Split-type arrangement method and structure of gas transformer

A gas transformer and layout structure technology, which is applied in transformers, fixed transformers, transformer/inductor cooling, etc., can solve problems such as poor ventilation environment, save floor space, reduce energy consumption and noise, and have good heat dissipation and ventilation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

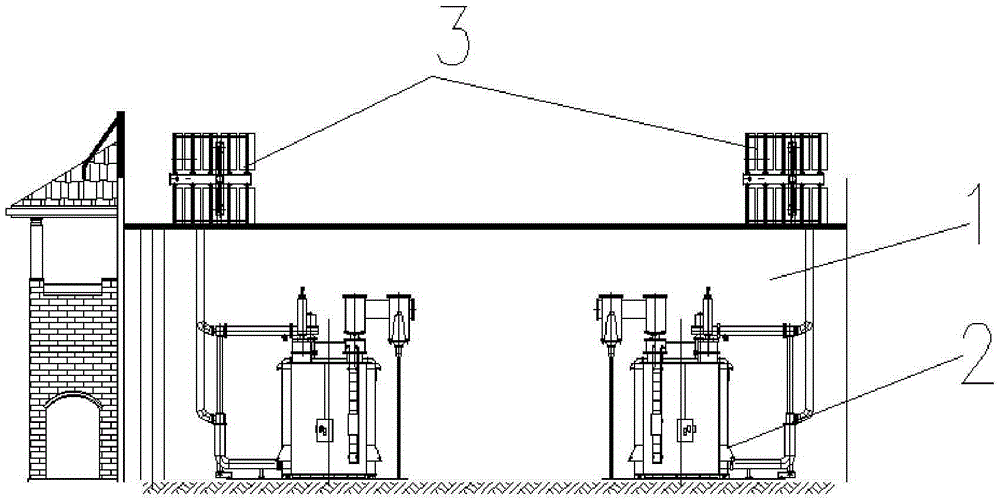

[0024] refer to figure 1 , the split layout structure involved in this embodiment includes a main transformer room 1 and a gas transformer 2, and the heat dissipation structure of the gas transformer 2 is a split independent structure, which constitutes a radiator 3 independent of the gas transformer 1; the gas transformer 2 is arranged In the interior of the main transformer chamber 1, the radiator 3 is arranged outside the main transformer chamber 1 to form a split structure; the fins of the radiator 3 are connected to the gas transformer 2 through heat transfer tubes to form a split heat dissipation structure.

[0025] In this example:

[0026] The main transformer room 1 is located in the semi-underground substation, underground substation or attached substation. The main body of the gas transformer 2 is installed in the semi-basement or basement. The radiator 3 is arranged on the roof of the main transformer room 1 and is in direct contact with the atmosphere. The coolin...

specific Embodiment 2

[0031] The characteristics of this embodiment 2 are: the main transformer room 1 is located in the room of the attached substation, the attached substation is arranged in a large building, the main body of the gas transformer 2 is installed in a special building attached to the large building, The radiator 3 is arranged in the ventilating place in the large building and is in direct contact with the atmosphere, and the fins of the radiator (3) are connected with the main body of the gas transformer 2 through heat transfer tubes. All the other are with specific embodiment 1.

[0032] The applicant's test application has proved that the arrangement method claimed in the present invention cleverly utilizes the insulating medium of the gas transformer 2—SF6 gas has a low density (only 1 / 60 of the insulating oil density) and light weight, and the radiator is flexibly arranged in the The heat dissipation effect is enhanced in a better ventilation environment, so as to better meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com