Homogenizing and emulsifying system for cosmetic production and using method

A technology of homogeneous emulsification and cosmetics, applied in chemical instruments and methods, mixing methods, chemical/physical processes, etc., can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

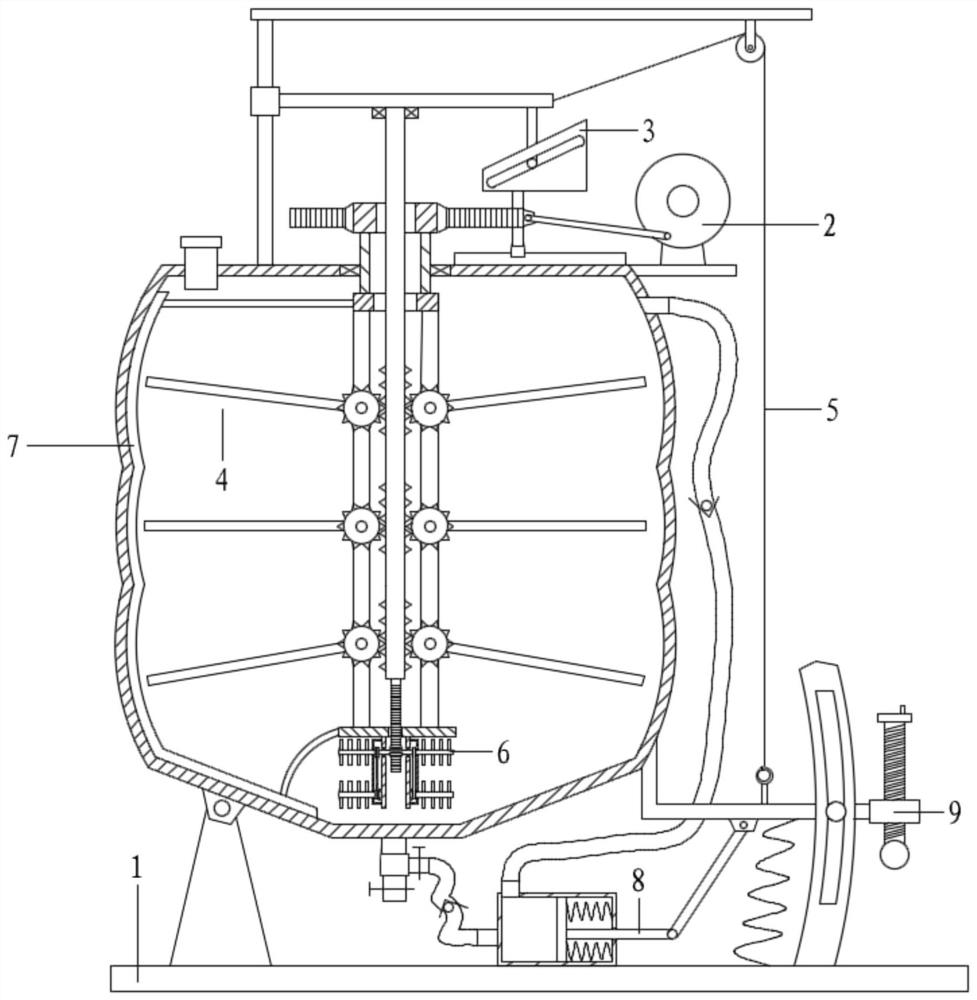

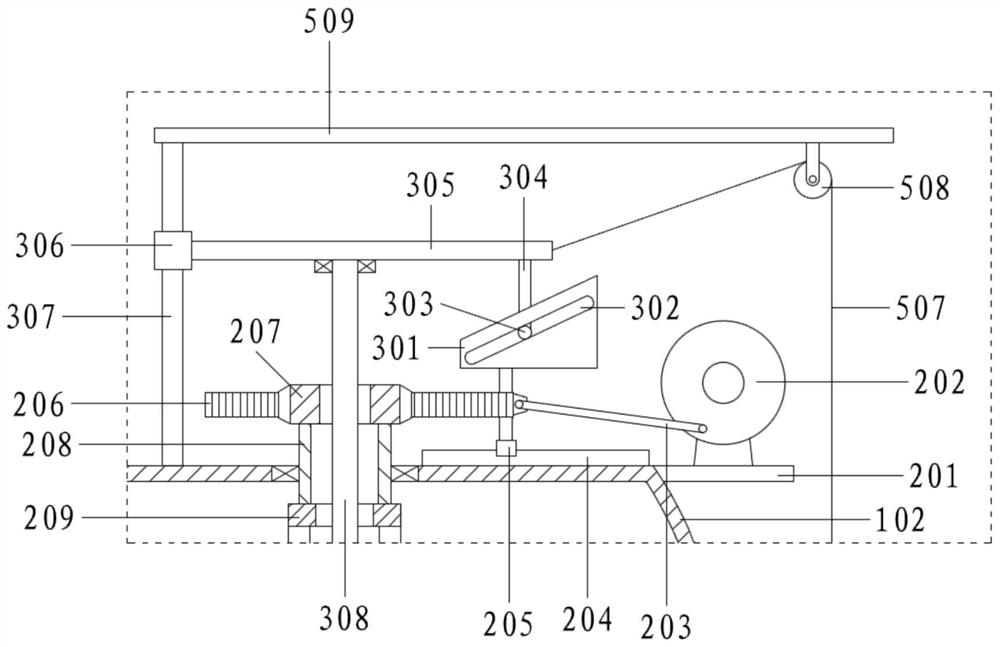

[0063] With reference to the accompanying drawings, a homogeneous emulsification system for cosmetic production includes a frame assembly 1, a reciprocating assembly 2, a lifting assembly 3, a homogeneous assembly 4 and a shaking assembly 5;

[0064] The frame assembly 1 includes a bottom plate 101, an emulsification tank 102, a feeding port 103 and a discharge pipe 104; the emulsification tank 102 is arranged above the bottom plate 101, and the lower part is connected to the bottom plate 101 through the shaking assembly 5; the top left end of the emulsification tank 102 is provided with a feeding port 103, A discharge pipe 104 is connected to the bottom, and a No. 1 valve is installed on the discharge pipe 104; a reciprocating assembly 2 is arranged on the outside of the top of the emulsification tank 102, and a type of homogeneous assembly 4, a reciprocating assembly 2 and a type of homogeneous assembly 4 are arranged in the emulsification tank 102 Cooperate; a lifting compon...

