Environmental barrier coating for boiler overtemperature control and preparation method thereof

An environmental barrier and coating technology, applied in the coating, metal material coating process, pressure inorganic powder coating and other directions, can solve the problem of long-term reliable use of thermal insulation coating, etc., to improve the long-term reliable use, reduce The effect of the risk of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

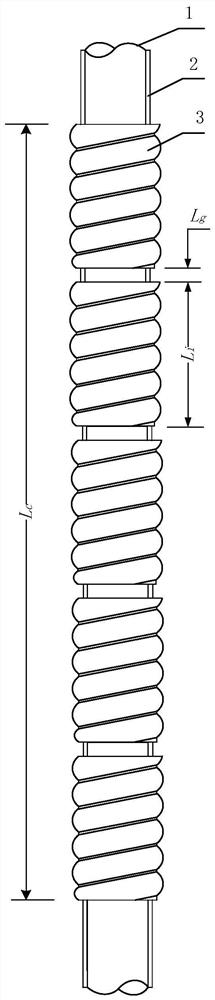

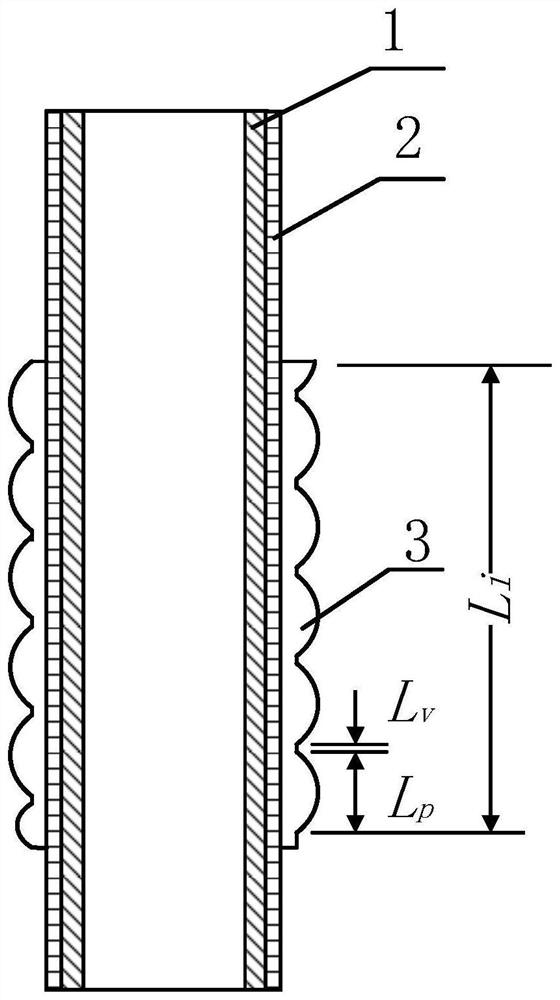

[0055] In addition, the present embodiment also provides a method for preparing an environmental barrier coating for preventing and controlling over-temperature of a boiler, which is used to form the above-mentioned environmental barrier coating for preventing and controlling over-temperature of a boiler on the surface of the furnace tube 1 of the boiler, including the following steps: calculating a furnace The length of the environmental barrier coating and the thickness of the thermal insulation layer 3 need to be set on the tube 1; sandblasting is performed on all areas where the environmental barrier coating needs to be set on the furnace tube 1; the transition layer 2 is sprayed on the surface of the sandblasted furnace tube 1 ; Spray the thermal insulation layer 3 on the surface of the furnace tube 1 sprayed with the transition layer 2 in sections.

[0056] The preparation method of the environmental barrier coating for boiler over-temperature prevention and control is us...

