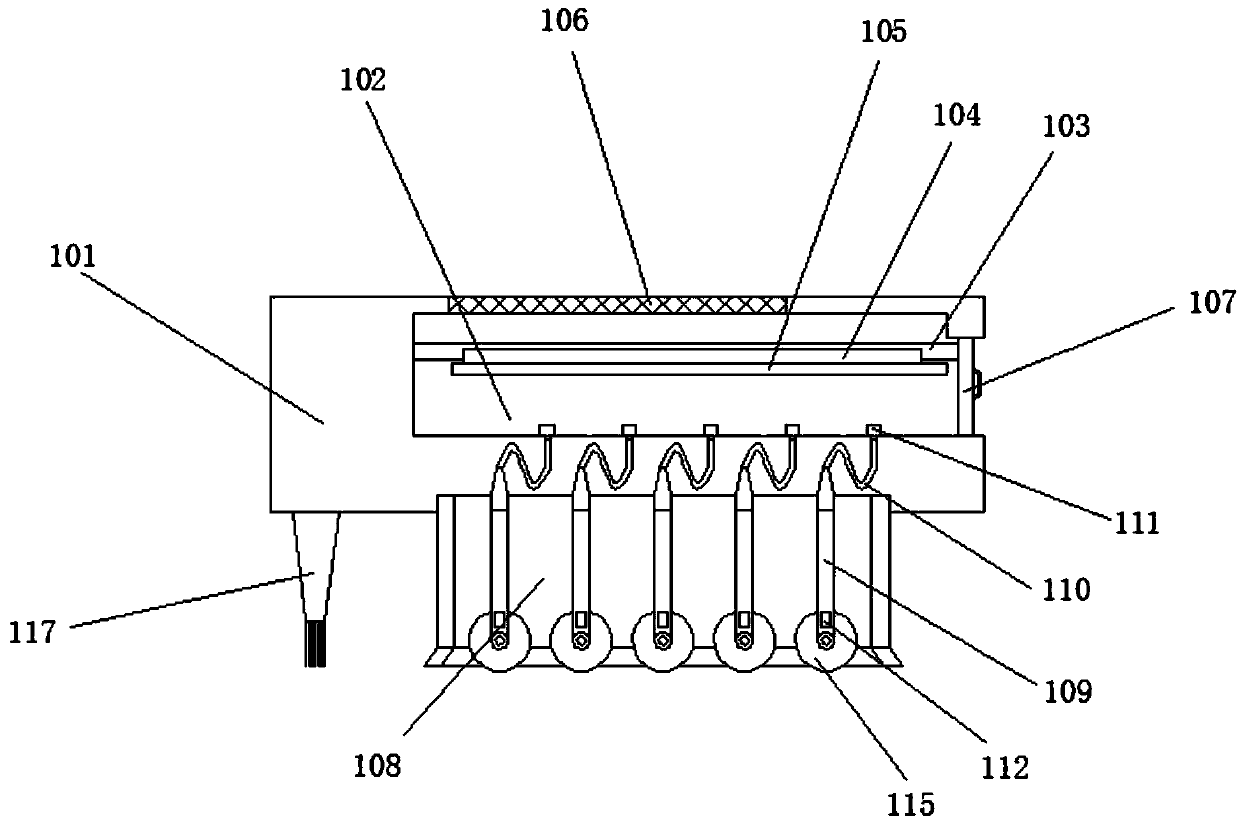

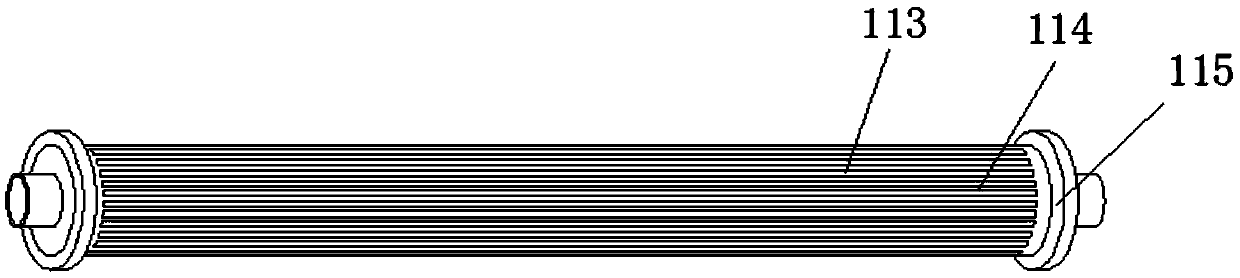

[0050] The inside of the dust removal bin 101 is provided with a dust collection chamber 102, the top of the dust collection chamber 102 is fixedly installed with a metal grid frame 106, and the upper part of the dust collection chamber 102 is fixedly installed with a slide rail 103, and the slide rail 103 A slide plate 104 is slidably connected to the bottom of the slide plate 104, a negative plate 105 is fixedly connected to the bottom of the slide plate 104, a door 107 is connected to the right side of the dust collection chamber 102 in rotation, and a sealed chamber 108 is fixedly connected to the bottom of the dust remova...

Embodiment 2

[0055] Embodiment 2: as Figure 1-22 As shown, an adjustable positioning conveyor table for extruded board processing equipment includes a conveyor table 301, and the top side of the conveyor table 301 is fixedly installed with a dust removal chamber 101, a printing table 201, and a drying chamber 401 in sequence from right to left. And beam frame 501.

[0056] The inside of the dust removal bin 101 is provided with a dust collection chamber 102, the top of the dust collection chamber 102 is fixedly installed with a metal grid frame 106, and the upper part of the dust collection chamber 102 is fixedly installed with a slide rail 103, and the slide rail 103 A slide plate 104 is slidably connected to the bottom of the slide plate 104, a negative plate 105 is fixedly connected to the bottom of the slide plate 104, a door 107 is connected to the right side of the dust collection chamber 102 in rotation, and a sealed chamber 108 is fixedly connected to the bottom of the dust remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com