Embodiment 2

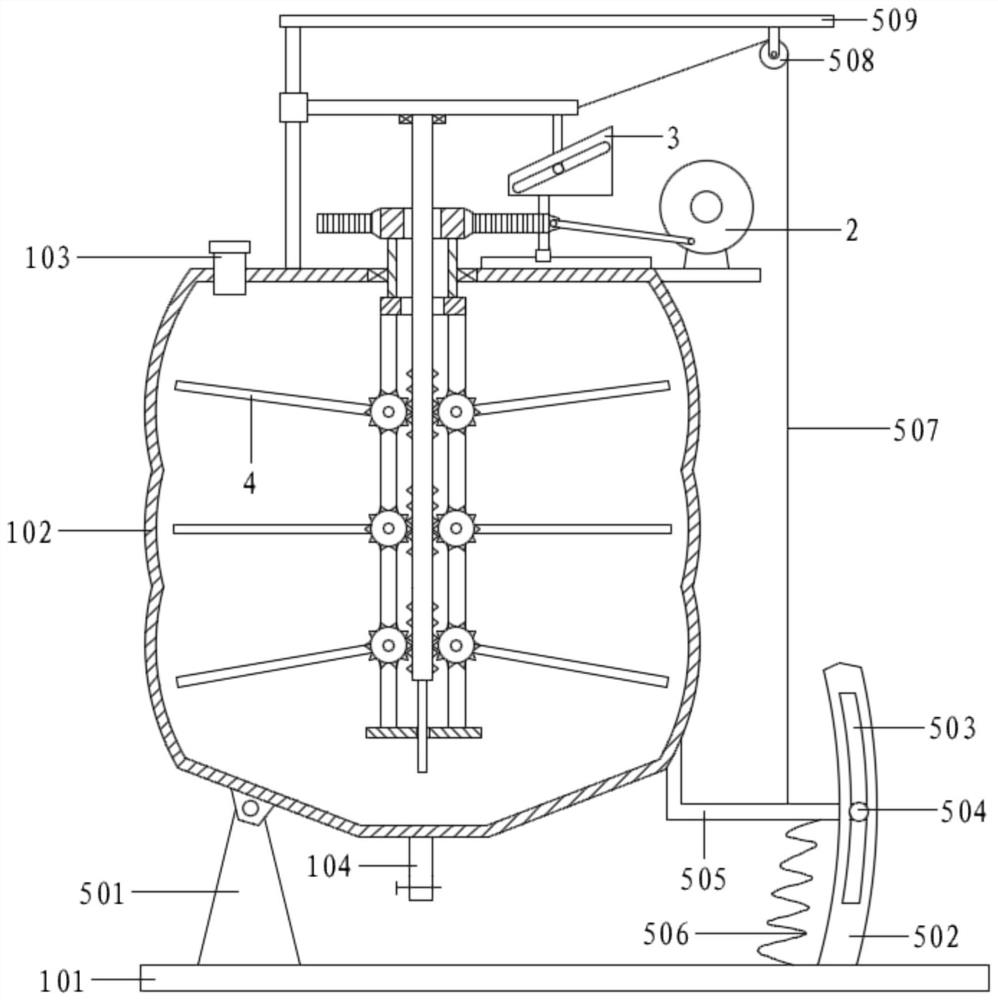

[0066] With reference to the accompanying drawings, a homogeneous emulsification system for cosmetic production includes a frame assembly 1, a reciprocating assembly 2, a lifting assembly 3, a homogeneous assembly 4 and a shaking assembly 5;

[0067] The frame assembly 1 includes a bottom plate 101, an emulsification tank 102, a feeding port 103 and a discharge pipe 104; the emulsification tank 102 is arranged above the bottom plate 101, and the lower part is connected to the bottom plate 101 through the shaking assembly 5; the top left end of the emulsification tank 102 is provided with a feeding port 103, A discharge pipe 104 is connected to the bottom, and a No. 1 valve is installed on the discharge pipe 104; a reciprocating assembly 2 is arranged on the outside of the top of the emulsification tank 102, and a type of homogeneous assembly 4, a reciprocating assembly 2 and a type of homogeneous assembly 4 are arranged in the emulsification tank 102 Cooperate; a lifting compon...

Embodiment 3

[0083] On the basis of embodiment 2,

[0084] It also includes a scraper assembly 7; the scraper assembly 7 includes a No. 3 connecting rod 701, a scraper 702 and a No. 4 connecting rod 703;

[0085] The scraper 702 is set corresponding to the shape of the inner wall of the emulsification tank 102, and is attached to the inner wall of the emulsification tank 102; the top of the scraper 702 is connected to the first plate 209 through the third connecting rod 701, and the bottom end is connected to the second plate 405 through the fourth connecting rod 703.

[0086] Specifically, the scraper 702 also rotates synchronously under the drive of the homogeneous component 4 to scrape the inner wall of the emulsification tank 102 to prevent the material from sticking to the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com