Multilayer ceramic capacitor of low ESL

A multi-layer ceramic and capacitor technology, applied in the direction of multilayer capacitors, fixed capacitor dielectrics, fixed capacitor terminals, etc., can solve the problems that capacitors cannot be applied to high-frequency circuits, the self-resonant frequency of capacitors decreases, and the equivalent inductance of capacitors increases. , to increase the adhesion amount and adhesion strength, increase the self-resonant frequency, and reduce the effect of ESL

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

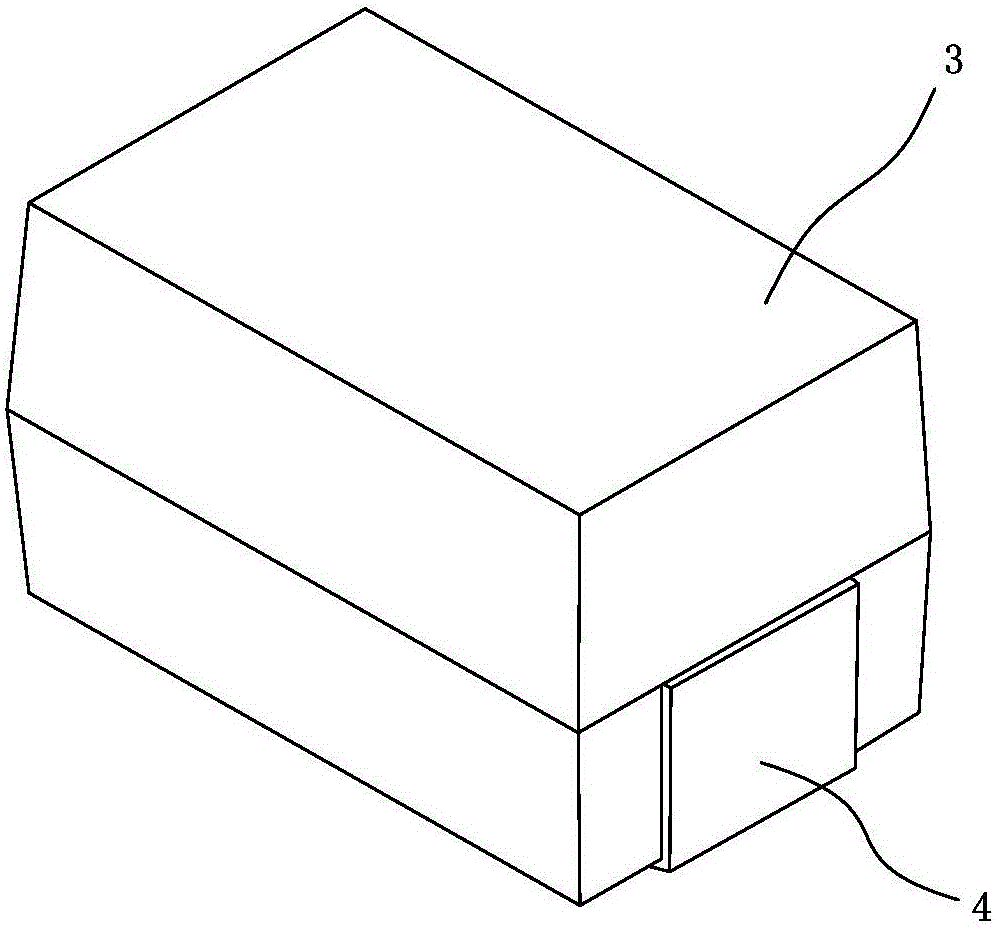

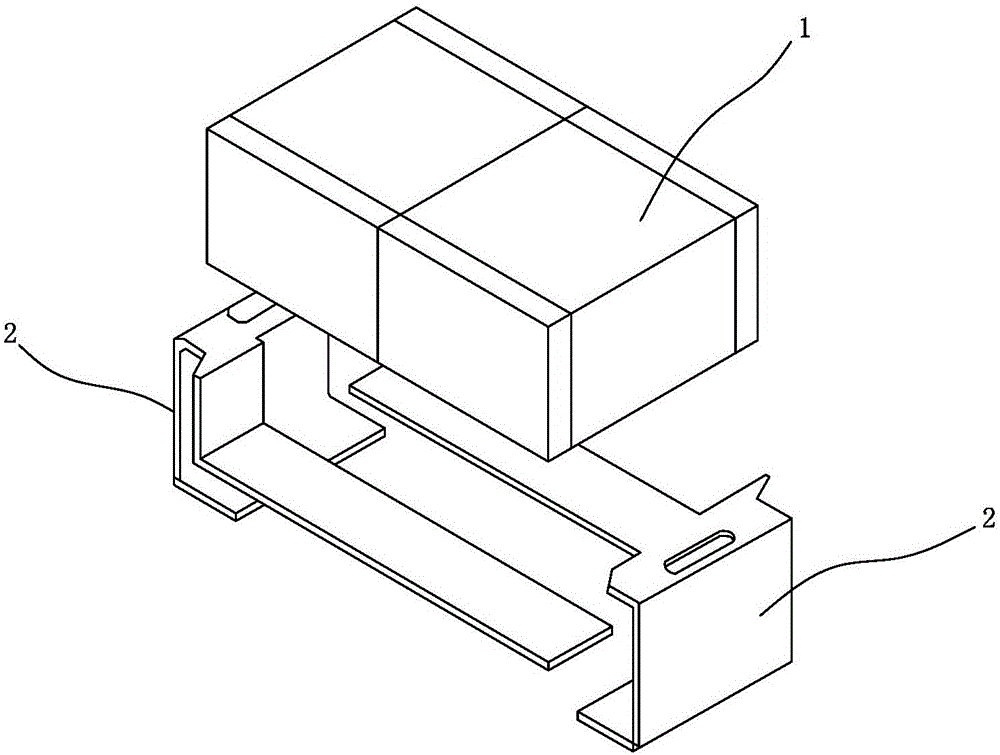

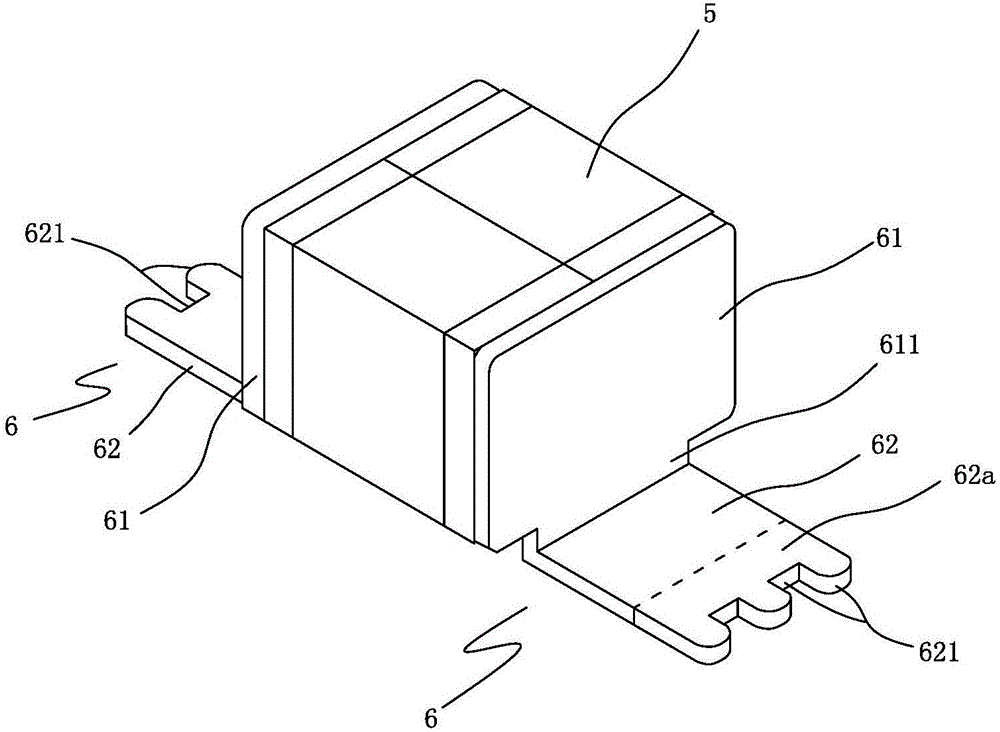

[0025] Example one, reference image 3 with Figure 4 As shown, a low ESL multilayer ceramic capacitor includes a ceramic core 5, two leads 6 and an insulating shell 7.

[0026] The ceramic core 5 is a rectangular parallelepiped, which is mainly composed of a dielectric, an inner electrode sheet and an outer electrode sheet. The two outer electrode sheets are arranged on two opposite faces of the ceramic core body 5. This is a well-known prior art and will not be described in detail here.

[0027] The lead 6 is an integrally formed "L"-shaped structure, which is composed of a conductive plate 61 and a welding plate 62 that are connected perpendicularly to each other. The conductive plate 61 and the welding plate 62 are approximately rectangular, and the conductive plate 61 has a protrusion connected to the welding plate 62 611.

[0028] The conductive plates 61 of the two leads 6 are respectively attached to the two opposite surfaces of the ceramic core 5 and electrically connected t...

Embodiment 2

[0029] The second embodiment, the basic structure is the same as the first embodiment, the main difference lies in the structure of the lead 8, which includes a vertically extending conductive plate 81, a horizontal welding plate 82 connected to the conductive plate 81 and extending horizontally, and a connecting horizontal welding plate 82 and a vertical welding plate 83 extending vertically. The conductive plate 81 is electrically connected to the ceramic core 5 and is covered by the insulating housing 7. The horizontal welding plate 82 is located at the bottom of the insulating housing 7, and the vertical welding plate 83 is located at the bottom of the insulating housing 7. At least the bottom surface of the horizontal welding plate 82 and the outer side surface of the vertical welding plate 83 are exposed outside the insulating housing 7. The vertical welding plate 83 is formed with three solder filling holes 831 close to the horizontal welding plate 82. The holes 831 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com