Heat insulation material

A technology of thermal insulation and raw materials, applied in the field of materials, can solve the problems of poor sealing performance of thermal insulation materials, easy powder drop during assembly and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

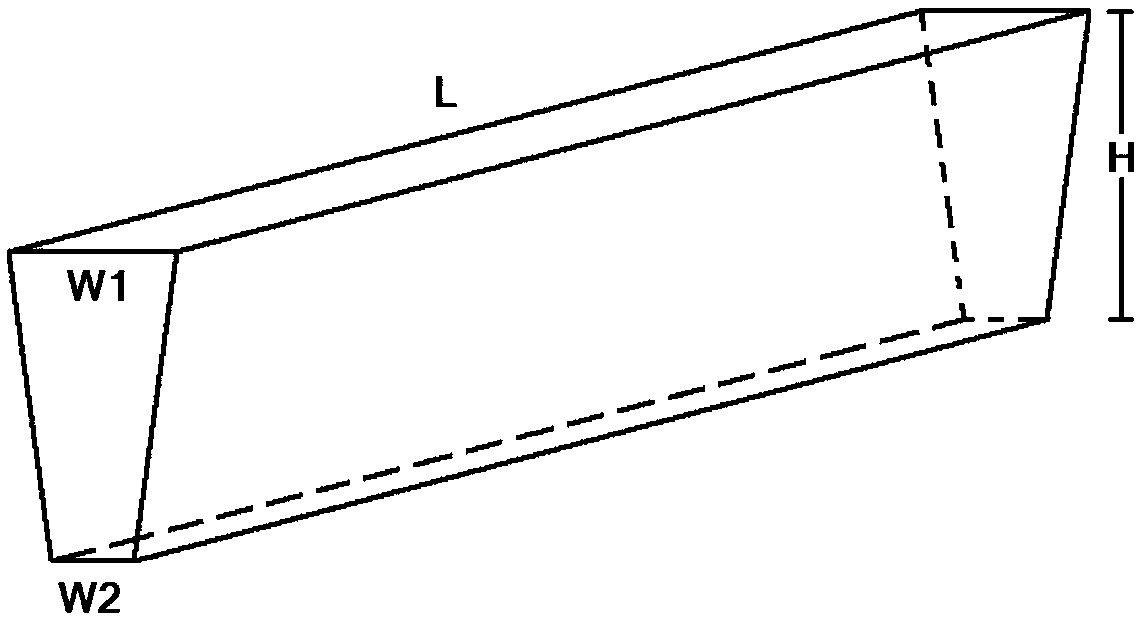

Image

Examples

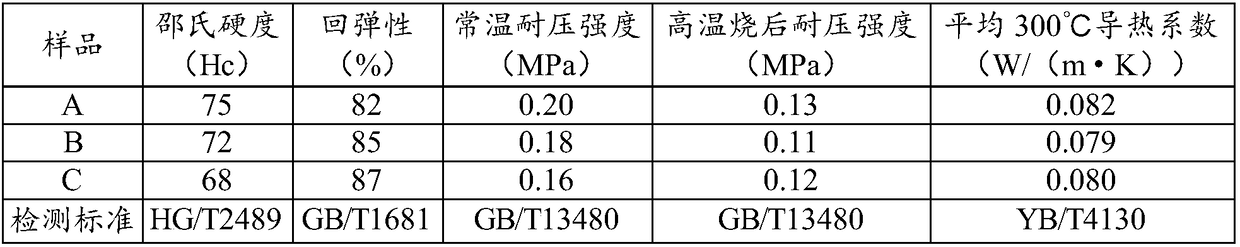

Embodiment 1

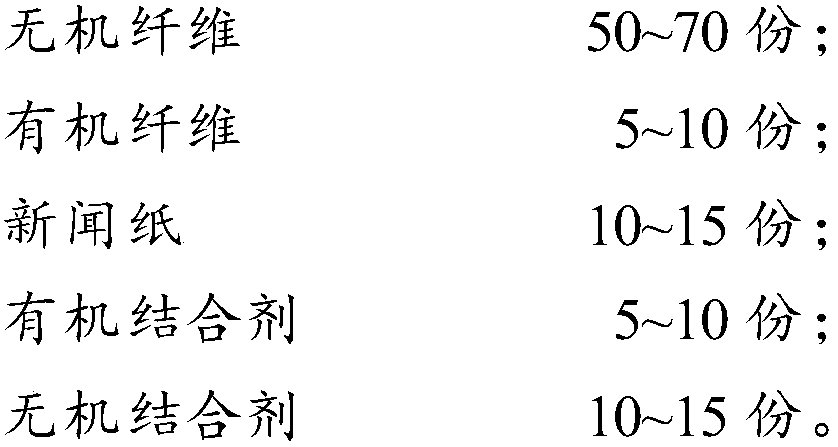

[0054] Weigh 50 parts by weight of ceramic fiber, 10 parts by weight of polypropylene fiber, 15 parts by weight of newspaper and 15 parts by weight of kaolin, add the weighed materials and 10,000 parts by weight of water into a volt beater, fully beat and mix, and the beating speed is 300r / min, add 5 parts by weight of starch and 5 parts by weight of acrylic acid emulsion after beating for 20 minutes, and continue beating for 5 minutes; 60r / min, weigh 2 parts by weight of aluminum sulfate solution and 3 parts by weight of anionic polyacrylamide solution into the slurry, stir until the supernatant appears around the slurry; input the adjusted flocculated slurry into the forming tank, It is formed by a vacuum suction filtration process, and then dried at a temperature of 80°C. After drying, a slab is obtained. The slab is calcined at 170°C for 0.5h in a calciner to obtain a thermal insulation material.

Embodiment 2

[0056] Weigh 60 parts by weight of basalt fiber, 10 parts by weight of polyethylene fiber, 10 parts by weight of newspaper and 10 parts by weight of attapulgite, add the weighed materials and 10,000 parts by weight of water into the volt beater and fully beat and mix evenly. 500r / min, add 3 parts by weight of starch and 7 parts by weight of acrylic acid emulsion after beating for 18 minutes, and continue beating for 8 minutes; 80r / min, weigh 3 parts by weight of polyaluminum chloride solution and 2 parts by weight of anionic polyacrylamide solution into the slurry, stir until the supernatant appears around the slurry; input the flocculated slurry into In the forming pool, the vacuum suction filtration process is used to form, and then dried at a temperature of 90°C. After drying, the slab is obtained, and the slab is calcined at 130°C for 1.5 hours in a calciner to obtain thermal insulation materials.

Embodiment 3

[0058] Weigh 70 parts by weight of quartz fiber, 5 parts by weight of polyethylene fiber, 10 parts by weight of newspaper and 10 parts by weight of coal gangue fine powder, add the weighed materials and 10,000 parts by weight of water into a volt beater, fully beat and mix, and beat The speed is 800r / min, add 2 parts by weight of starch and 3 parts by weight of flexible acrylic emulsion after beating for 15 minutes, and continue beating for 10 minutes; Stirring speed is 100r / min, weigh 4 parts by weight of polyaluminum chloride solution and 4 parts by weight of anionic polyacrylamide solution into the slurry, stir until the supernatant appears around the slurry; put the adjusted flocculated slurry The material is input into the forming tank, formed by vacuum suction filtration process, and then dried at a temperature of 105°C. After drying, the slab is obtained, and the slab is calcined at 150°C for 1 hour in a calciner to obtain thermal insulation materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com