Claw type vacuum pump rotor surface treatment process

A rotor surface treatment, vacuum pump technology, applied in the direction of vacuum evaporation plating, metal material coating process, ion implantation plating, etc., can solve the problems of vacuum pump performance degradation, corrosion resistance, stable pumping speed, etc., to improve fatigue performance, reduced risk of coating spalling, improved corrosion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

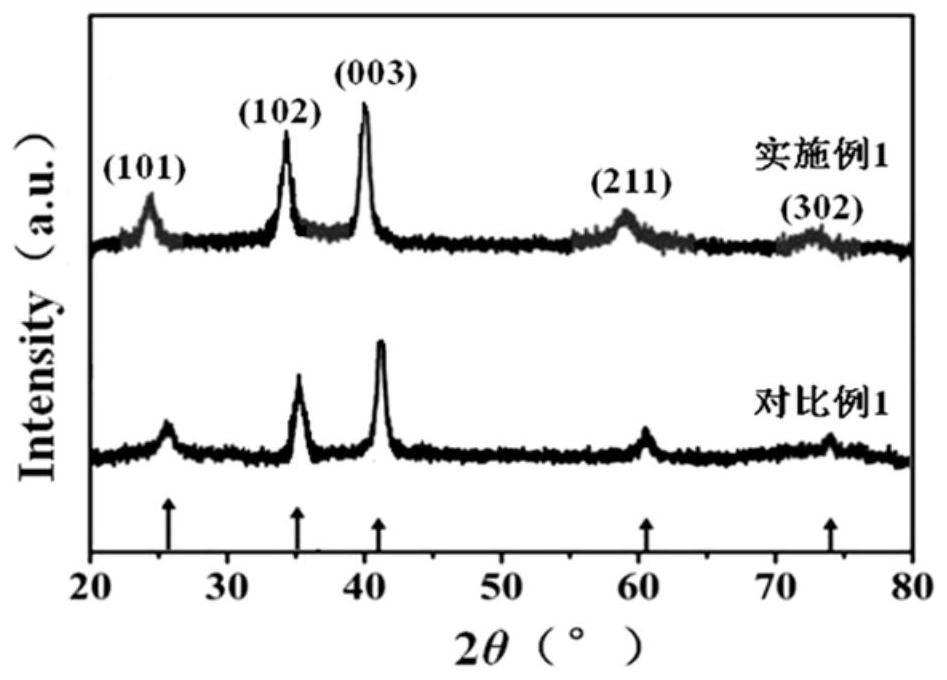

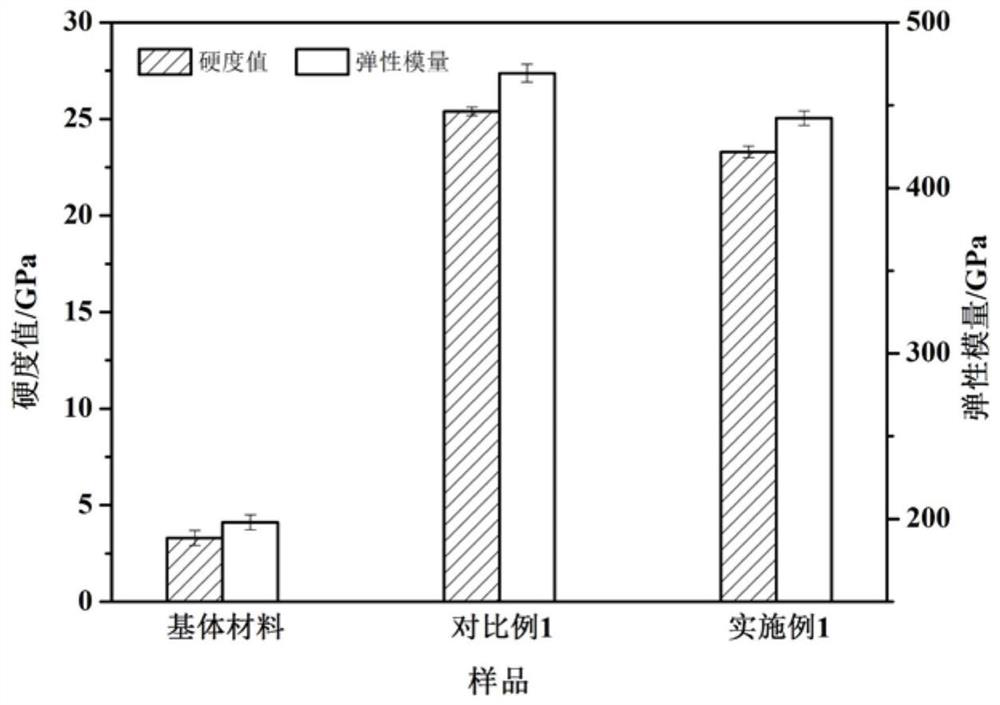

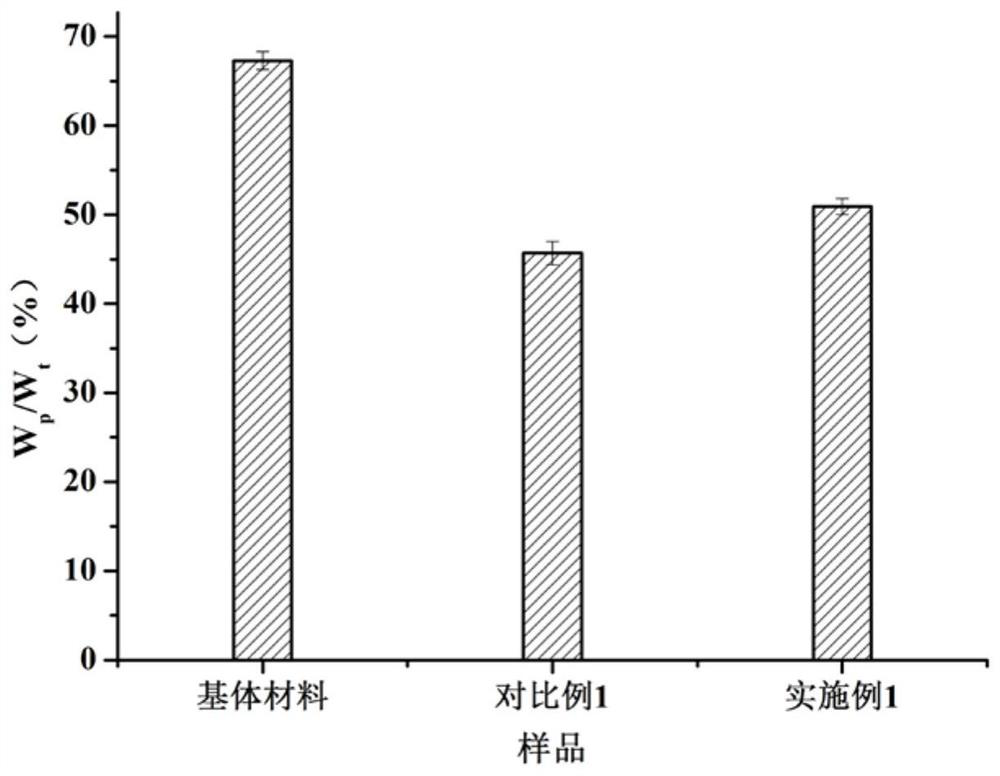

Embodiment 1

[0036] Target preparation:

[0037] Put Ta powder, Si powder, Cr powder and Bi powder into the ball mill jar according to the material ratio of 2:7:0.7:0.3 for uniform mixing, pour in absolute ethanol; then use planetary ball mill at 300r / min ball milling for 10 hours at a high speed. Then pour it into a clean container and put it in the oven to dry. Then adopt the cold isostatic pressing technique, press the uniformly mixed powder into a target with a pressure of 600MPa, and sinter in an argon atmosphere. When the temperature in the furnace chamber rises to 1000°C, keep it warm for 3 hours to obtain a deposited target.

[0038] A claw vacuum pump rotor surface treatment process, comprising:

[0039] S1: Pretreatment, quenching and tempering treatment on the matrix; the matrix is The quenching and tempering process is oil cooling at a quenching temperature of 850°C and air cooling at a tempering temperature of 570°C; followed by rough grinding to fine grinding with sandpap...

Embodiment 2

[0047] The difference between the preparation of the target material and that of Example 1 is that the mass ratio of Ta powder, Si powder, Cr powder and Bi powder is 2:7:0.8:0.4.

[0048] A claw vacuum pump rotor surface treatment process is the same as that of Example 1. Wherein, the coating thickness is 10 μm.

Embodiment 3

[0050] The difference between the preparation of the target material and that of Example 1 is that the mass ratio of Ta powder, Si powder, Cr powder and Bi powder is 2:7:0.75:0.5.

[0051] A claw vacuum pump rotor surface treatment process is the same as that of Example 1. Wherein, the coating thickness is 13 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com