Middle-mounted chain transmission wheel core drive electric drive automatic speed change system

A technology of chain drive wheel and automatic speed change, which is applied in the direction of wheel drive, chain/belt drive, vehicle gearbox, etc. It can solve the problem of difficulty in setting up deceleration and shifting mechanisms, the inability to use high-speed motors, and unsatisfactory motor efficiency, etc. problem, to achieve the effect of reducing distance change, strong climbing and heavy load capacity, and extending the deceleration transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

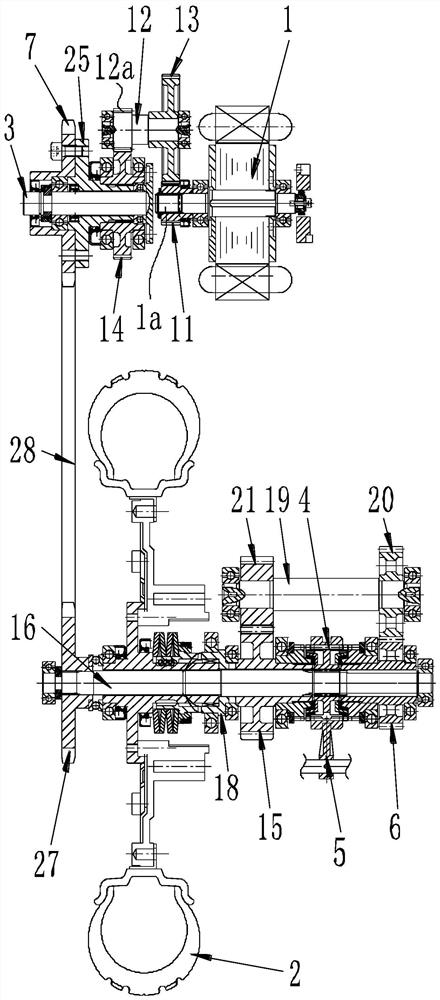

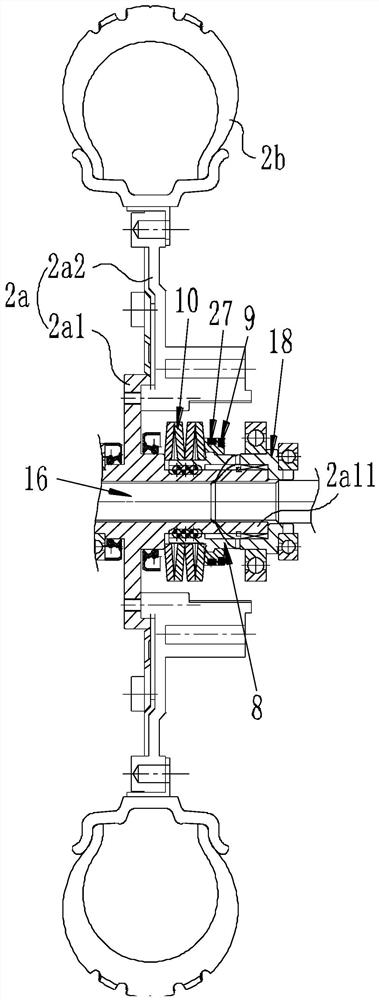

[0031] Such as figure 1 As shown, a center-mounted chain transmission wheel core drives an electric drive automatic transmission system, which mainly includes a power input mechanism, a driving wheel 2, a deceleration input mechanism arranged on the outer intermediate shaft 3, and a chain drive assembly connected to the outer middle of the wheel. The wheel installation shaft 16 connected to the shaft 3 and the gear shifting transmission mechanism and power output components all arranged on the wheel installation shaft 16, the driving wheel 2 is set on the wheel installation shaft 16, and the power input mechanism passes through the deceleration input mechanism and the chain transmission assembly in turn. , the wheel mounting shaft 16, the shift transmission mechanism and the power output component transmit power to the drive wheel 2.

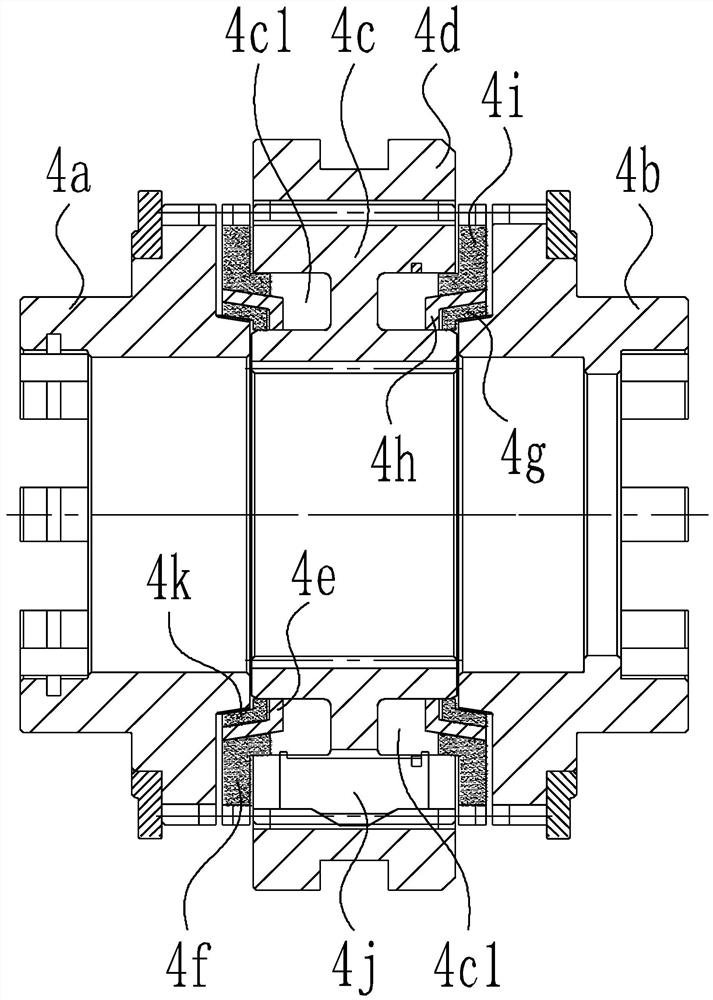

[0032]The shift transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com