Special configuration blade for improving surface cavitation flow characteristics

A technology of flow characteristics and surface cavitation, which is applied to components of pumping devices for elastic fluids, engine components, climate sustainability, etc., can solve product and design method blanks, and special configuration blades have no impact on performance Sufficient knowledge and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

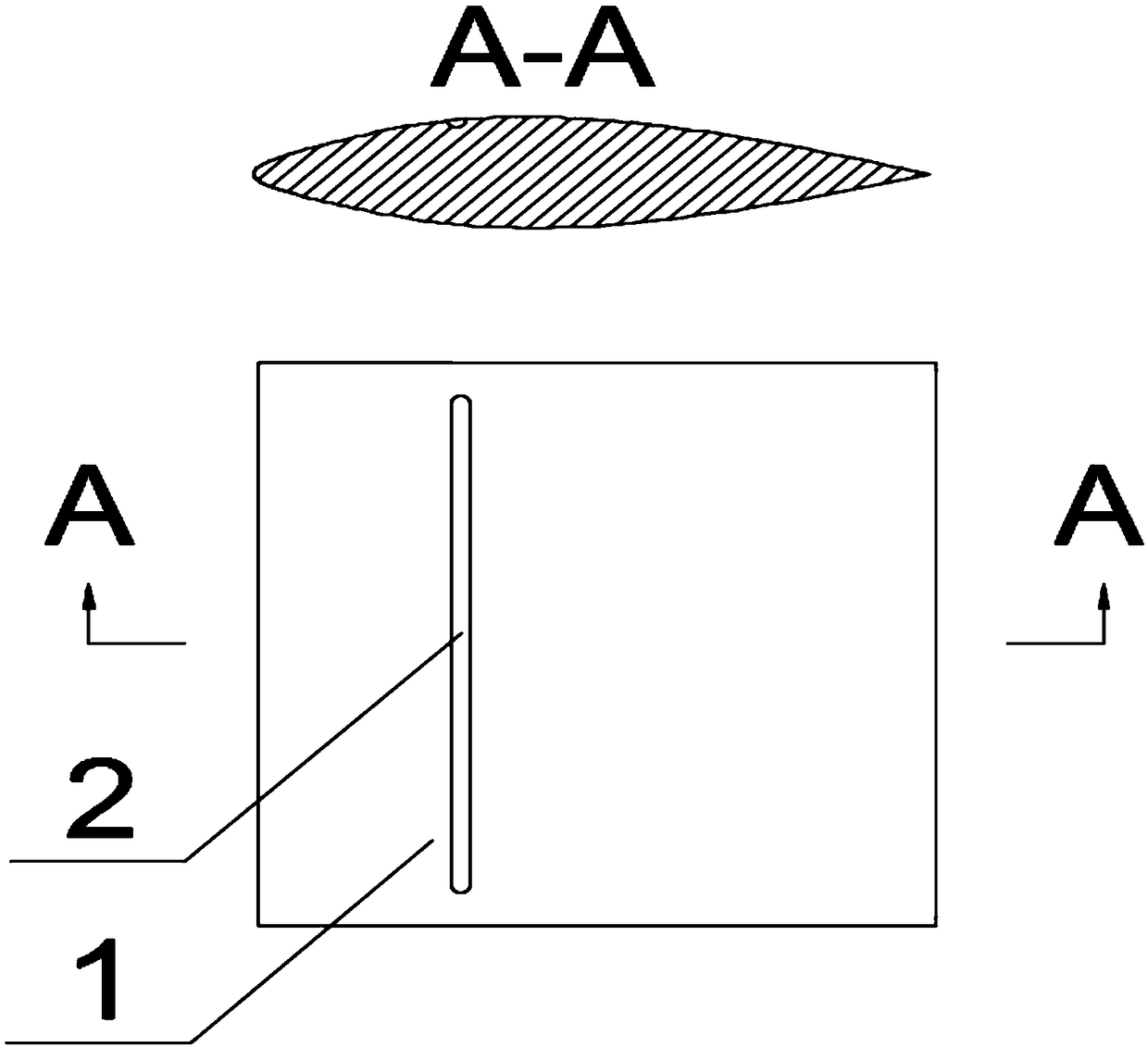

[0018] Such as figure 1 As shown, the present invention includes a blade with a special configuration to improve surface cavitation flow characteristics, mainly consisting of a blade 1 and a pit 2;

[0019] (1) According to the design requirements, the original hydraulic machinery blade 1 structure is NACA66 (MOD) airfoil, the angle of attack of the incoming flow of the blade is 8°, the incoming flow velocity is 7.832m / s, the incoming flow pressure is 101.325kPa, and the temperature is 20°C , the working medium is water, and the cavitation number at this time is 0.91.

[0020] (2) For the NACA66 (MOD) airfoil with no pits on the blade surface in the design, carry out numerical analysis of the cavitation flow field through physical and mathematical modeling, and obtain the specific state of cavitation occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com