Preparing of compound organic blocking remover and application of compound organic blocking remover to low-permeability oil field

A kind of plugging remover, organic technology, applied in the preparation of compound organic plugging remover and in low permeability oilfield application field, can solve the problems of formation shortage, destruction and poor plugging effect in the near wellbore area, and inhibit the migration of clay particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

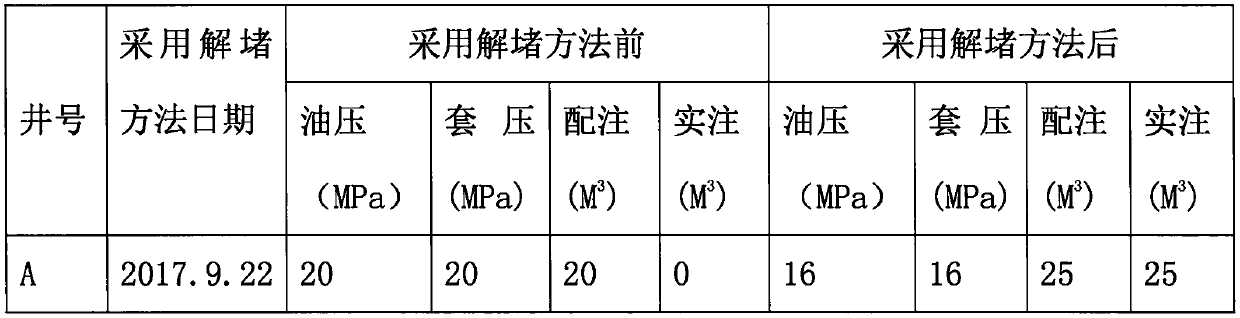

Image

Examples

Embodiment 1

[0020] Embodiment 1, formula

[0021] The ratio of organic acid, surfactant and descaling agent is 4:3:3

[0022] The ratio of anti-scaling agent, anti-swelling agent and water is 3:2:5.

[0023] The organic acid is composed of organic dicarboxylic acid, ethylene glycol, methanesulfonic acid, sulfamic acid, oxalic acid and citric acid, and its ratio is: 3:0.5:2.5:0.5:1.5:2.

[0024] The surfactant is composed of isopropanol, diffusing agent MF and fluorocarbon surfactant, and its ratio is: 3:3:4.

[0025] The descaling agent is composed of polyamino polyether methylene phosphoric acid, ethylenediamine, sodium hydroxide and water, and the ratio is 2.5:2.5:1:4.

[0026] Preparation method: Mix and stir organic acid, surfactant and descaling agent according to the ratio to make the main liquid.

[0027] The protective solution is composed of anti-scaling agent, anti-swelling agent and water, and the ratio is: 4:2:4

[0028] Preparation method: Mix and stir the anti-scaling ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com