Carbon fiber silk supplying machine

A wire feeding machine and carbon fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of unstable wire feeding tension, reducing carbon fiber quality, and non-uniform wire feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

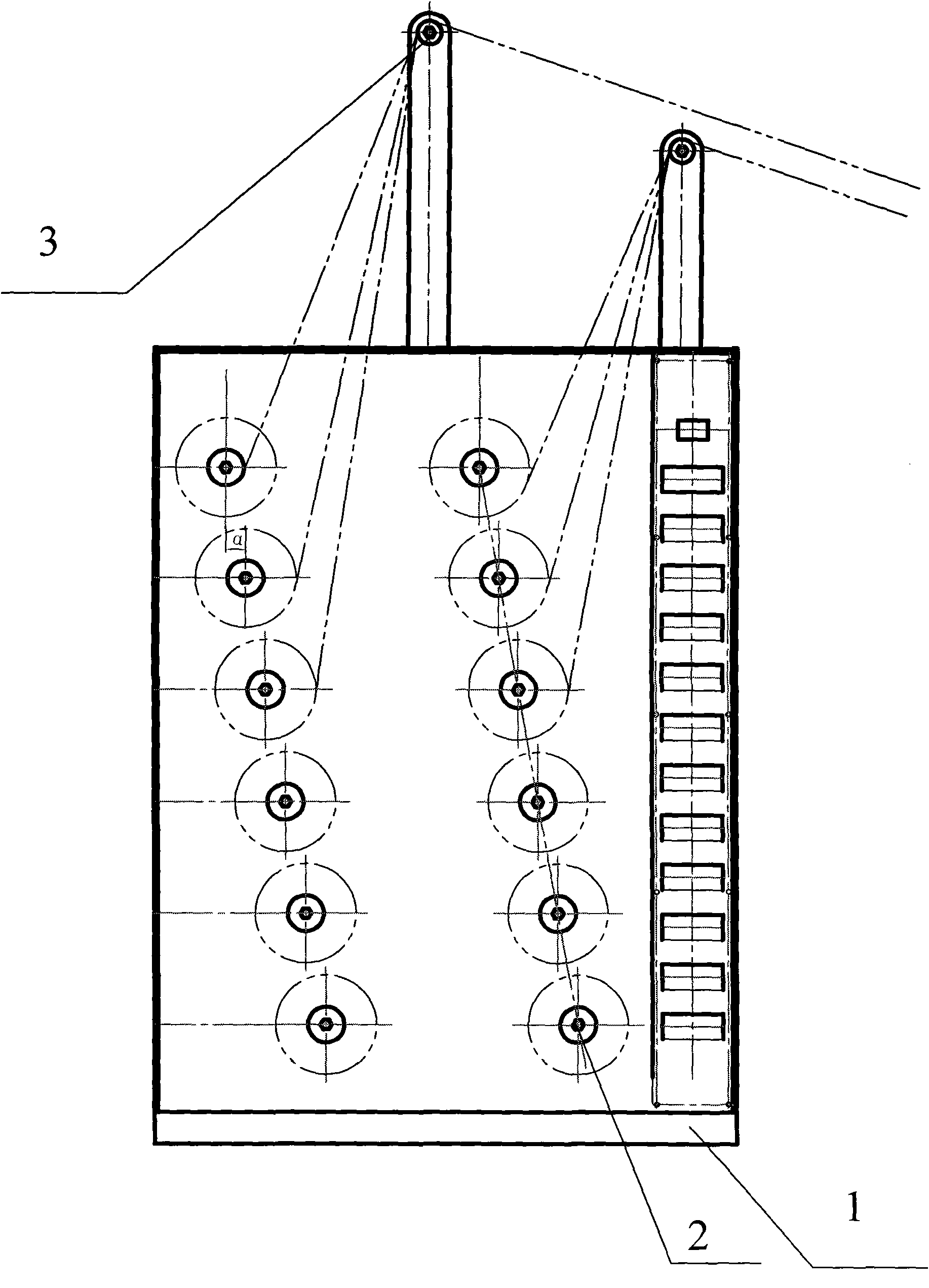

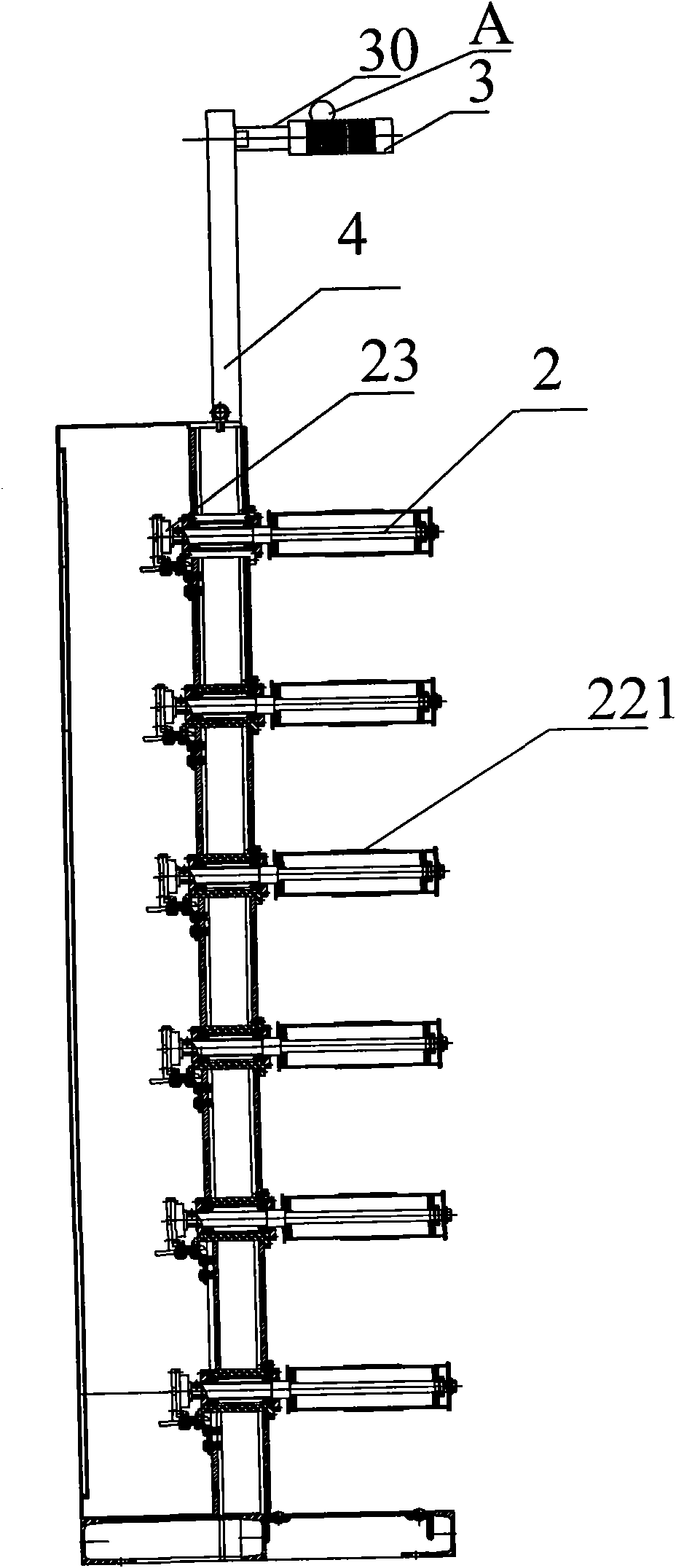

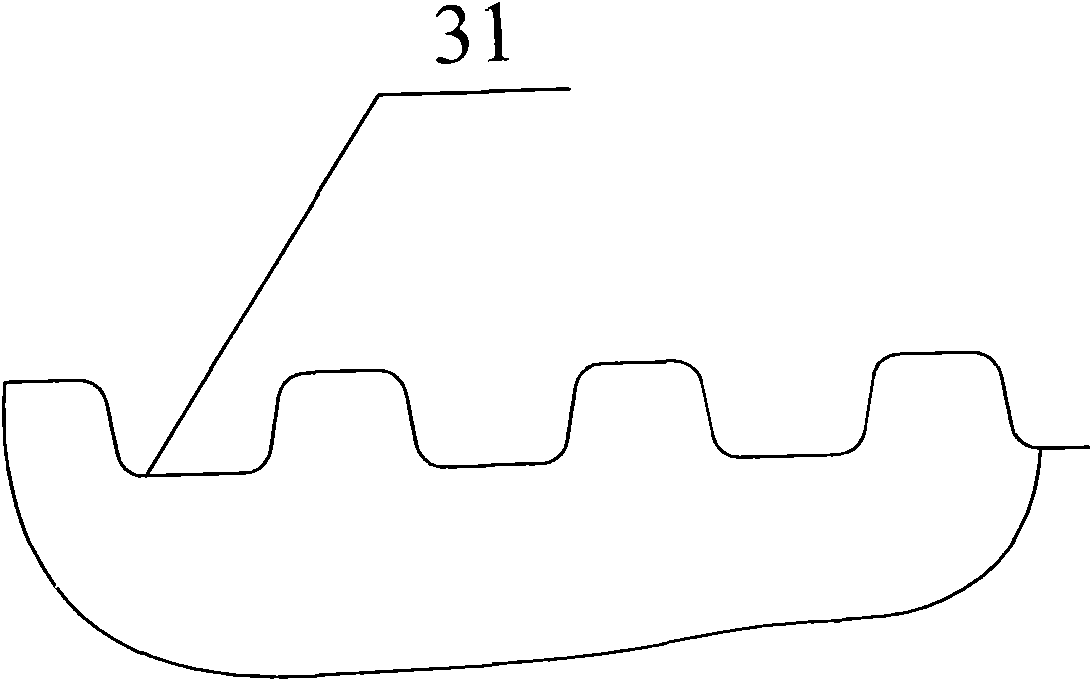

[0014] As shown in the figure, in order to solve the above-mentioned technical problems, a carbon fiber wire feeding machine of the present invention includes a frame 1, a plurality of wire releasing rollers 2, and a wire godet 3, and the wire releasing rollers 2 are divided into several rows and arranged uniformly On one side of the machine base 1, when the wire-feeding rollers 2 are vertically arranged in each row, the longitudinally adjacent wire-releasing rollers 2 can be arranged in alignment, and a horizontal direction can also be provided between the axes of the longitudinally adjacent said wire-releasing rollers 2. In this embodiment, a gap α in the horizontal direction is preferably provided between the longitudinally adjacent pay-off rollers 2 . Since a gap α in the horizontal direction is provided between the longitudinally adjacent wire-feeding rollers 2, when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| damping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com