Ascending coal gas dust blocker

A technology of coal gas and gray board, which is applied in gas dust removal, combustible gas production, petroleum industry, etc. It can solve problems such as flushing and leakage of upstream gas pipelines, unstable operation of gas generators, and thinning of dust collector linings, etc., to achieve The effect of saving operating costs, simple structure, and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

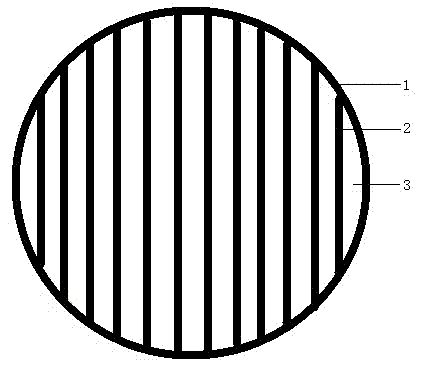

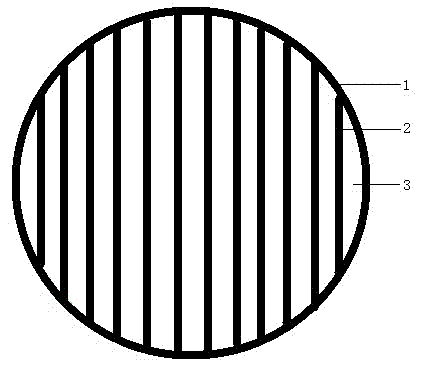

[0009] As shown in the figure, a ash retaining plate 2 is installed on the circular casing 1, and there are air outlet holes 3 between the ash retaining plates 2. The ash retaining plate 2 is in a "V" shape and is bent inward.

[0010] When the gas passes through the upward gas ash blocking device, it will slow down and fall back after being blocked by the "V"-shaped ash blocking plate 2, so as to achieve the purpose of blocking dust without affecting the passage of gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com