Shearing device and cloth production process using shearing device

A technology of shearing and wool rollers, applied in the direction of fabric elongation, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of different fluff lengths and reduce fabric quality, etc., to reduce fluff debris, improve quality, reduce stacking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-8 The application is described in further detail.

[0047] The embodiment of the application discloses a shearing device.

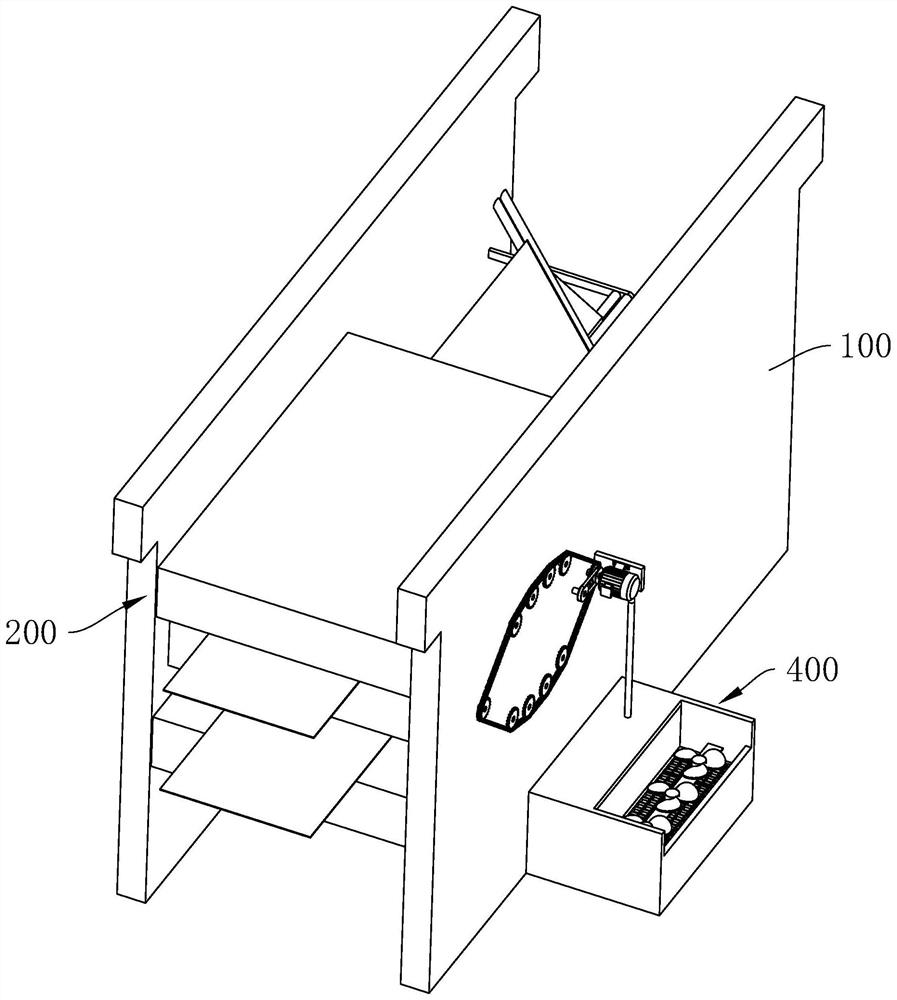

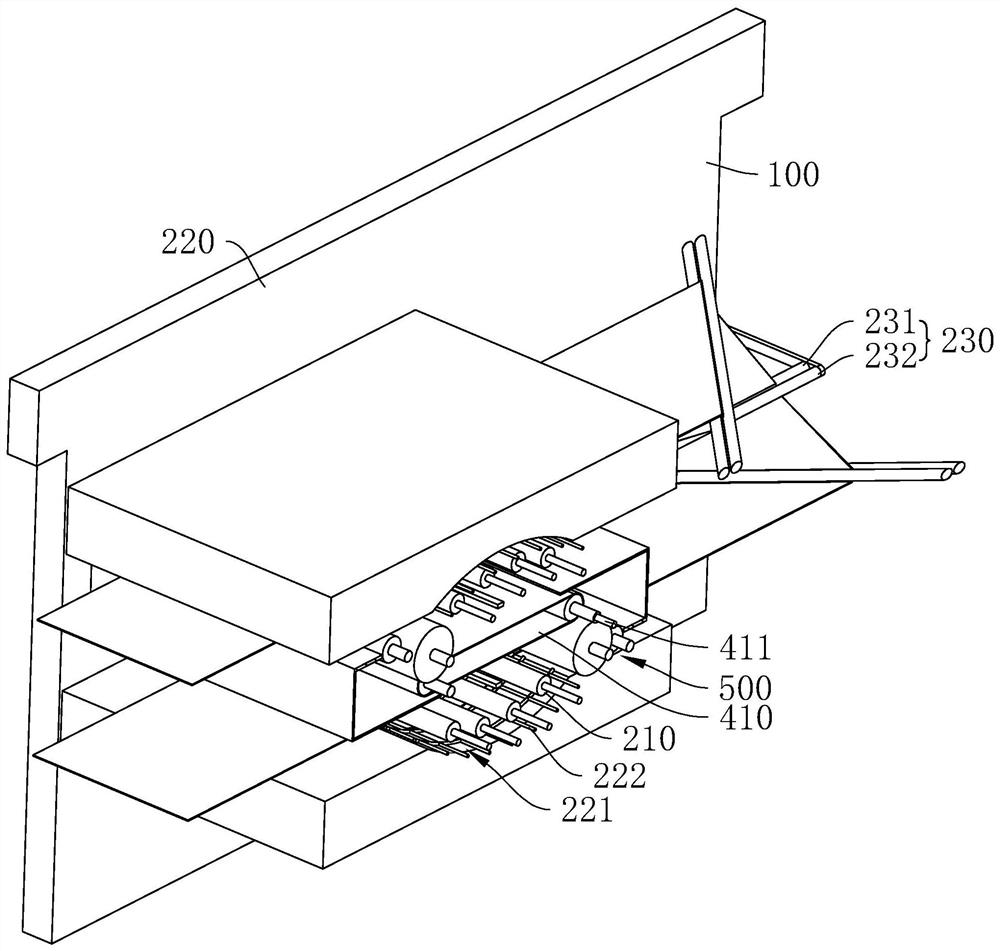

[0048] refer to figure 1 and figure 2 , a shearing device, comprising a frame 100, a shearing mechanism 200 is provided on the frame 100, the shearing mechanism 