Chemical device for preparing chemical raw material

A technology for chemical equipment and chemical raw materials, which is applied in the field of chemical equipment for preparing chemical raw materials, can solve problems such as incomplete mixing, increased enterprise costs, uneven mixing, etc., and achieves the goal of increasing the mixing range, improving work efficiency, and improving mixing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

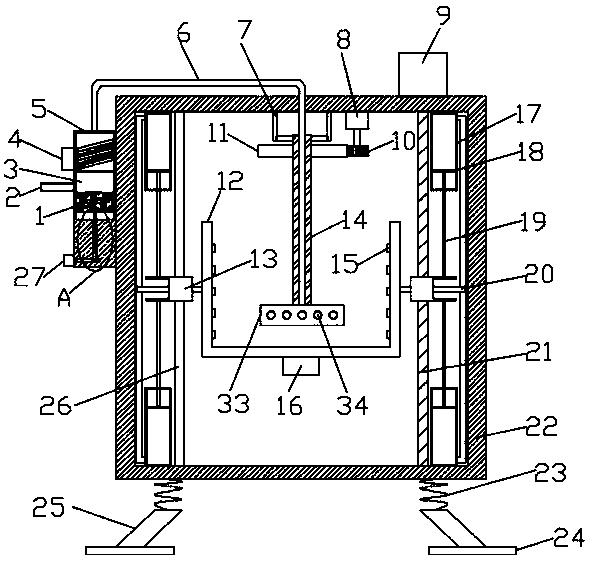

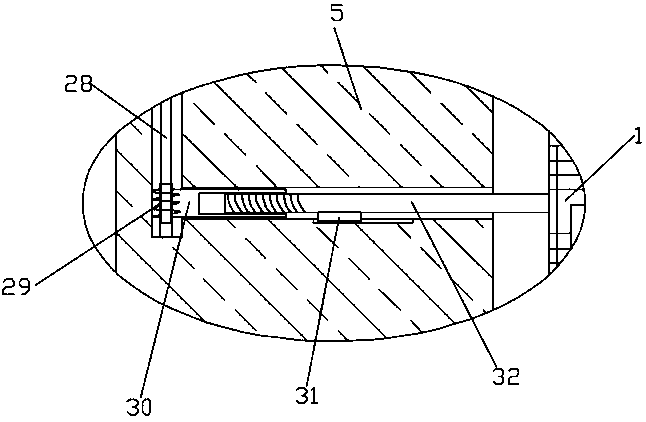

Method used

Image

Examples

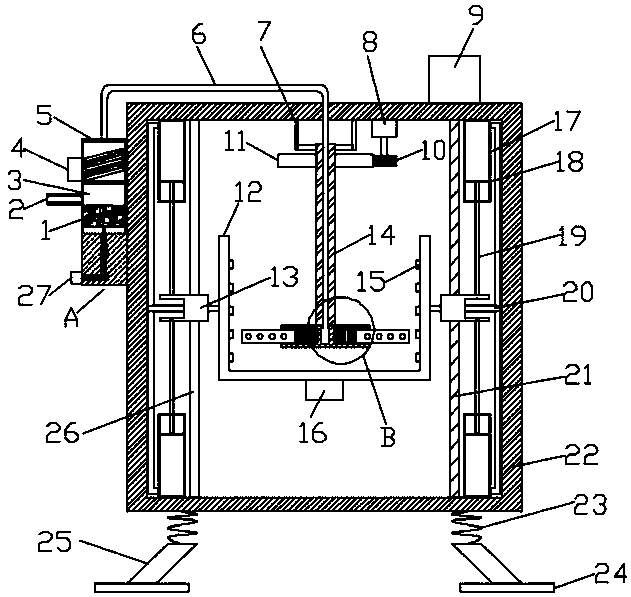

Embodiment 2

[0036] refer to Figure 3-5 , in this embodiment, the stirring device comprises a stirring rod 33 fixedly connected to the lower end of the hollow tube 14, the two ends of the stirring rod 33 are provided with a first circular cavity, the hollow tube 14 communicates with the first circular cavity, and the first circular cavity The cavity is provided with a telescopic air bag 37, and the telescopic air bag 37 communicates with the first round cavity. The end of the telescopic air bag 37 away from the inner wall of the first round cavity is fixedly connected with a sealing slide 36, and the side wall of the sealing slide 36 is fixedly connected with an exhaust pipe. 35 , the side wall of the sealing slide plug 36 is penetrated with a through hole connecting the first circular chamber and the exhaust pipe 35 , and the side wall of the exhaust pipe 35 is evenly distributed with exhaust holes 34 .

[0037] In this embodiment, the rotation of the hollow tube 14 drives the stirring r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com