Gravel screening device

A screening device and stone crushing technology, which is applied in the direction of filter screen, grille, and liquid separation agent, can solve the problems of being unable to prevent dust from being mixed, affecting the rotation of the roller, and affecting the screening effect, so as to improve the use efficiency and use value , Reduce the possibility of accumulation, improve the effect of separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

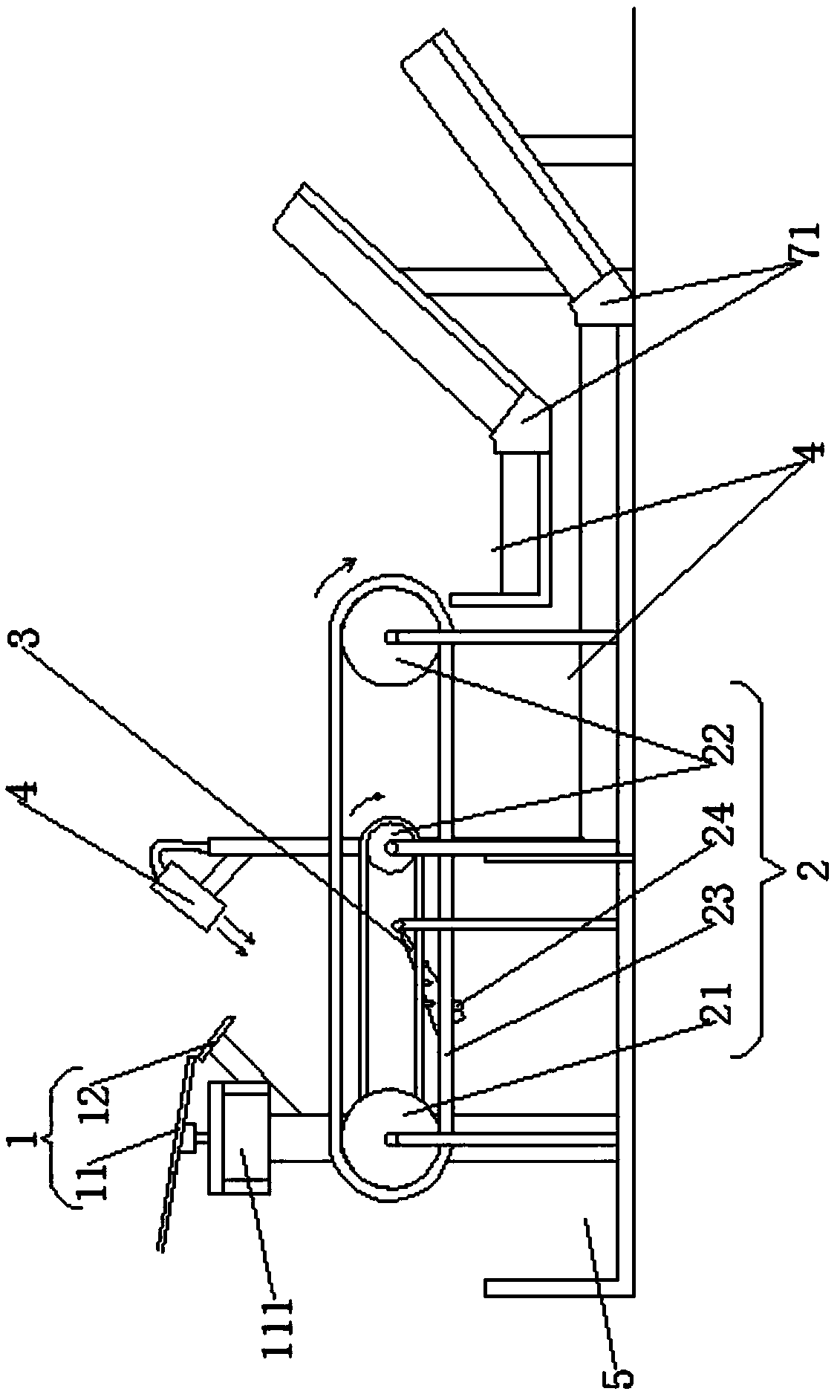

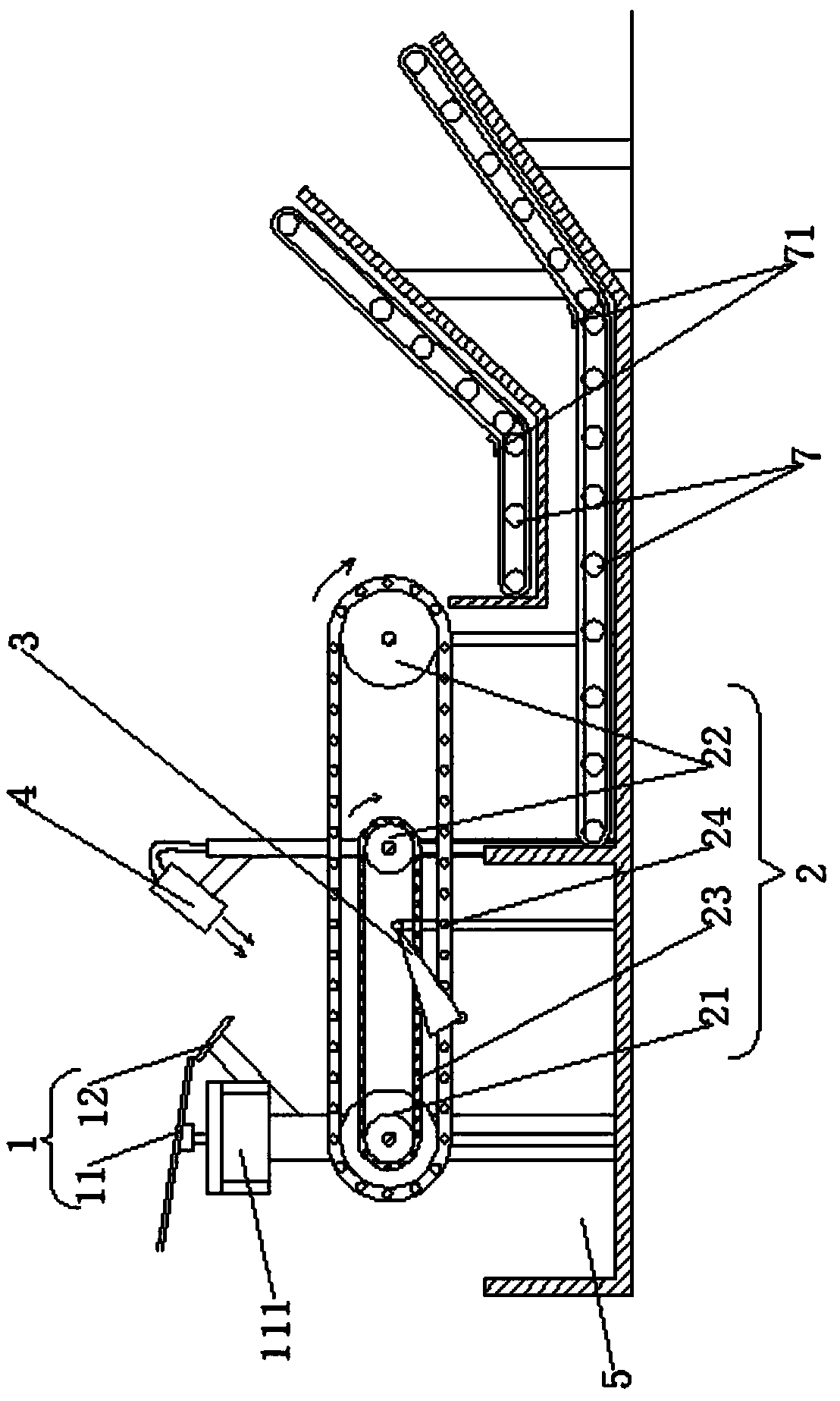

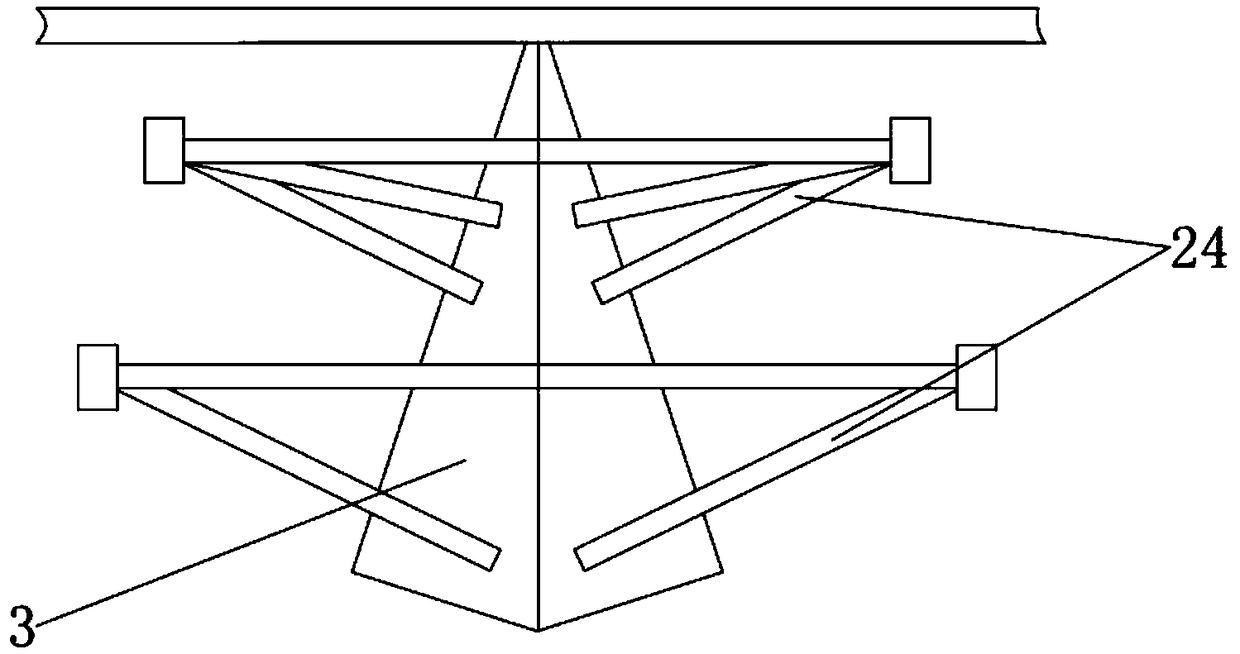

[0022] Embodiments of the present invention are as follows: Figures 1 to 4 As shown, a crushed stone screening device includes a discharge port 1, a conveyor belt 2 for screening crushed stones of different sizes, and a collection device. The conveyor belt 2 includes a driving wheel group 21 and at least one driven wheel 22. The driving wheel group 21 includes a driving wheel corresponding to the driven wheel 22 one-to-one, the driving wheel and the driven wheel 22 are connected by two chains 23, a plurality of support rods 24 are symmetrically arranged between the two chains 23, and the support rod 24 and the chain 23 are reset by Spring connection, the conveyor belt 2 is provided with a bump 3 that can make the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com