Magnesia castable and production process of slag baffling component for tundish

A technology of magnesia castables and magnesia, which is applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of reducing the performance of magnesia refractory materials and intensifying erosion behavior, so as to ensure construction performance and use performance, meet long-distance transportation and hoisting, and improve the effect of normal temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

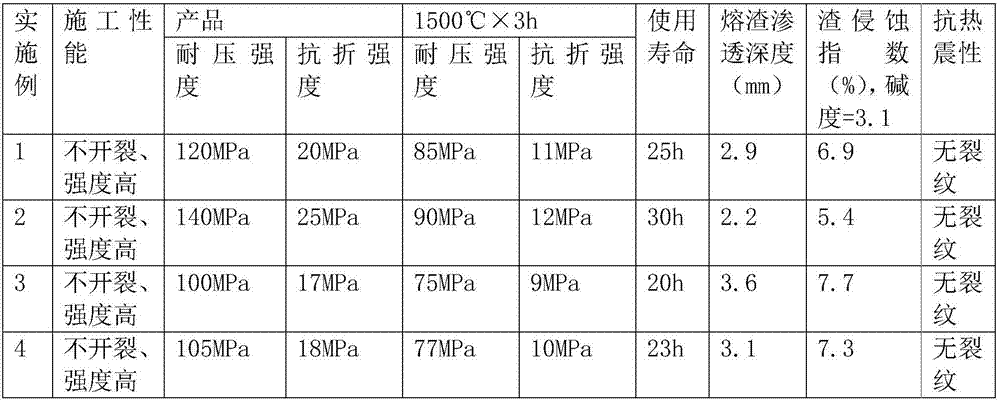

Examples

Embodiment 1

[0034] The magnesia castable in this embodiment is composed of the following raw materials: 90 kg of magnesia composed of magnesia aggregate and magnesia fine powder, 6 kg of silica, waste magnesia-chrome brick aggregate and waste magnesia-chrome brick powder composed of waste magnesia Chrome brick 12kg, SiO 2 Micro powder 3.5 kg, sodium tripolyphosphate 0.2 kg, organic fiber 0.05 kg, steel fiber 0.5 kg.

[0035] The magnesia is fused magnesia with a mass fraction of MgO of 93%; magnesia with a particle size of 0.088 mm or less and greater than 0 mm, magnesia with a particle size of 8 mm or less and greater than 5 mm accounted for 15% of the total weight of magnesia, and magnesia with a particle size of 5 mm or less and greater than 3 mm Magnesia accounts for 15% of the total weight of magnesia, magnesia with particle size less than or equal to 3mm and greater than 1mm accounts for 20% of the total weight of magnesia, and magnesia with particle size less than or equal to 0.08...

Embodiment 2

[0046] The magnesia castable in this embodiment is composed of the following raw materials: 90 kg of magnesia composed of magnesia aggregate and magnesia fine powder, 15 kg of silica, waste magnesia-chrome brick aggregate and waste magnesia-chrome brick fine powder. Chrome brick 30 kg, SiO 2 Micro powder 4.5 kg, sodium tripolyphosphate 0.3 kg, organic fiber 0.05 kg, steel fiber 0.5 kg.

[0047] The magnesia is fused magnesia with a mass fraction of MgO of 90%; magnesia with a particle size of 0.088 mm or less and greater than 0 mm, magnesia with a particle size of 8 mm or less and greater than 5 mm accounted for 18% of the total weight of magnesia, and magnesia with a particle size of 5 mm or less and greater than 3 mm Magnesia accounts for 17% of the total weight of magnesia, magnesia with particle size less than or equal to 3mm and greater than 1mm accounts for 25% of the total weight of magnesia, and magnesia with particle size less than or equal to 0.088mm and greater tha...

Embodiment 3

[0058] The magnesia castable in this example consists of the following raw materials: 90 kg of magnesia, 4 kg of silica, 30 kg of waste magnesia-chrome brick aggregate and waste magnesia-chrome brick fine powder, SiO 2 Micro powder 5 kg, sodium hexametaphosphate 0.1 kg, organic fiber 0.05 kg, steel fiber 0.5 kg.

[0059] The magnesia is fused magnesia with a mass fraction of MgO of 94%; magnesia with a particle size of 0.088 mm or less and greater than 0 mm, magnesia with a particle size of 8 mm or less and greater than 5 mm accounted for 21% of the total weight of magnesia, and magnesia with a particle size of 5 mm or less and greater than 3 mm Magnesia accounts for 20% of the total weight of magnesia, magnesia with particle size less than or equal to 3mm and greater than 1mm accounts for 30% of the total weight of magnesia, and magnesia with particle size less than or equal to 0.088mm and greater than 0mm accounts for magnesia weight The percentages are 40% respectively; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com