Tundish impurity removal and flow control device assembly for casting

A tundish and component technology, which is used in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of difficult separation and floating, limited ability of inclusion movement trajectory, and low inclusion removal rate, and achieves a simple overall structure. , Improve the probability of collision, good high temperature thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

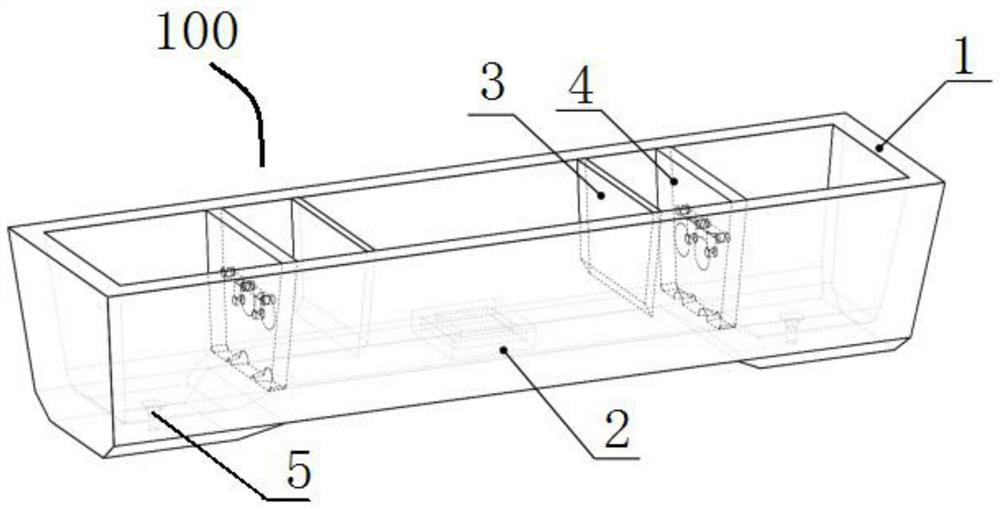

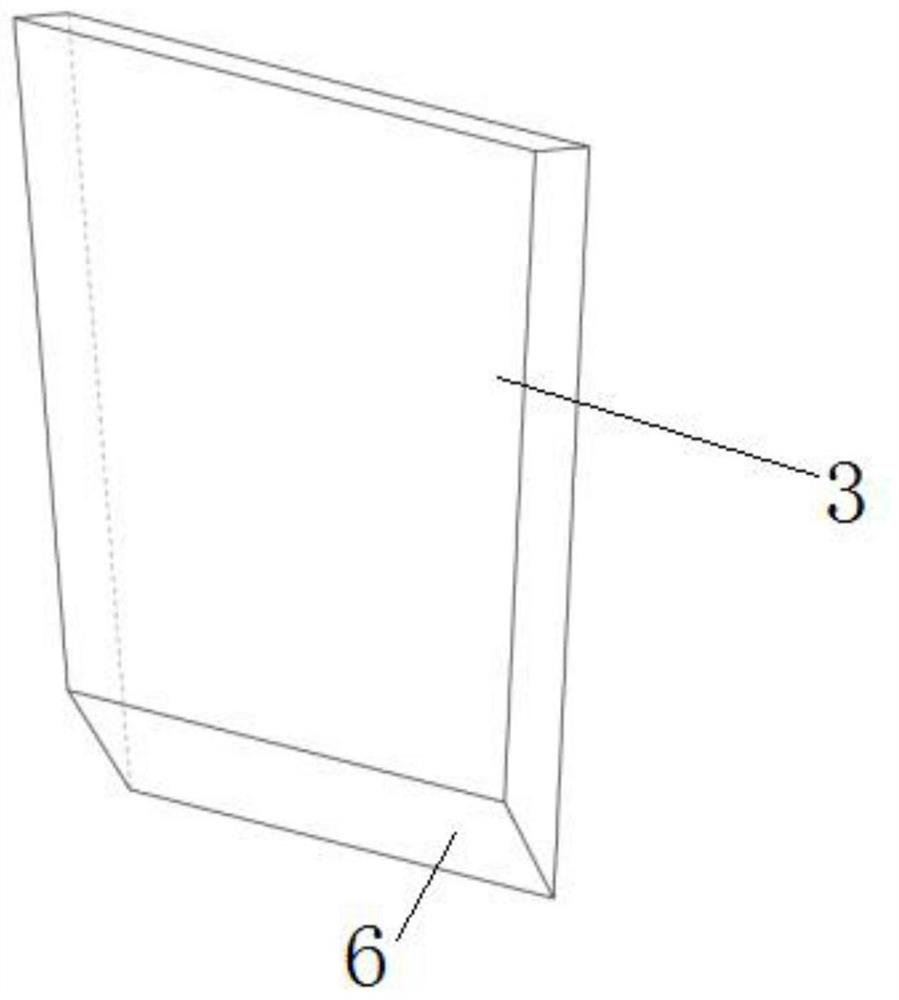

[0030] The structure of a casting tundish removal and flow control device assembly 100 provided in this embodiment is as follows: figure 1 As shown, it includes two weirs 3 and two filters 4 vertically arranged in the tundish 1, a turbulence suppressor 2 is arranged at the inner bottom of the tundish 1, and two symmetrical tundish nozzles are opened at both ends of the bottom of the tundish 1 5. A weir 3 and a filter 4 are arranged between the turbulence suppressor 2 and each tundish nozzle 5, the bottom of the weir 3 is provided with an upflow inclined surface 6, and the bottom of the filter 4 is symmetrically provided with two horizontally arranged Semi-circular frustum-shaped discharge hole 7, two tapered holes 8 are provided on the upstream surface of the filter 4, and three circular holes 9 are provided on the backflow surface of the filter 4, and the passage between the tapered holes 8 and the circular holes 9 The circular channel 10 is connected; the surface of the weir...

Embodiment 2

[0036]The structure of a casting tundish removal and flow control device assembly provided in this embodiment is the same as that of Embodiment 1, except that the chemical composition of the weir 3 and the filter 4 is MgO 98wt%, SiO 2 1wt%, ZrO 2 1 wt%, the distance between the vertical center plane of the weir 3 and the vertical center plane of the filter 4 is equal to 800 mm. The distance between the center of the circular hole 9 on the backflow surface of the filter 4 and the free surface of the molten metal is 80mm.

[0037] The weir 3 has a thickness of 90mm.

[0038] The thickness of the filter 4 is 180mm, the diameter of the tangential circle of the conical hole 8 at the end face of the upstream surface is 160mm, the diameter of the tangential circle of the conical hole 8 and the connection end of the circular channel 10 is 60mm, and the two ends of the conical hole 8 are large circles The vertical distance between the small circle and the small circle is 50mm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com