Drying boxes for hot-blast air furnace

A technology of drying oven and hot blast stove, which is applied in the direction of drying gas arrangement, local agitation dryer, static material dryer, etc., which can solve the problems of slow drying speed, large wind resistance of hot air, long drying cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

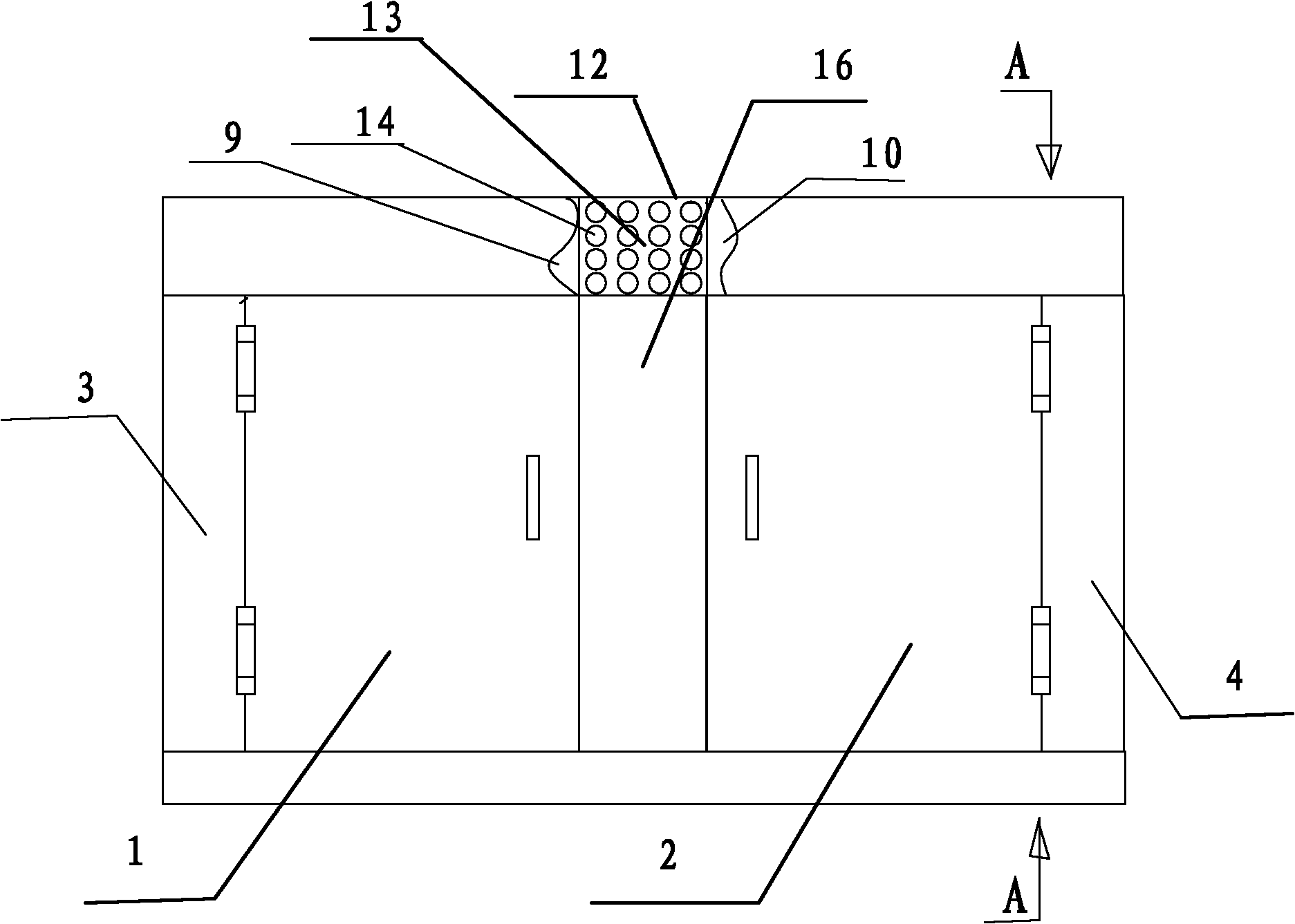

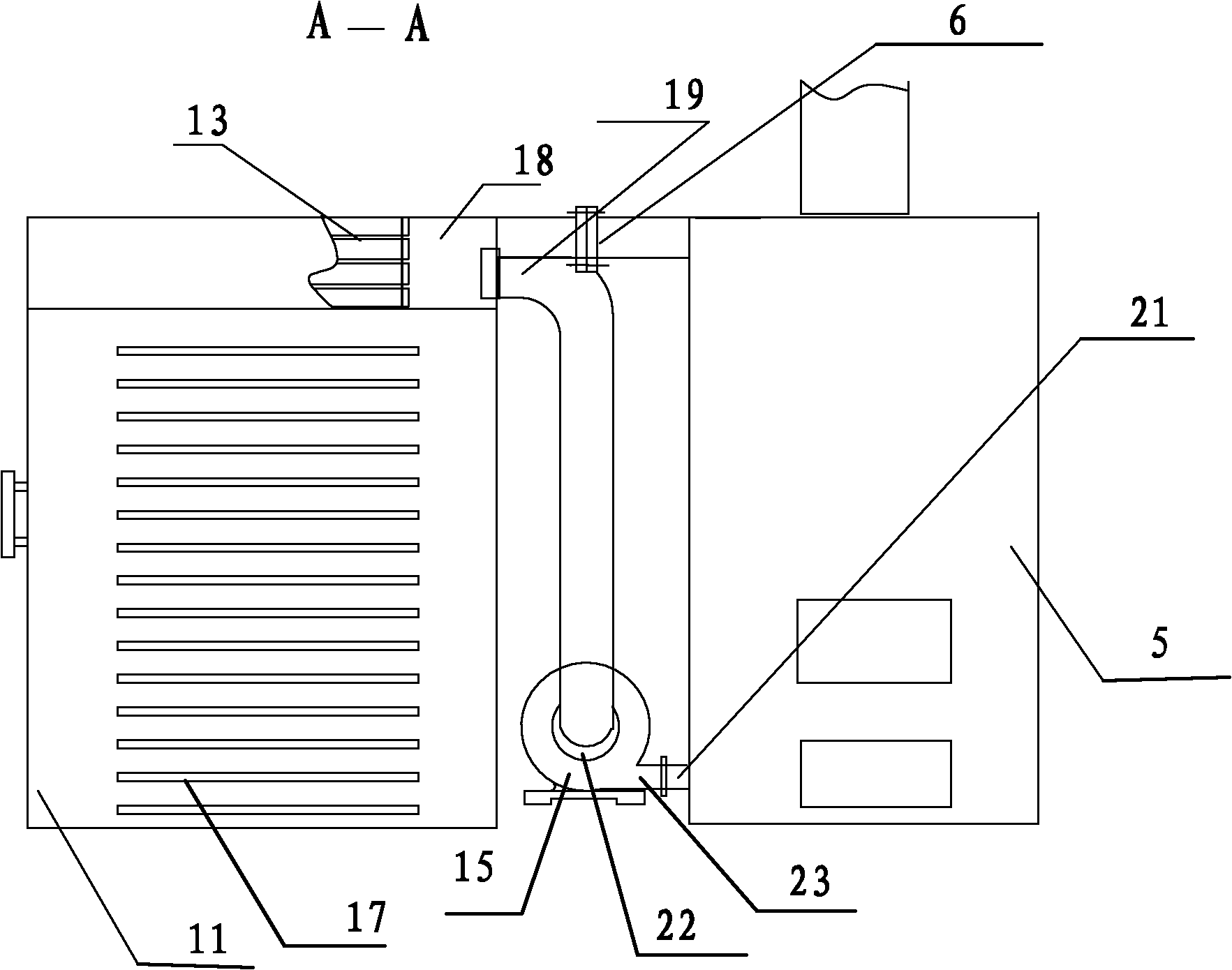

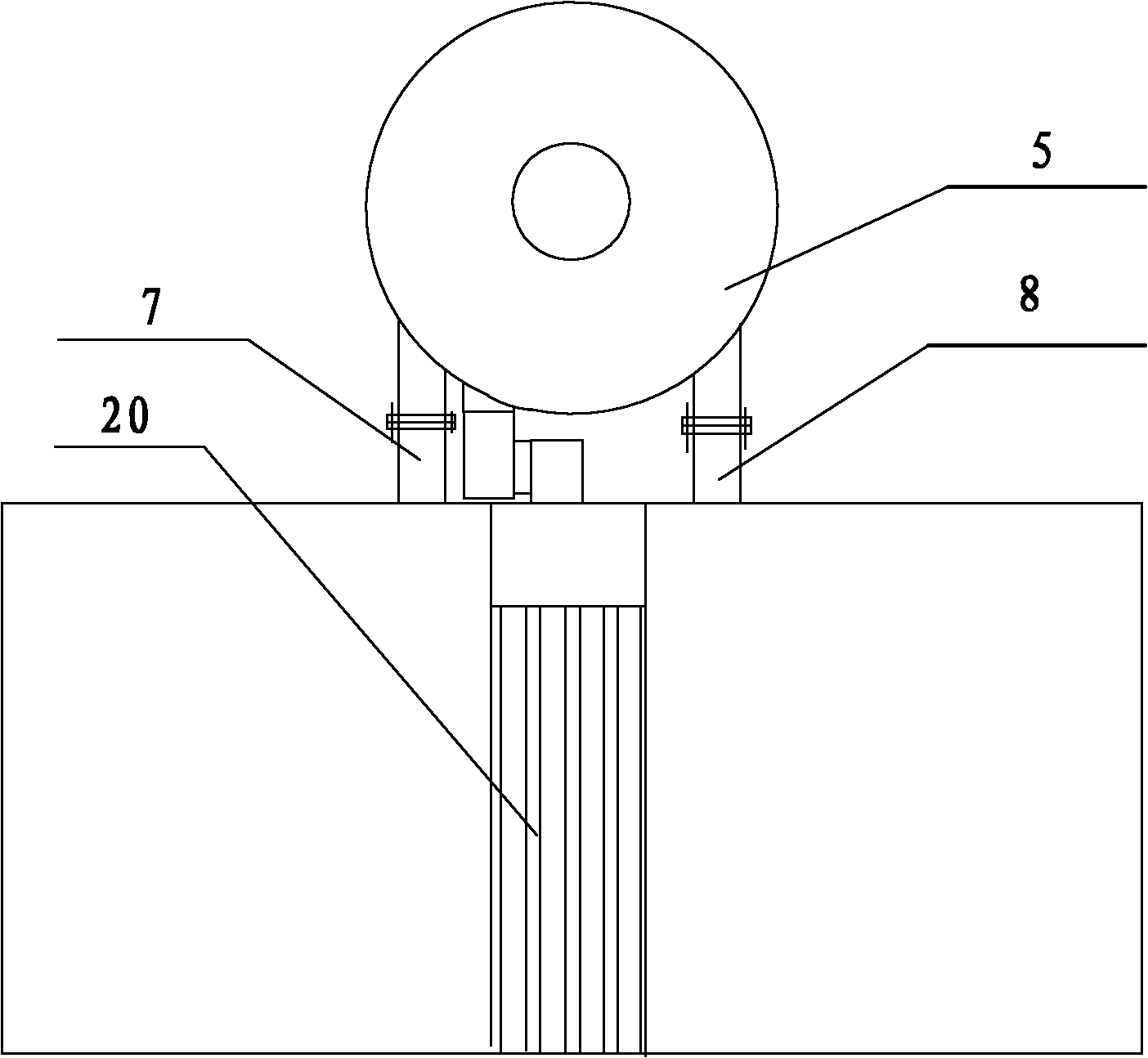

[0010] see figure 1 , 2 , 3, in the picture, 1. left drying box, 2. right drying box, 3. left equalizing hot air box, 4. right equalizing hot air box, 5. hot blast stove, 6. hot air outlet, 7. left hot air output pipe, 8 .Right hot air output pipe, 9.Left hot air duct, 10.Right hot air duct, 11.Separator, 12.Waste heat recovery box, 13.Tubular heat exchanger, 14.Fresh air inlet, 15.Centrifugal fan, 16 .Humidity exhaust box, 17. Balanced air inlet, 18. Air collection box, 19. Air duct, 20. Humidity exhaust port, 21. Air inlet of hot blast stove. 22. Air inlet of centrifugal fan.

[0011] The left drying box 1 and the right drying box 2 are respectively arranged on the left and right sides of the moisture removal box 16, and the left end of the left drying box 1 is provided with a balanced hot air box 3, and the right end of the right drying box 2 is provided with a balanced hot air box 4. The top of the dehumidification box 16 is provided with a waste heat recovery box 12. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com