Cavitation suppressionwing section device

An airfoil and cavitation technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve problems such as flow instability on the suction surface, achieve the effects of suppressing cavitation, reducing production cycle, and increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

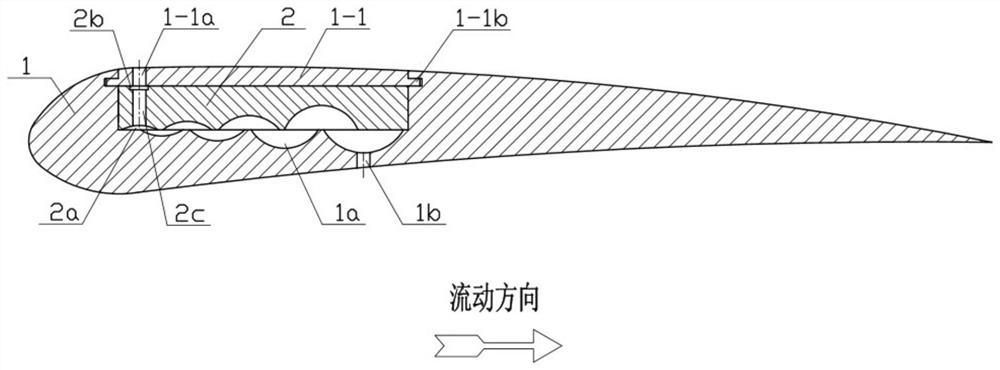

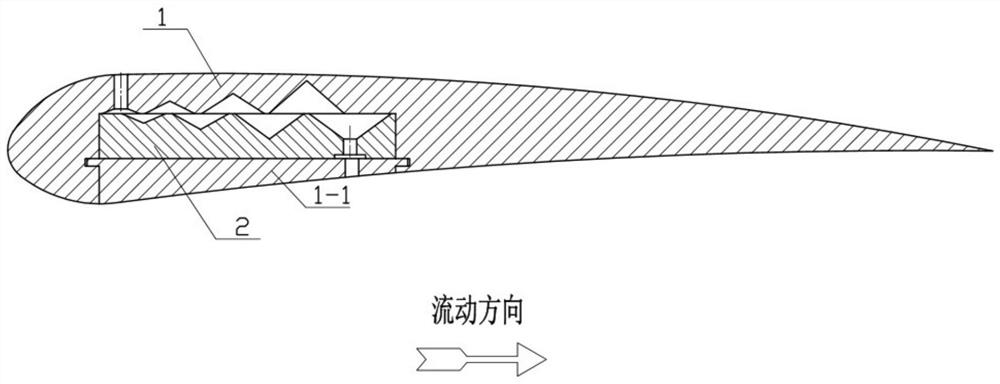

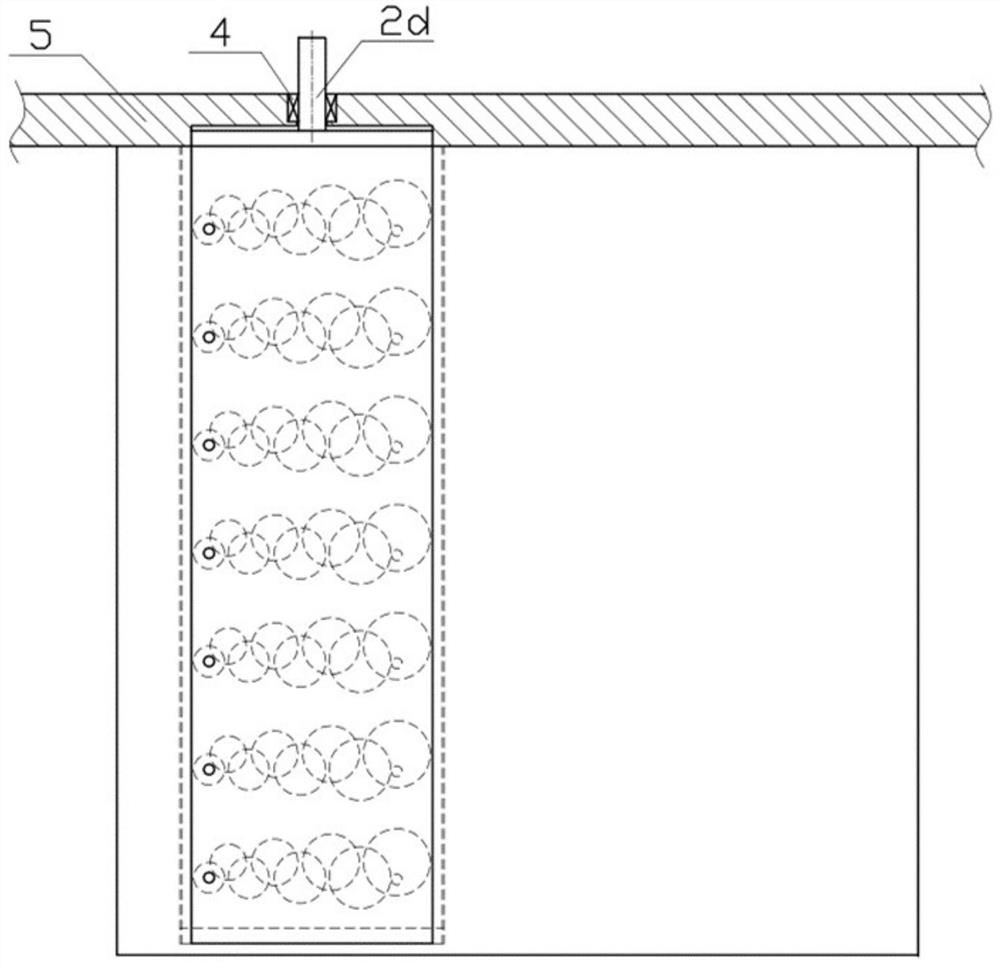

[0033] Such as figure 1 with Figure 4 As shown, the cavitation suppression airfoil device of the present invention includes an airfoil 1 and a slider 2, the slider 2 is movably installed in the airfoil 1, and any sliding surface of the slider 2 is provided with Several second grooves 2a arranged in a rectangle, the surface of the airfoil 1 in contact with any sliding surface is provided with a number of rectangular first grooves 1a, through the movement of the slider 2, any slider 2 The second groove 2a on the sliding surface communicates with at least the adjacent first groove 1a on the surface of the airfoil 1 that is in contact with it, so as to form at least one pressure-reducing channel along the flow direction; The airfoil 1 is provided with an inlet and outlet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com