Slant-insert type molten iron pretreatment lance and manufacturing method thereof

A technology of molten iron pretreatment and manufacturing method, which is applied in the direction of manufacturing tools, spraying devices, casting equipment, etc., can solve the problems that the spray gun has not been effectively improved, the service life of the spray gun is affected, and the spray gun is bent and damaged, so as to increase the working distance and stir Areas, Enhanced Blending Effects, Effects that Increase Strength and Stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

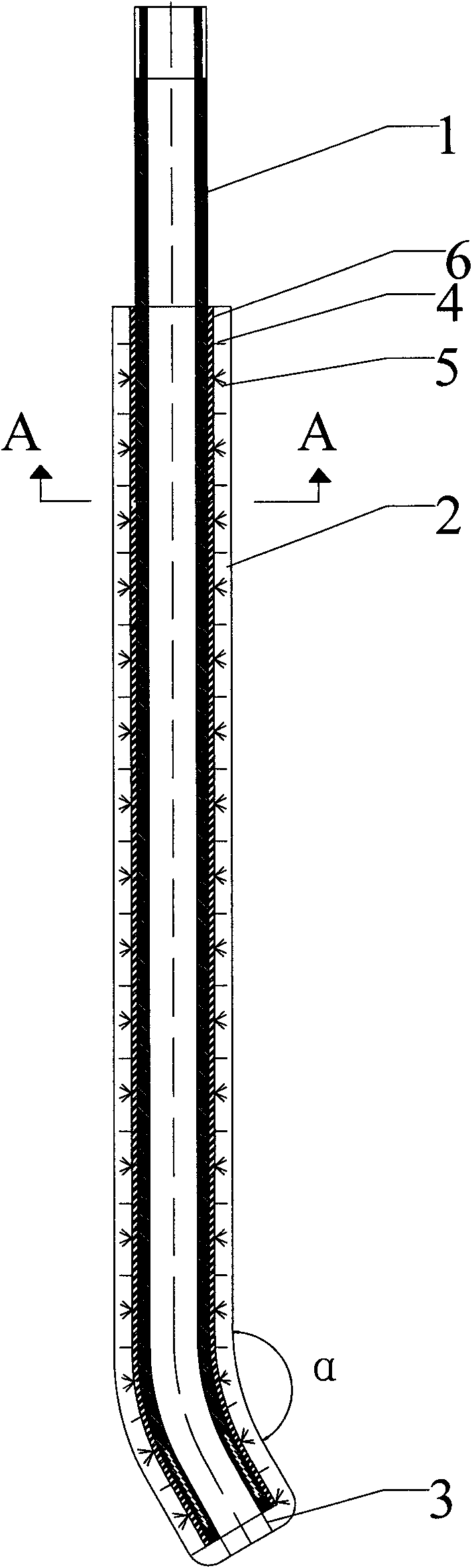

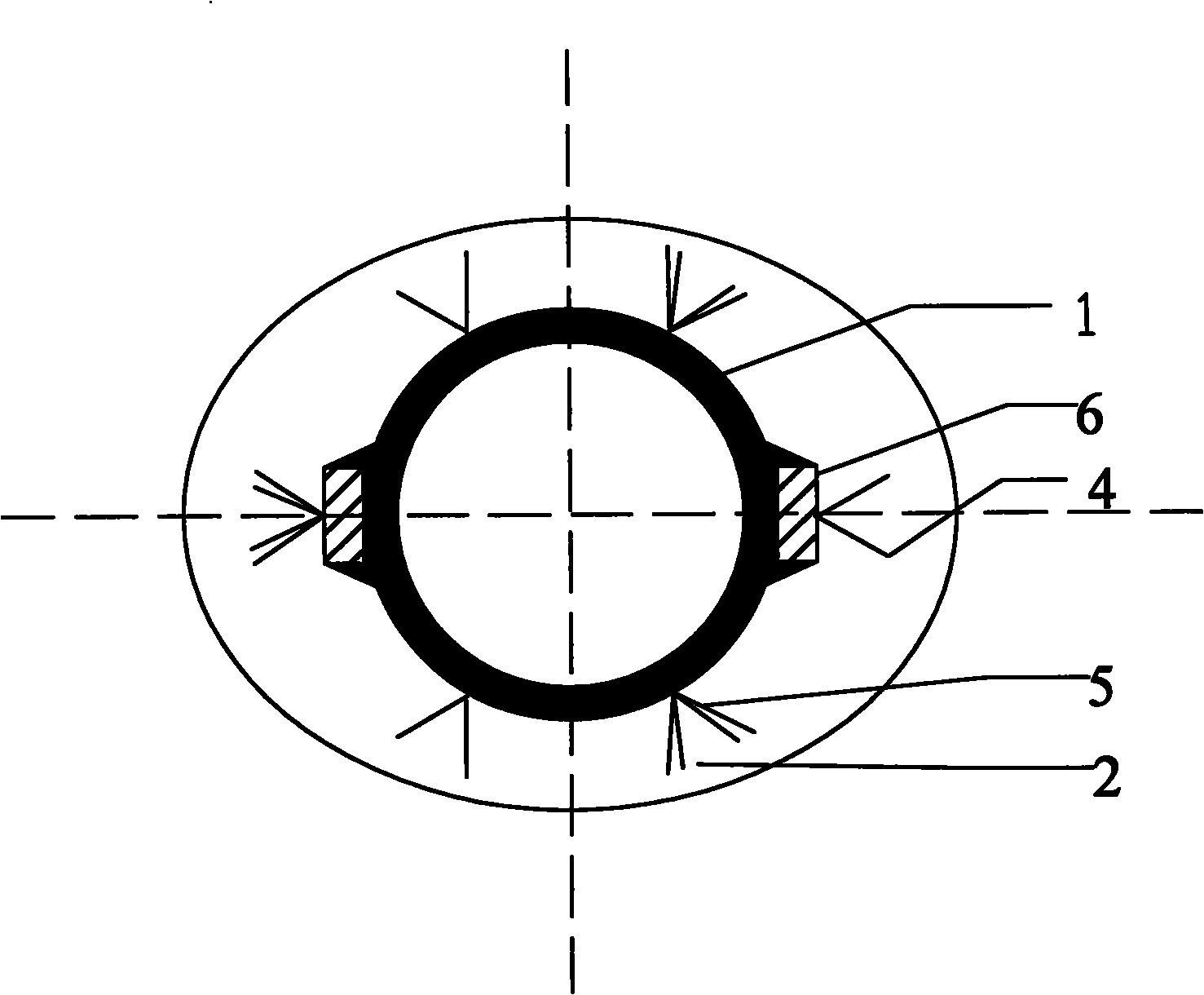

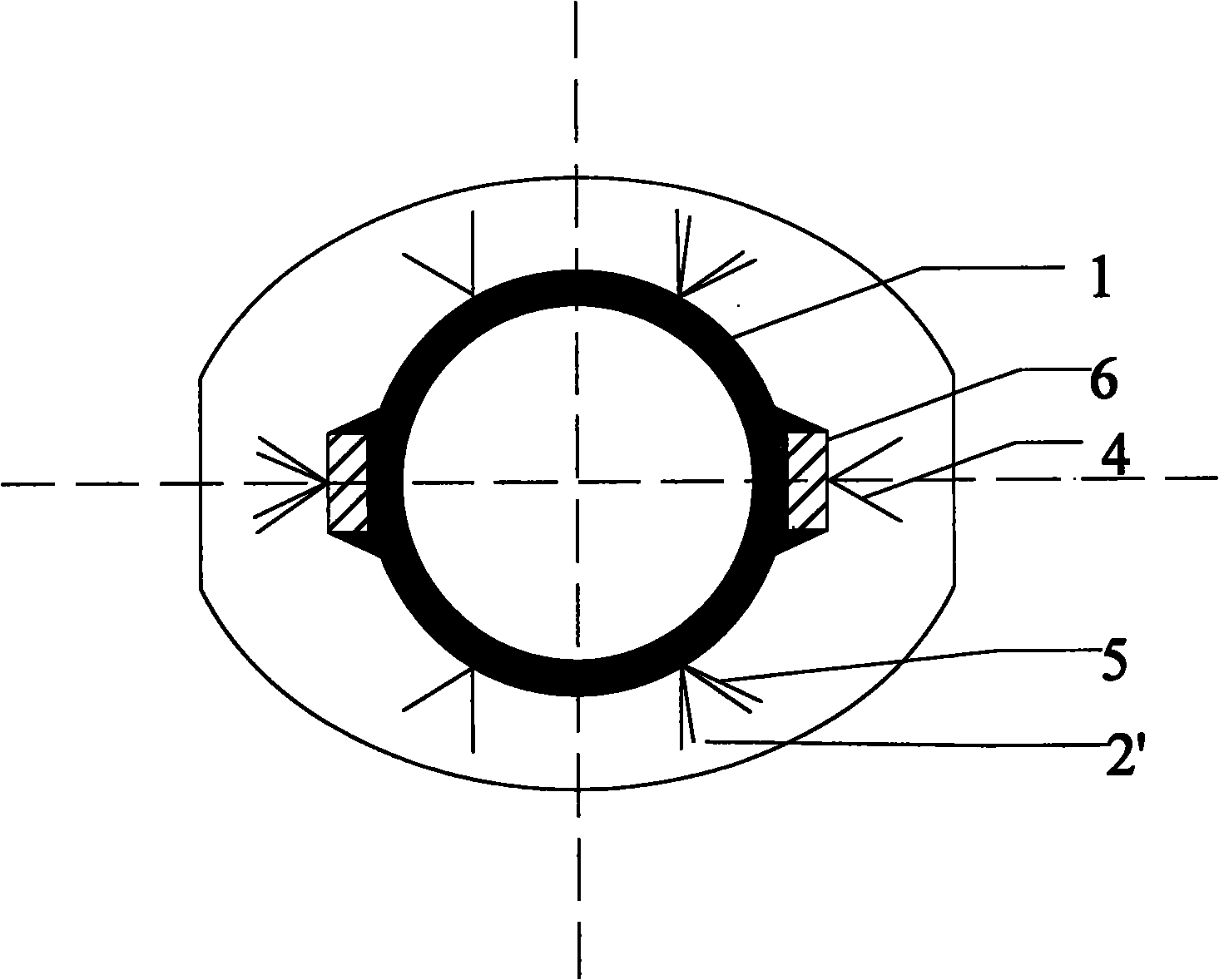

[0020] like figure 1 As shown, the first embodiment of the obliquely inserted molten iron pretreatment spray gun of the present invention includes a gun core steel pipe 1, a refractory material gun lining 2 and several anchors, one end of the gun core steel tube 1 is bent to form a gun head 3, and the refractory material The gun liner 2 covers the outer surface of the gun core steel pipe 1 , and the anchor is fixed on the outer surface of the gun core steel tube 1 and is located in the refractory material gun liner 2 . The outer surface of the gun core steel pipe 1 is located on both sides of the axial section in the bending direction of the gun head 3. An axial reinforcing rib 6 is respectively arranged on the outer surface, and the axial reinforcing rib 6 is also covered on the refractory material gun lining. within 2. As a prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com