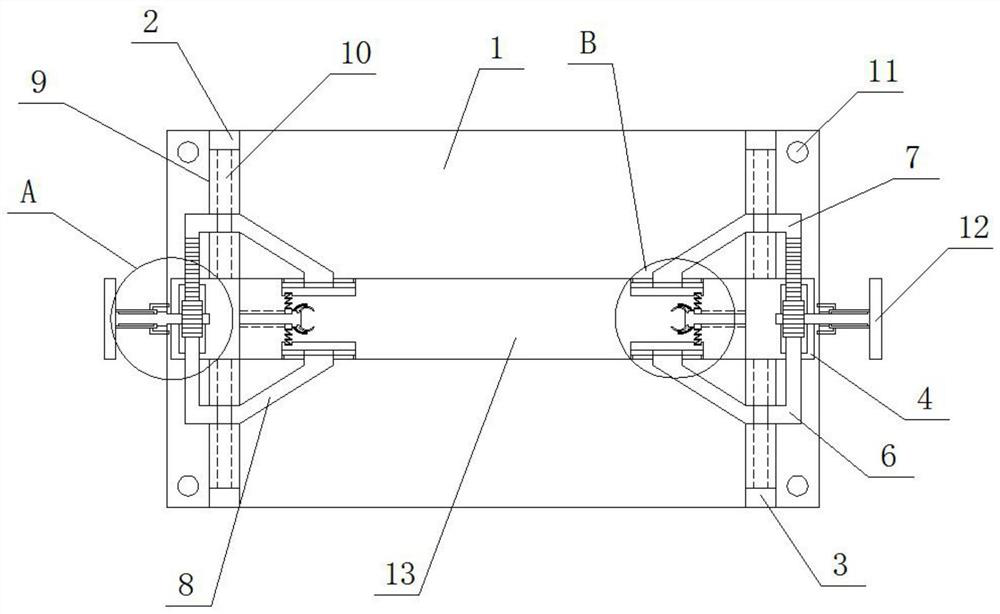

High-stability fixing clamp for machining

A technology for machining and fixing fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, cleaning methods and appliances, etc., can solve the problems of reducing workpiece processing accuracy, workpiece processing influence, and poor clamping effect, so as to improve processing efficiency, Easy to clamp and fix, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

