Composite material part having a ceramic matrix, and method for manufacturing same

A technology of ceramic matrix and composite materials, which is applied in the direction of thin material processing, layered products, transportation and packaging, etc. It can solve the problems of the limitation of self-healing matrix cohesion, reduce the risk of peeling, and enhance the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

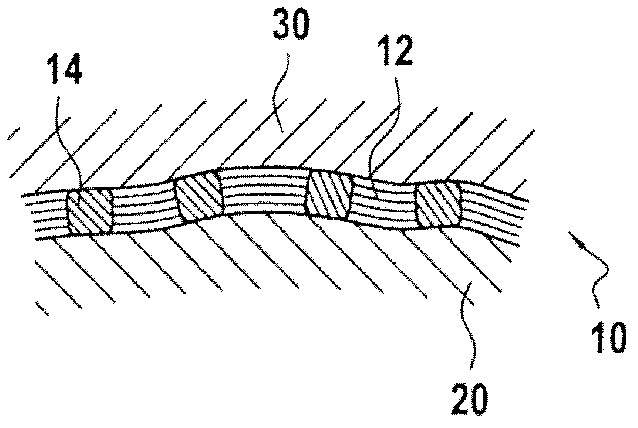

[0090] An ensemble is made on a silicon substrate: SiC / SiC+PyC interface / SiC / SiC+PyC interface / SiC, wherein:

[0091] - the SiC layer is prepared in a known manner from MTS+H by CVI at a temperature of about 1000°C and a pressure of about 5 kPa 2 The stoichiometric layer obtained in the gas phase, H 2 The ratio α between the ratio and the MTS ratio is about 6,

[0092] - The SiC+PyC interface from MTS+H via CVI 2 obtained in the gas phase, resulting in a first exfoliated phase PyC with a layered structure and a second phase consisting of PyC crystallites, under the same conditions as those leading to obtaining stoichiometric SiC, except for the ratio α, which was chosen to be 1 the following.

[0093] For the formation of each interface, by choosing a ratio α equal to approximately 0.1 (full) and a duration of 1.5 minutes, an interface with a thickness approximately equal to 30 nm and containing 80% atoms of PyC (the rest formed by SiC crystallites) is obtained.

[0094] ...

Embodiment 2

[0096] Using the same procedure as in Example 1, but using a ratio α approximately equal to 0.25 and a duration of 5 minutes during the preparation of each interface, a SiC+PyC with a thickness approximately equal to 0.3 microns and containing 70% atoms is obtained The interface of PyC (the rest is formed by SiC crystallites).

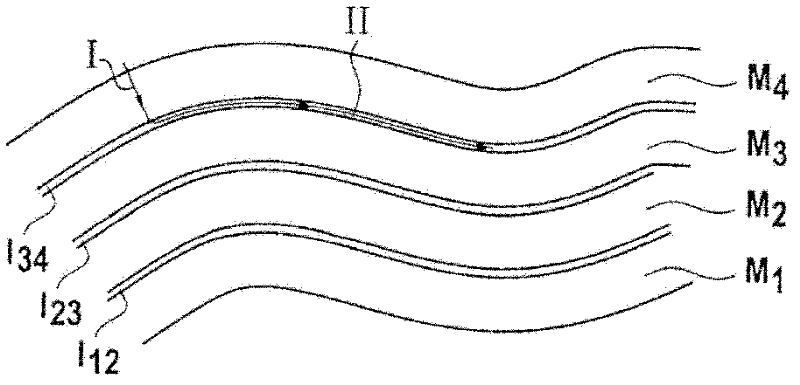

[0097] Figure 10 The path of the crack caused by the dent under load is shown. It can be seen that there is no transition from Mode I to Mode II in the second interface, and this transition redirected to Mode I occurs in the first interface.

Embodiment 3

[0099] Using the same procedure as in Example 1, but using a ratio α approximately equal to 0.5 and a duration of 5 minutes during the preparation of each interface, a PyC having a thickness approximately equal to 0.2 μm and containing 60% atoms (the remainder Formed from SiC crystallites) at the SiC+PyC interface.

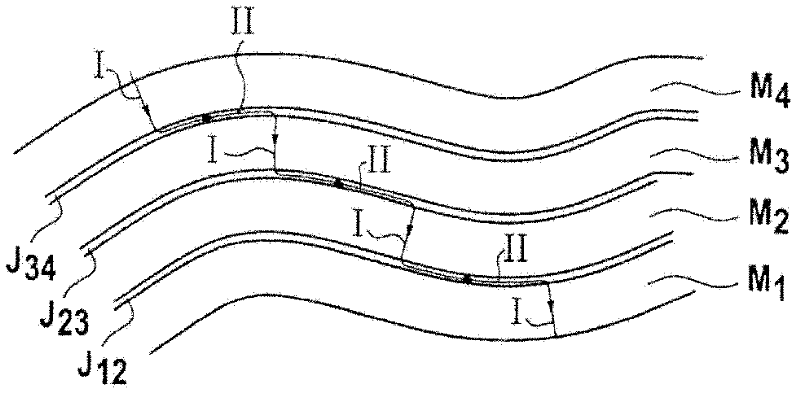

[0100] Figure 11 The path of the crack caused by the dent under load is shown. It can be seen that there is no transition from mode I to mode II in both interfaces, which reflects the insufficient existence of the exfoliated phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com