High-melt-index halogen-free flame-retardant polypropylene material and preparation method thereof

A flame-retardant polypropylene and high-melt finger technology, applied in the field of flame-retardant materials, can solve problems such as lower interfacial tension, low flame-retardant efficiency, and high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

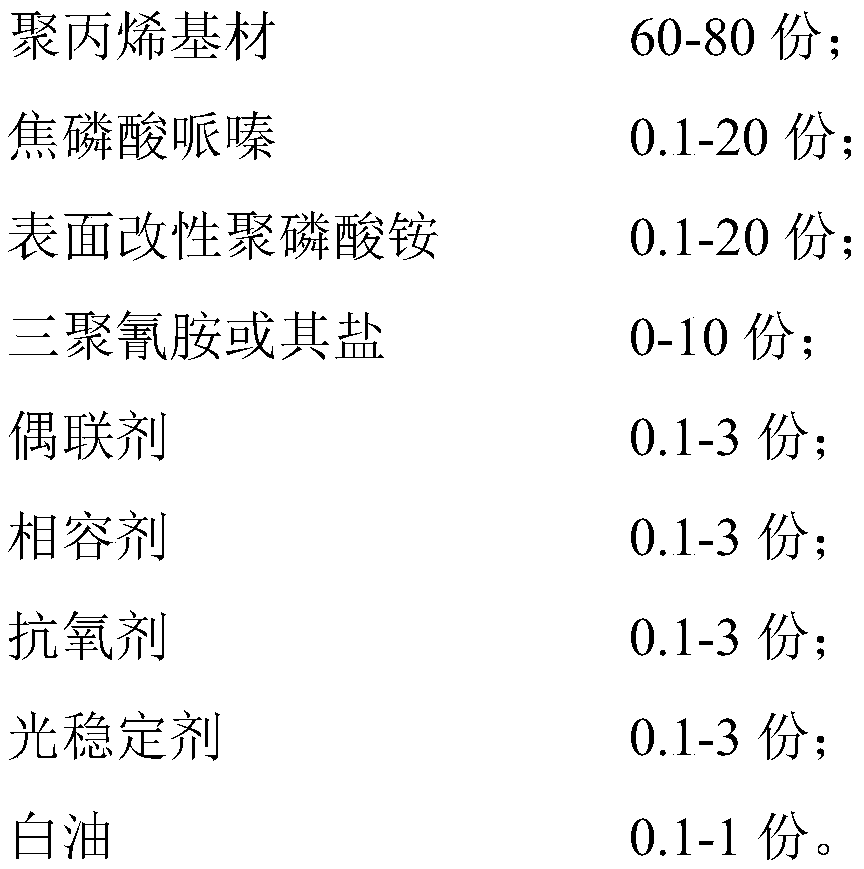

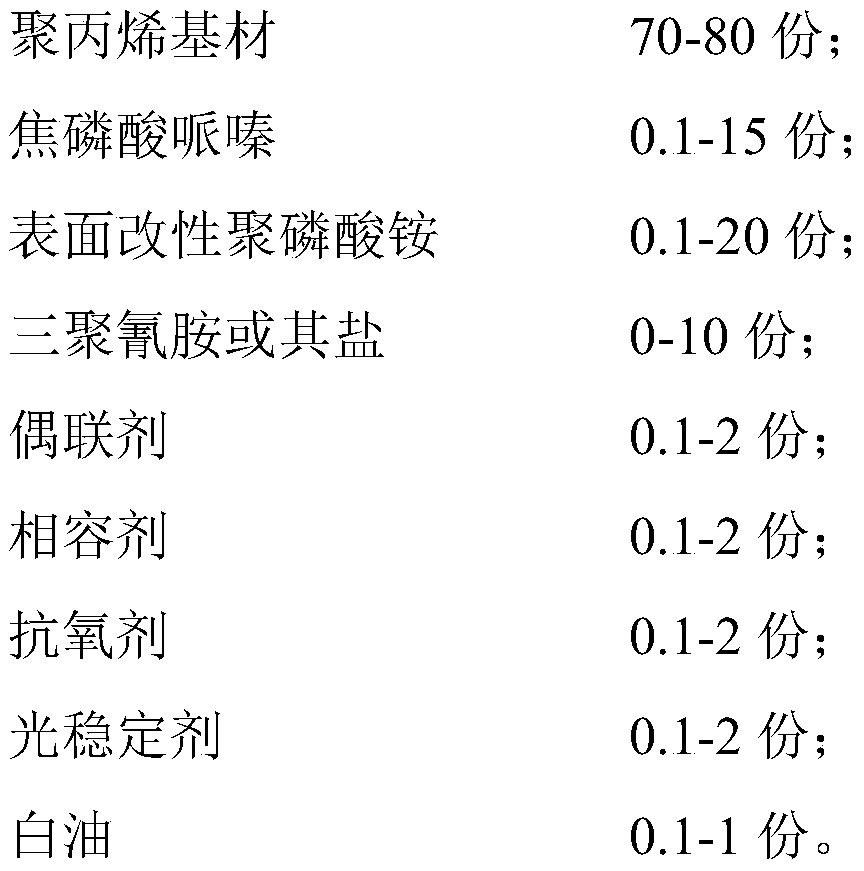

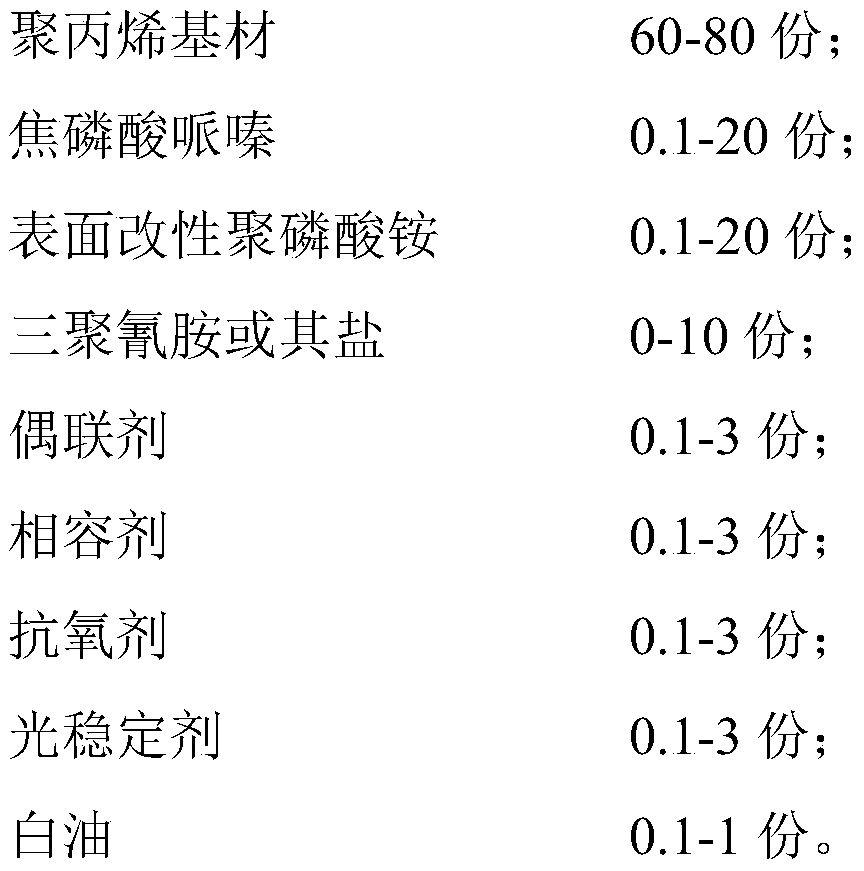

Method used

Image

Examples

Embodiment 1

[0074] The preparation of pyro(poly)piperazine phosphate:

[0075] (1) In a three-necked flask with a stirring paddle, feed nitrogen for 0.5-1 hour, evacuate the internal air, then weigh phosphoric acid (97.97g) and piperazine phosphate (184.1g) (the molar ratio is: n phosphoric acid: n phosphoric acid Piperazine=1:1), added to the three-necked flask, heated to 80-100°C in a water bath, continuously fed with nitrogen protection, started stirring, the stirring rate was 40-60rpm, and the reaction time was 2-3 hours. After the reaction was complete, cool to room temperature, filter and dry, and pulverize to obtain the white intermediate product piperazine diphosphate.

[0076] (2) Weigh 264g of piperazine diphosphate and 97.97g of phosphoric acid (the molar ratio is: n piperazine diphosphate: n phosphoric acid = 1:1), add them into a three-necked flask, heat the oil bath to 180-220°C, and continue to pass Enter nitrogen protection, start stirring, continue to stir for 2-3 hours,...

Embodiment 2

[0085] See Example 1 for the preparation of piperazine pyro(poly)phosphate and the preparation of surface-modified ammonium polyphosphate.

[0086] Preparation of high melting point halogen-free flame retardant polypropylene material:

