Engine cooling apparatus

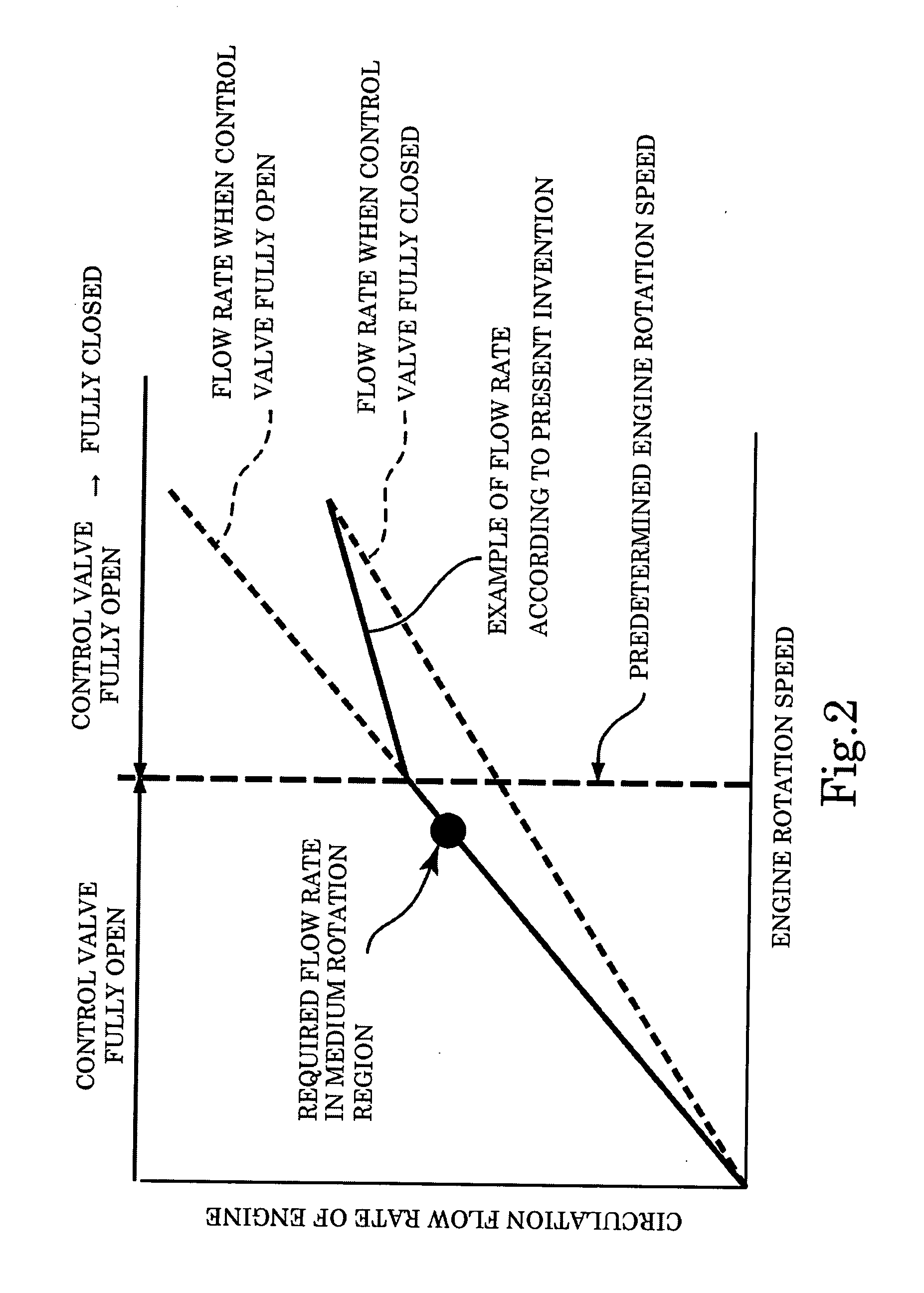

a cooling apparatus and engine technology, applied in the direction of engine cooling apparatus, machine/engine, measurement device, etc., can solve the problems of increased cavitation probability, reduced engine output, increased cavitation probability, etc., to achieve sufficient cooling performance, reduce the flow resistance of the cooling water circuit, and suppress the effect of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

