Rapid preparation device for cooling liquid used for machining tool

A technology for processing machine tools and coolants, applied in mixer parts, mixers, transportation and packaging, etc., can solve the problems of incomplete reaction, cumbersome operation, uneven quality of coolant, etc., and achieve the effect of ensuring the mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

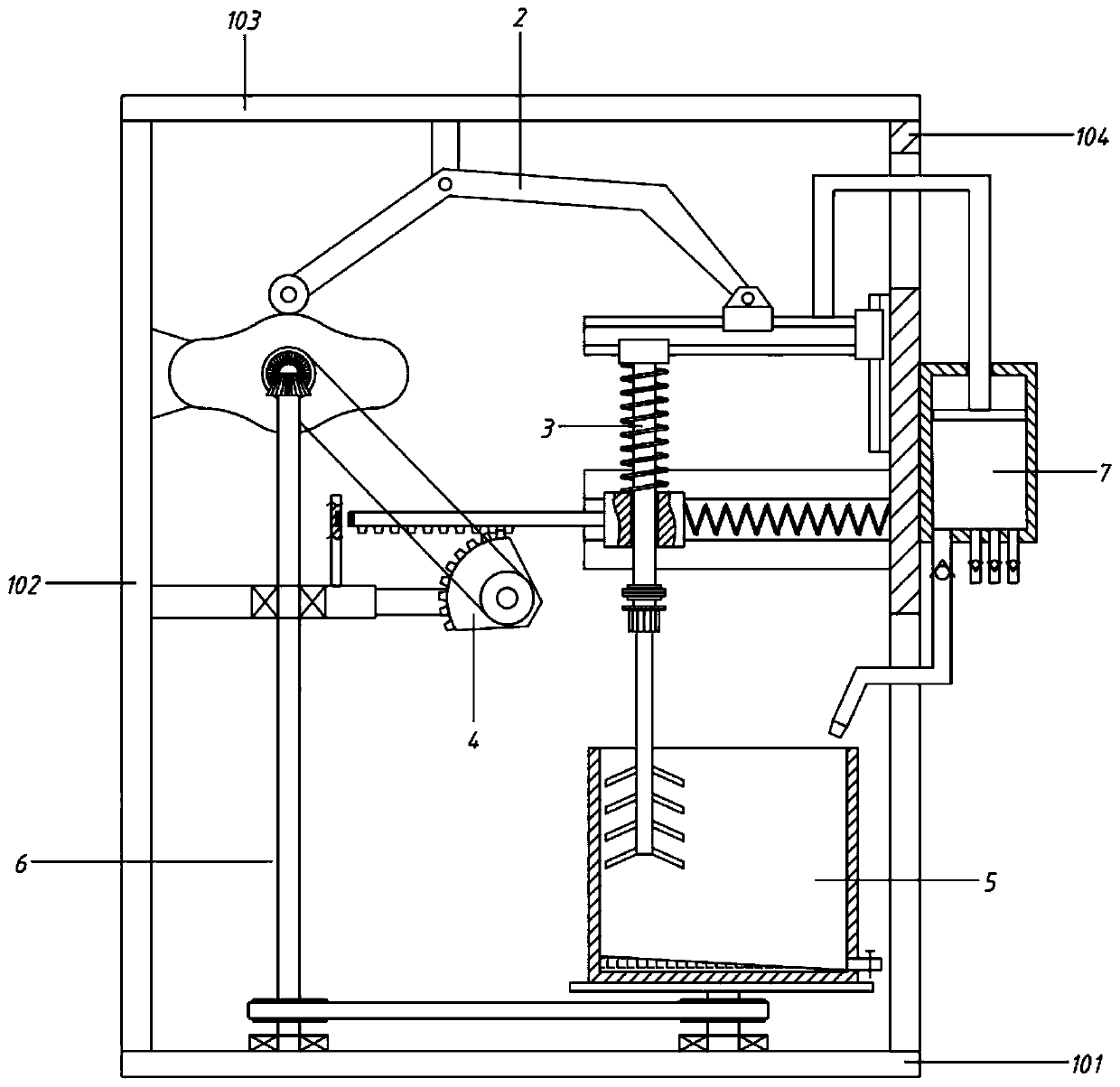

[0053] A cooling liquid rapid preparation device for processing machine tools, including a frame, a lifting component 2, a stirring component 3 and a mixing bucket 5;

[0054] The frame includes a bottom plate 101, a left side plate 102, a top plate 103 and a right side plate 104, which are connected end to end to form a rectangular frame body;

