Patents

Literature

45 results about "Tooth chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

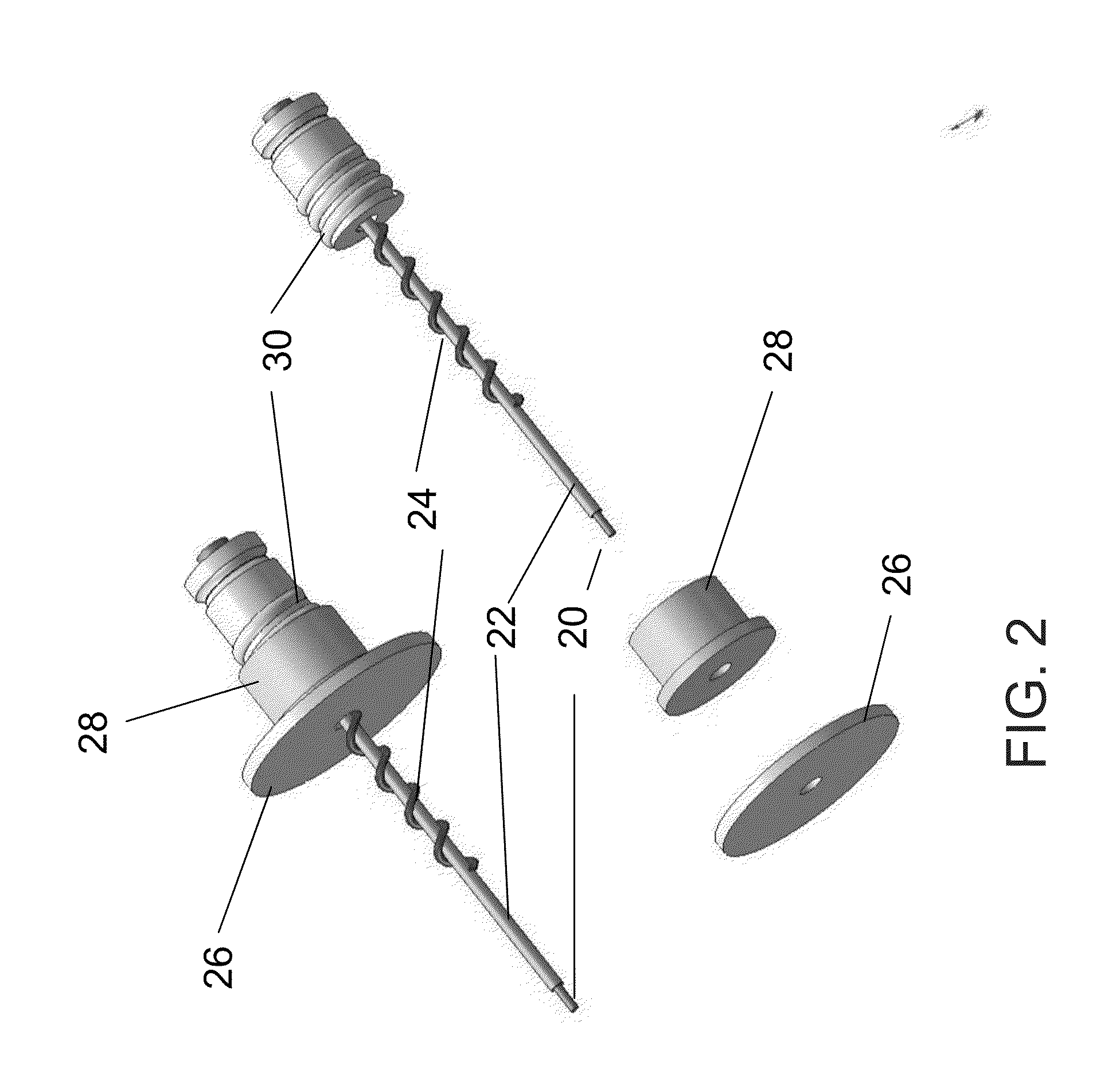

Device and method for dental cavity treatment

A device for disinfecting and / or sterilization of a dental cavity comprising:an electrode pair adapted to extend into said cavity to provide current along at least a portion of the cavity; anda controller configured for sending controlled electrical energy to said cavity via current flowing between the electrodes when located in said cavity, thereby to provide electrical energy for said disinfection and / or sterilization.

Owner:MDT MICRO DIAMOND TECH LTD

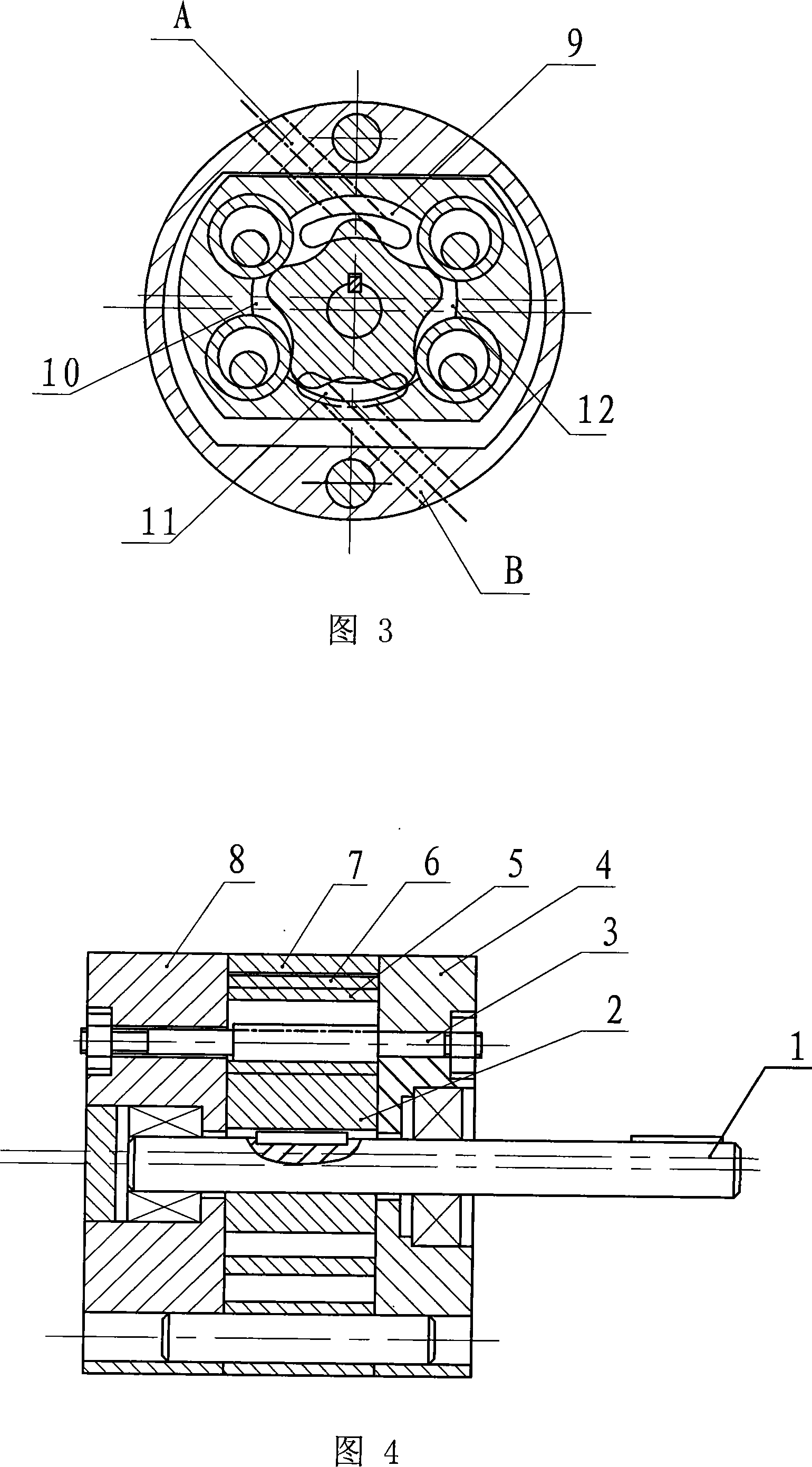

Gear pump

InactiveUS6896500B2Reliable preventionSimple designOscillating piston enginesEngine of intermeshing engagement typeGear pumpEngineering

A bottom portion of an intake port is provided with a sloped bottom surface formed of a plane such that sloped bottom surface approaches the side surfaces of external teeth and internal teeth from an upstream side to a downstream side in rotational direction of two rotors. Fluid that flows in the intake port is regulated by the sloped bottom surface and smoothly guided into individual inter-teeth chambers that are expanding. Since the sloped bottom surface on the bottom portion of the intake port is formed of a plane without spiral or twisting, design and manufacturing of a gear pump is extremely easy.

Owner:AISIN AW CO LTD

Liquid coating comb

The invention discloses a liquid coating comb comprising a comb body and comb teeth connected with the comb body, wherein a comb body chamber is arranged inside the comb body; a comb tooth chamber which is communicated with the comb body chamber is arranged inside the comb teeth; the comb tooth chamber is provided with a liquid inlet and the comb tooth chamber is provided with a liquid outlet; and a liquid coating device which is communicated with the liquid outlet is arranged at the end parts of the comb teeth. The liquid coating comb disclosed by the invention can uniformly coat liquid on scalps and does not scratch the scalps and hair follicles; and meanwhile, the massage can be performed on a head.

Owner:WINERGEN TECH WEIFANG

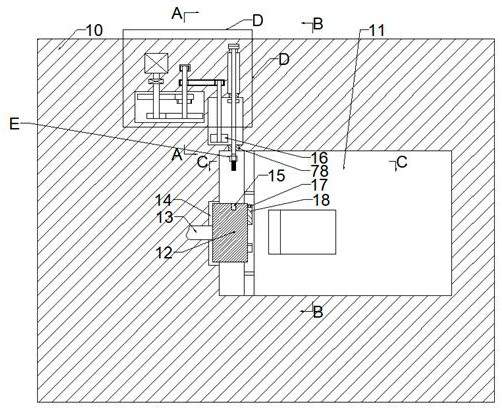

Device suitable for rust removal of inner walls of metal pipes with different diameters and different lengths

InactiveCN112077682AThorough rust removalImprove rust removal effectBlast gunsRevolution surface grinding machinesGear wheelMining engineering