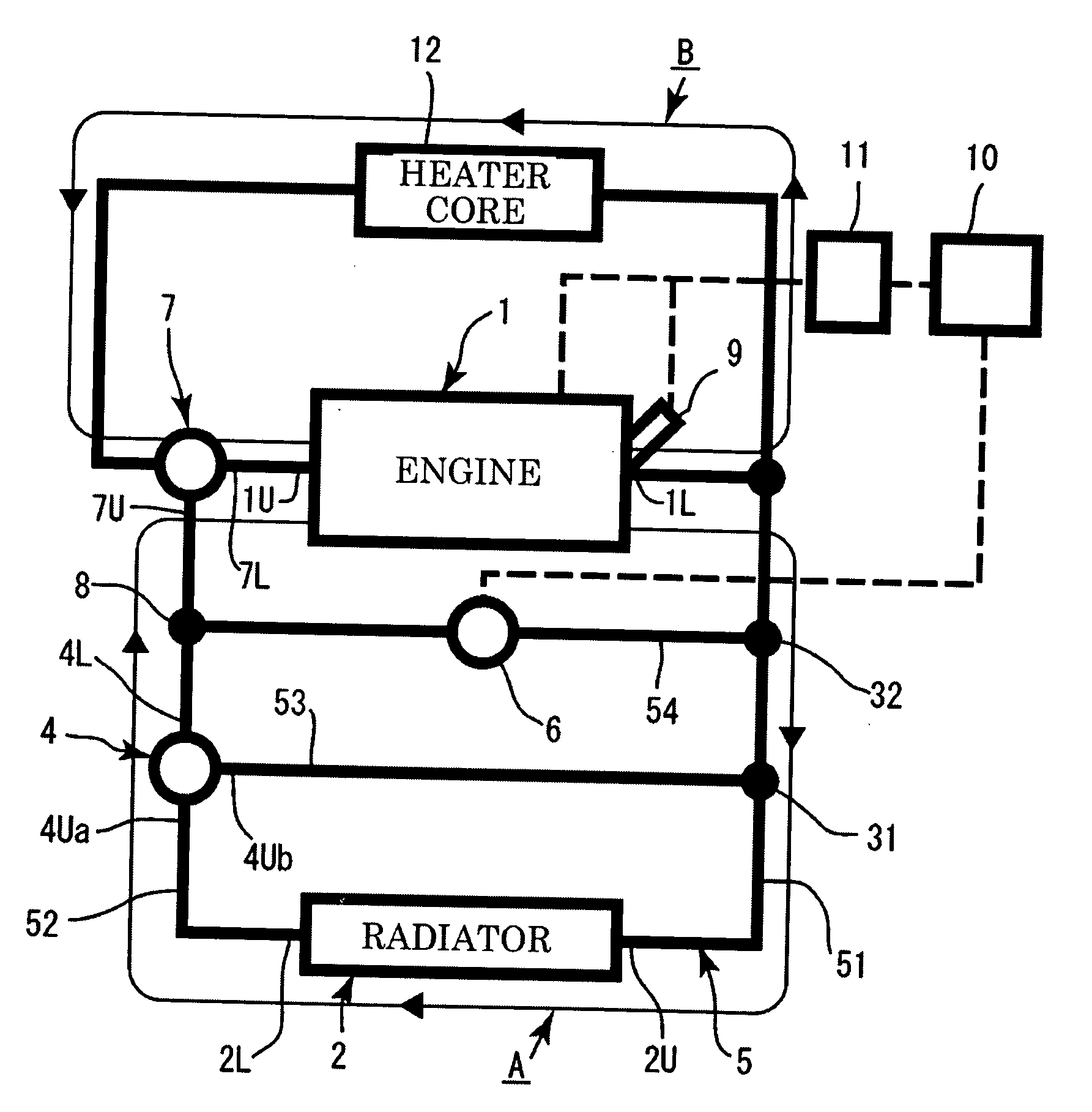

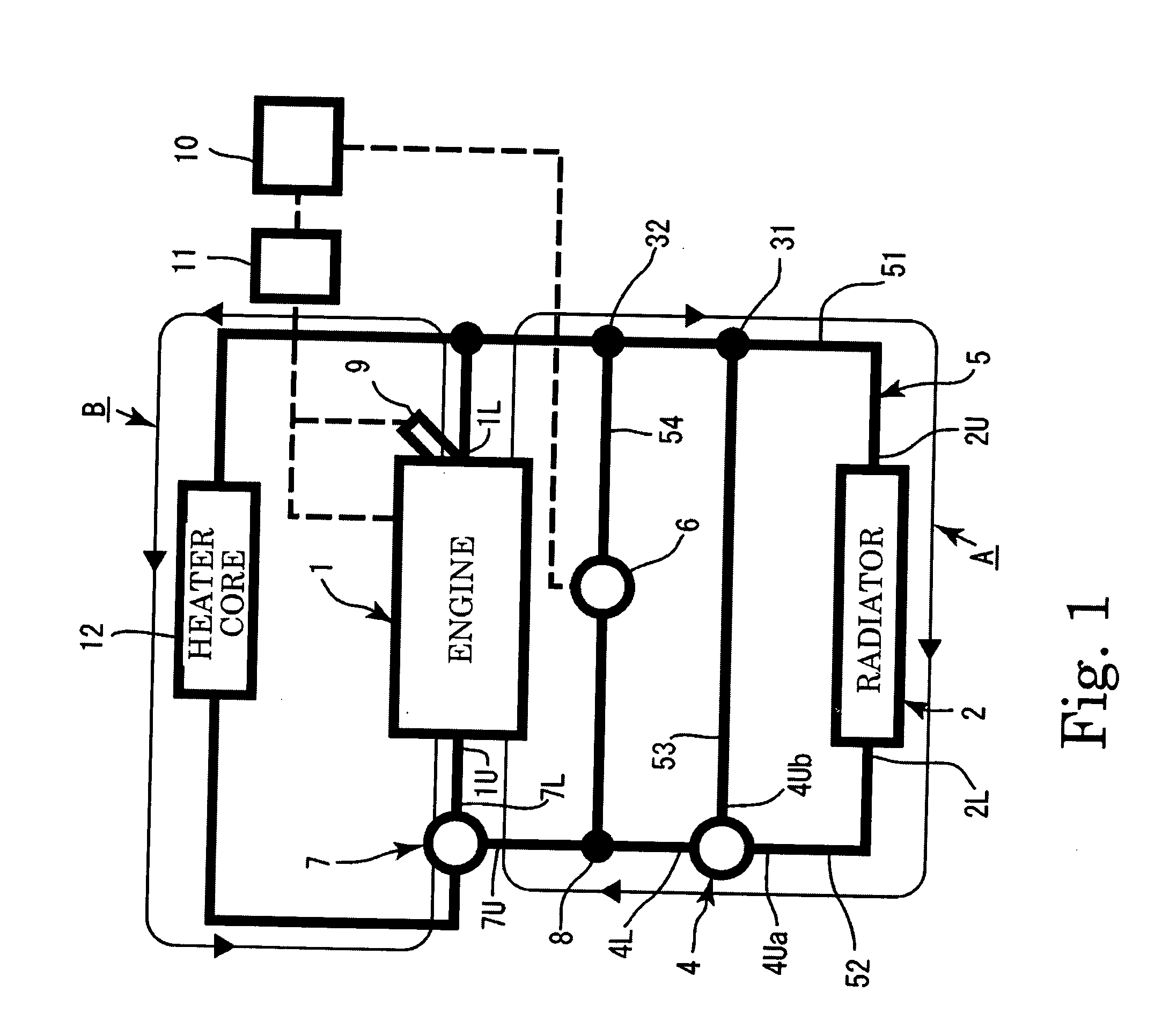

[0019]An embodiment of the present invention will be described below on the basis of the drawings. The present invention is a circuit for circulating cooling water between an engine 1 and a radiator 2, which is mainly constituted by a main cooling water circuit A, a first bypass flow passage 53, and a second bypass flow passage 54. A heater circuit B having a flow passage that passes through an engine 1 and a heater core 12 provided in the flow passage is provided in addition to the main cooling water circuit A.

[0020]FIG. 1 shows the cooling water circuit according to the present invention. In the following description, a side of internal components of the cooling water circuit such as the radiator 2 and a thermostat 4 on which the cooling water flows into the components will be referred to as an upstream side and indicated by affixing a reference symbol “U” to the respective components, and a side on which the cooling water flows out of the components will be referred to as a downs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com