Embodiment 1

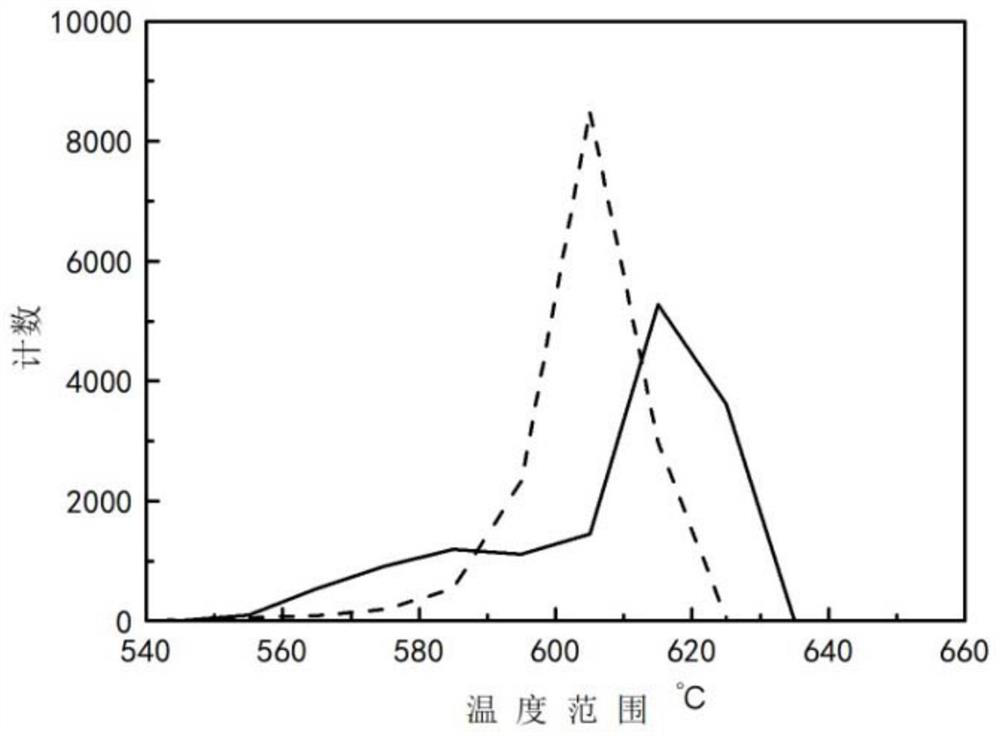

[0074] For a 1000MW unit final-stage superheater furnace tube 1, the over-temperature reaches 10 °C through the furnace top temperature measurement point. First, check that the steam inlet temperature of the final-stage superheater is 491 °C. It is detected that the outlet temperature of the furnace tube 1 is 630° C., and the total length L of the furnace tube 1 is 33 m. According to the requirements of the power plant, the cooling range needs to be 15℃. By reasonably selecting the value of the thermal insulation guarantee coefficient β, according to the above formula It can be calculated that the length Lc of the furnace tube 1 that needs to be insulated is 7.12m.

[0075] Then, the surface of the furnace tube 1 is sandblasted, and a transition layer 2 made of NiCrAl is sprayed by plasma spraying with a thickness of 0.25 mm. In order to ensure the reliability of the heat insulation of the furnace tube 1, the length of the transition layer 2 is set to is 9m (greater than Lc...

Embodiment 2

[0083] In view of the over-temperature phenomenon of furnace tube 1 reaching 110 °C found by the panel reheater of a 350MW unit through the temperature measurement points in the furnace, three furnace tubes 1 are taken, and each furnace tube 1 is based on the total length of the environmental barrier coating. Spray for 1.5m. Before spraying, install an in-furnace temperature measuring thermocouple on the surface of the furnace tube 1, and then perform coating spraying on the surface of the in-furnace thermocouple.

[0084] First, the plasma sprayed NiCrAlY (nickel-chromium-aluminum-yttrium) coating with a thickness of 0.22 mm is used in the spraying area of each furnace tube 1 as the transition layer 2; then, the surface of the transition layer 2 is sprayed with yttrium oxide to stabilize oxidation Zirconium (YSZ) is used as the insulating ceramic layer. The insulating ceramic layer of each section of furnace tube 1 is divided into two sections with an interval of 5mm. And ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com