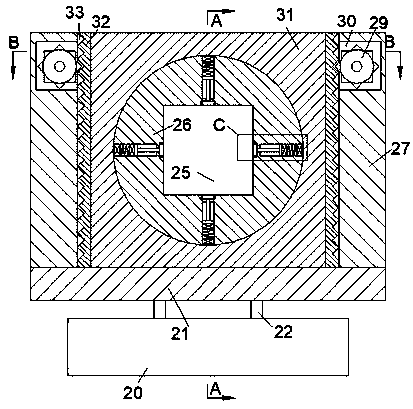

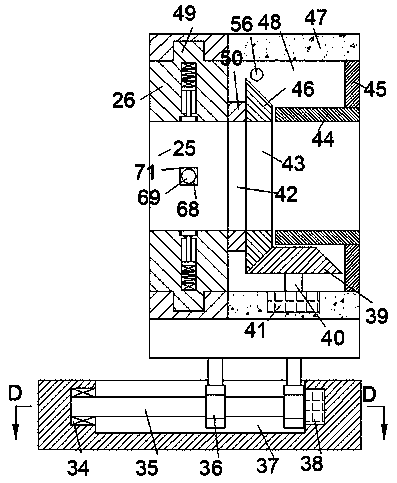

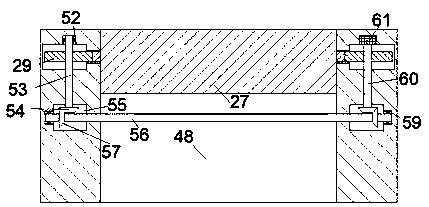

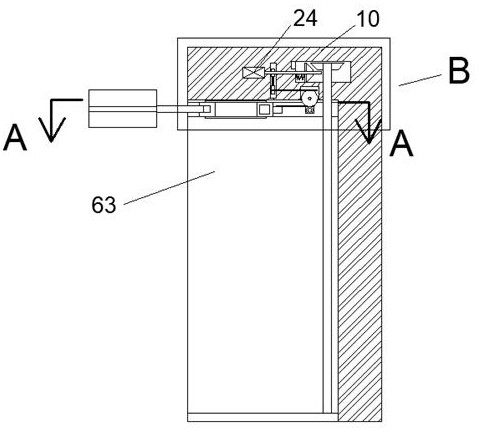

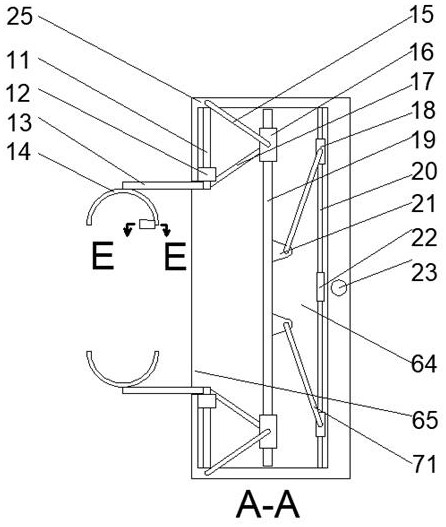

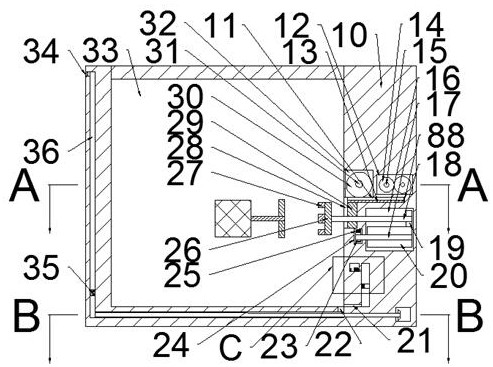

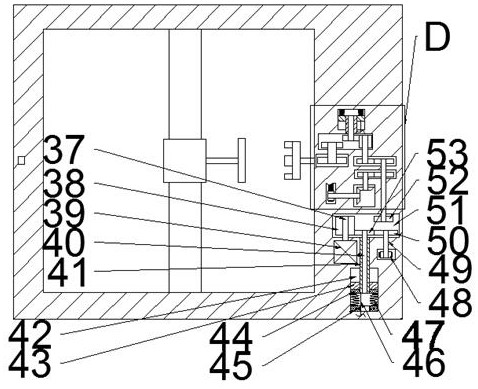

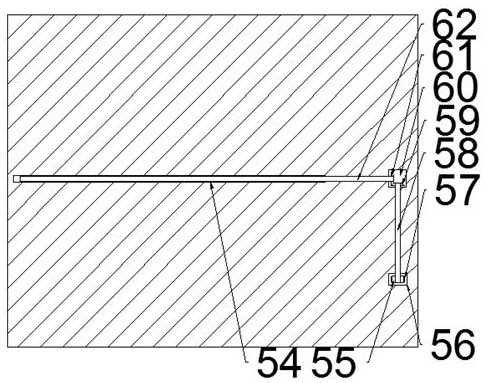

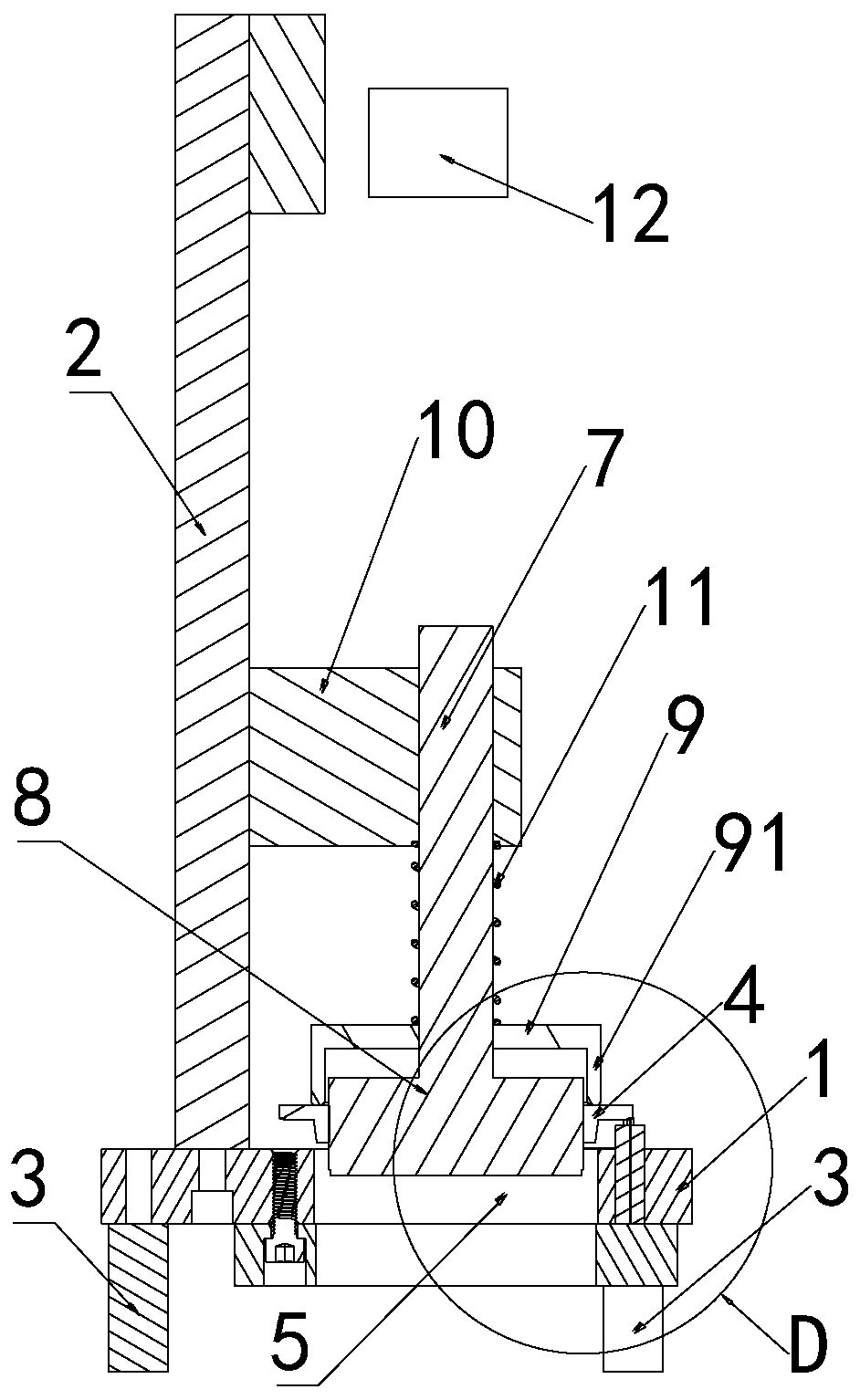

The invention relates to the field of metal materials, and discloses a device suitable for rust removal of inner walls of metal pipes with different diameters and different lengths. The device comprises a main box body, wherein a transmission large gear cavity is formed in the main box body; telescopic gear cavities which are symmetrical left and right by taking the transmission large gear cavityas a center are formed in the left side and the right side of the transmission large gear cavity in a communicating mode; a transmission gear cavity is formed in the left side of the telescopic gear cavity on the left side in a communicating mode; an end face tooth cavity is formed in the lower side of the transmission gear cavity; and a sliding bevel gear cavity, a telescopic advancing wheel anda rust removal brush are arranged on the left side of the transmission gear cavity. According to the device, the device is suitable for rust removal operation of the inner walls of the metal pipes with different diameters, the advancing wheel drives the device to advance, so that rust removal operation of the metal pipes with different lengths can be realized; the rust removal brush is matched with sand blasting for rust removal, so that rust removal of the inner walls of the metal pipes is more thorough; and meanwhile, automatic rust removal of the device replaces manual operation, so that the rust removal effect of the metal pipes is better, the efficiency is higher, and meanwhile, the problem that the rust removal operation of the pipes with the long length cannot be well carried out manually is solved.