[0087] 1) Weigh raw materials by weight, pre-mix 70 parts of dry copolymerized polypropylene (K8003) and 0.5 part of white oil in a double-motion mixer for 5 minutes, the speed of the double-motion mixer body is 20rpm, and the speed of the internal blades is 30rpm, the tilt angle of the body is 0° to achieve uniform mixing.

[0088] 2) Add in parts by weight, 15 parts of piperazine pyrophosphate, 15 parts of surface modified ammonium polyphosphate (APP-60), 0.5 part of coupling agent, 0.2 part of compatibilizer, 0.2 part of antioxidant, 0.2 part of light Stabilizer, double-motion mixer body speed is 30rpm, internal blade speed is 40rpm, body tilt angle is 0°, continue mixing for 5 minutes to obtain a homogeneous mixture.

[0089] 3) See Examp...

Embodiment 3

[0092] See Example 1 for the preparation of piperazine pyro(poly)phosphate and the preparation of surface-modified ammonium polyphosphate.

[0093] Preparation of high melting point halogen-free flame retardant polypropylene material:

[0094] 1) Weigh raw materials by weight, pre-mix 70 parts of dry copolymerized polypropylene (K8003) and 0.5 part of white oil in a double-motion mixer for 5 minutes, the speed of the double-motion mixer body is 20rpm, and the speed of the internal blades is 30rpm, the tilt angle of the body is 0° to achieve uniform mixing.

[0095] 2) Add in parts by weight, 15 parts of piperazine pyrophosphate, 15 parts of surface modified ammonium polyphosphate (APP-70), 0.5 part of coupling agent, 0.2 part of compatibilizer, 0.2 part of antioxidant, 0.2 part of light Stabilizer, double-motion mixer body speed is 30rpm, internal blade speed is 40rpm, body tilt angle is 0°, continue mixing for 5 minutes to obtain a homogeneous mixture.

[0096] 3) See Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com