Header pressure heat exchanger

A pressure-bearing, heat-exchanger technology, applied in the direction of heat-exchanger shell, indirect heat-exchanger, heat-exchanger type, etc. Vertical installation and other problems, to achieve the effect of easy penetration of welds, improved resistance to intergranular corrosion, and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

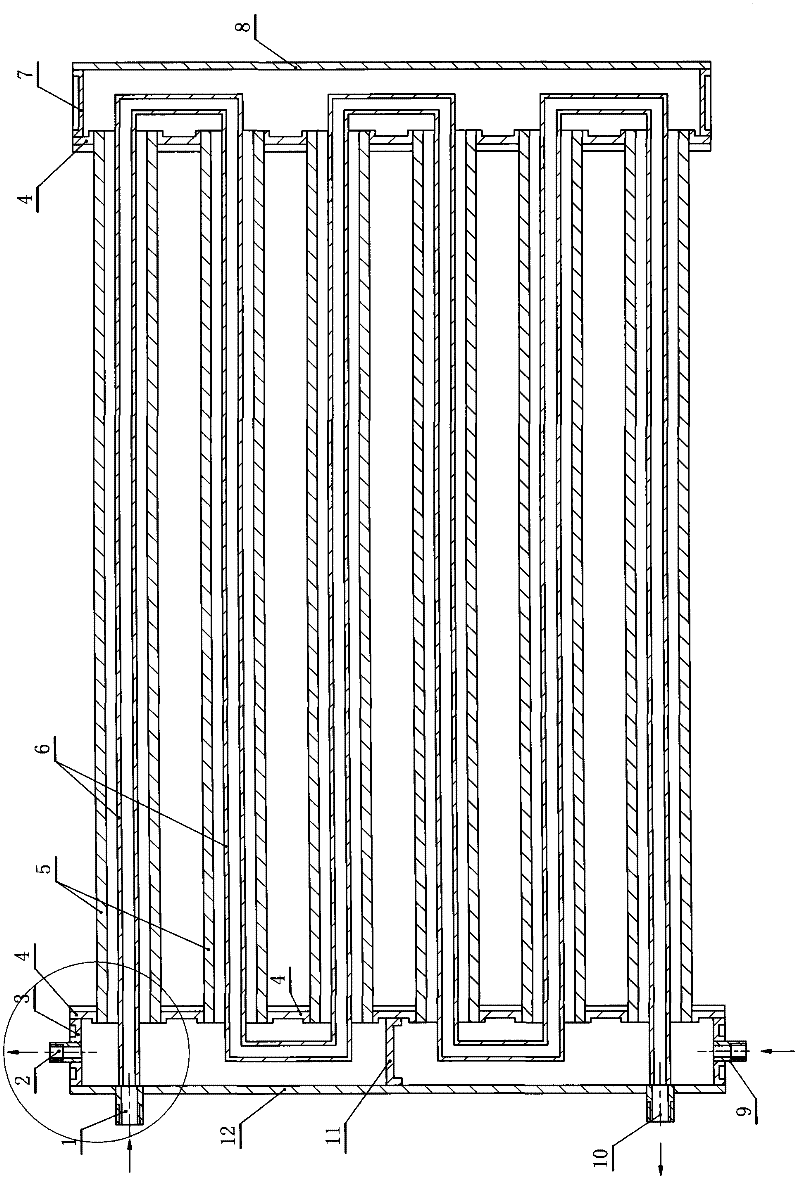

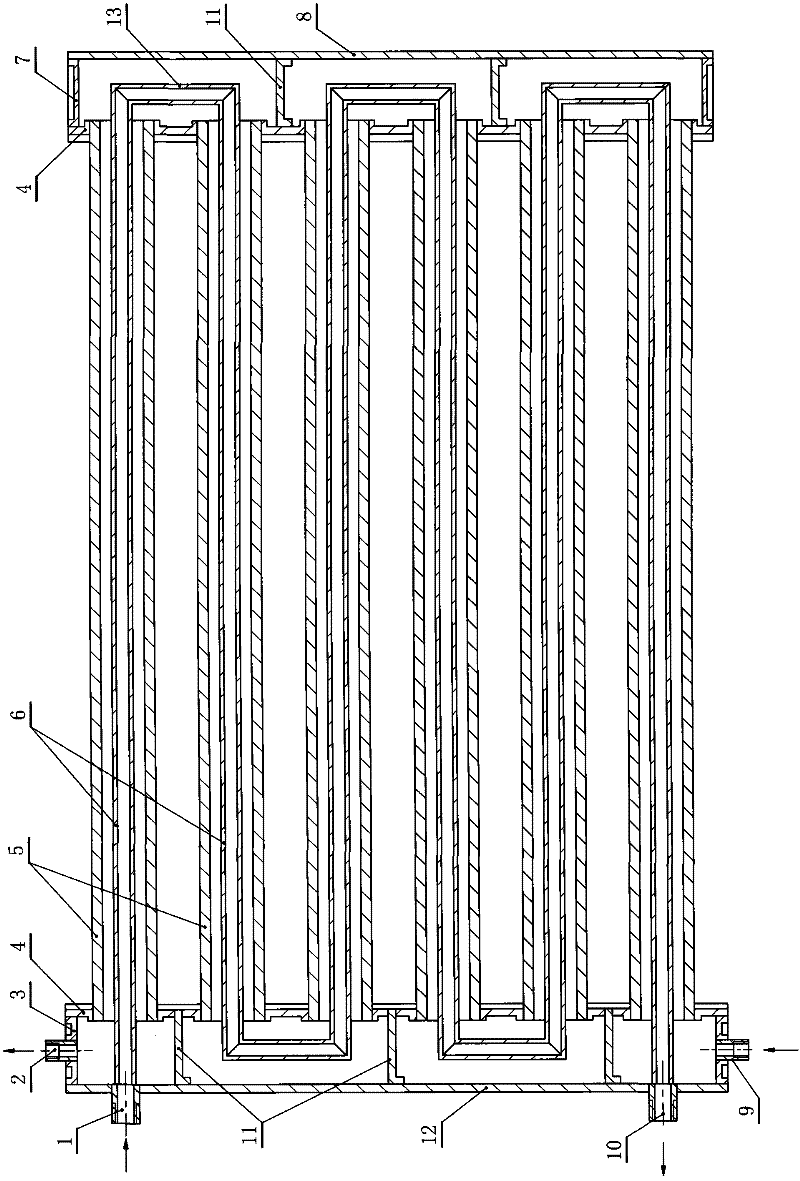

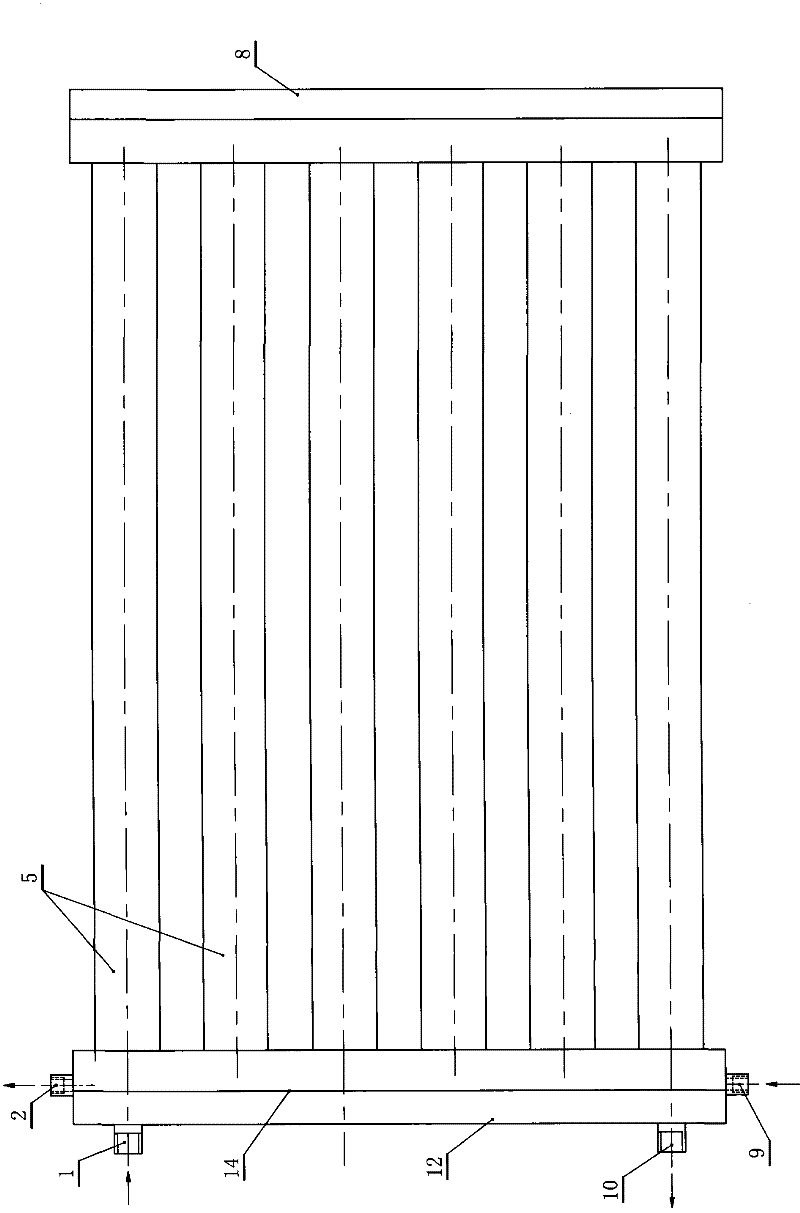

[0041] The header pressure-bearing heat exchanger of the present invention is as figure 1 , figure 2 As shown, it includes: two headers, the headers include a header shell, an orifice 4 and a cover plate, and the headers are fixedly connected with a heating water inlet 1, a heating water outlet 10, a tap water inlet 9 and a tap water outlet 2; Two or more tap water heat-absorbing pipes 5 are fixedly connected between the two headers, and the tap water heat-absorbing pipes 5 are provided with heating pipes 6. The heating pipes 6 are connected, and the connected heating pipes are connected. One end of the pipe 6 is connected to the heating water inlet 1, and the other end of the heating heating pipe 6 is connected to the heating water outlet 10; the characteristic is that one or more water blocking plates are arranged in one of the headers 11.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com