Owner:SHANGYU ZHONGTAI MEDICAL TECH

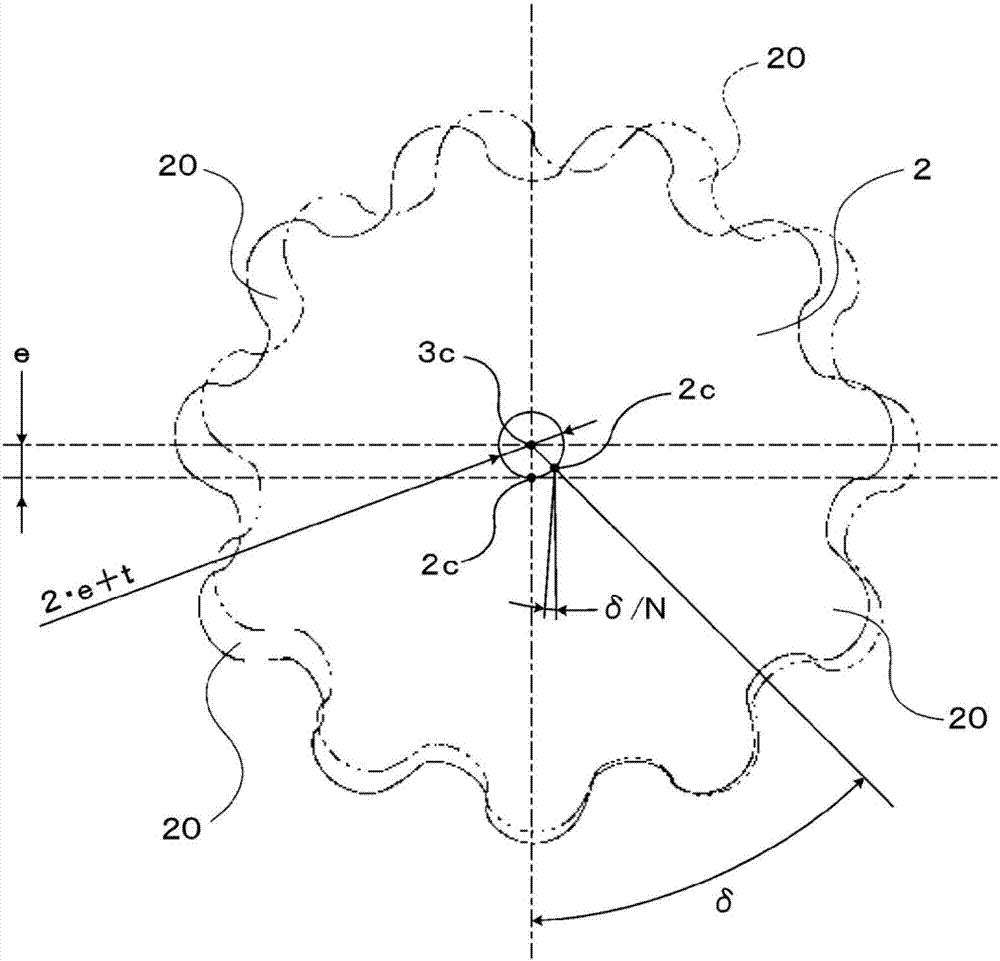

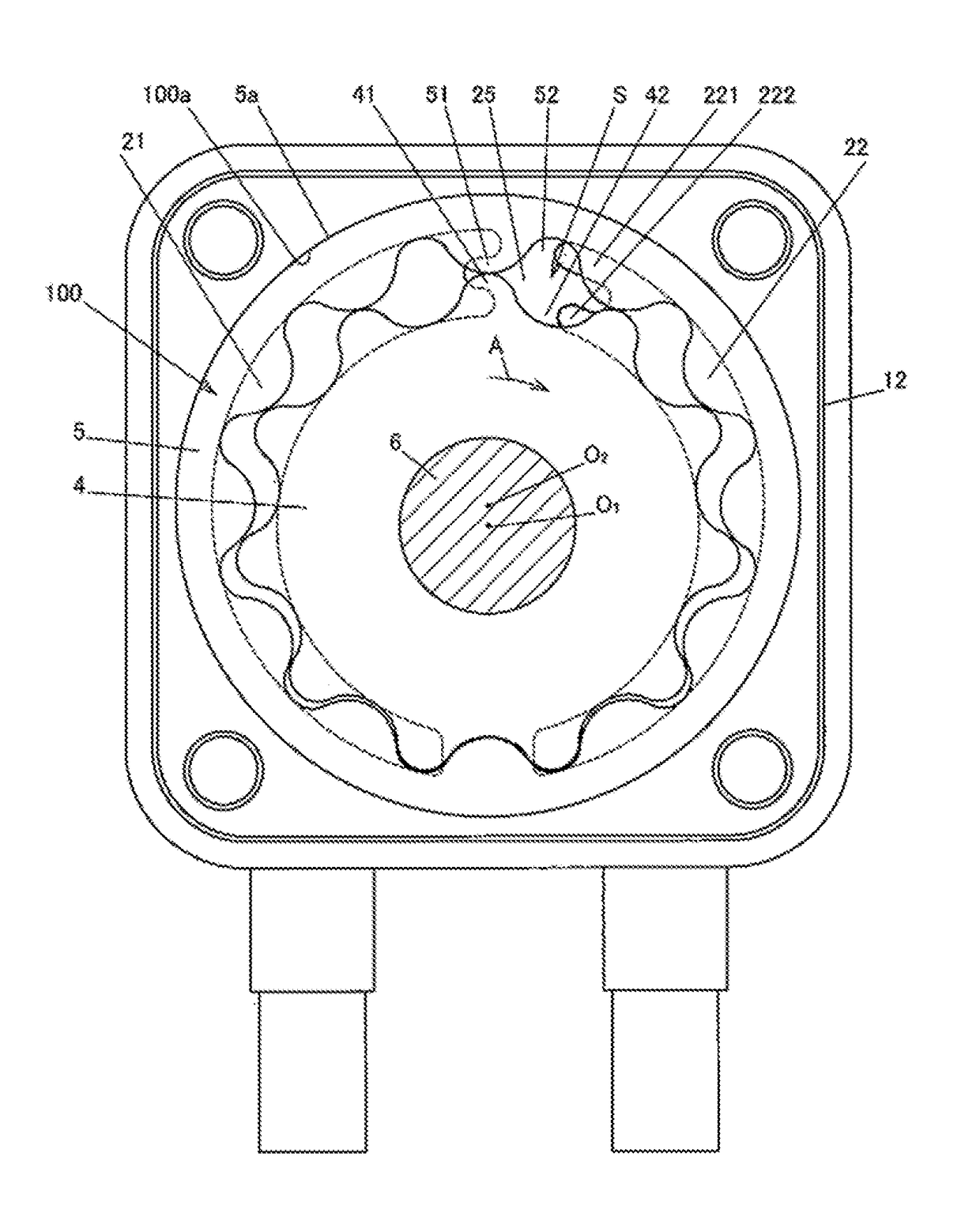

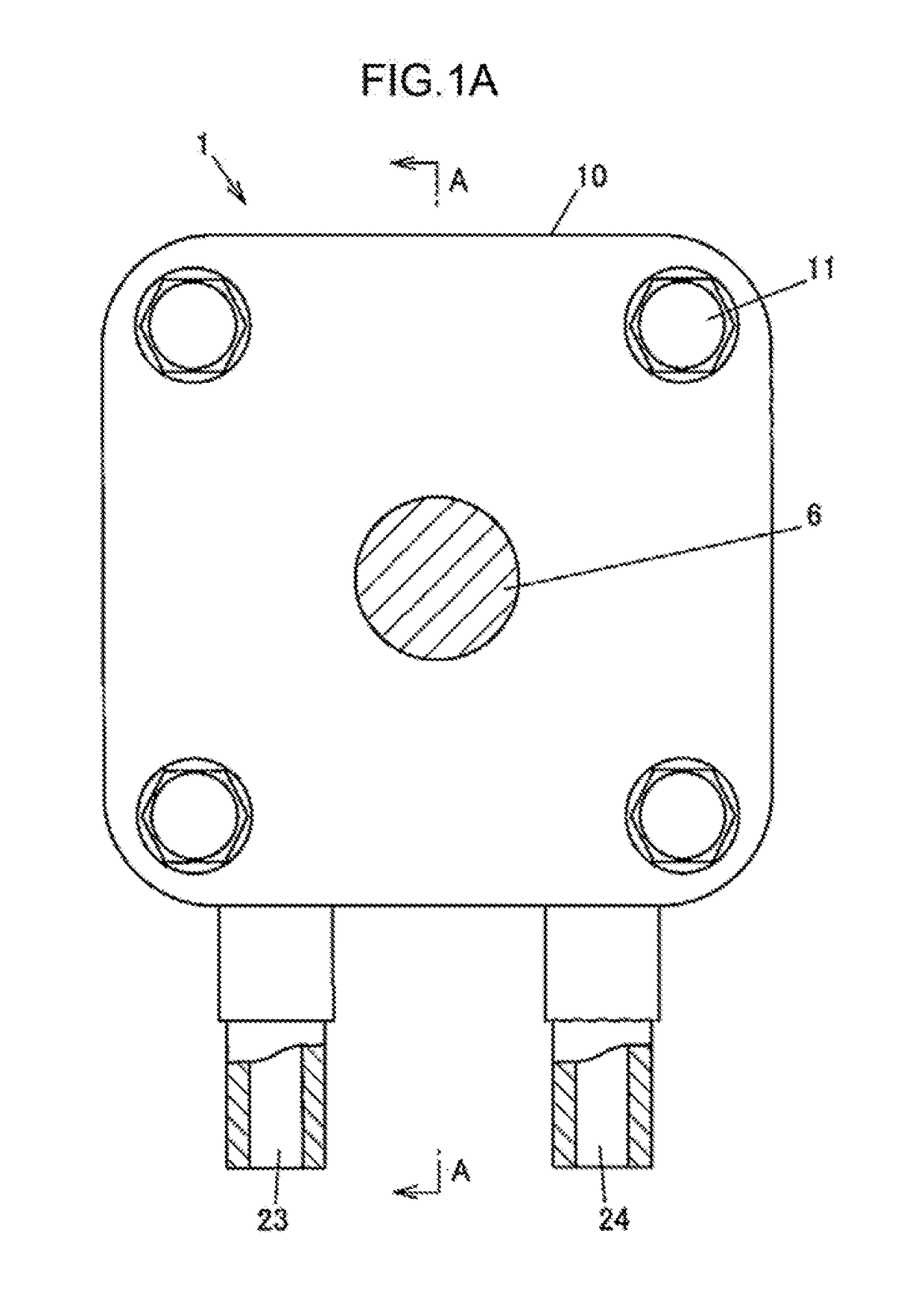

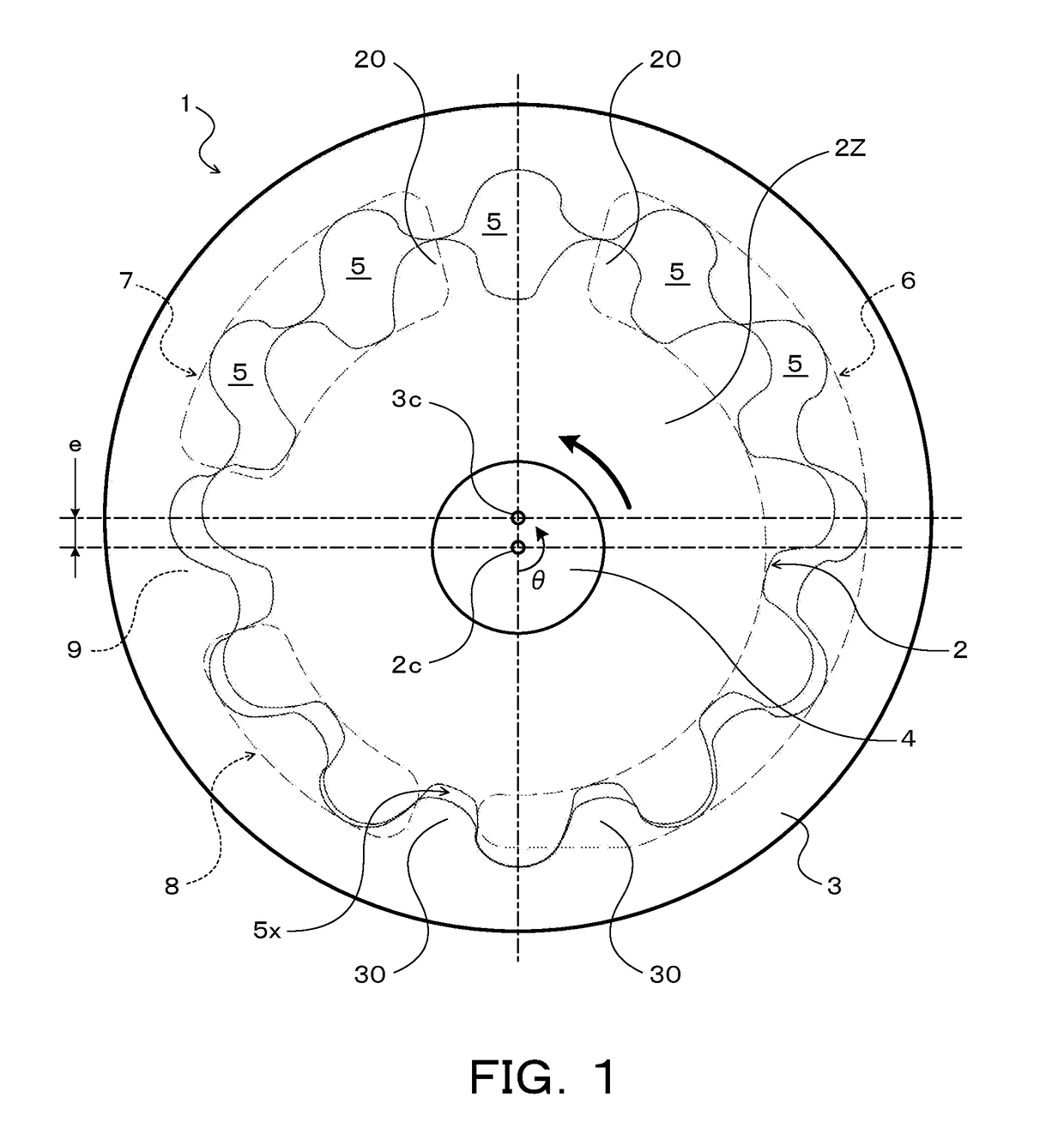

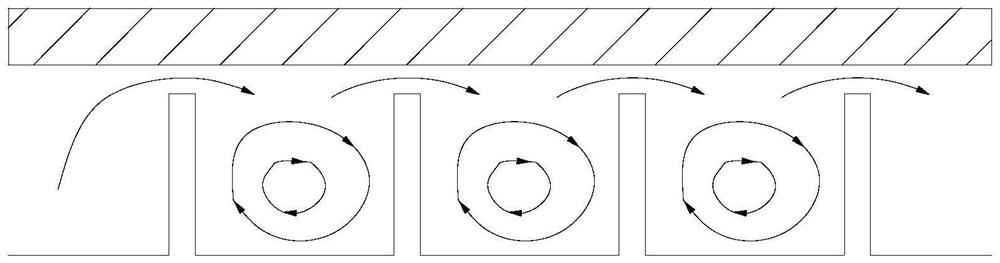

Gear pump

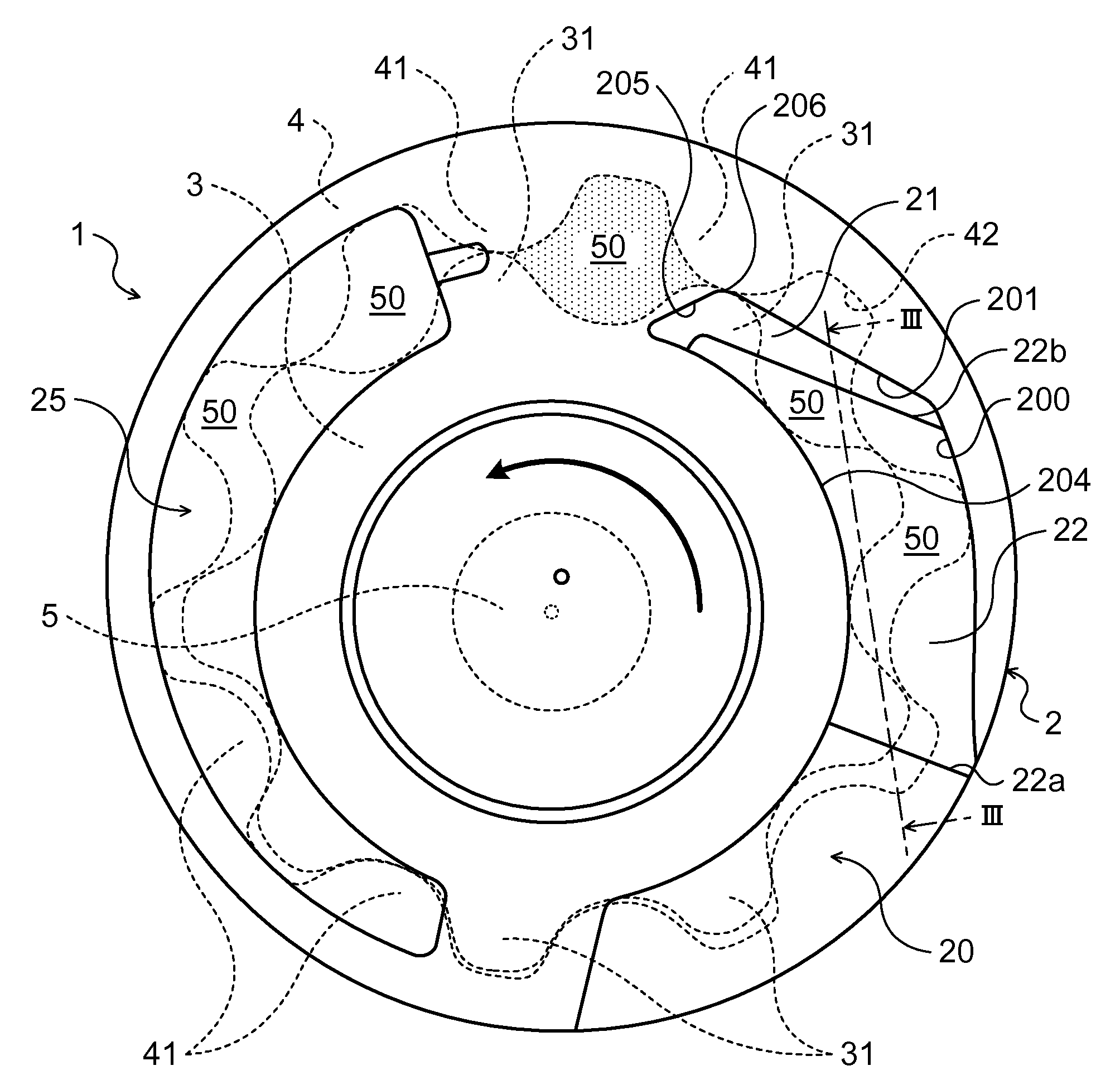

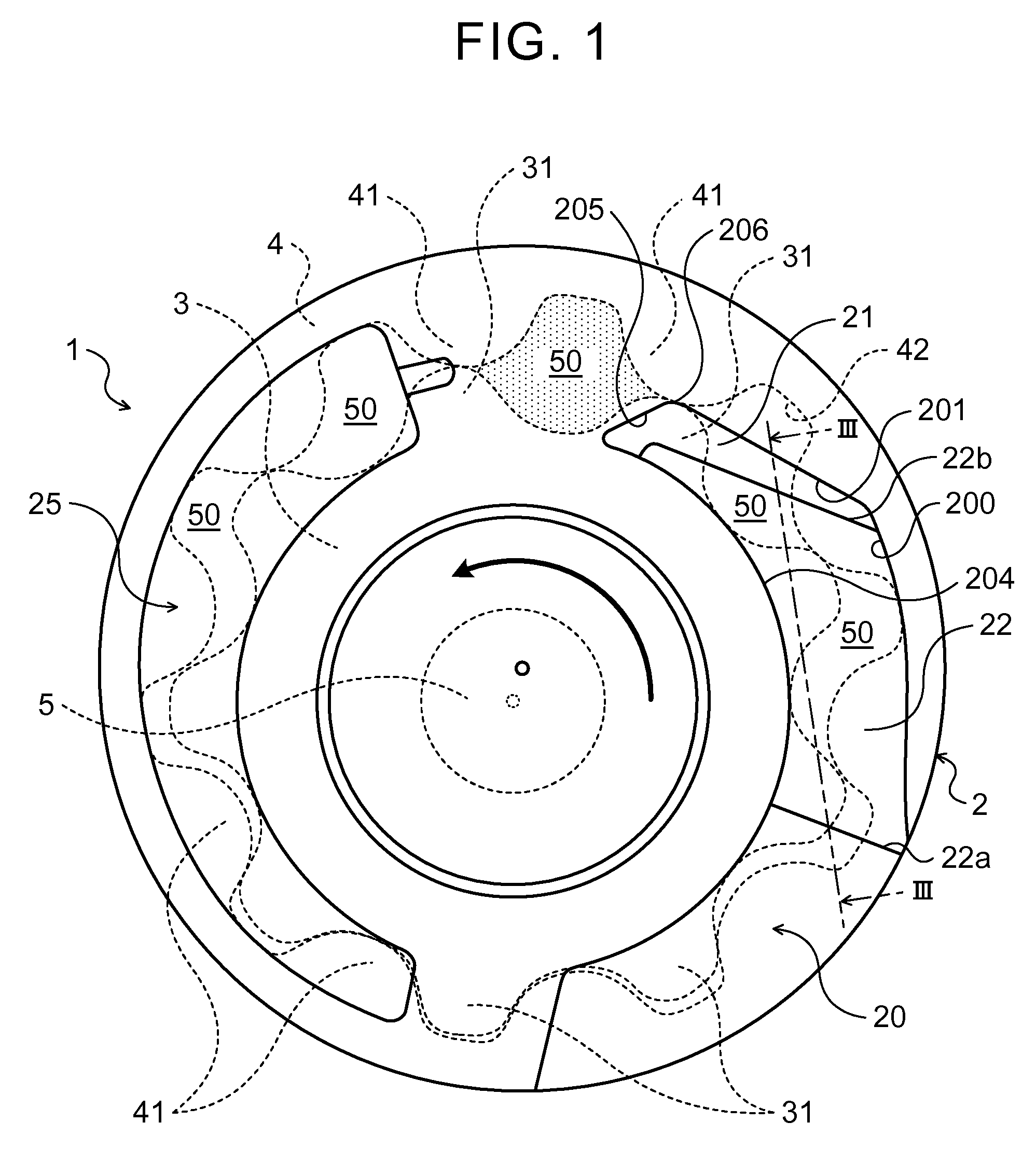

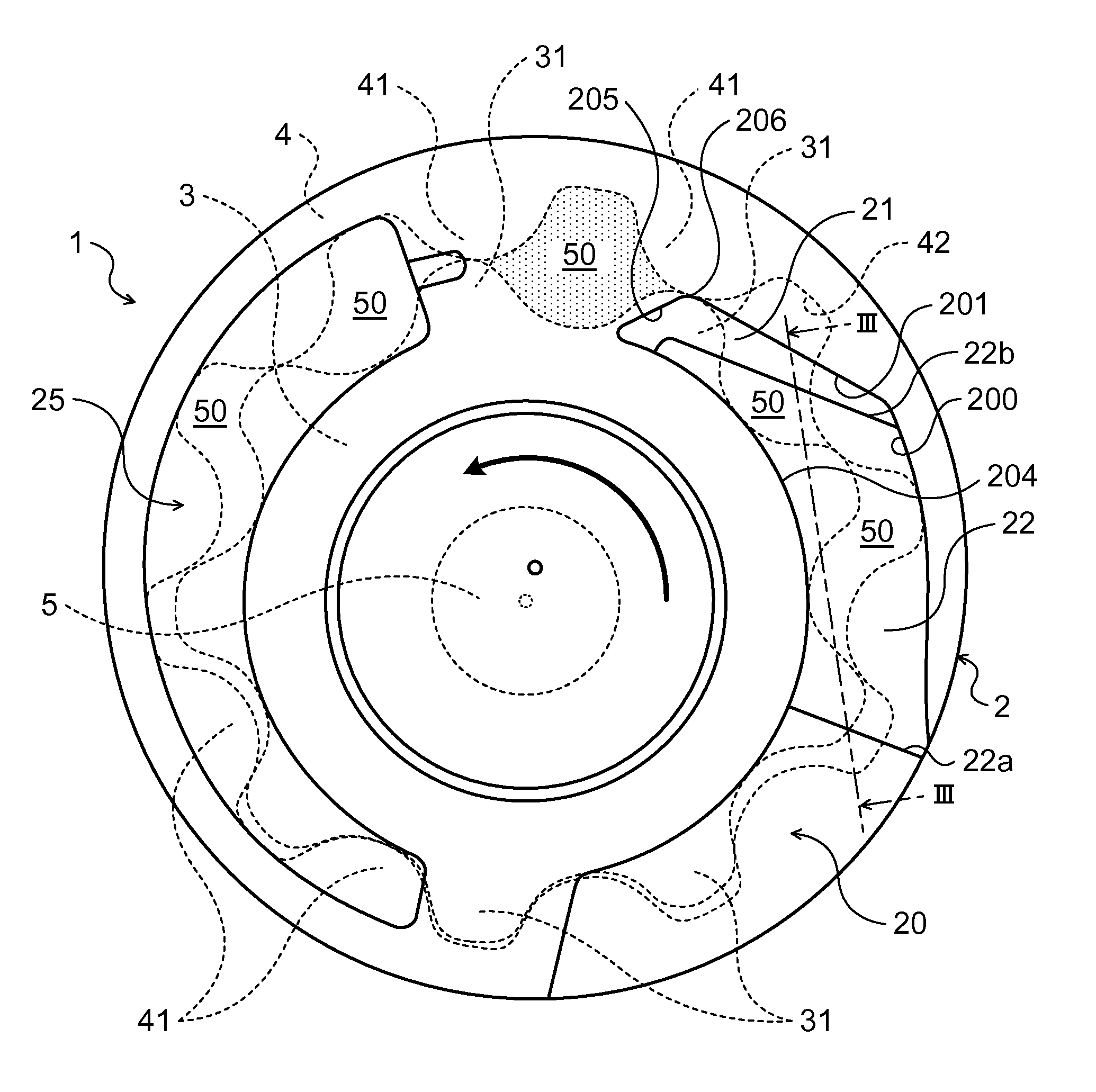

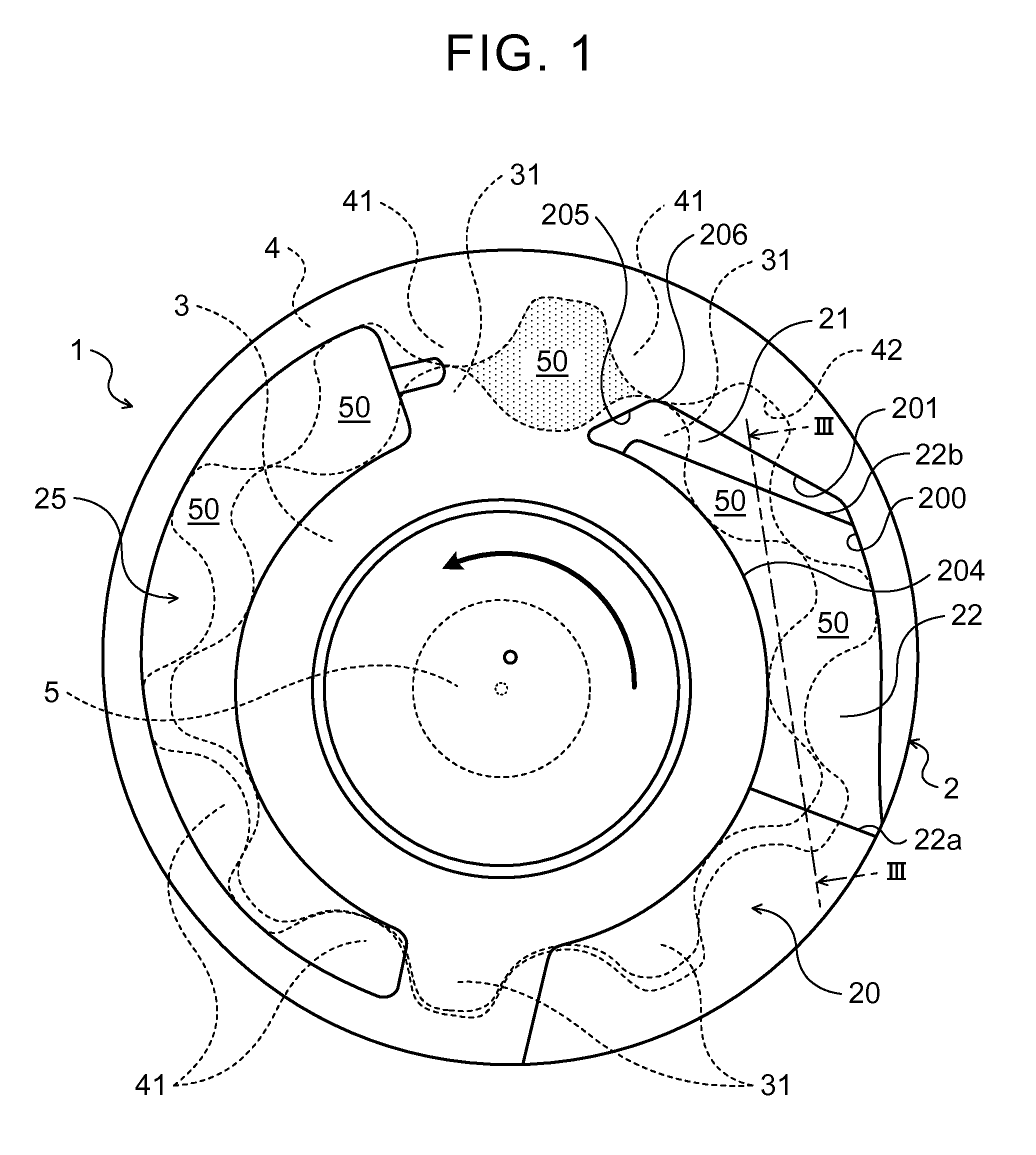

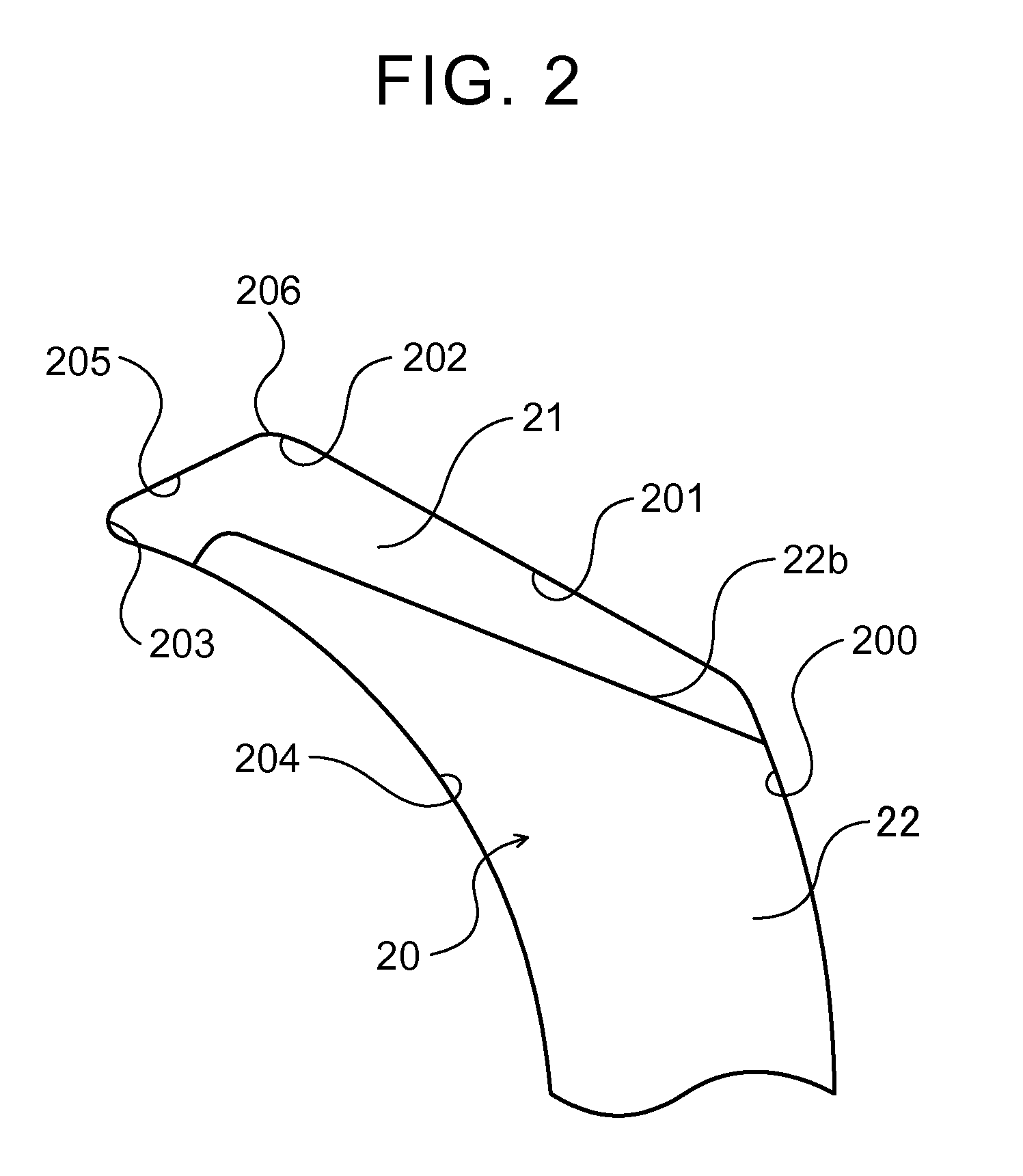

ActiveUS20150219097A1Suppress cavitationImprove suction efficiencyEngine of intermeshing engagement typeRotary piston pumpsGear pumpEngineering

In a gear pump, an outer inner wall surface of a suction port which is located on a downstream side in a rotor rotation direction, that is, a first inner wall surface, is located inward of a bottom land between internal teeth of an outer rotor, and the suction port has a shallow portion extended inward from the first inner wall surface on the downstream side in the rotor rotation direction, and a deep portion that is formed so as to be continuous with the shallow portion and that is deeper than the shallow portion. Communication between an inter-tooth chamber and the suction port is cut off with the inter-tooth chamber facing only the shallow portion.

Owner:AISIN AW CO LTD

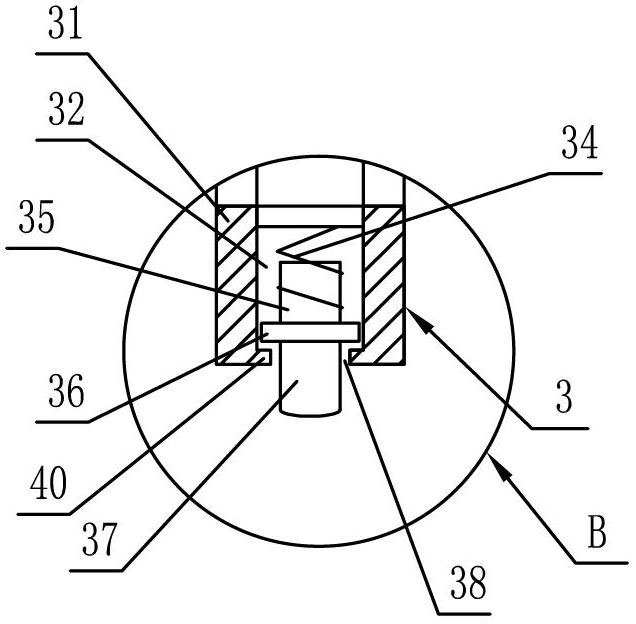

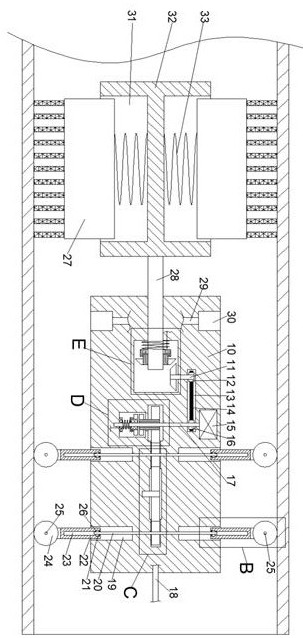

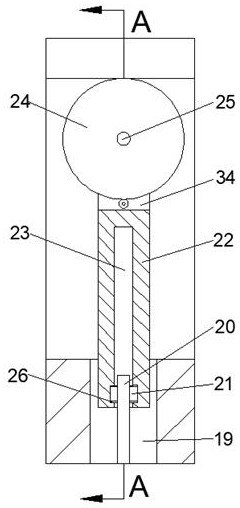

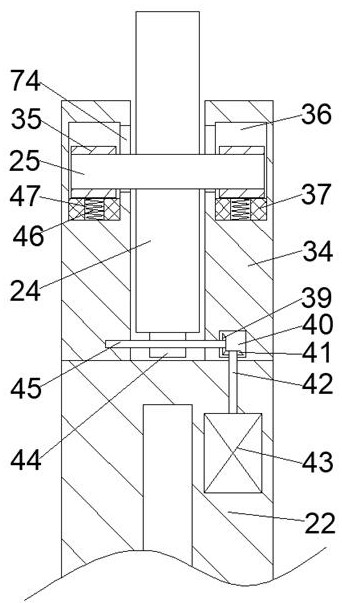

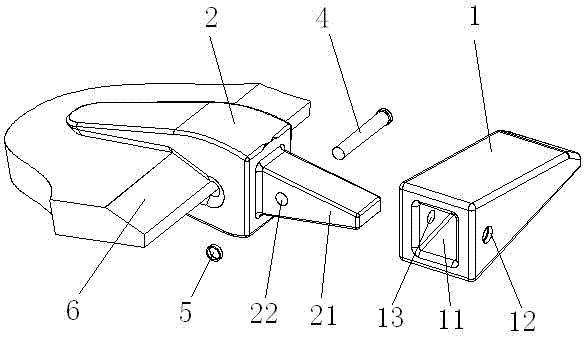

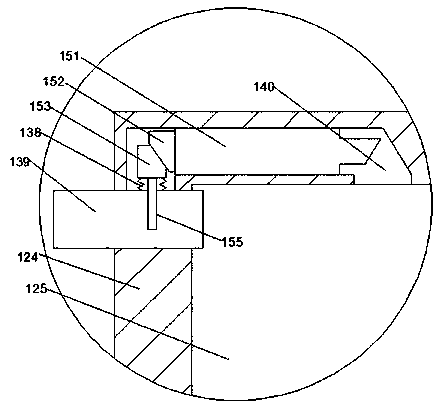

Bucket tooth installation structure convenient for rapid disassembly and assembly

InactiveCN102418363AIncrease lateral stiffnessImprove fastening forceSoil-shifting machines/dredgersEngineeringStructural engineering

