Cleaning method used before coating of hard alloy numerical control blade

A cemented carbide, pre-coating technology, applied in the field of carbide CNC coated blade production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

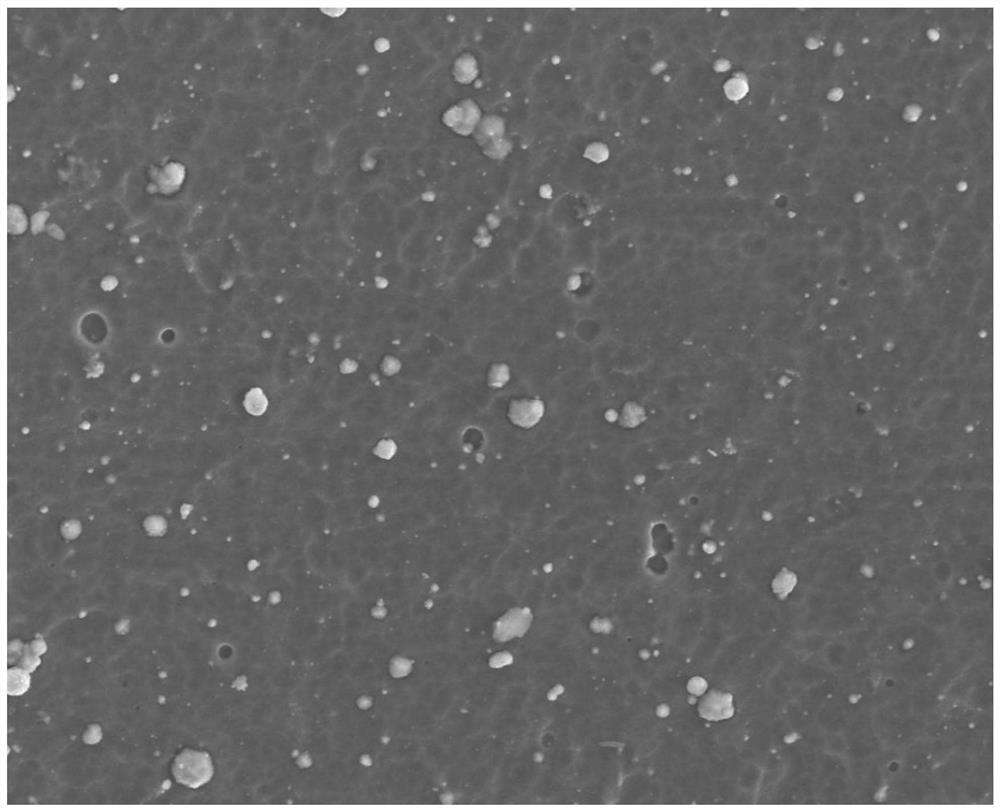

[0053] Embodiment 1: Cleaning before coating of cemented carbide CNC inserts

[0054] The specific operation steps are as follows:

[0055] S1. Add No. 1 cleaning solution (strong alkaline metal cleaning solution) to No. 1 cleaning tank of the ultrasonic cleaner, set the heating temperature of the tank to 60°C, and set the ultrasonic rinsing time to 6.5 minutes;

[0056] Preparation of No. 1 cleaning solution: Mix 5L of A solution, 5L of B solution and 90L of deionized pure water to obtain 100L of No. 1 cleaning solution; wherein: A solution contains 22% potassium hydroxide in terms of mass percentage , polyethylene glycol 3%, dimethyl betaine 3%, polyhydroxy acid 3%, and the balance is pure water; B solution contains aminoethanol 22%, polyoxyethylene fatty amine 10%, fat amide 10%, ammonium chloride 10%, coconut acid diethanolamide 3%, ethylene glycol 3%, and the balance is pure water.

[0057] S2. Add No. 2 cleaning solution into the No. 2 cleaning tank of the ultrasonic c...

