Quantitative filling equipment for enzyme beverage production

A beverage and equipment technology, which is applied in the field of quantitative filling equipment for enzyme beverage production, can solve the problems of complex structure, large difference in product concentration, and low cost, and achieve the effect of expanding the stirring area, improving uniformity, and reducing sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

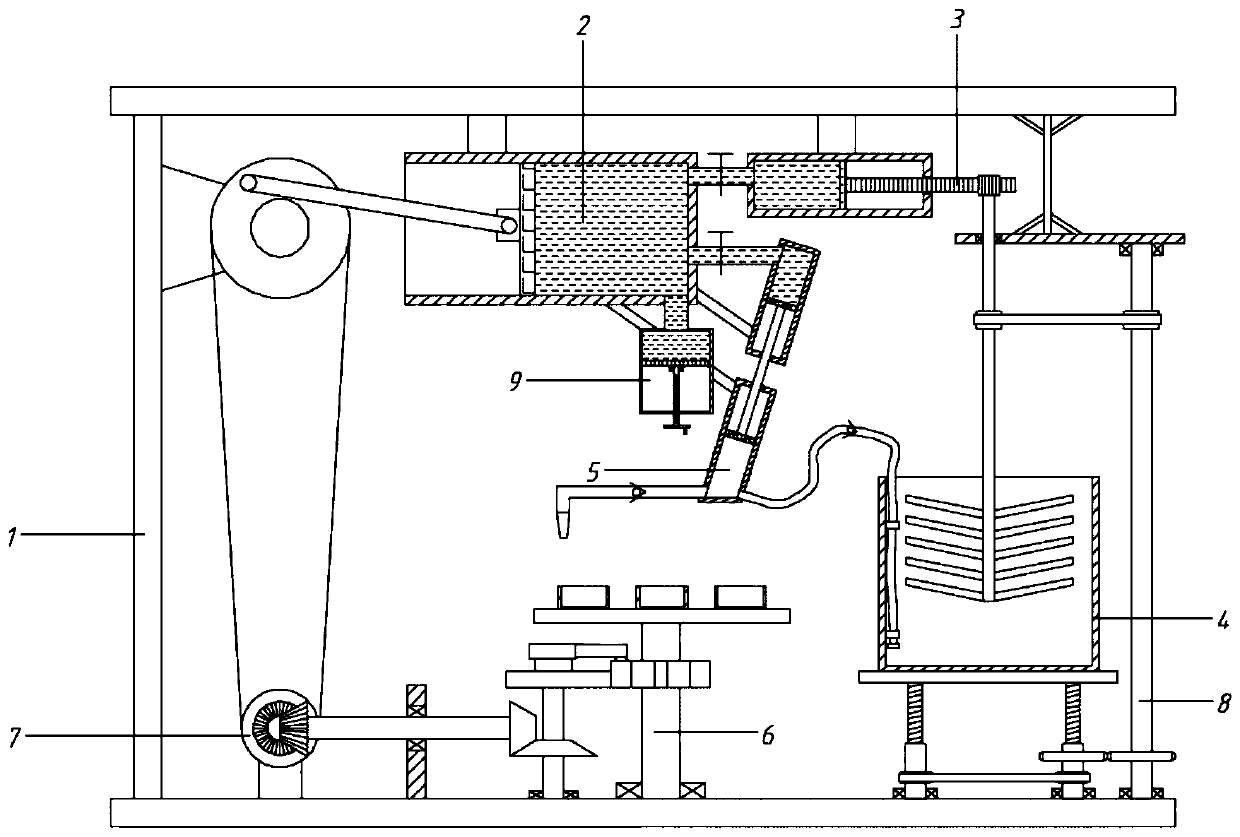

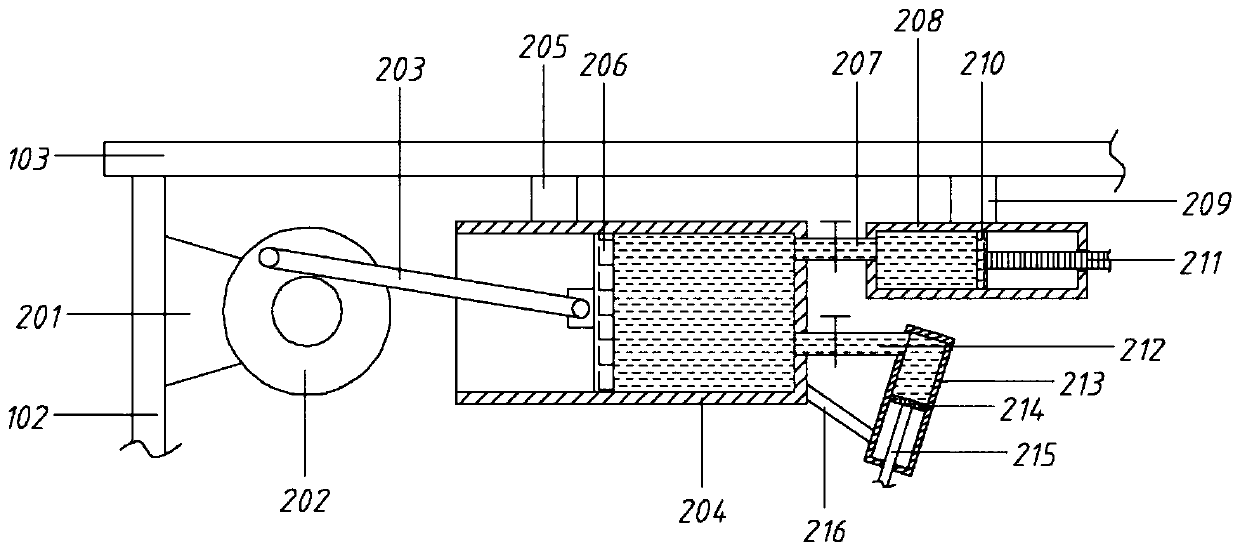

[0070] With reference to the accompanying drawings, a quantitative filling device for enzyme beverage production includes a frame 1, a piston assembly 2, a stirring assembly 3, a pumping assembly 5, a transmission assembly 7 and a switching assembly 6;

[0071] The frame 1 includes a base 101, a left side plate 102 and a top plate 103, the left end of the base 101 and the top plate 103 are connected through the left side plate 102; a piston assembly 2 is arranged below the top plate 103, and a stirring assembly 3 is provided on the right side of the piston assembly 2; the base 101 The right part is provided with a liquid storage tank 4, and the lower section of the stirring assembly 3 extends into the liquid storage tank 4; the right side of the piston assembly 2 is also provided with a pumping assembly 5; the middle part of the base 101 is provided with a switching assembly 6, and the switching assembly 6 passes through the transmission assembly 7 is connected with the piston ...