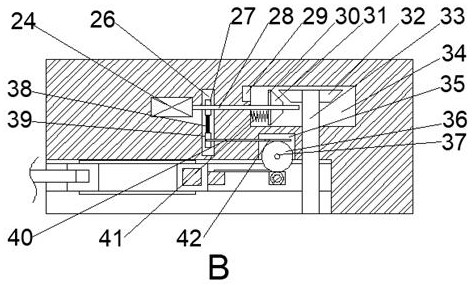

The invention discloses a bucket tooth installation structure convenient for rapid disassembly and assembly. The bucket tooth installation structure comprises a bucket tooth, a tooth seat and a pin assembly, wherein the bucket tooth is internally provided with a bucket tooth cavity, the front part of the tooth seat is provided with a tooth seat head, the bucket tooth cavity is complementary with the tooth seat head in shape, and the bucket tooth is fixedly connected with the tooth seat head through the pin assembly; the left side wall and the right side wall of the big end of the bucket toothcavity are symmetrically provided with coaxial holes in a mirroring way, wherein the coaxial holes are vertical to the central surface of the bucket tooth, and an inner hole and an outer hole of the bucket tooth cavity form an annular concave table; one end of a pin in the pin assembly is provided with a pin cap, the pin cap is arranged in the annular concave table at one side of the bucket tooth, and a memory alloy expanding and contracting ring is arranged outside the other end of the pin and arranged in the annular concave table at the other side of the bucket tooth; or the other end of the pin is provided with an annular groove, and the memory alloy expanding and contacting ring is arranged in the annular groove and arranged in the annular concave table at the other side of the buckettooth. According to the invention, the pin assembly provided with the memory alloy expanding and contracting ring is adopted, rapid assembly and disassembly of the bucket teeth are realized by electrodes or flame heating, and the pin assembly has large transverse rigidity, provides large fastening force and is reliable to connect.