Embodiment 2

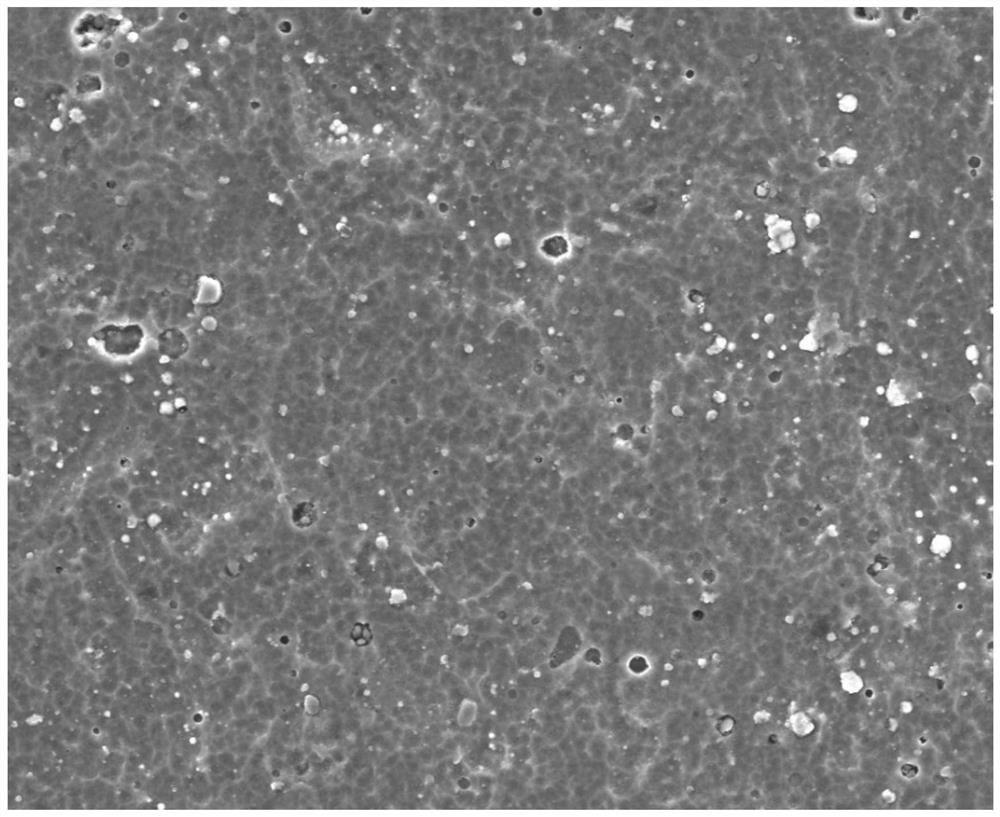

[0068] Embodiment 2: Cleaning before coating of cemented carbide CNC inserts

[0069] The specific operation steps are as follows:

[0070] S1. Add No. 1 cleaning solution (strong alkaline metal cleaning solution) into the No. 1 cleaning tank of the ultrasonic cleaning machine, and set the heating temperature of the tank to 50°C, and set the ultrasonic rinsing time to 7 minutes;

[0071] Preparation of No. 1 cleaning solution: Mix 6L of A solution, 6L of B solution and 88L of deionized pure water to obtain 100L of No. 1 cleaning solution; wherein: A solution contains 30% potassium hydroxide in terms of mass percentage , polyethylene glycol 5%, dimethyl betaine 5%, polyhydroxy acid 5%, and the balance is pure water; B solution contains aminoethanol 30%, polyoxyethylene fatty amine 15%, fat amide 15%, ammonium chloride 15%, coconut acid diethanolamide 5%, ethylene glycol 5%, and the balance is pure water.

[0072] S2. Add No. 2 cleaning solution into the No. 2 cleaning tank of...

