Environment-friendly green printing method

A printing method, a green technology, applied in the field of ink printing, can solve problems such as high labor intensity, uneven surface of the carrier, and defects in printed works, and achieve the effect of avoiding the accumulation of impurities and fluff, scientific and reasonable structure, and avoiding flying around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

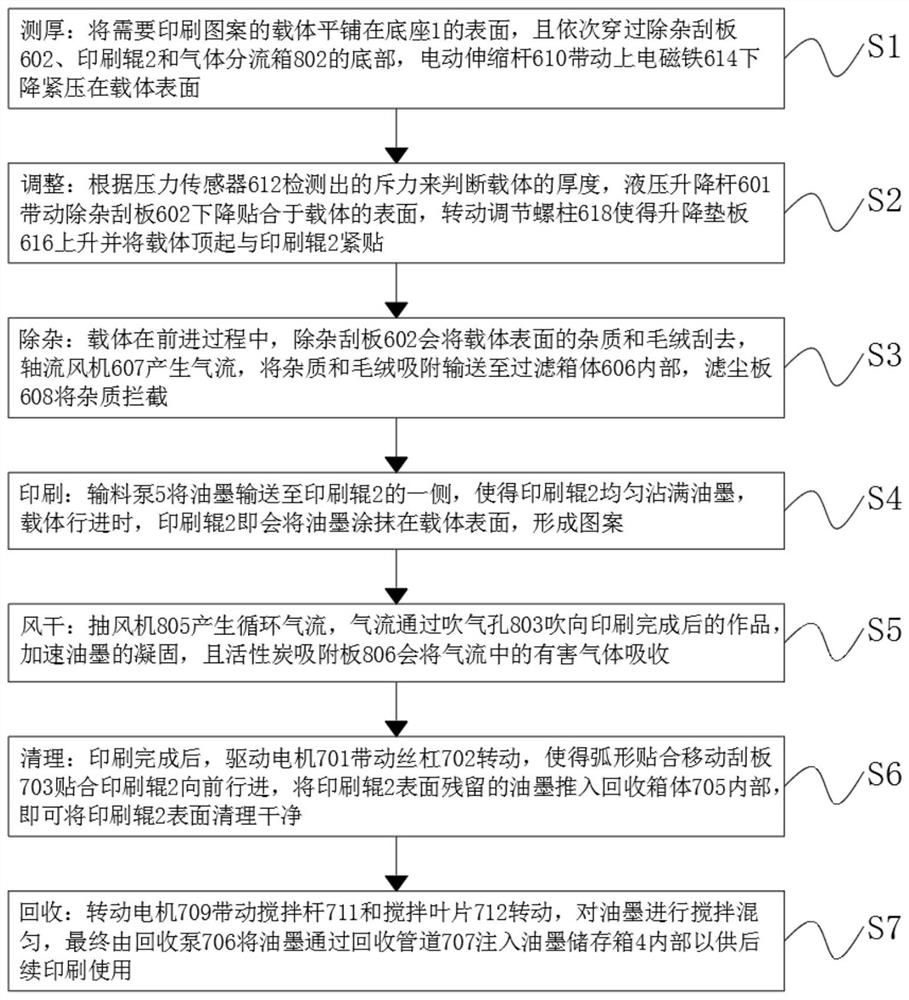

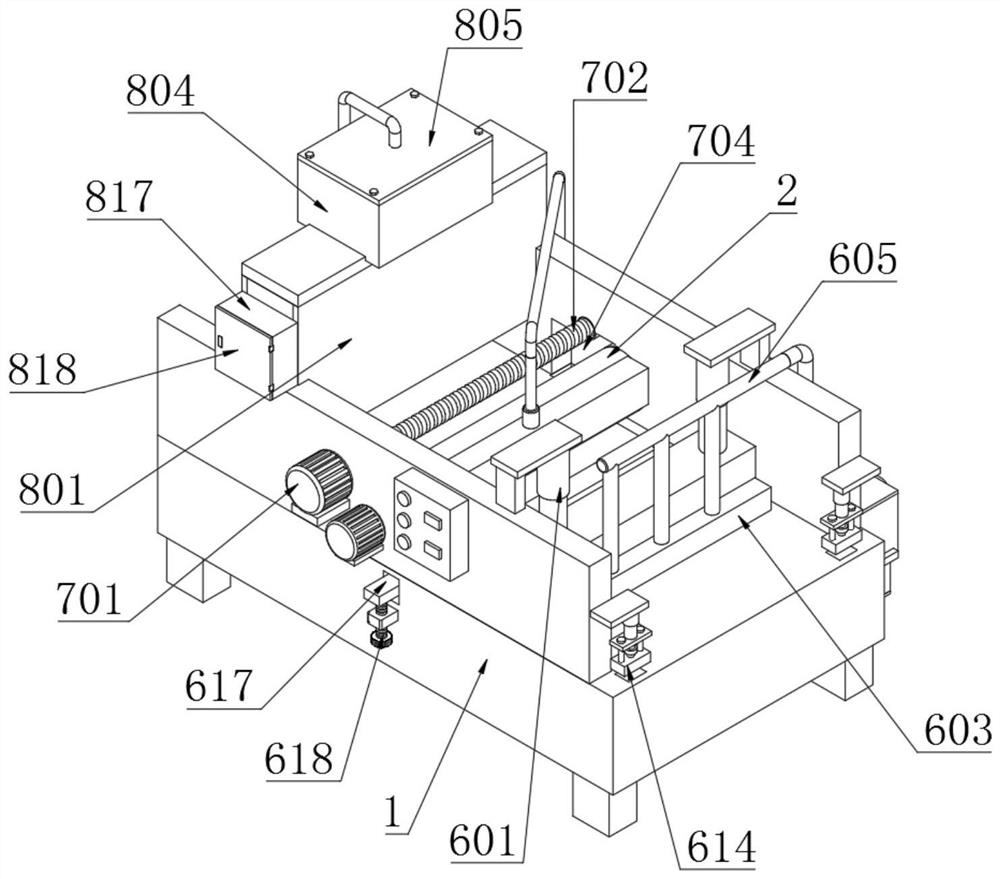

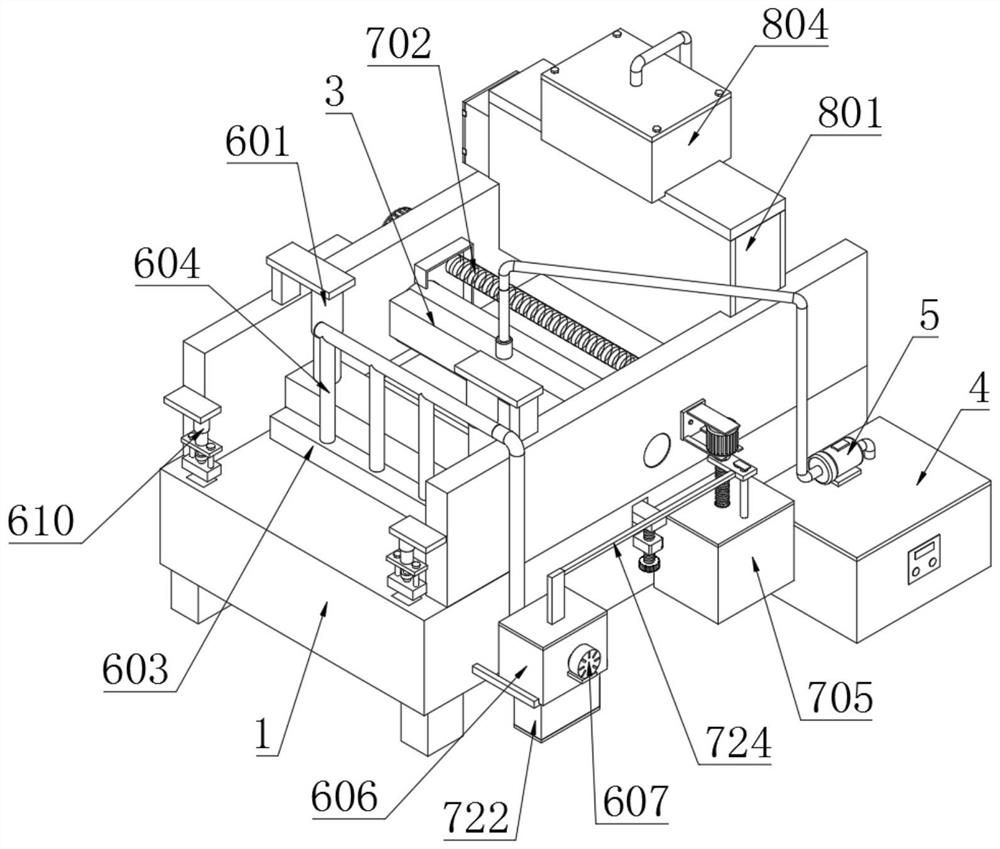

[0042] Example: such as figure 1 As shown, the present invention provides a technical solution, an environmentally friendly green printing method, comprising the following steps:

[0043] S1. Thickness measurement: spread the carrier to be printed on the surface of the base 1, and pass through the impurity removal scraper 602, the printing roller 2 and the bottom of the gas distribution box 802 in sequence, and the electric telescopic rod 610 drives the upper electromagnet 614 down Pressed tightly on the surface of the carrier;

[0044] S2. Adjustment: The thickness of the carrier is judged according to the repulsive force detected by the pressure sensor 612. The hydraulic lifting rod 601 drives the impurity removal scraper 602 down to fit on the surface of the carrier, and the adjusting stud 618 is turned to make the lifting backing plate 616 rise and move the carrier The jacking is close to the printing roller 2;

[0045] S3. Impurity removal: When the carrier is moving fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com