Owner:ZHEJIANG UNIV

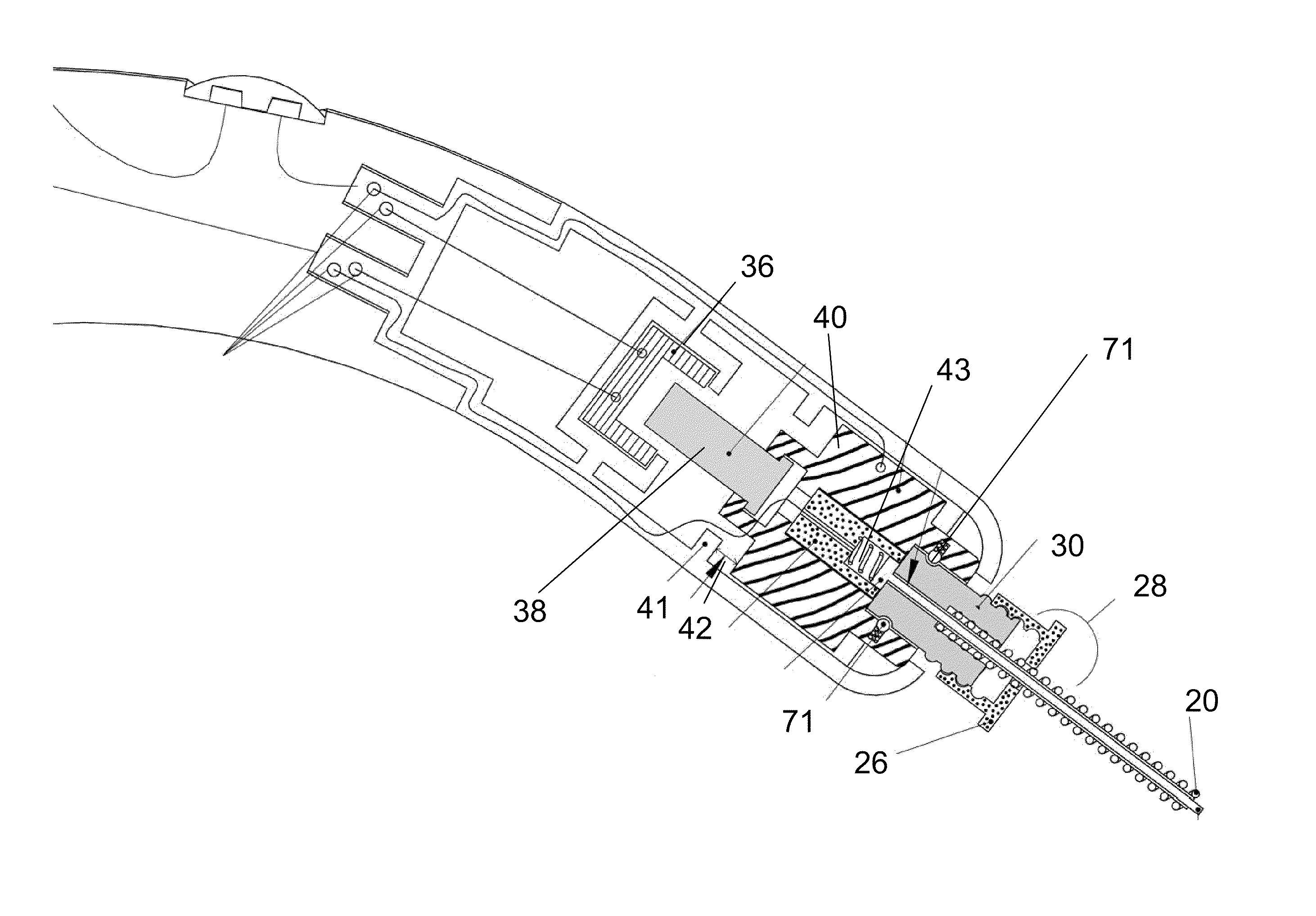

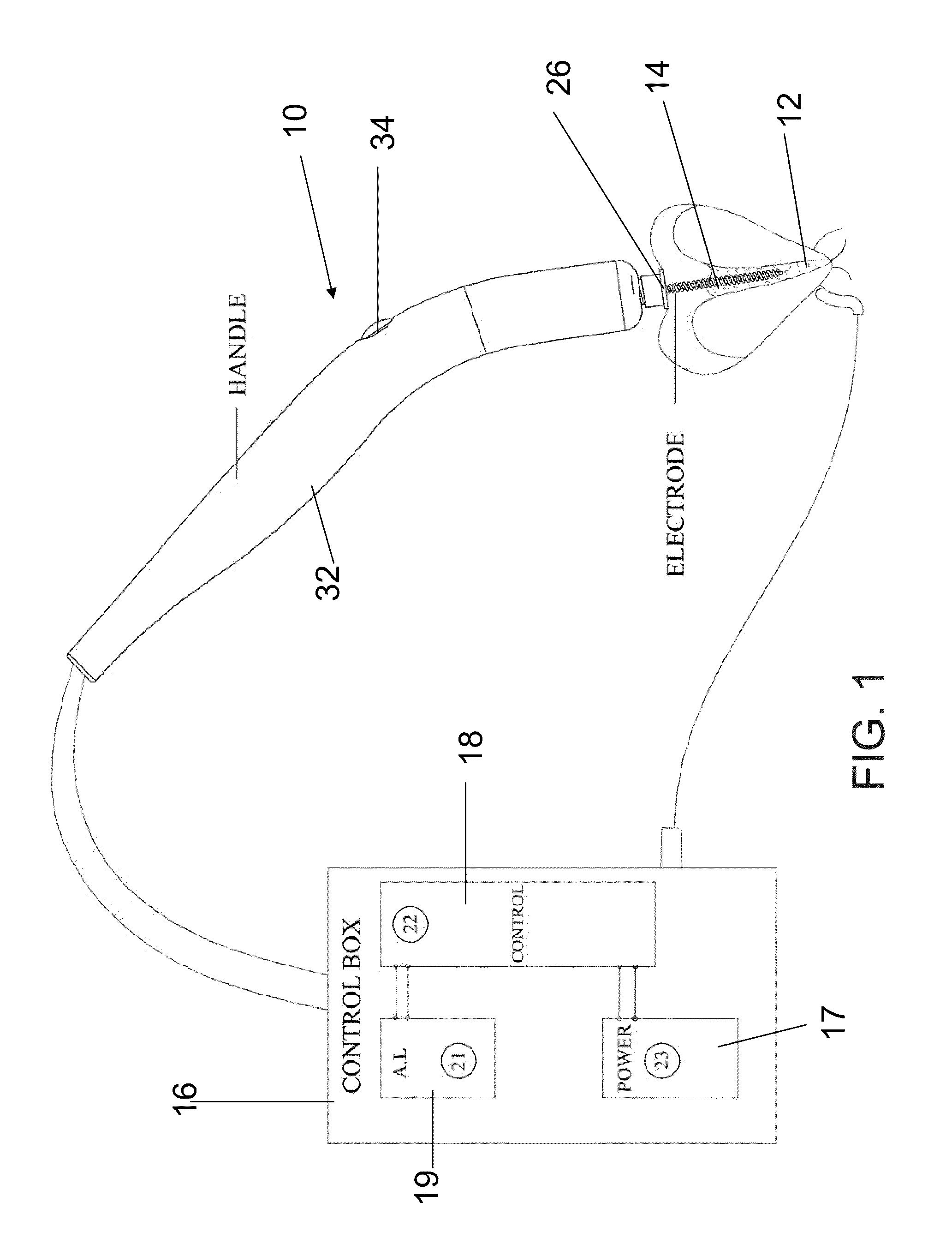

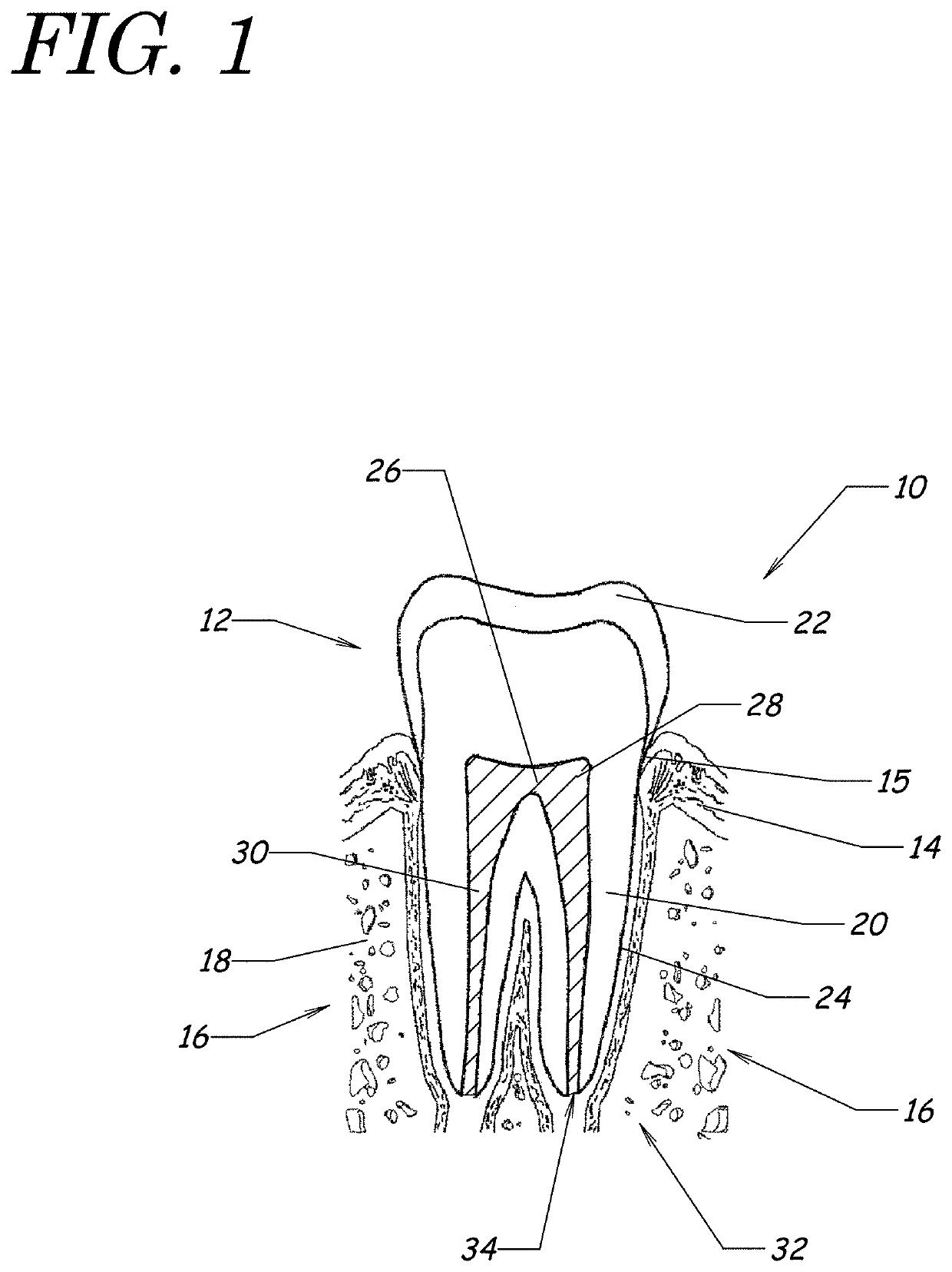

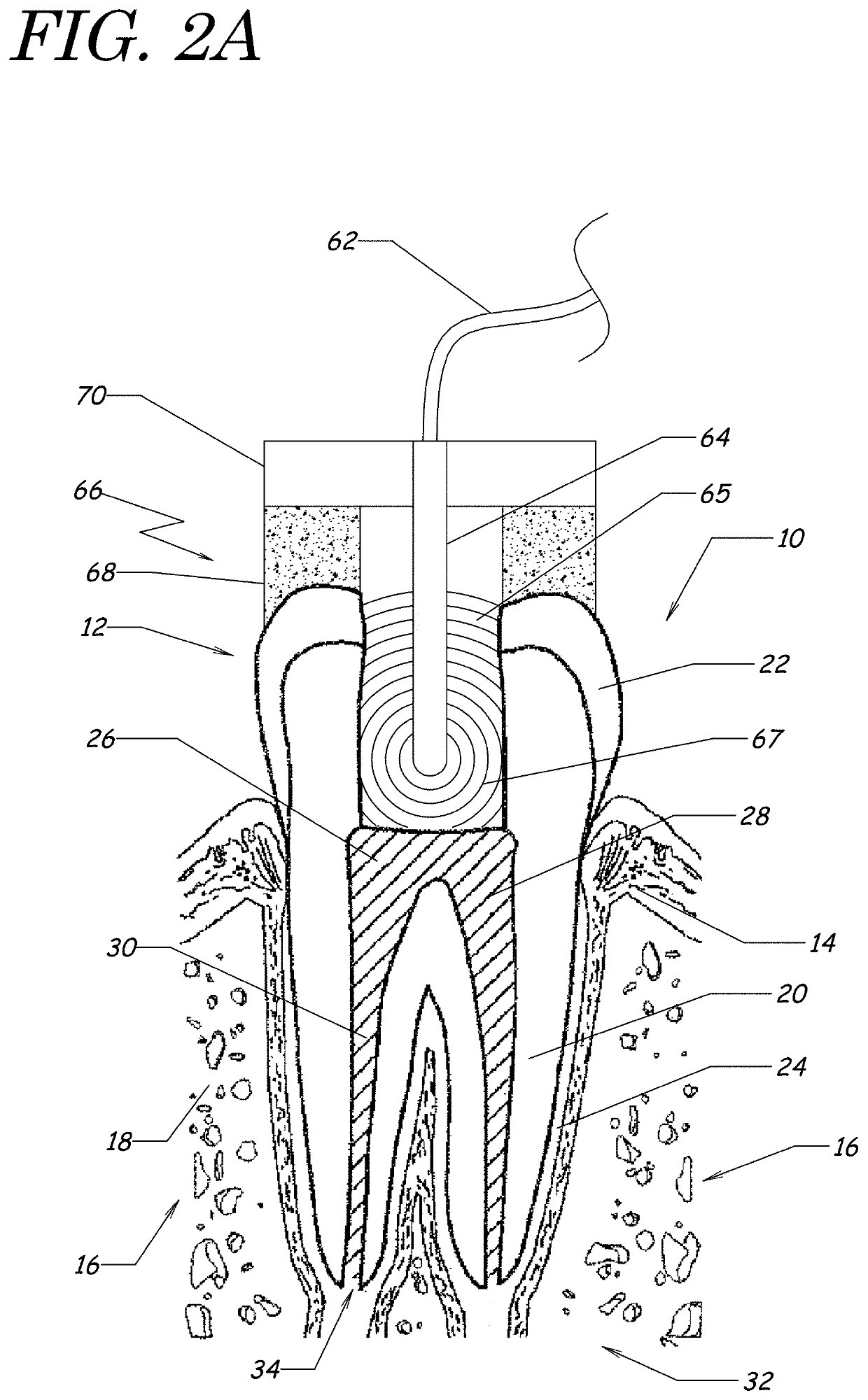

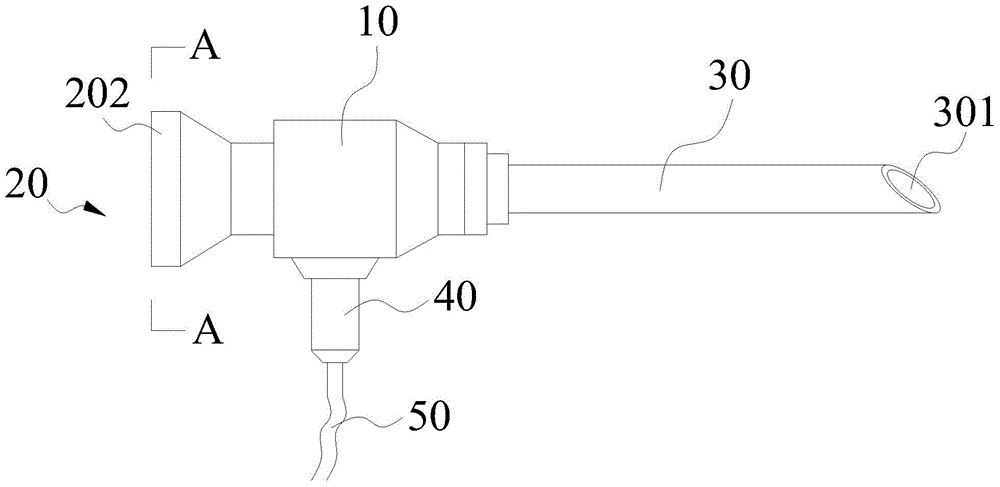

Apparatus, methods, and compositions for endodontic treatments

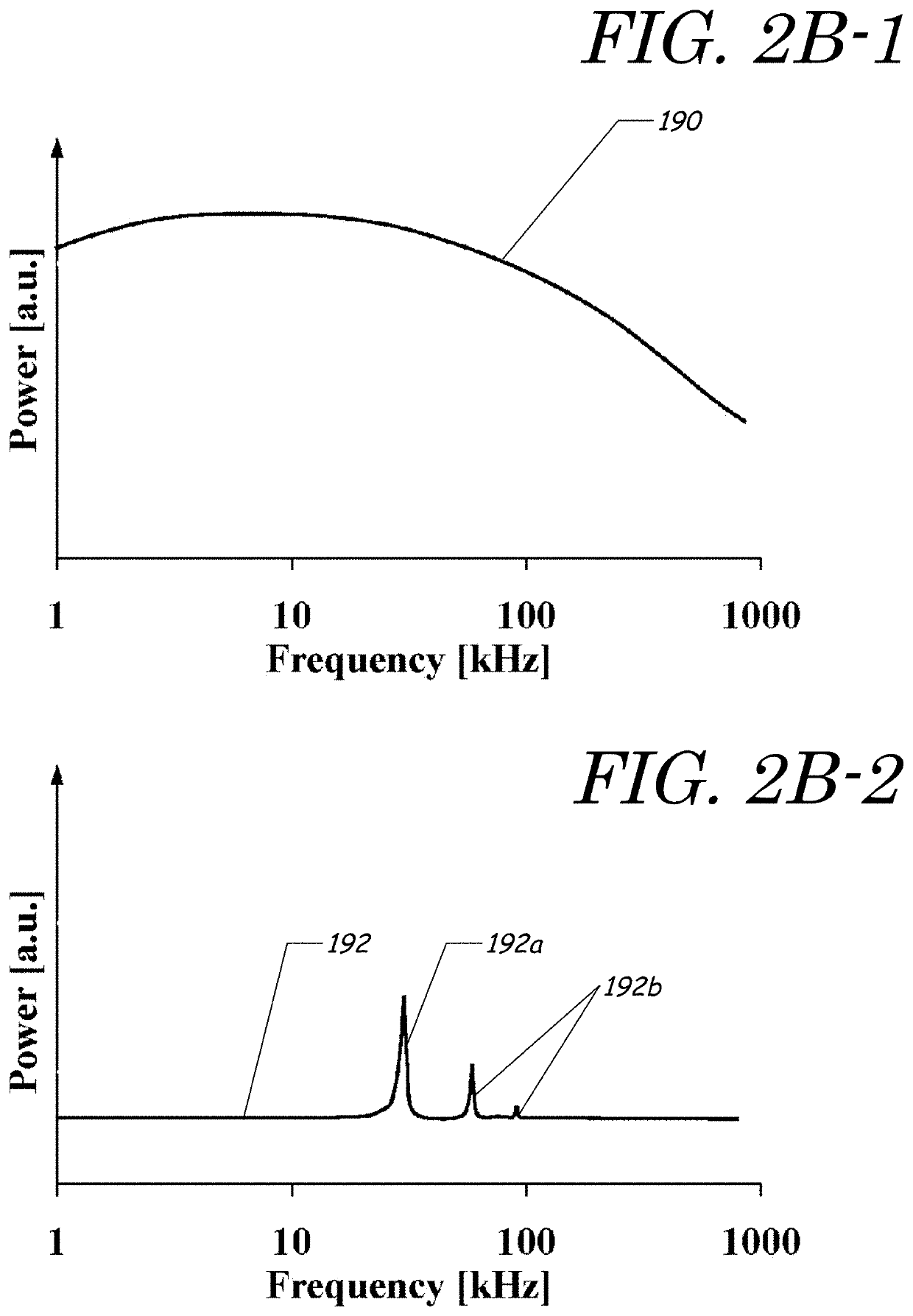

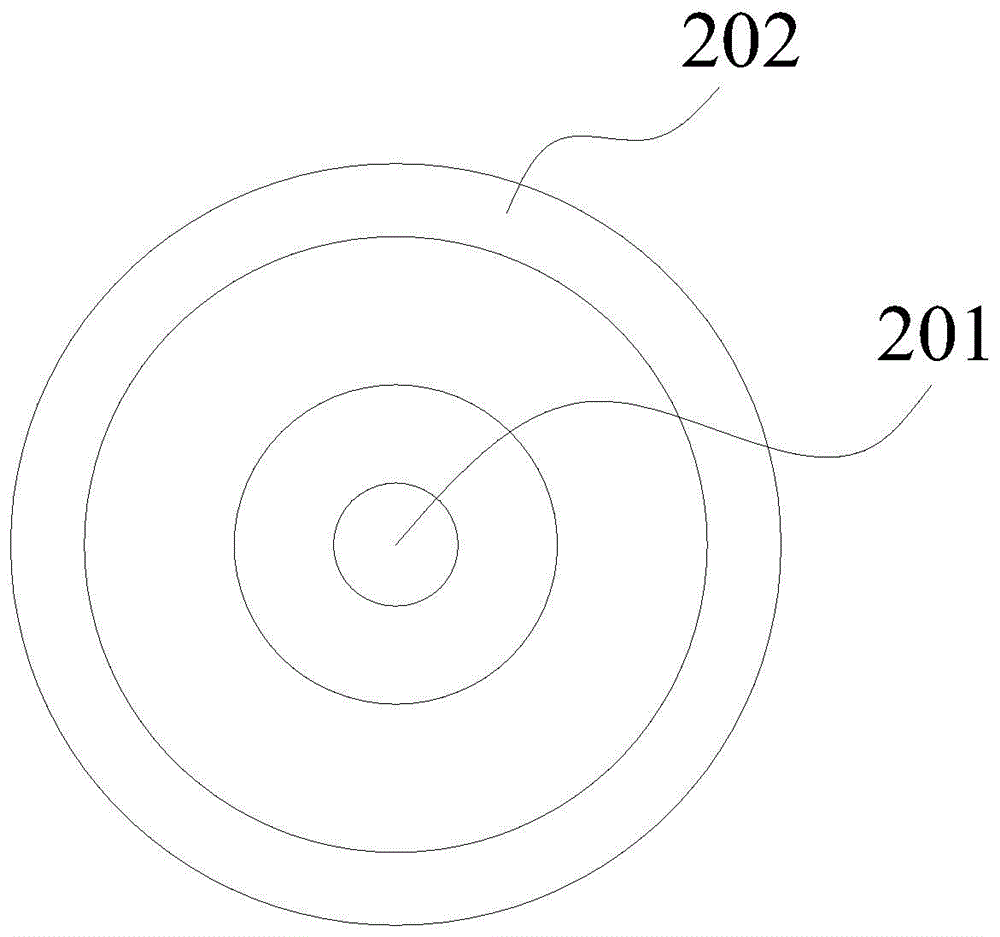

ActiveUS20200038140A1Easy to cleanBonding is loosenedNerve needlesTeeth cappingEndodontic therapyAcoustic wave