Embodiment 3

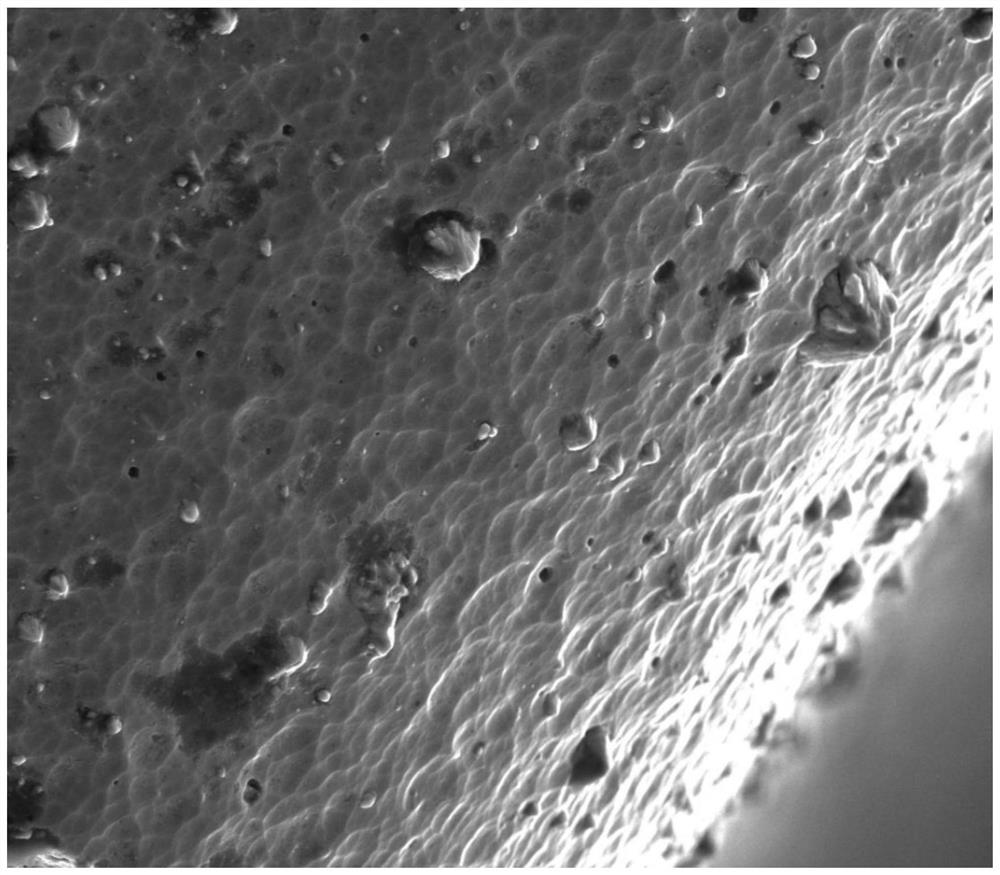

[0083] Embodiment 3: Cleaning before coating of cemented carbide numerically controlled inserts

[0084] The specific operation steps are as follows:

[0085] S1. Add No. 1 cleaning solution (strong alkaline metal cleaning solution) into the No. 1 cleaning tank of the ultrasonic cleaning machine, and set the heating temperature of the tank to 65°C, and set the ultrasonic rinsing time to 6 minutes;

[0086] Preparation of No. 1 cleaning solution: Mix 4L of A solution, 4L of B solution and 92L of deionized pure water to obtain 100L of No. 1 cleaning solution; wherein: A solution contains 15% potassium hydroxide in terms of mass percentage , polyethylene glycol 1%, dimethyl betaine 1%, polyhydroxy acid 1%, and the balance is pure water; B solution contains aminoethanol 15%, polyoxyethylene fatty amine 5%, fat amide 5%, ammonium chloride 5%, coconut acid diethanolamide 1%, ethylene glycol 1%, and the balance is pure water.

[0087] S2. Add No. 2 cleaning solution into the No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com