Control method for surface oxidation pocking defects of hot-rolled pickled plate

A technology of hot-rolled pickling and surface oxidation, applied in the direction of contour control, etc., can solve problems such as oxidation pitting defects, achieve the effects of reducing the probability of occurrence, improving quality, and solving uniformity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

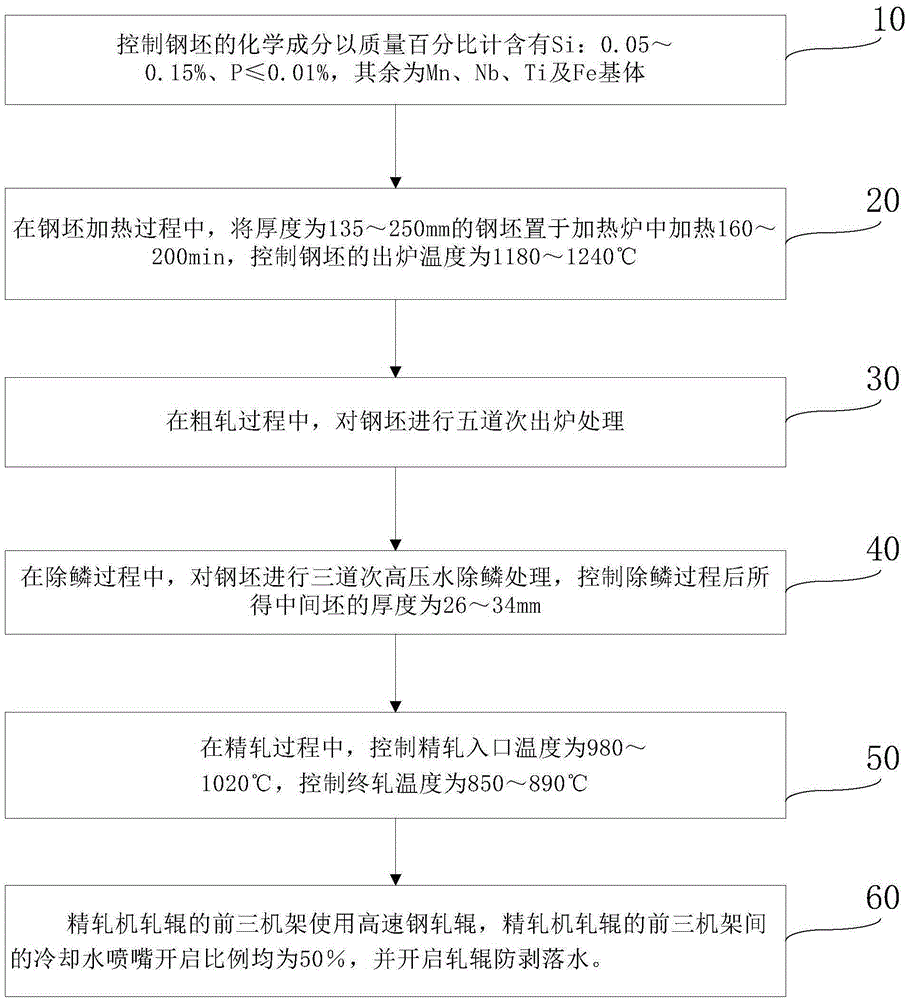

[0028] This embodiment provides a method for controlling oxidation pitting defects on the surface of a hot-rolled pickled plate, the thickness of the hot-rolled pickled plate is ≤2 mm, and the tensile strength is ≥500 MPa. The manufacturing process of the hot-rolled pickled plate is steel billet Heating, rough rolling, descaling, finish rolling and pickling. The method includes:

[0029] The chemical composition of the steel slab is controlled to contain Si: 0.06%, P: 0.008% in terms of mass percentage, and the rest is Mn, Nb, Ti and Fe matrix. Put the steel billet with a thickness of 200mm into the heating furnace for heating for 160min, control the temperature of the billet out of the furnace to 1200°C, and conduct rough rolling and high-pressure descaling water descaling treatment on the billet out of the furnace. 5 passes of rough rolling process, 3 passes of high-pressure descaling water descaling, for example, 1, 3 and 5 passes can be opened for high-pressure descaling ...

Embodiment 2

[0031] This embodiment provides a method for controlling oxidation pitting defects on the surface of a hot-rolled pickled plate, the thickness of the hot-rolled pickled plate is ≤2 mm, and the tensile strength is ≥500 MPa. The manufacturing process of the hot-rolled pickled plate is steel billet Heating, rough rolling, descaling, finish rolling and pickling. The method includes:

[0032] The chemical composition of the steel slab is controlled to contain Si: 0.1%, P: 0.006% in terms of mass percentage, and the rest is Mn, Nb, Ti and Fe matrix. Put the steel billet with a thickness of 200mm into the heating furnace for heating for 160min, control the temperature of the billet out of the furnace to 1200°C, and conduct rough rolling and high-pressure descaling water descaling treatment on the billet out of the furnace. 5 passes of rough rolling process, 3 passes of high-pressure descaling water descaling, for example, 1, 3 and 5 passes can be opened for high-pressure descaling w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com