Examples of apparatus, methods, and compositions for endodontic treatments are described. The apparatus can include a fluid platform configured to substantially retain fluid in a tooth chamber during treatment. The fluid platform can help maintain fluid circulation in the tooth chamber as fluid flows into and out of the tooth chamber. The apparatus can also include a pressure wave generator configured to generate acoustic waves that can be used for cleaning root canals and tooth surfaces in the tooth chamber. Examples of pressure wave generators include a liquid jet, an electromagnetic energy delivery device, and an ultrasonic device. The fluid can include antiseptic or antibacterial solutions to assist in tooth cleaning. The fluid may be degassed to have a reduced dissolved gas content (compared to non-degassed fluids used in endodontic treatments), which may improve the effectiveness of the pressure wave generation or the cleaning.

Owner:SONENDO

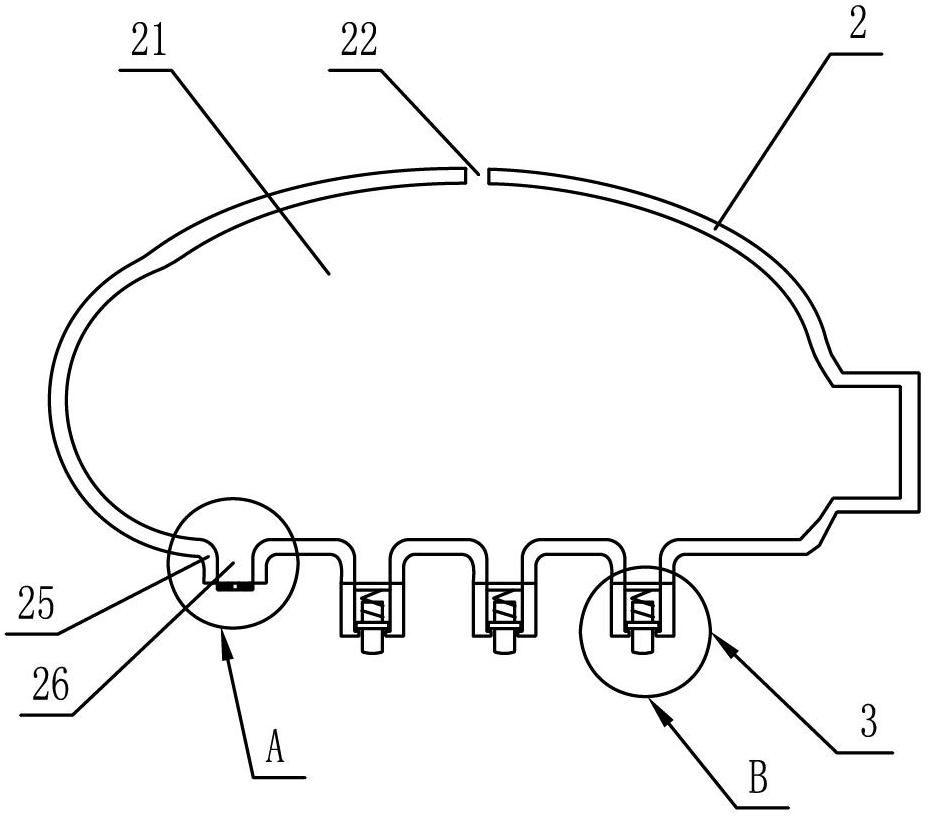

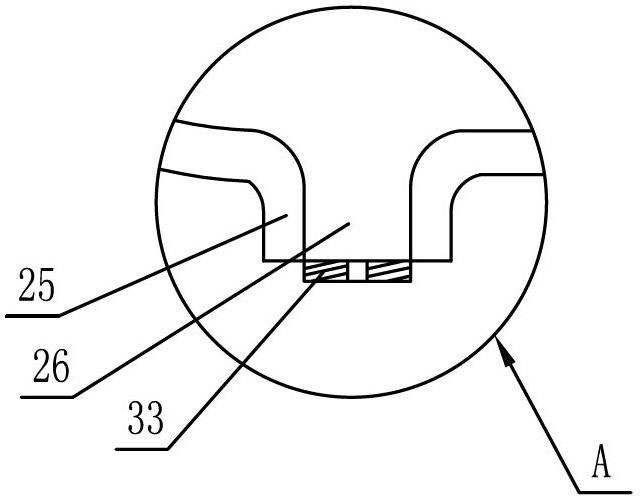

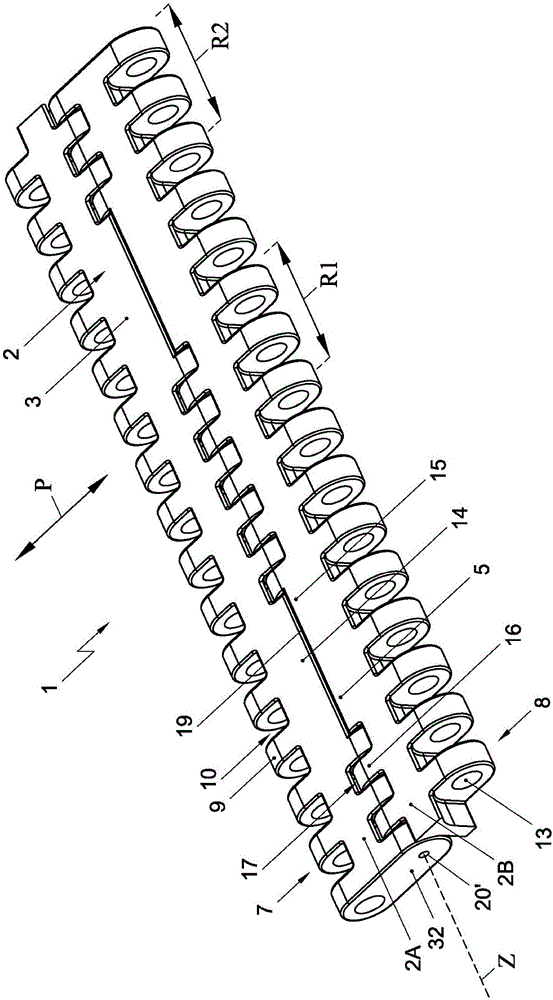

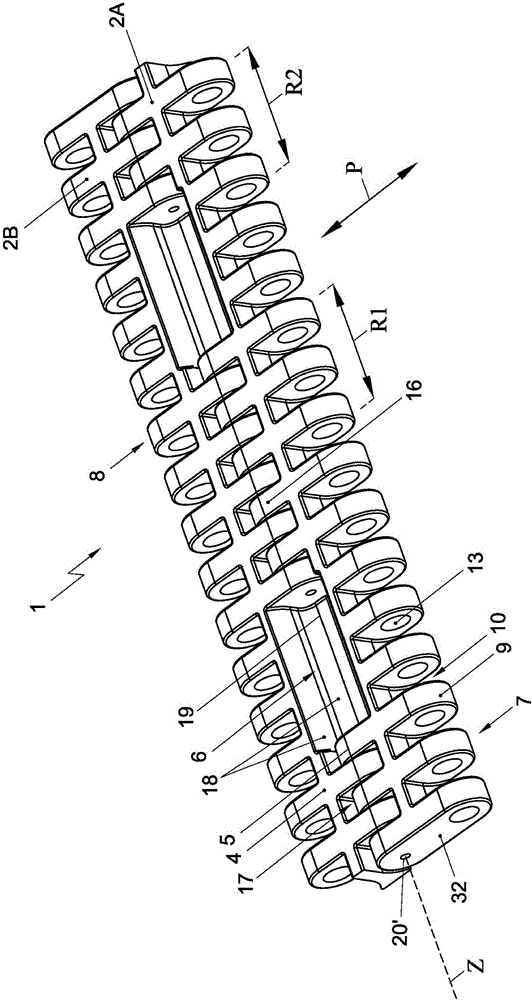

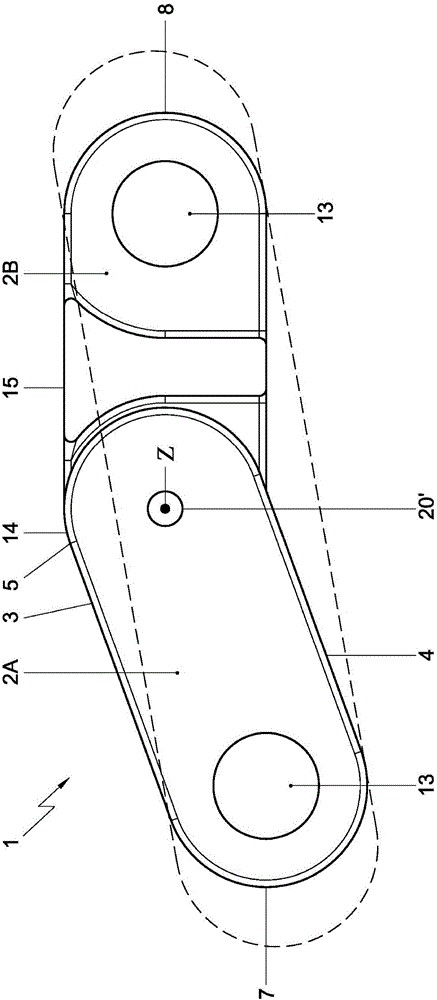

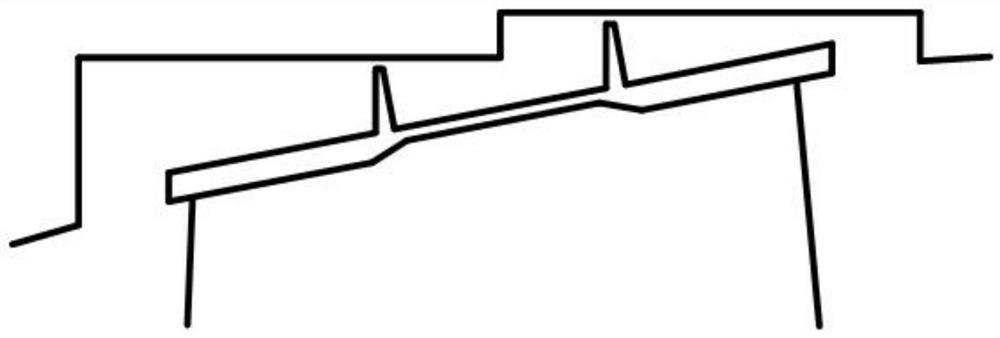

