Photoresist composition and photoresist

A composition and photoresist technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of inconsistent reaction degree, high mobility, photoresist peeling, etc., and achieve the effect of reducing the risk of peeling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The photoresist composition in this embodiment includes: 8% by mass of resin matrix, 8% by mass of pigment / dye, 4% by mass of reactive diluent monomer, and 80% by mass of solvent.

[0084] The resin matrix contains four components: unsaturated polyester, epoxy acrylic resin, polyurethane acrylic resin, and self-initiating resin, wherein the mass percentage of self-initiating resin is 2%, and the mass percentage of self-initiating resin is relatively high here, so A photoinitiator may not be added to the photoresist composition.

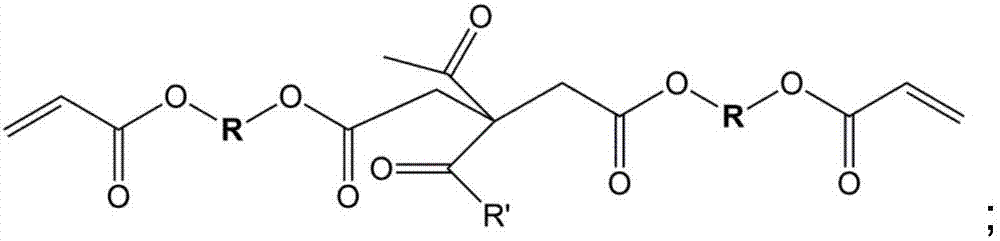

[0085] The structure of A is as follows:

[0086]

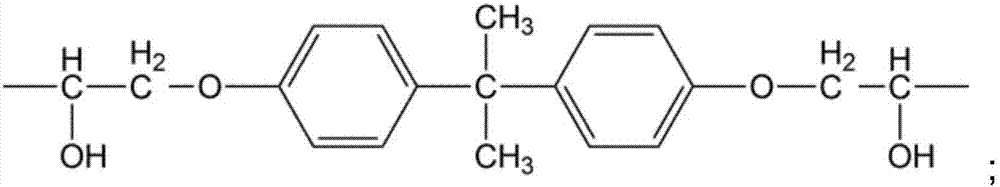

[0087] The structure of B is as follows:

[0088]

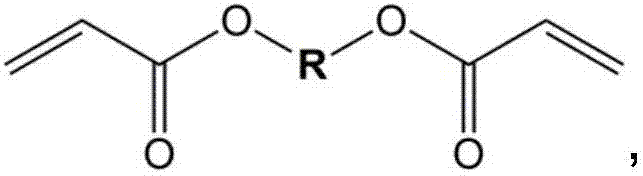

[0089] The reaction mechanism between structure A and structure B is as follows:

[0090]

[0091] The chemical structural formula of the self-initiating resin obtained is as follows:

[0092]

[0093] The mechanism by which self-initiating resins initiate photopolymerization is as follows:

[0094]

[0095] Of course, self...

Embodiment 2

[0100] The photoresist composition in this embodiment includes: a resin matrix with a mass percentage of 10%, a pigment / dye with a mass percentage of 6.6%, a reactive diluent monomer with a mass percentage of 3%, a solvent with a mass percentage of 80%, A photoinitiator with a mass percentage of 0.2%, and an additive with a mass percentage of 0.2%.

[0101] The resin matrix contains four components: unsaturated polyester, polyether acrylic resin, pure acrylic resin and self-initiating resin, wherein the mass percentage of self-initiating resin is 1.5%.

Embodiment 3

[0103] The photoresist composition in this embodiment includes: a resin matrix with a mass percentage of 9%, a pigment / dye with a mass percentage of 7%, a reactive diluent monomer with a mass percentage of 3.8%, a solvent with a mass percentage of 80%, The mass percentage is 0.1% photoinitiator, and the mass percentage is 0.1% additive.

[0104] The resin matrix contains four components: unsaturated polyester, polyether acrylic resin, pure acrylic resin and self-initiating resin, wherein the mass percentage of self-initiating resin is 1.8%.

[0105] In summary, in the resin matrix of the photoresist composition provided by the present invention, the self-initiating resin can initiate photopolymerization and curing reaction like a photoinitiator, and the self-initiating resin is fully mixed with the acrylic resin in the resin matrix , so that the pigments and dyes in the photoresist composition can also be initially dispersed, and can also promote the dispersion of other compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com