Curved culvert type marine propeller

A marine propeller and ducted technology, applied in the direction of rotating propellers, rotating propellers, etc., can solve the problems of uneven force, difficult cavitation, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with accompanying drawing.

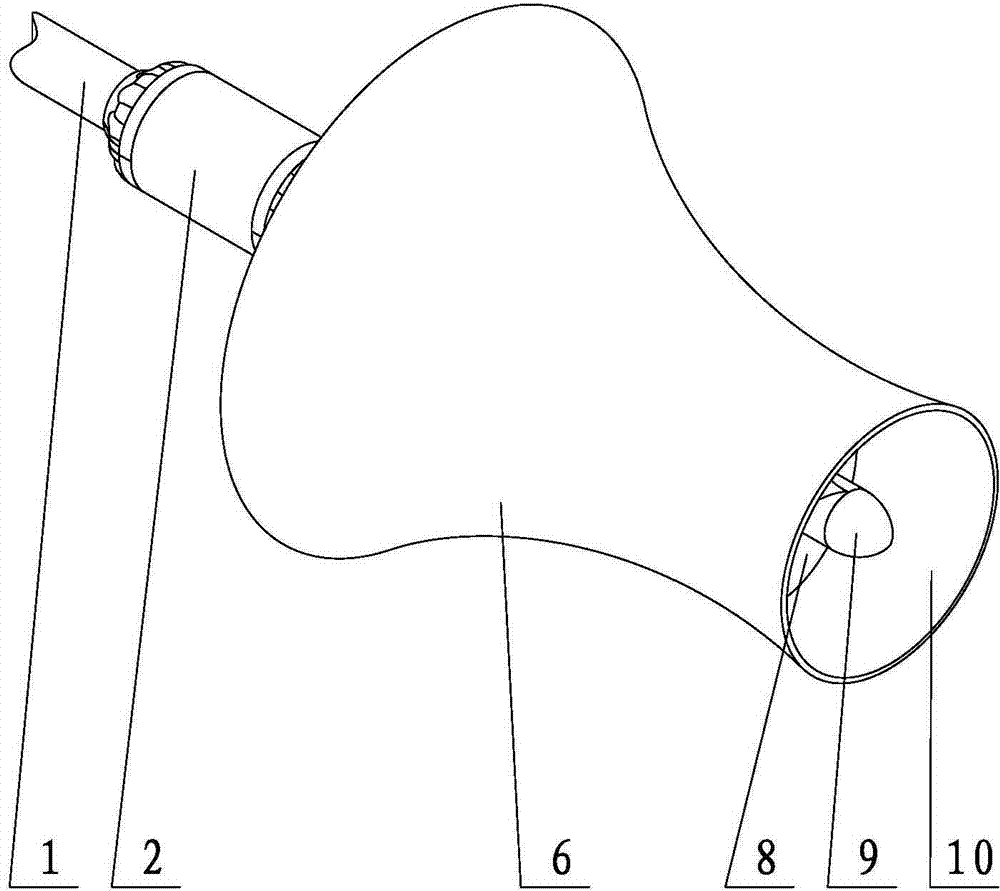

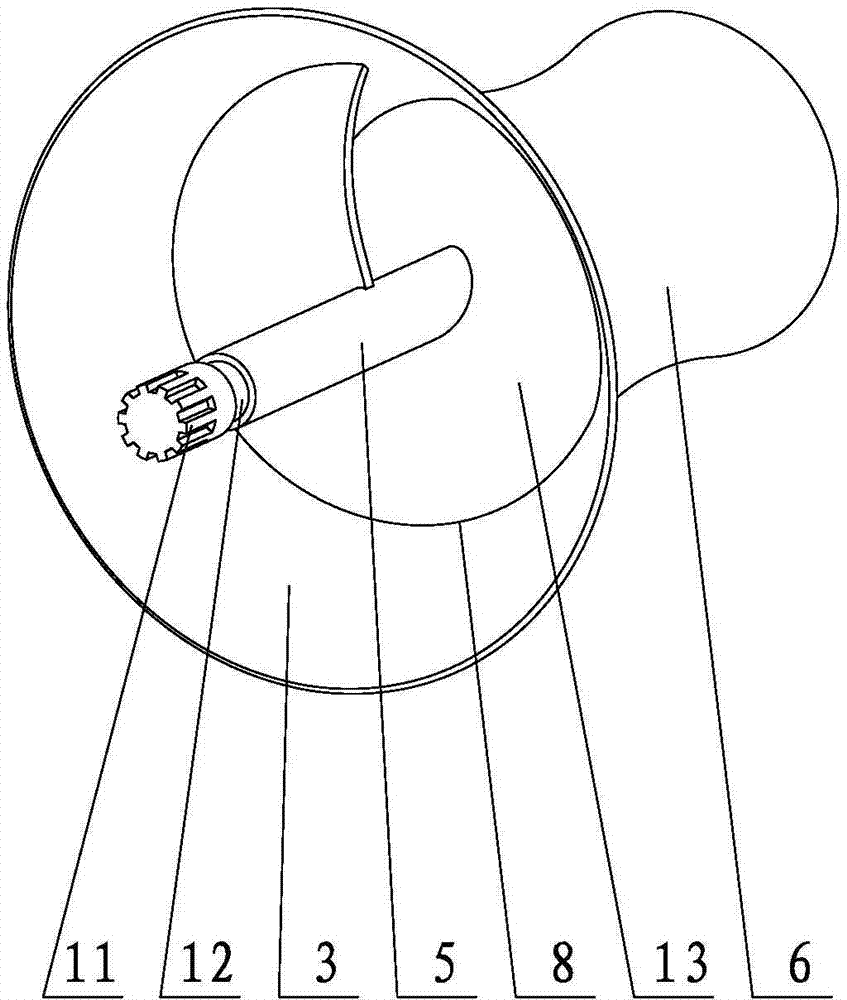

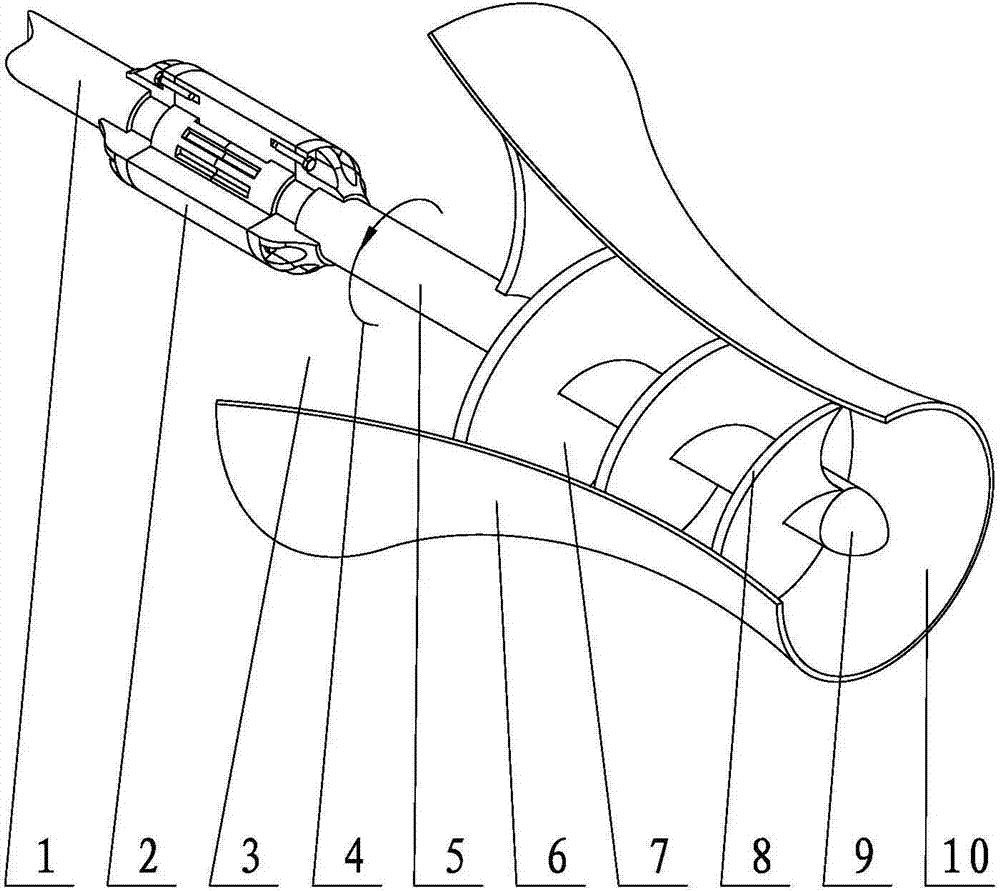

[0024] refer to figure 1 , figure 2 and image 3, the curved ducted marine propeller is mainly composed of a coupling part 2, a paddle shaft 5, a curved duct 6, a blade 8, and a tail cone 9. The paddle shaft 5 and the tail cone 9 are connected together in turn, and several blades 8 Fixed on the paddle shaft 5, the curved duct 6 is covered on the outside of several blades 8, and the inner surface of the curved duct 6 is connected with the tip of several blades 8. The shaft coupling part 2 connects the curved duct type marine propeller and the ship shaft 1 together.

[0025] refer to Figure 5 , the curved duct 6 is trumpet-shaped, and the curved duct 6 is respectively the duct front edge 17, the duct throat 18, and the duct rear edge 19 from front to back. The cross-sectional diameter of the duct front 17 is the largest, and the duct throat 18 has the smallest cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com