Liquid-level-self-adaptive scaling powder coating device

A coating device and flux technology, which is applied to the surface coating liquid device, coating, manufacturing coaxial cables, etc., can solve the problems of copper wire stress cannot be eliminated, product quality decline, etc., to ensure coating quality , product quality assurance, the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

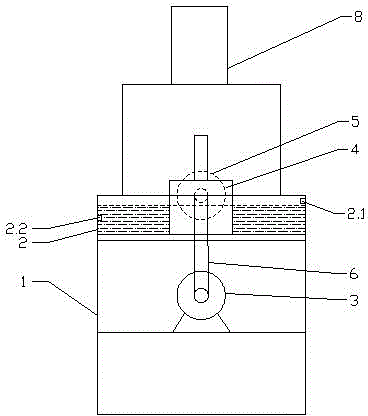

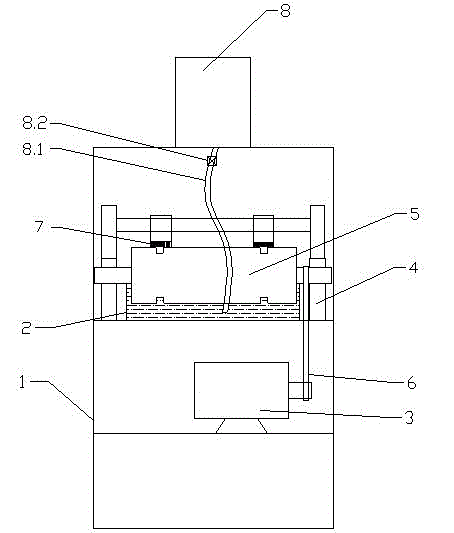

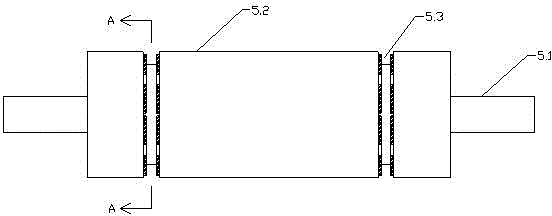

[0016] see Figure 1~Figure 4 , a liquid level self-adaptive flux coating device related to the present invention, which includes a flux coating frame 1, and the flux coating frame 1 is provided with a flux tank 2 arranged up and down and a motor 3, The inner wall of the flux tank 2 is provided with a first liquid level gauge 2.1 and a second liquid level gauge 2.2 arranged up and down, the first liquid level gauge 2.1 and the second liquid level gauge 2.2 are used to sense the flux in the flux tank 2 The height of the flux liquid level, the flux coating frame 1 at the front and rear ends of the flux tank 2 is provided with a support frame 4, the bottom of the support frame 4 is arranged in a chute in the left and right direction, and the support frame 4 can be placed in the chute Move left and right to adjust the position. A longitudinally arranged flux application roller 5 is erected between the lower sections of the support frame 4, and the roller shaft of the flux applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com