Embodiment 2

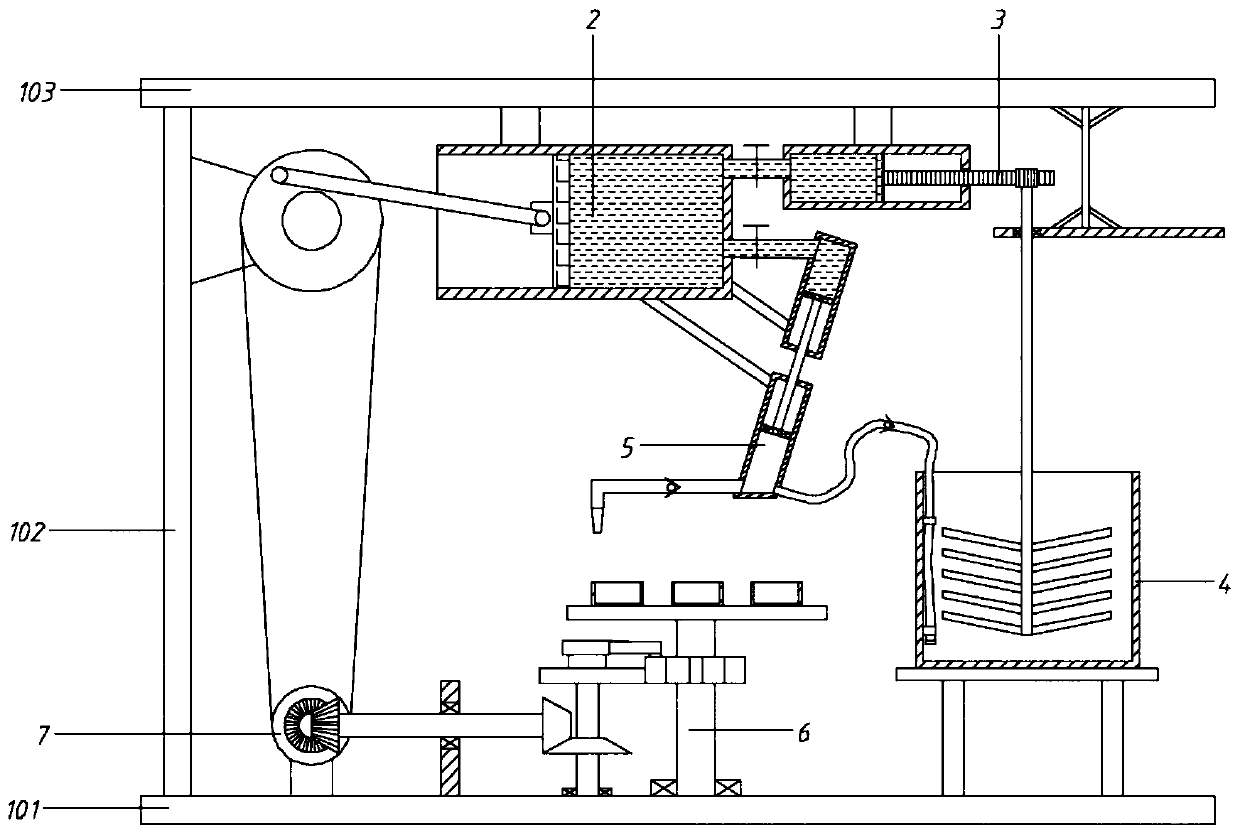

[0073] With reference to the accompanying drawings, a quantitative filling device for enzyme beverage production includes a frame 1, a piston assembly 2, a stirring assembly 3, a pumping assembly 5, a transmission assembly 7 and a switching assembly 6;

[0074] The frame 1 includes a base 101, a left side plate 102 and a top plate 103, the left end of the base 101 and the top plate 103 are connected through the left side plate 102; a piston assembly 2 is arranged below the top plate 103, and a stirring assembly 3 is provided on the right side of the piston assembly 2; the base 101 The right part is provided with a liquid storage tank 4, and the lower section of the stirring assembly 3 extends into the liquid storage tank 4; the right side of the piston assembly 2 is also provided with a pumping assembly 5; the middle part of the base 101 is provided with a switching assembly 6, and the switching assembly 6 passes through the transmission assembly 7 is connected with the piston ...

Embodiment 3

[0098] On the basis of embodiment 2,

[0099] It also includes a lifting assembly 8; the lifting assembly 8 includes a second type transmission wheel 801, a second transmission belt 802, a fifth rotating shaft 803 and a third gear 804;

[0100] The fifth pole 401 is composed of an internally threaded pipe 4011 and a lifting screw 4012; the bottom end of the internally threaded pipe 4011 is rotationally connected with the base 101, and the internally threaded pipe 4011 is correspondingly equipped with a first-class transmission wheel 4013 and is driven by a No. 1 transmission belt 4014. connection, the internal thread pipe 4011 on the right side is also equipped with No. 2 gear 4015; the lower part of the lifting screw 4012 is screwed into the internal thread pipe 4011, and the top is fixedly connected with the placement plate 402; the fifth rotating shaft 803 is arranged on the right side of the placement plate 402, up and down The ends are respectively connected to the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com