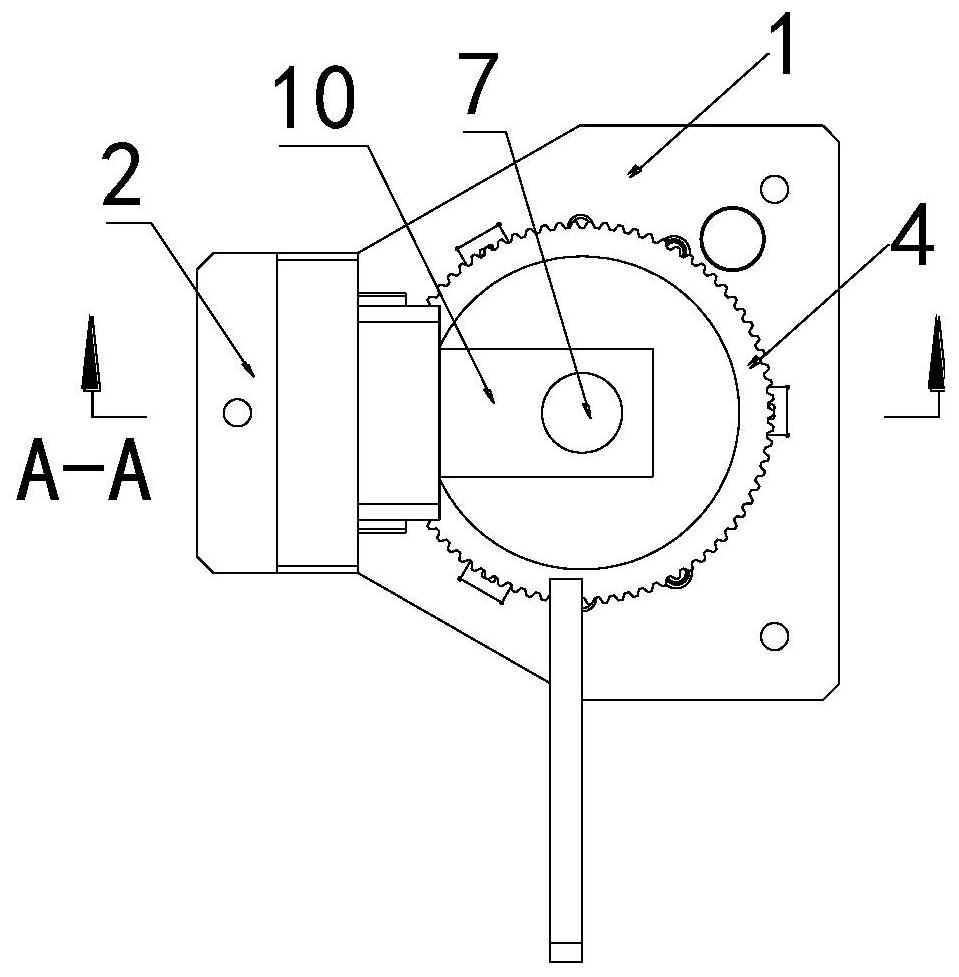

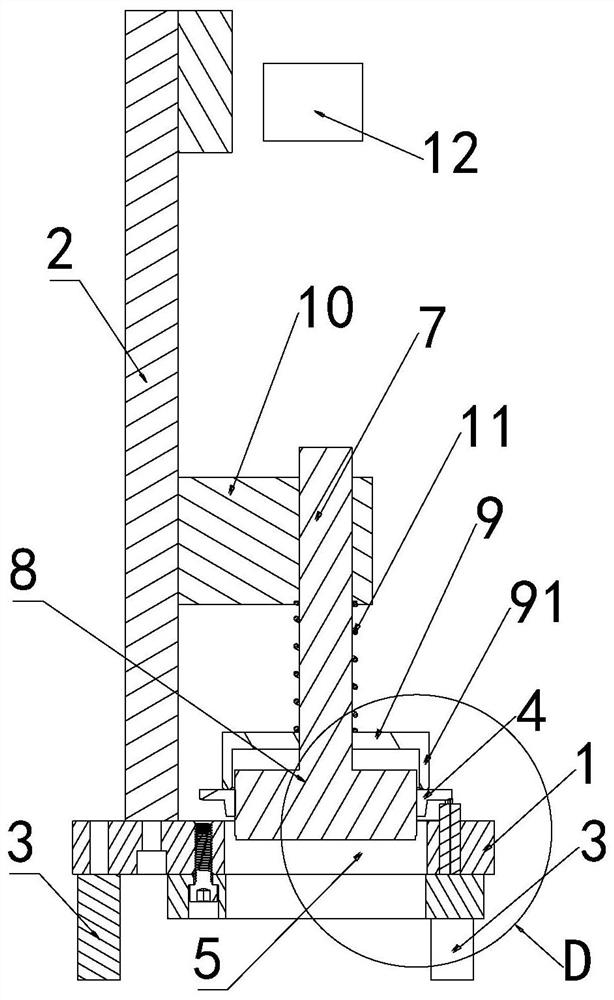

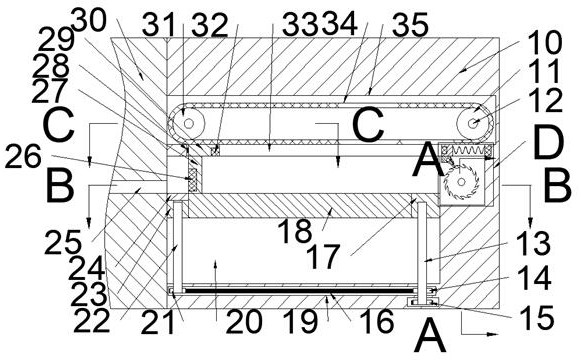

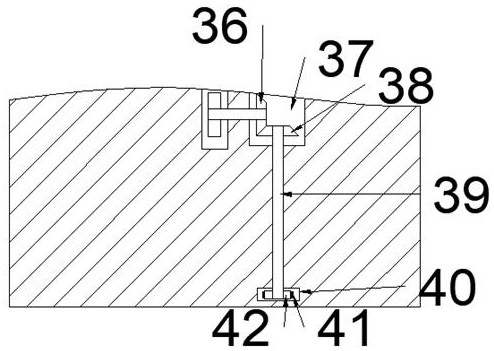

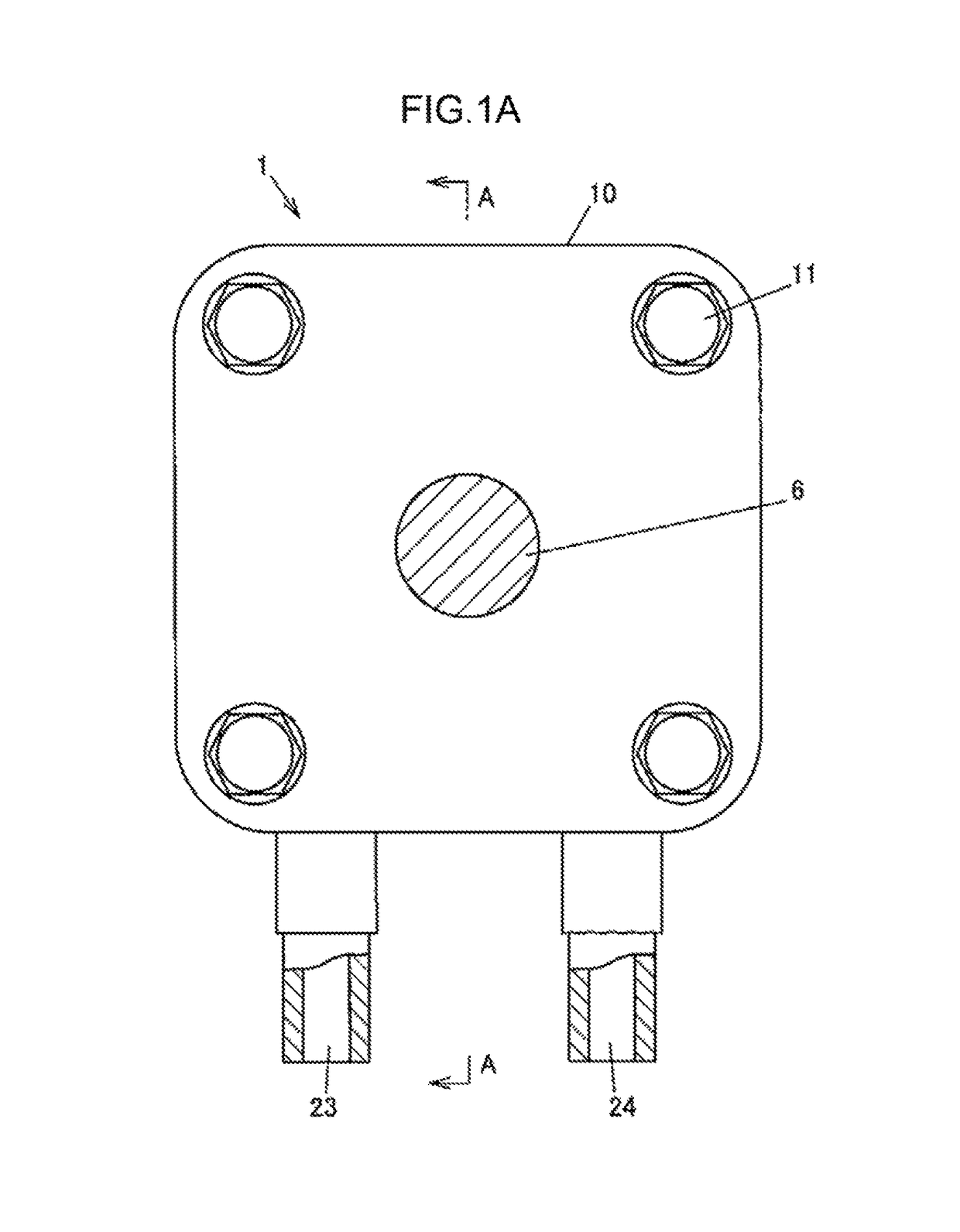

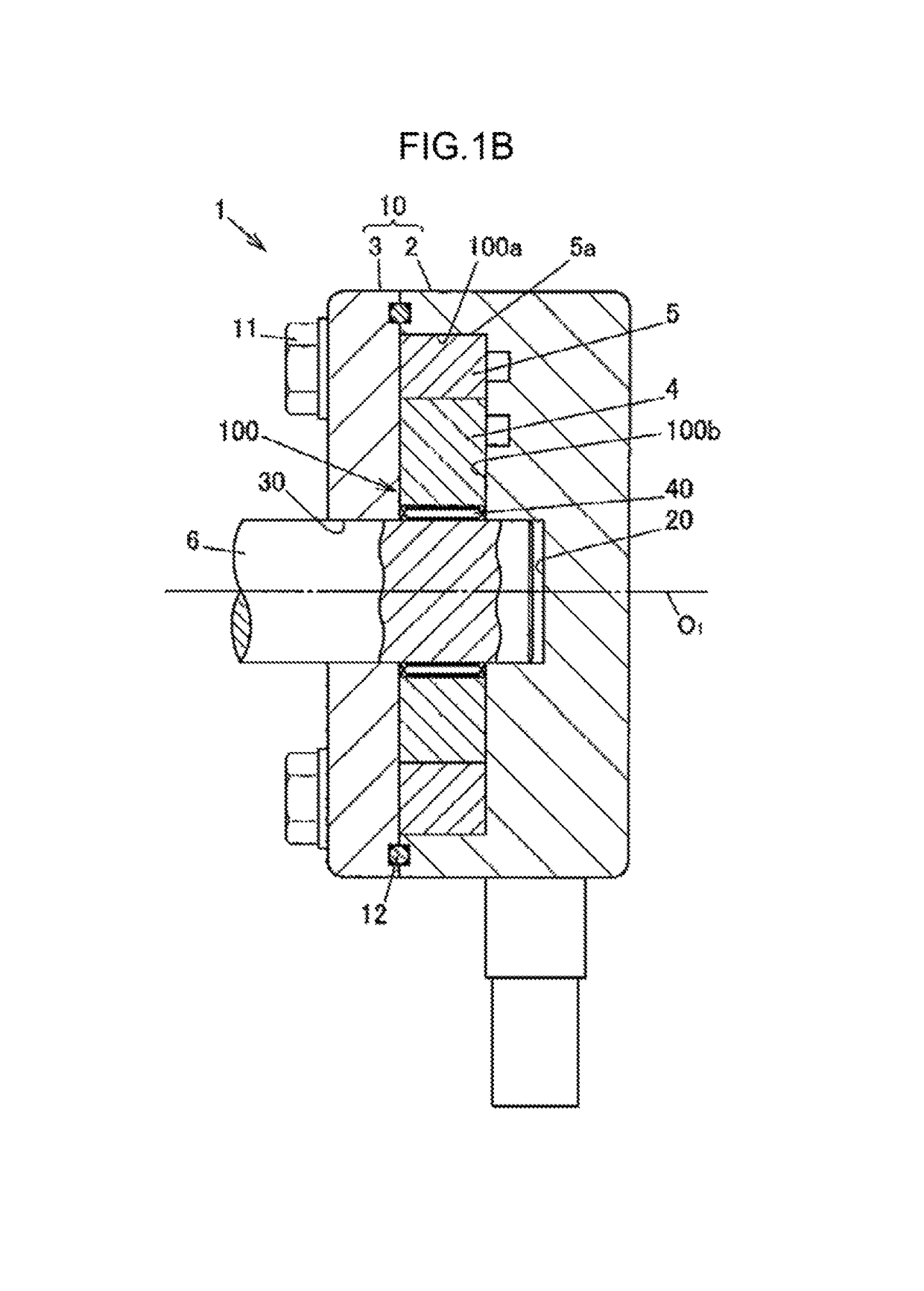

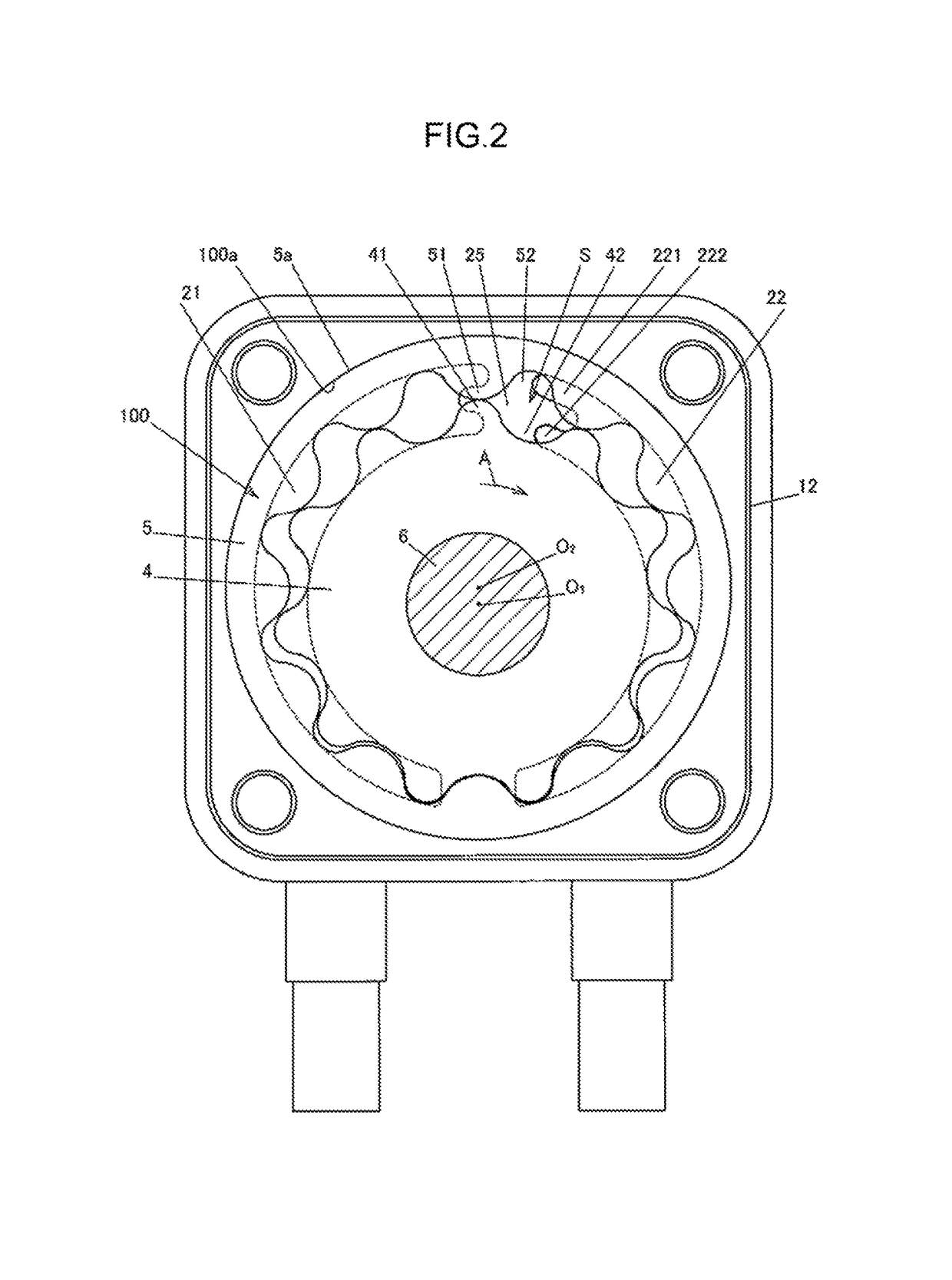

Modular conveyor mat and module therefor, and sprocket wheel and conveyor system

Module (1) for a modular conveyor mat, comprising a body part (2) extending transversely to a conveying direction with a top (3) and a bottom (4), which bottom is provided with a tooth chamber (6) for receiving a driving tooth of a sprocket wheel. The body part, at a front (7) and rear (8), is provided with a series of hinge parts (9) and receiving spaces (10) alternately successive transversely to the conveying direction, so that successive modules (1) are hingedly couplable using hinge pins (11) extending through hinge bores (13) provided in the hinge parts. The front is part of a front body part (2A) of the module and the rear is part of a rear body part (2B) of the module. The front and rear body parts are hingedly connected with each other relative to a pivoting axis (Z), which traverses the tooth chamber (6).

