Part, plasma reaction device and part machining method

A plasma and reaction device technology, applied in the field of plasma reaction device and parts processing, can solve the problems of failure of plasma-resistant coating protection function, peeling off, substrate corrosion damage, etc., so as to reduce the risk of peeling and prolong the transmission path, the effect of enhanced bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

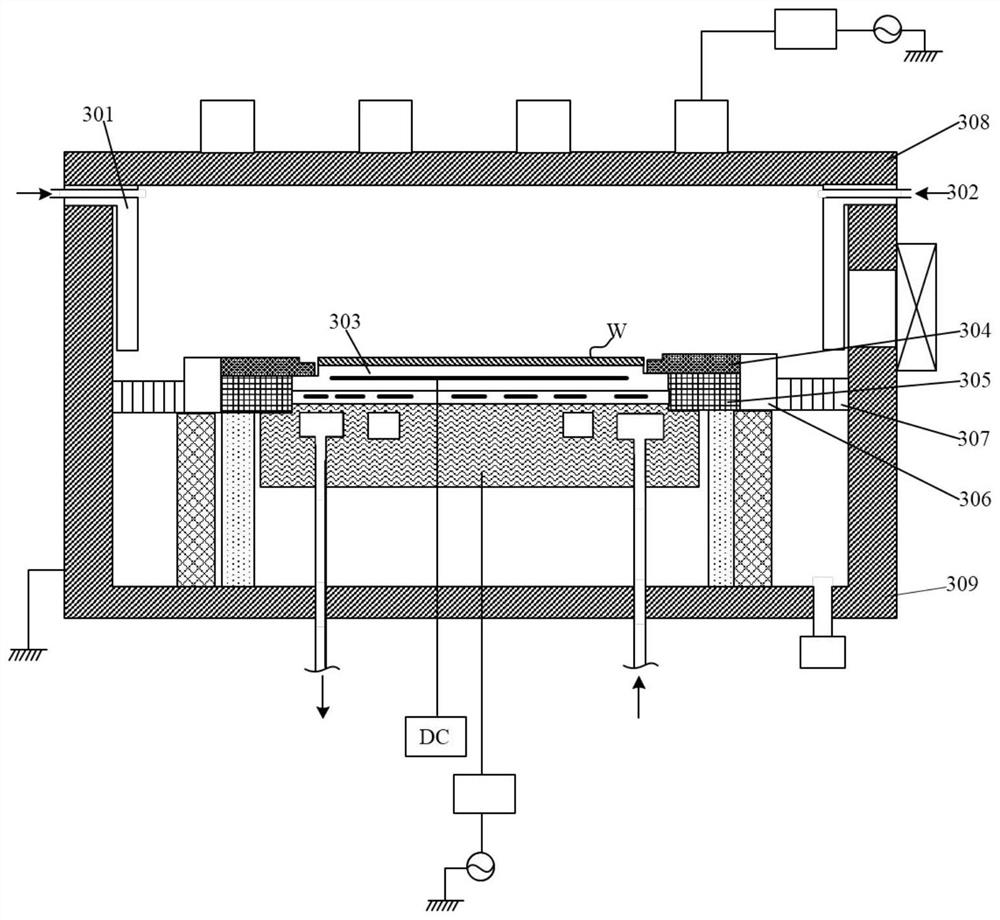

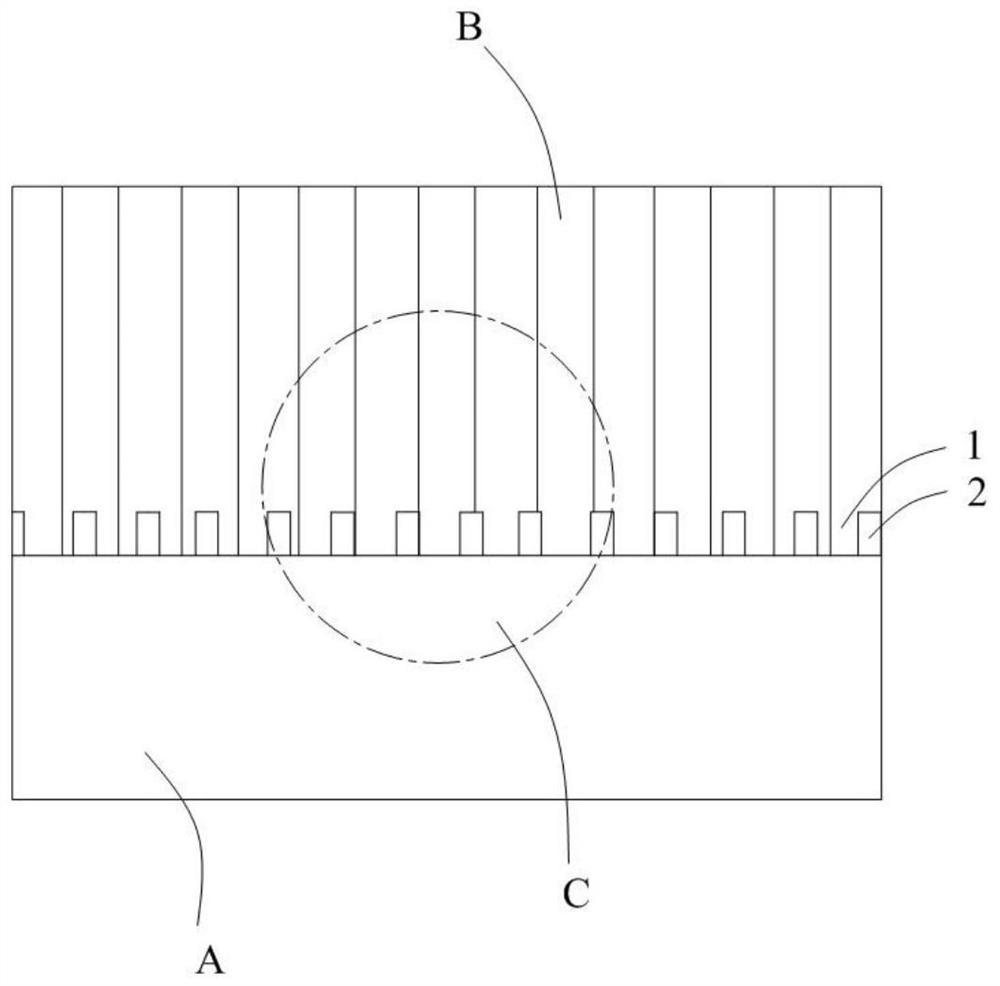

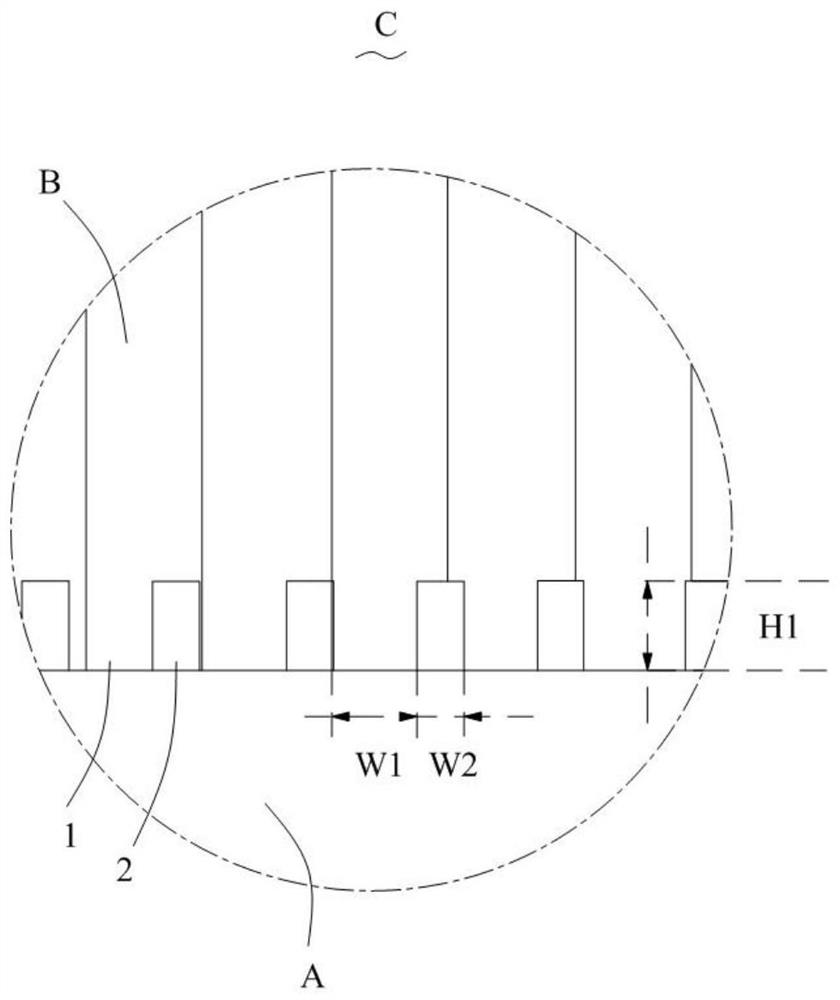

[0042] The plasma reaction device includes a reaction chamber, the reaction chamber is a plasma environment, and the parts are exposed to the plasma environment. Since the plasma is highly corrosive, it is necessary to coat the substrate surface with a corrosion-resistant coating to Prevent plasma from corroding the substrate. However, in the existing manufacturing process of semiconductor devices, the plasma-resistant coating coated on the substrate is easy to crack and peel off. The study found:

[0043] An anodized layer is arranged between the metal substrate and the plasma-resistant coating, and the anodized layer is used to realize the transition of different thermal expansion coefficients between the metal substrate and the plasma-resistant coating. Its specific manufacturing method includes firstly performing anodic oxidation treatment on the metal substrate to form a layer of anodized layer, and then coating a layer of plasma-resistant coating on the surface of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com