Raw material stirring device for chemical gas production

A gas production and stirring device technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as restricting the industry's prosperity, unsatisfactory mixing efficiency, and huge new production capacity at the supply end. The mixing area is large, the production efficiency is improved, and the mixing effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

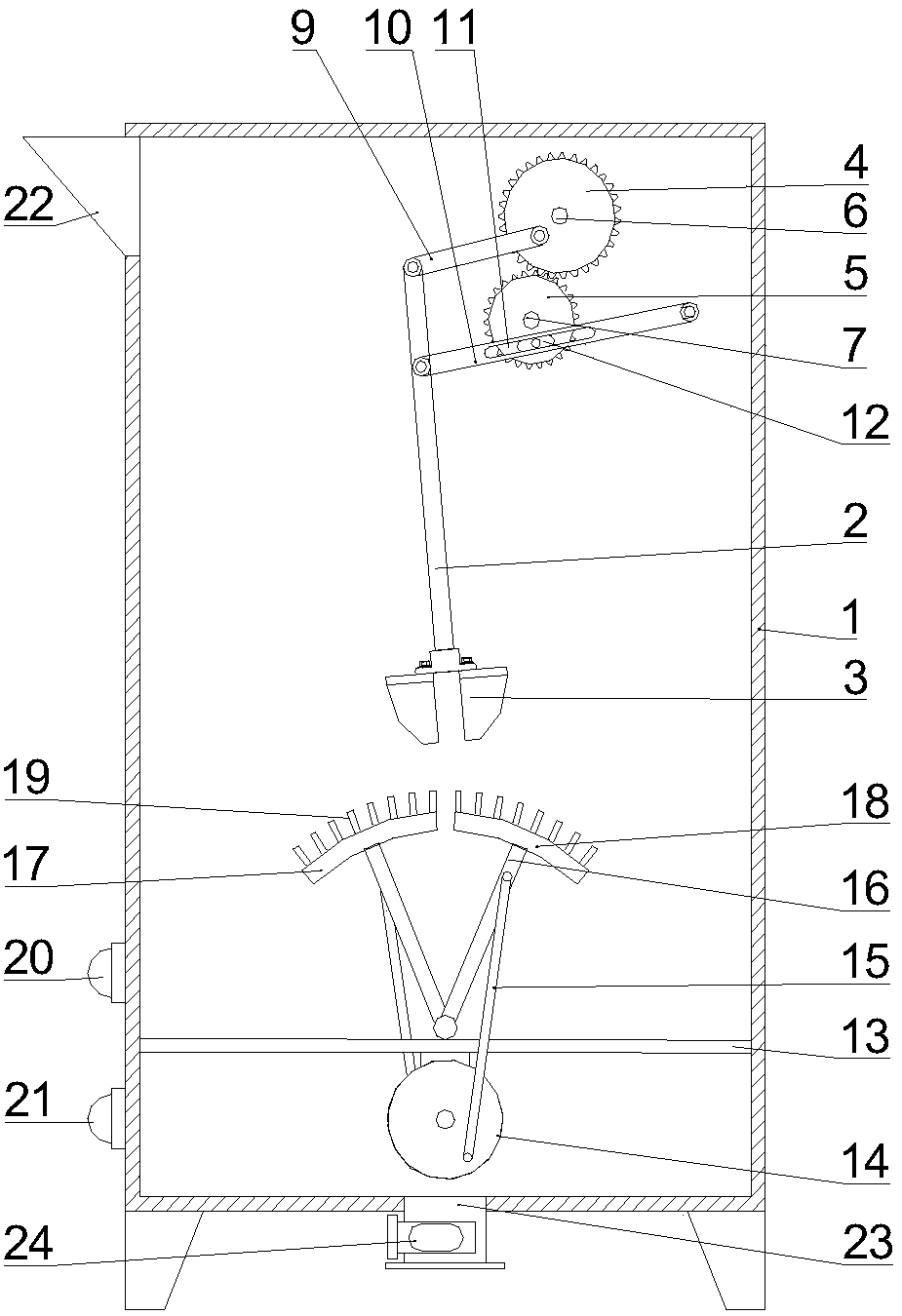

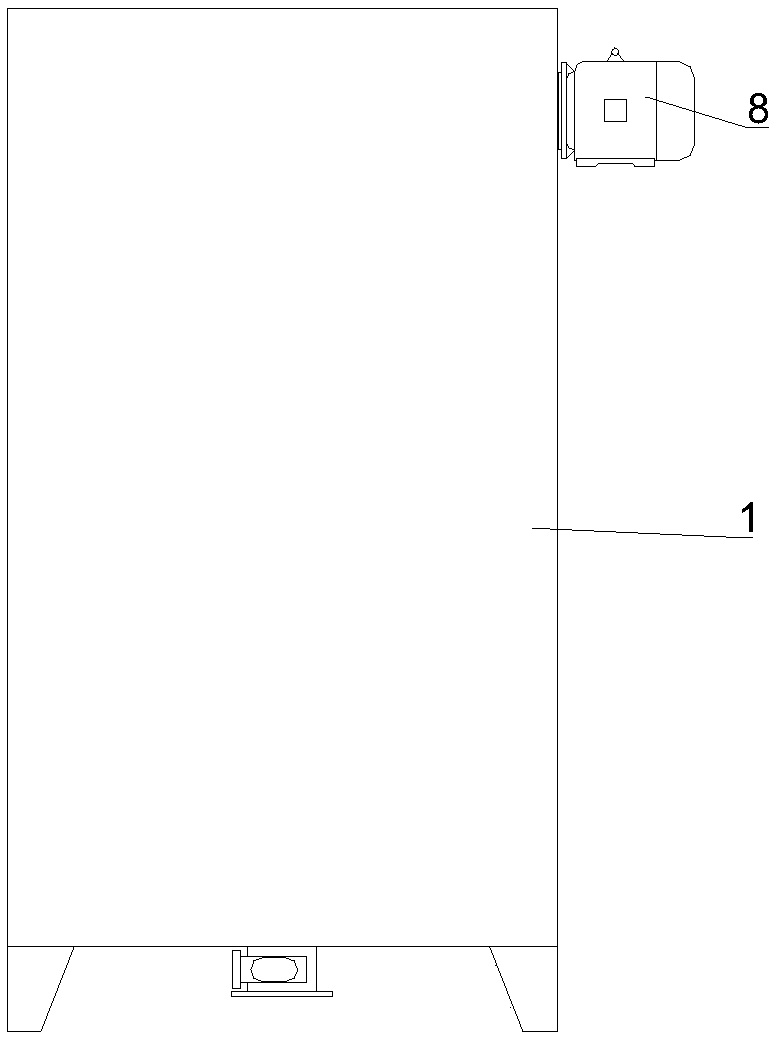

[0016] see Figure 1-2 , a raw material stirring device for chemical gas production, comprising a stirring tank 1, the inner upper side of the stirring tank 1 is provided with a driving gear 4 and a driven gear 5 that are meshed and connected, and the installation of the driving gear 4 and the driven gear 5 The holes are respectively fixedly sleeved with the first rotating shaft 6 and the second rotating shaft 7 which are rotatably connected with the stirring tank. The inside of the stirring tank 1 is provided with a stirring rod 2, and the bottom end of the stirring rod 2 is fixedly connected with a stirring paddle 3. The top of the stirring rod 2 is hinged with a first connecting rod 9, the stop end of the first connecting rod 9 is hinged with the side eccentric part of the driving gear 4, and the stirring rod at the bottom of the first connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com