Reverse variable geometric turbine with low-viscosity and no-lift adjustable static blades

A static impeller, low-consistency technology, applied in the field of turbines, can solve the problems of affecting turbine efficiency, aggravating the complexity of the internal flow field of the adjustable vanes, and the leakage loss of the vanes, achieving convenient processing and engineering applications, and improving multiple working conditions. Efficiency, the effect of reducing leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

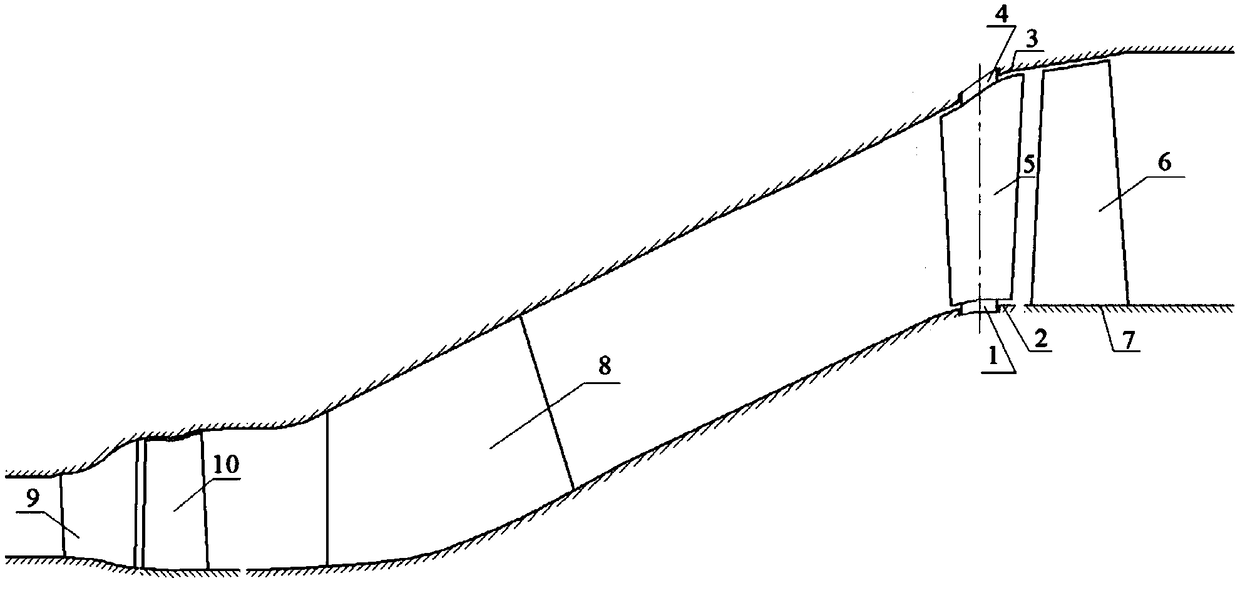

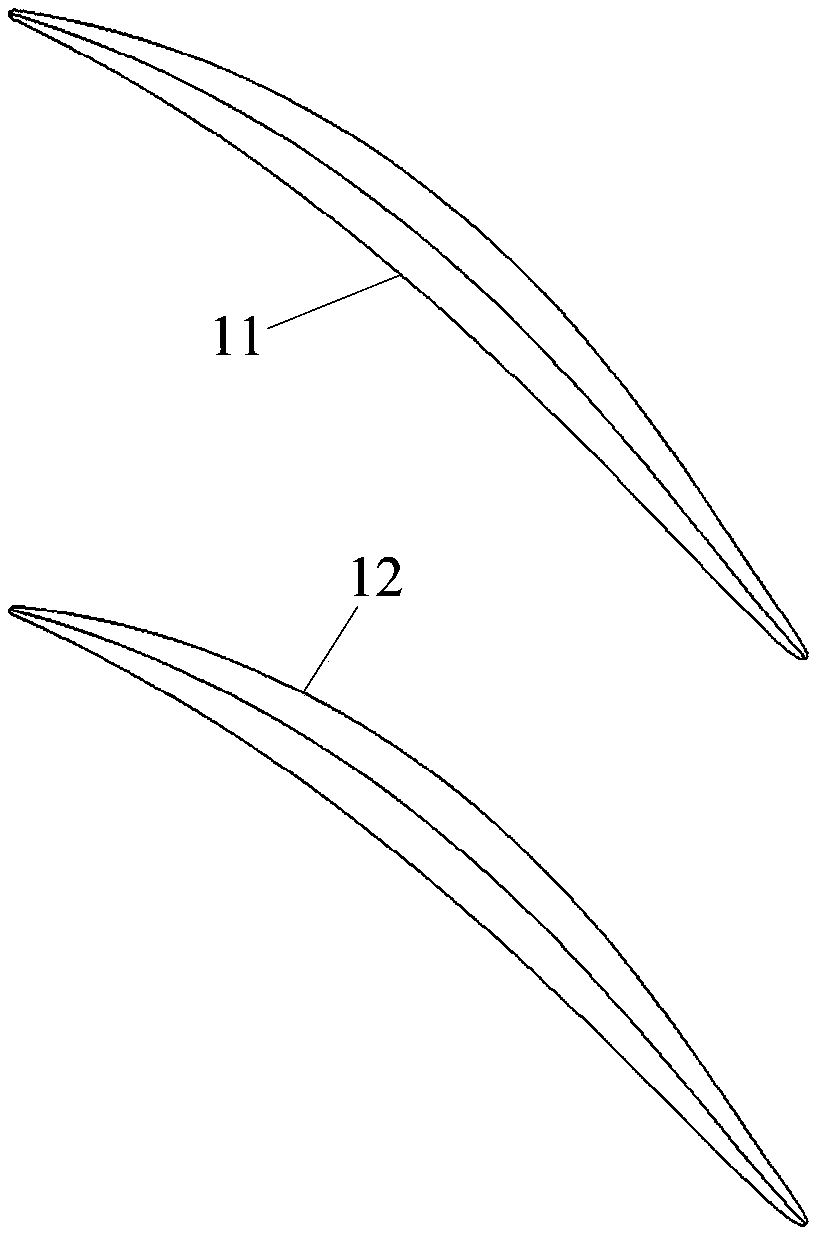

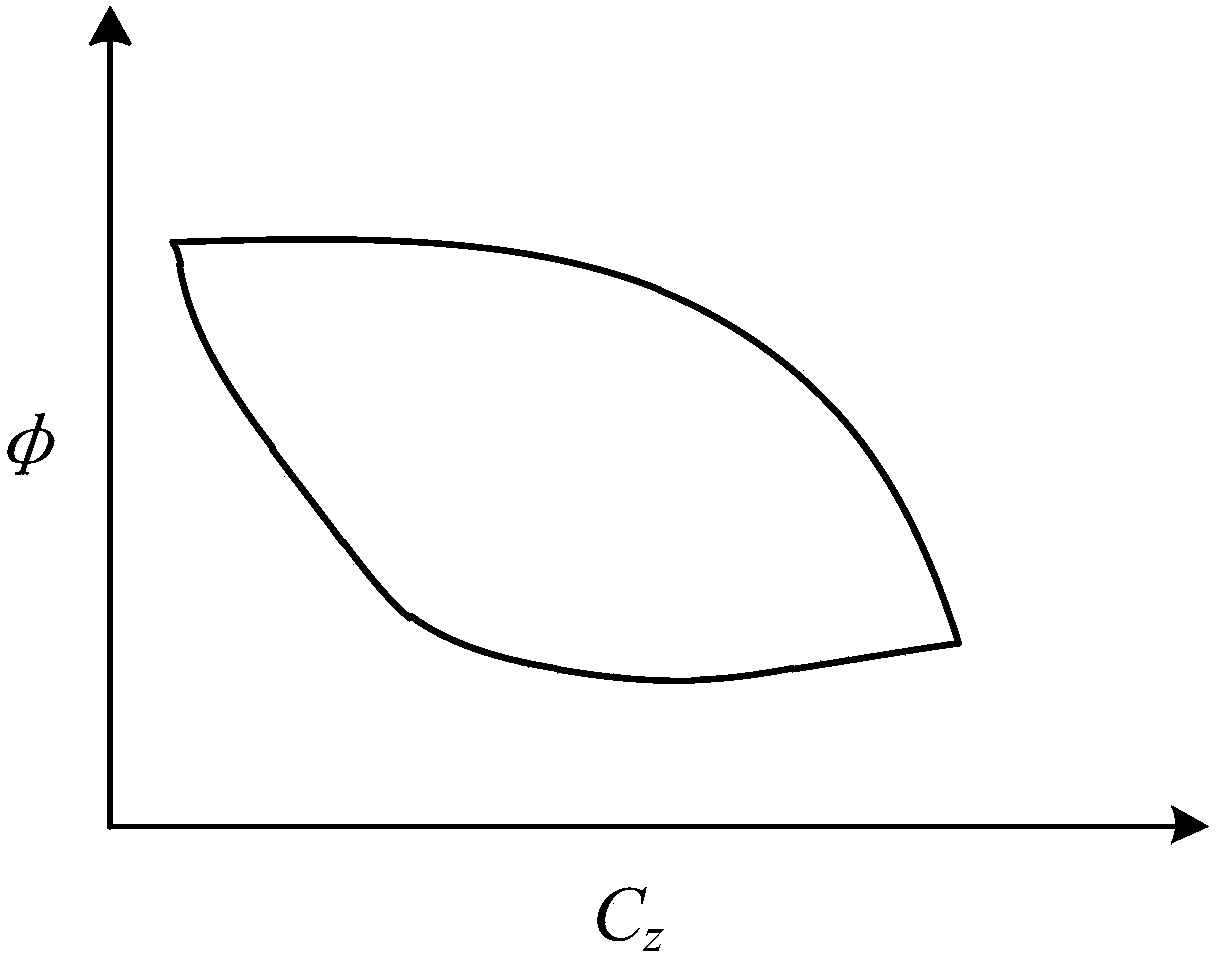

[0015] combine Figure 1~3 , the present invention is made up of case 3, adjustable stationary vane 5, moving vane 6, stationary vane hub 2 and moving vane hub 7, adjustable stationary vane 5 is evenly installed along the circumferential direction between hub 2, 7 and casing 3 With the moving blade 6, the adjustable stationary blade 5 is in the front, and the moving blade 6 is behind. The upper and lower end surfaces of the adjustable stationary blade 5 are respectively provided with an upper rotating shaft 4 and a lower rotating shaft 1, and their axes are on the same rotating axis. The upper rotating shaft 4 is embedded in the casing 3, and the lower rotating shaft 1 is embedded in the hub 2. The shaft diameter of the upper rotating shaft 4 is larger than that of the lower rotating shaft 1, and the lower rotating shaft 1 only serves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com