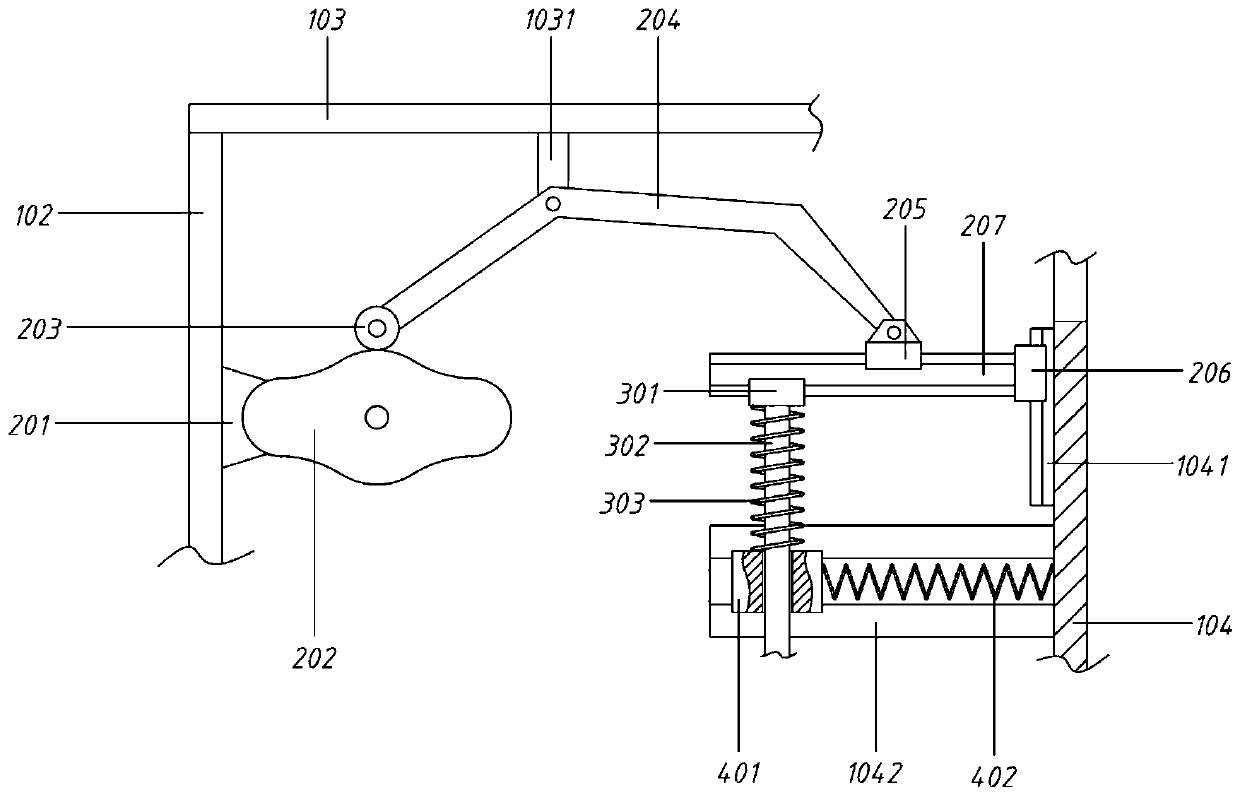

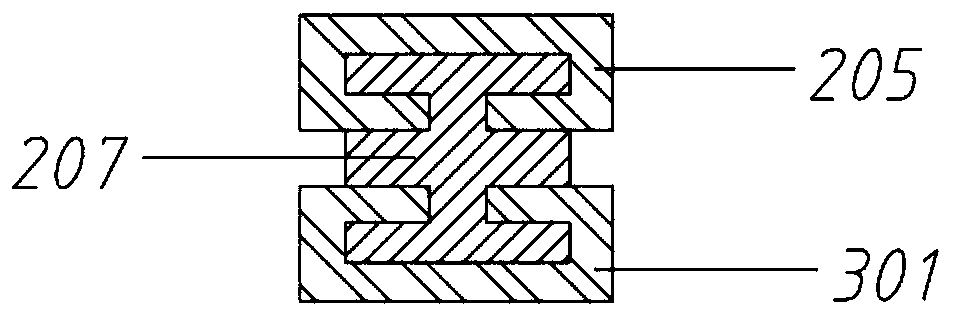

[0055] Lifting assembly 2 includes No. 1 servo motor, cam 202, rocker 204, double-sided slide rail 207 and No. 2 slide rail 1042; No. 1 servo motor is installed on the right side of left side plate 102 through motor base 201, and No. 1 servo motor The output end of the output end protrudes forward and is connected with a cam 202; a roller 203 is fitted on the top of the cam 202; Hinged; one end of the rocker 204 is connected with the roller 203, and the other end is hinged with the No. 2 slider 205; the double-sided slide rail 207 is horizontally arranged, and the right end is vertically slidably connected with the right side plate 20...

Embodiment 2

[0062] A cooling liquid rapid preparation device for processing machine tools, including a frame, a lifting component 2, a stirring component 3 and a mixing bucket 5;

[0063] The frame includes a bottom plate 101, a left side plate 102, a top plate 103 and a right side plate 104, which are connected end to end to form a rectangular frame body;

[0064] Lifting assembly 2 includes No. 1 servo motor, cam 202, rocker 204, double-sided slide rail 207 and No. 2 slide rail 1042; No. 1 servo motor is installed on the right side of left side plate 102 through motor base 201, and No. 1 servo motor The output end of the output end protrudes forward and is connected with a cam 202; a roller 203 is fitted on the top of the cam 202; Hinged; one end of the rocker 204 is connected with the roller 203, and the other end is hinged with the No. 2 slider 205; the double-sided slide rail 207 is horizontally arranged, and the right end is vertically slidably connected with the right side plate 20...

Embodiment 3

[0074] A cooling liquid rapid preparation device for processing machine tools, including a frame, a lifting component 2, a stirring component 3 and a mixing bucket 5;

[0075] The frame includes a bottom plate 101, a left side plate 102, a top plate 103 and a right side plate 104, which are connected end to end to form a rectangular frame body;

[0076] Lifting assembly 2 includes No. 1 servo motor, cam 202, rocker 204, double-sided slide rail 207 and No. 2 slide rail 1042; No. 1 servo motor is installed on the right side of left side plate 102 through motor base 201, and No. 1 servo motor The output end of the output end protrudes forward and is connected with a cam 202; a roller 203 is fitted on the top of the cam 202; Hinged; one end of the rocker 204 is connected with the roller 203, and the other end is hinged with the No. 2 slider 205; the double-sided slide rail 207 is horizontally arranged, and the right end is vertically slidably connected with the right side plate 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com