Rotor winding pole coil and manufacturing die thereof as well as casing copper bar edgewind wrench

A magnetic pole coil and rotor winding technology, which is applied in the field of rotor winding magnetic pole coils, can solve the problems of not meeting the requirements of the flat winding process, the inability to carry out flat winding, and the four corners of the bowl, so as to improve the insulation and heat resistance level and electrical performance, and meet the safety requirements. Reliable operation, the effect of reducing the bending angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

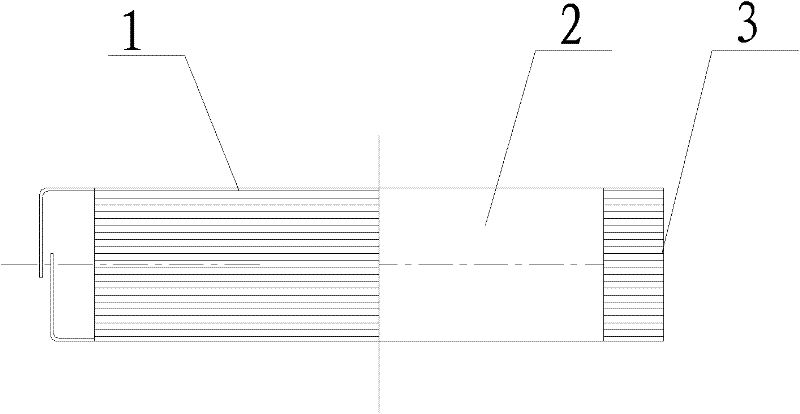

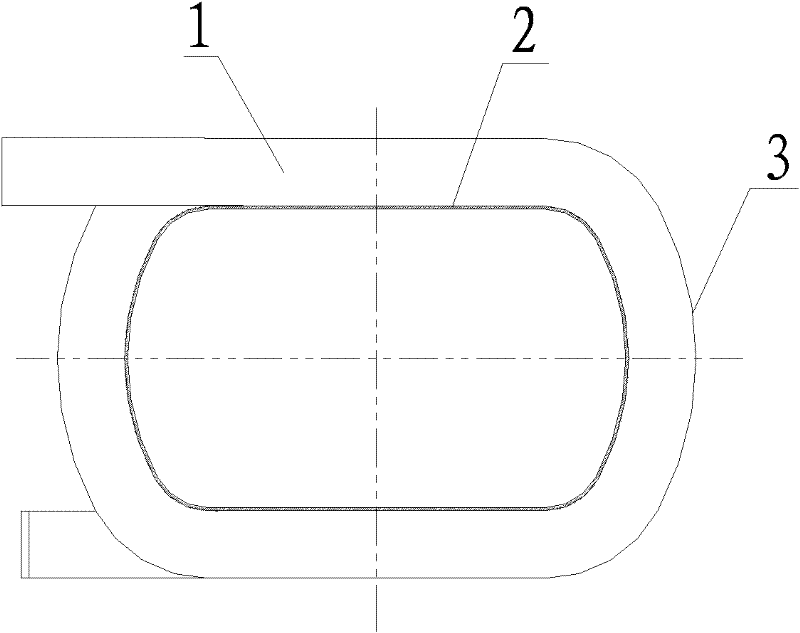

[0021] Such as figure 1 , figure 2 In the rotor winding magnetic pole coil shown, the annular coil 1 is made of copper bars, and the arc angles are formed at the four corners of the annular coil. The length direction of the annular coil is linear, and the width direction of the annular coil is arc-shaped 3. A 0.5 mm glass cloth plate 2 is pasted on the inner diameter of the ring coil.

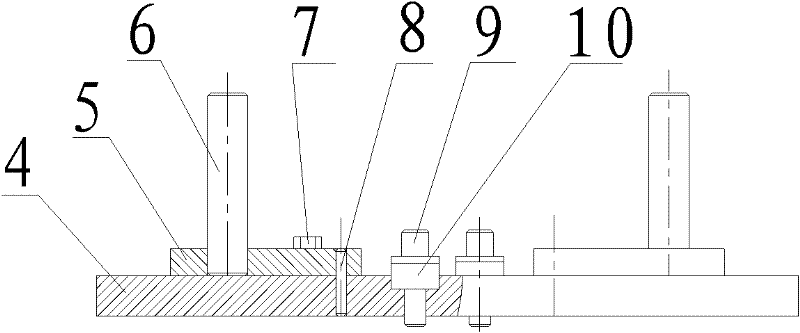

[0022] Such as image 3 , Figure 4 The shown rotor winding magnetic pole coil mold has a bottom plate 4 on which a mold core 5 is symmetrically installed and a column 6 is vertically installed on the mold core. The outer side of the mold core in the width direction is arc-shaped, and the length of the bottom plate is Line crimping hooks 10 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com