Finned spiral tube

A spiral tube and fin technology, applied in the field of new spiral tube devices, can solve the problems of unfavorable heat exchange efficiency of the fluid flow pattern in the tube, and achieve the effects of changing the flow pattern, enhancing the mass transfer effect, and increasing the degree of turbulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

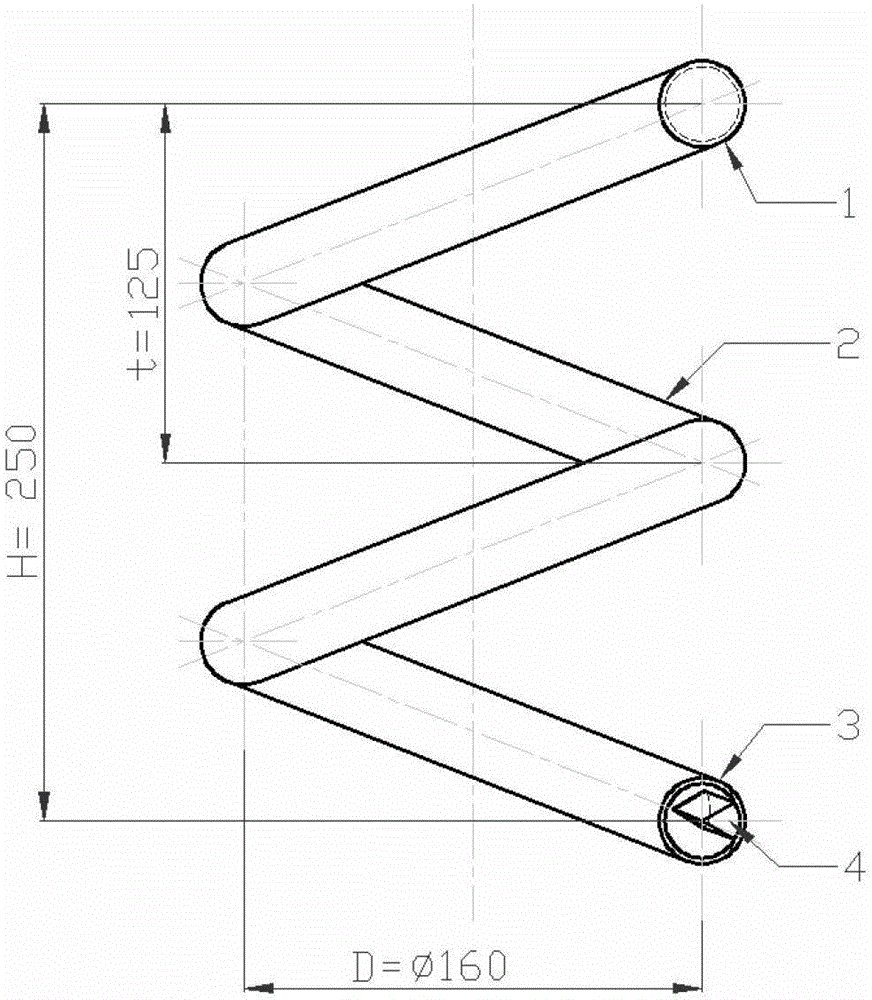

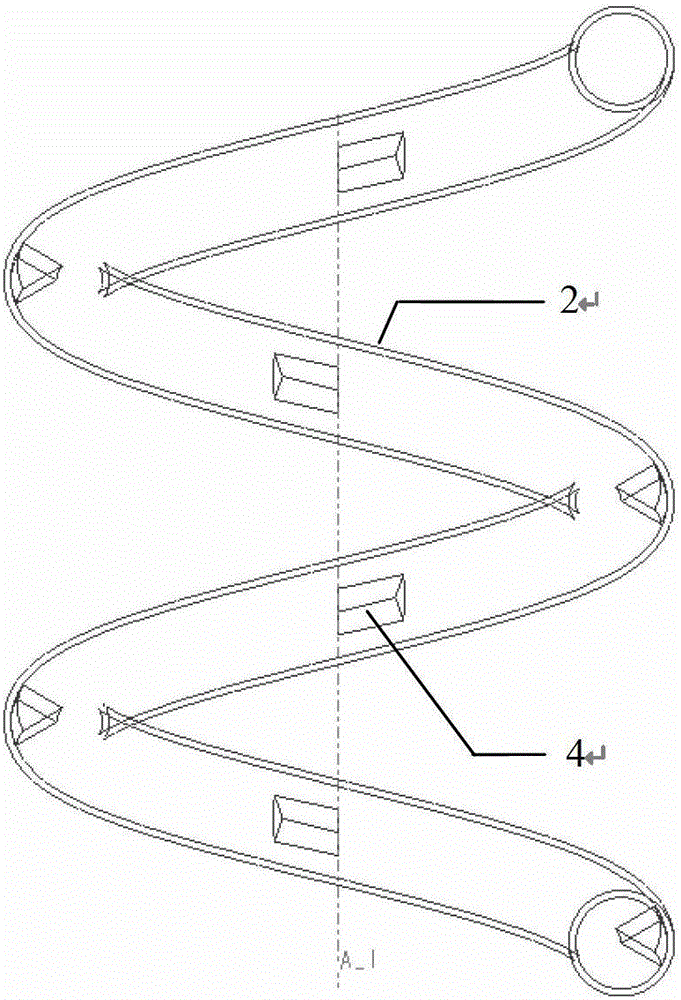

[0013] In the figure 1. Spiral tube outlet, 2. Spiral tube, 3. Spiral tube inlet, 4 fins.

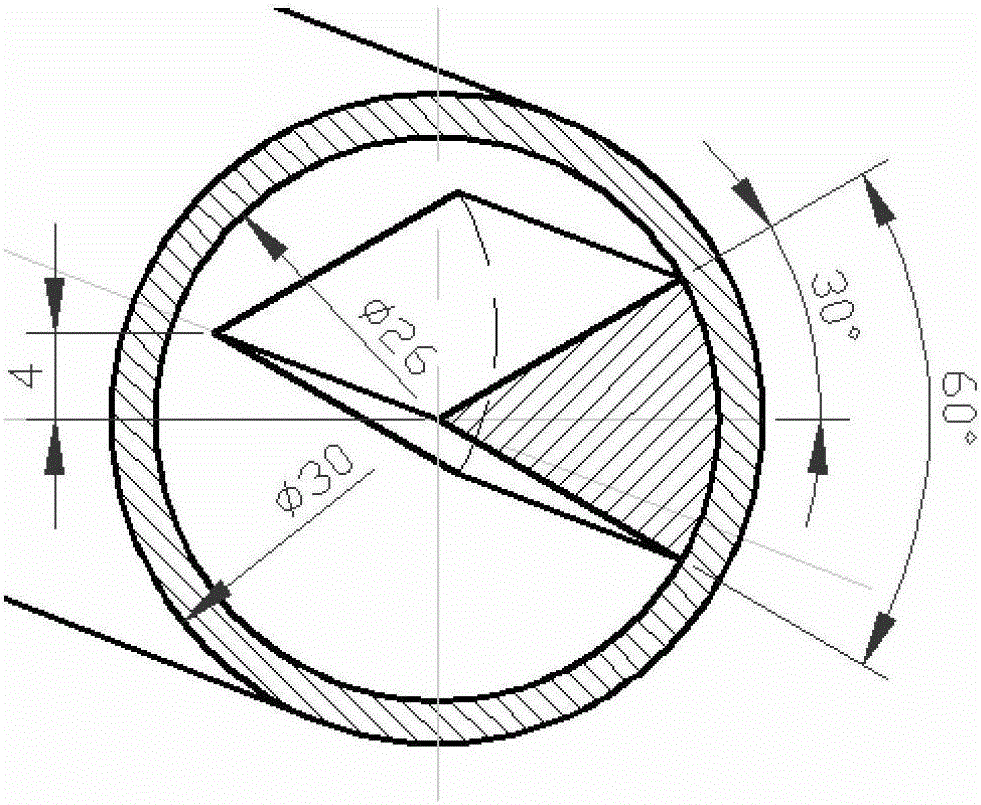

[0014] The finned spiral tube includes a spiral tube 2 with a circular section, and several fins 4 are evenly arranged on the inner wall of the spiral tube 2. For the convenience of processing and manufacturing, the fin 4 is a spiral structure with the same lead as the spiral tube 2; the fin 4 The cross-sectional shape of the fan is fan-shaped, and its radius is the same as that of the circular surface of the inner wall of the section of the spiral tube 2. The fins are arranged on the outer side of the inner wall of the spiral tube, and the center of the sector of the fin coincides with the center of the spiral tube.

[0015] exist figure 1 Among them, the invention is a helical tube with a pitch of t=125mm, the number of turns of the helical tube is n=2, the height of the helical tube is H=t×n=250mm, the helix of the helical tube is a cylindrical helix, and the diameter of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com