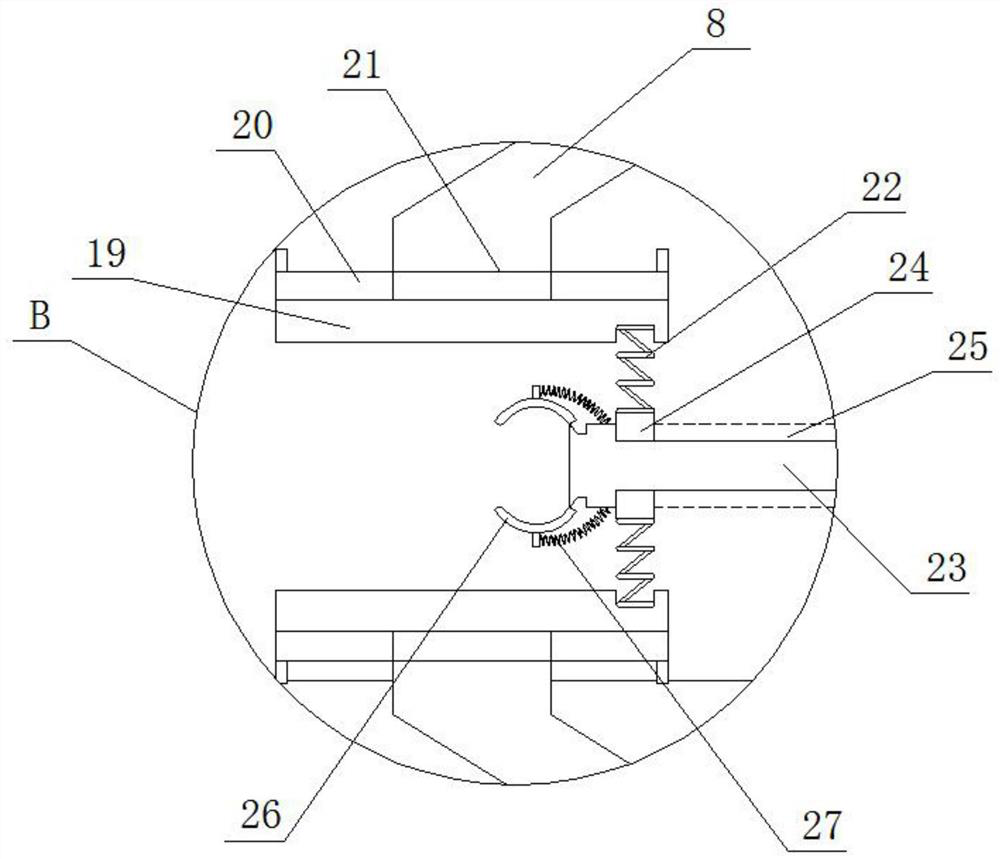

[0030] As a preferred embodiment of the present invention, the two ends of the splint slider 20 are provided with limiting plates, and the splint slider 20 is slidably arranged inside the splint chute 21, and the splint slider 20 and the splint chute The shapes of 21 are all "T" shapes, which can limit the clamping plate 19 and facilitate the sliding of the clamping plate 19 at one end of the fixed cover plate 8 .

[0031] As a preferred embodiment of the present invention, the shape of the fixed rod slider 24 and the fixed rod chute 25 is "T" shape, which can limit the fixed rod slider 24, so that the fixed rod slider 24 is convenient for fixing. Slide on rod 23.

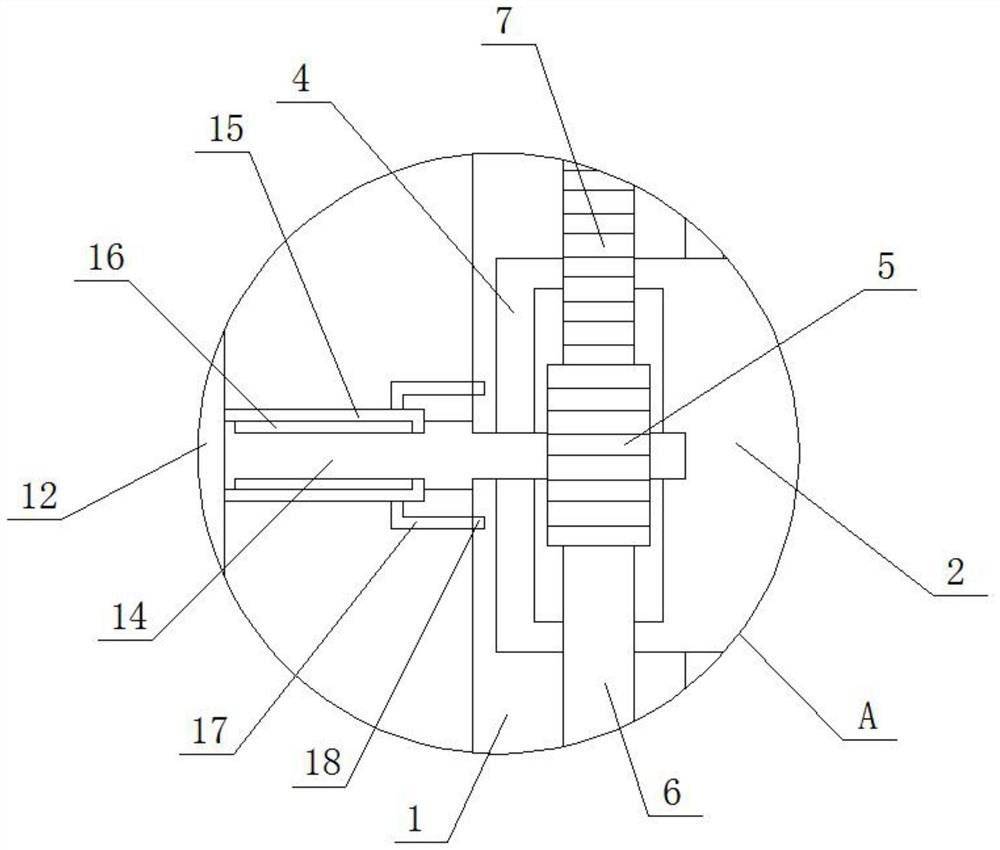

[0032] As a preferred embodiment of the present invention, the two racks and gears 5 mesh with each other and are arranged in parallel to facilitate transmission and adjust the upper support rod 6 and the lower support rod 7 .

[0033] As a preferred embodiment of the present invention, both the inner side of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com