200 includes two groups of shearing rollers 210, two limiting blocks 220 and a steering member 230, the limiting block 220 is rectangular, and the limiting Both ends of the positioning block 220 are horizontally and fixedly connected to opposite sides of the frame 100 respectively, and the two limiting blocks 220 are vertically spaced apart and parallel to each other.

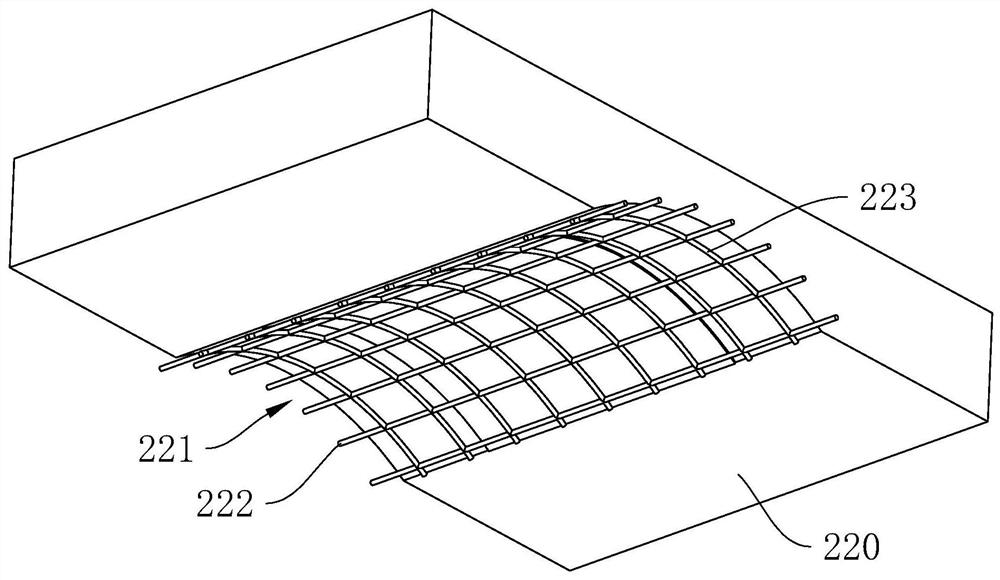

[0049] refer to figure 2 and image 3 The opposite side walls of the two limit blocks 220 are provided with elongated relief grooves 221, the length direction of the relief grooves 221 is parallel to the length direction of the limit blocks 220, and the two ends of the relief groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com