Owner:REXNORD FLATTOP EURO SRL

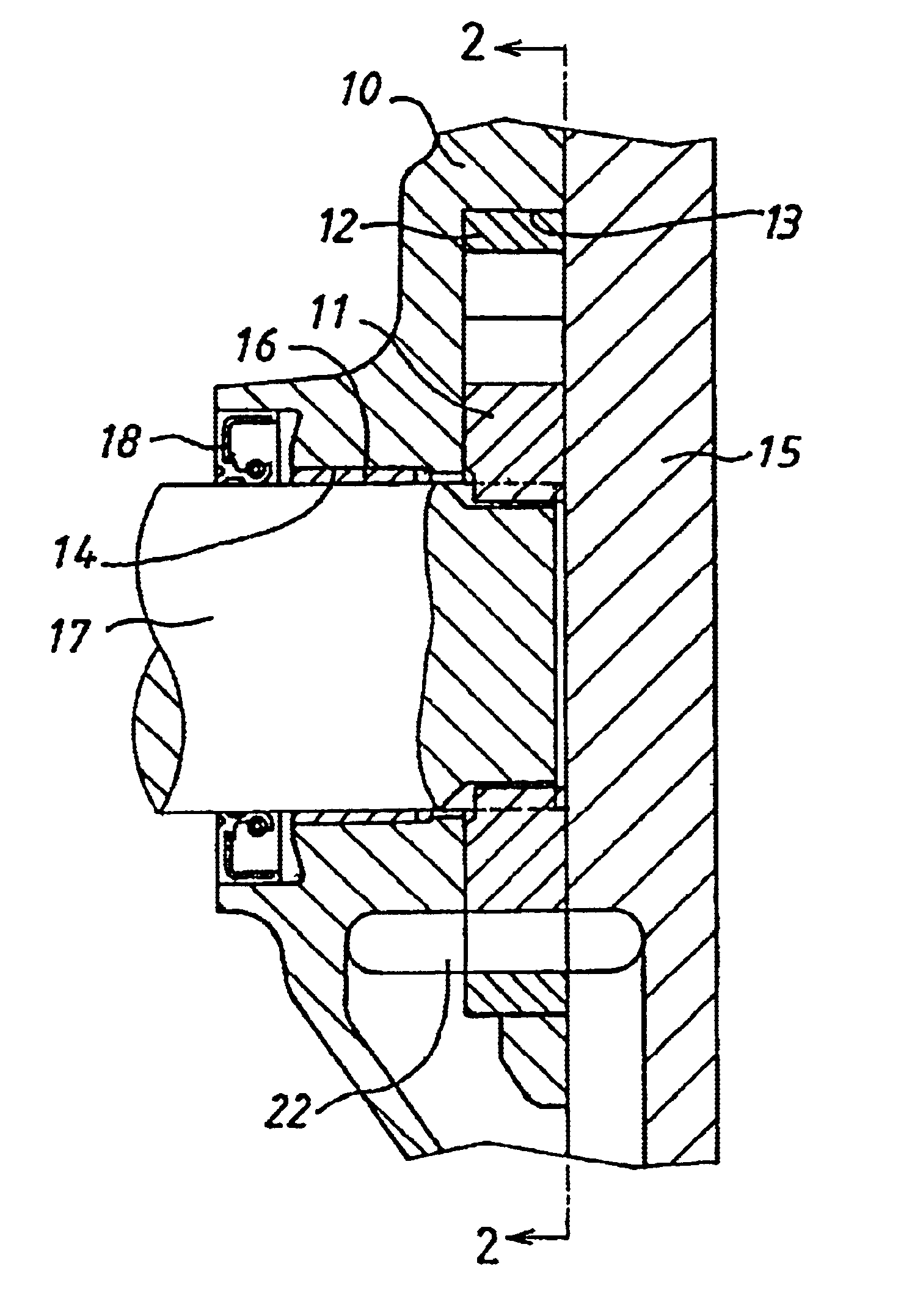

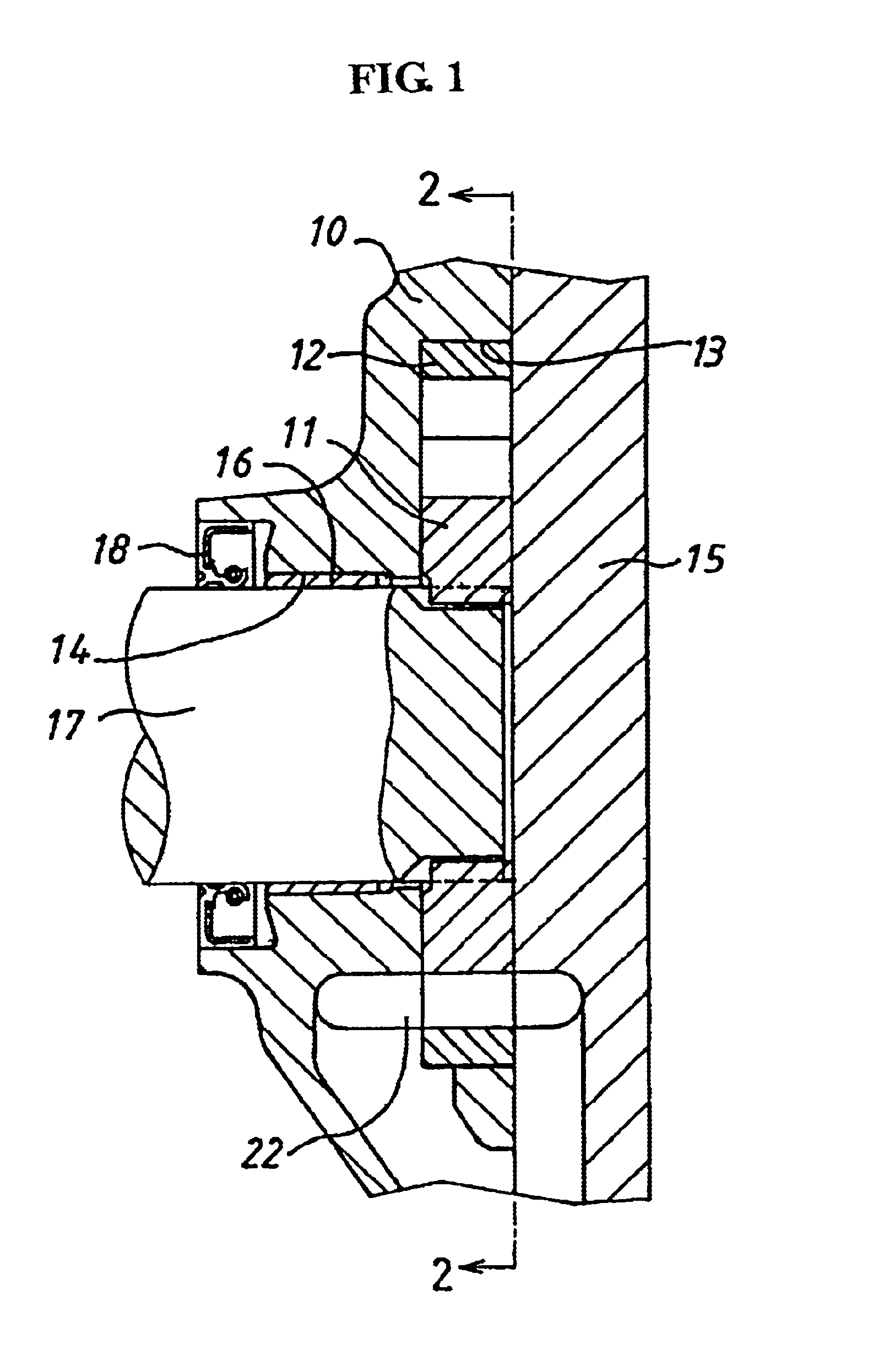

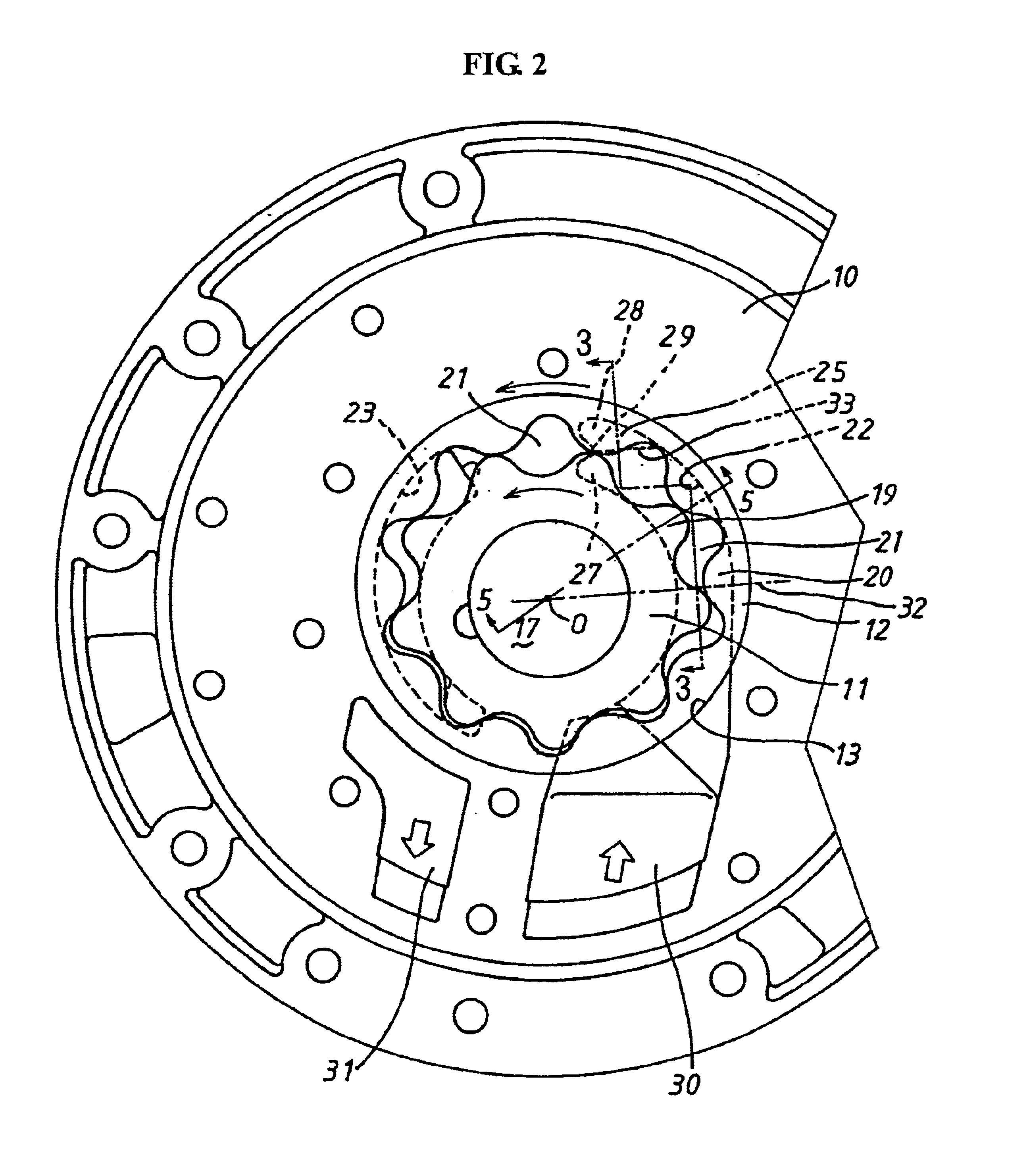

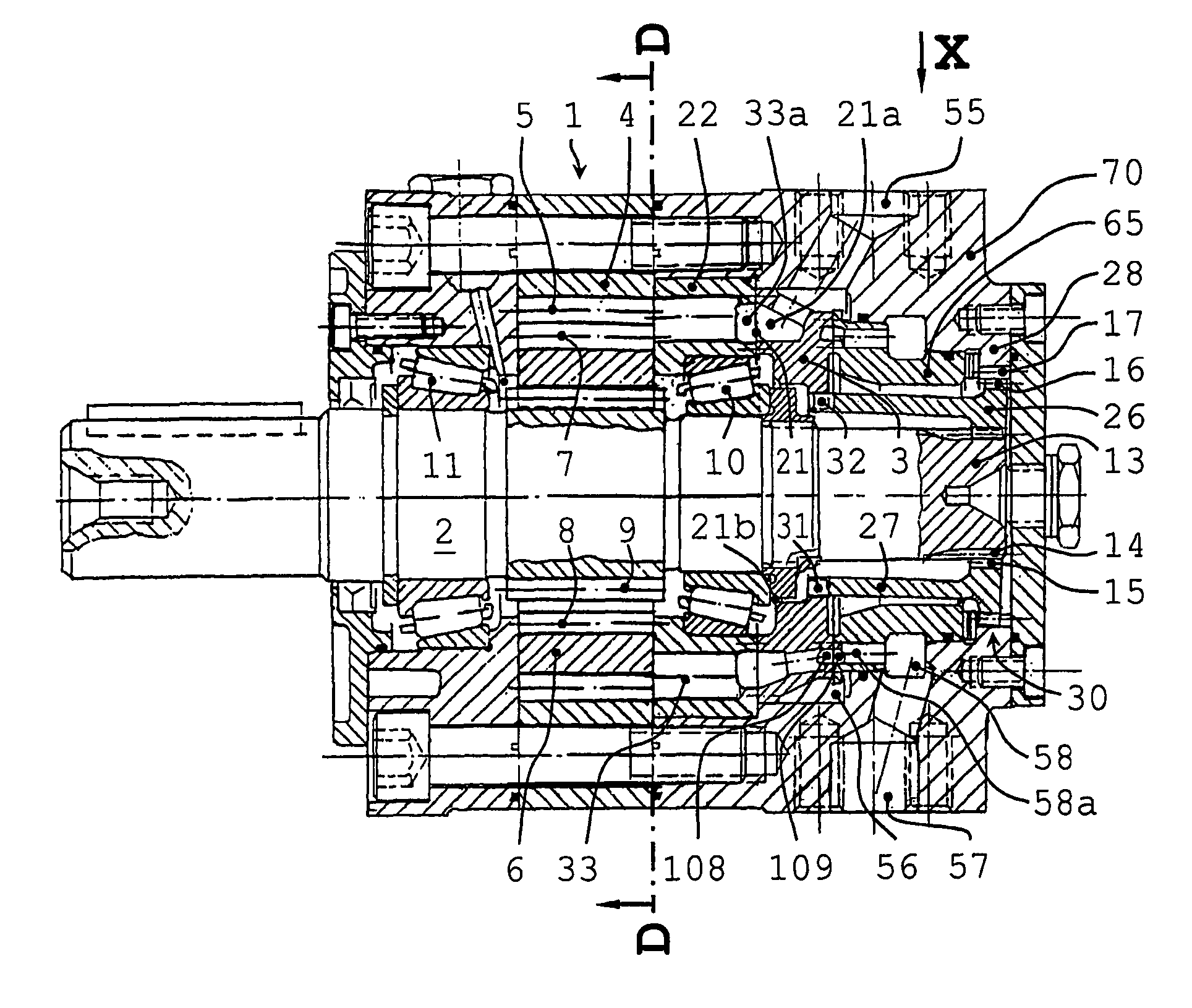

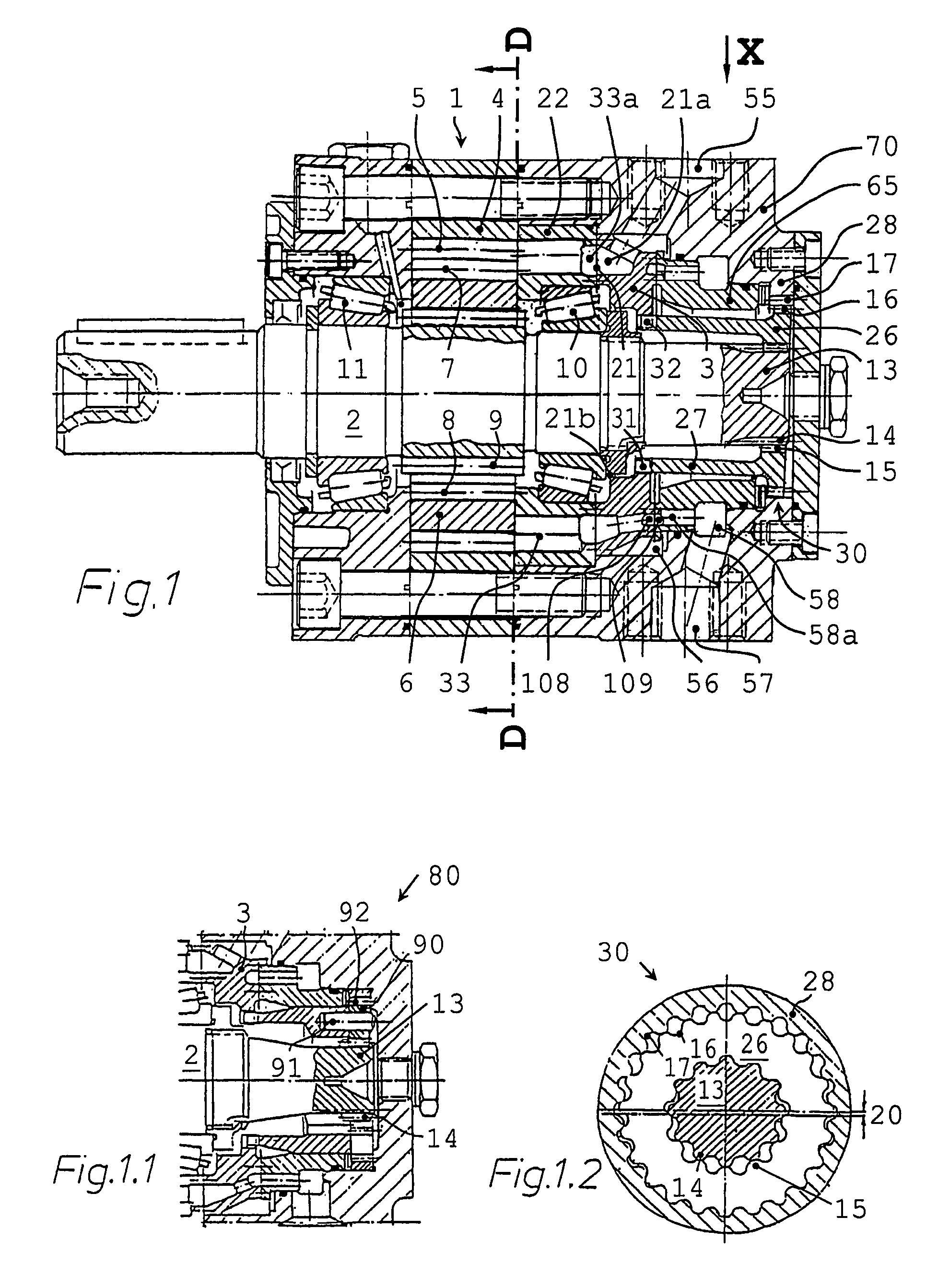

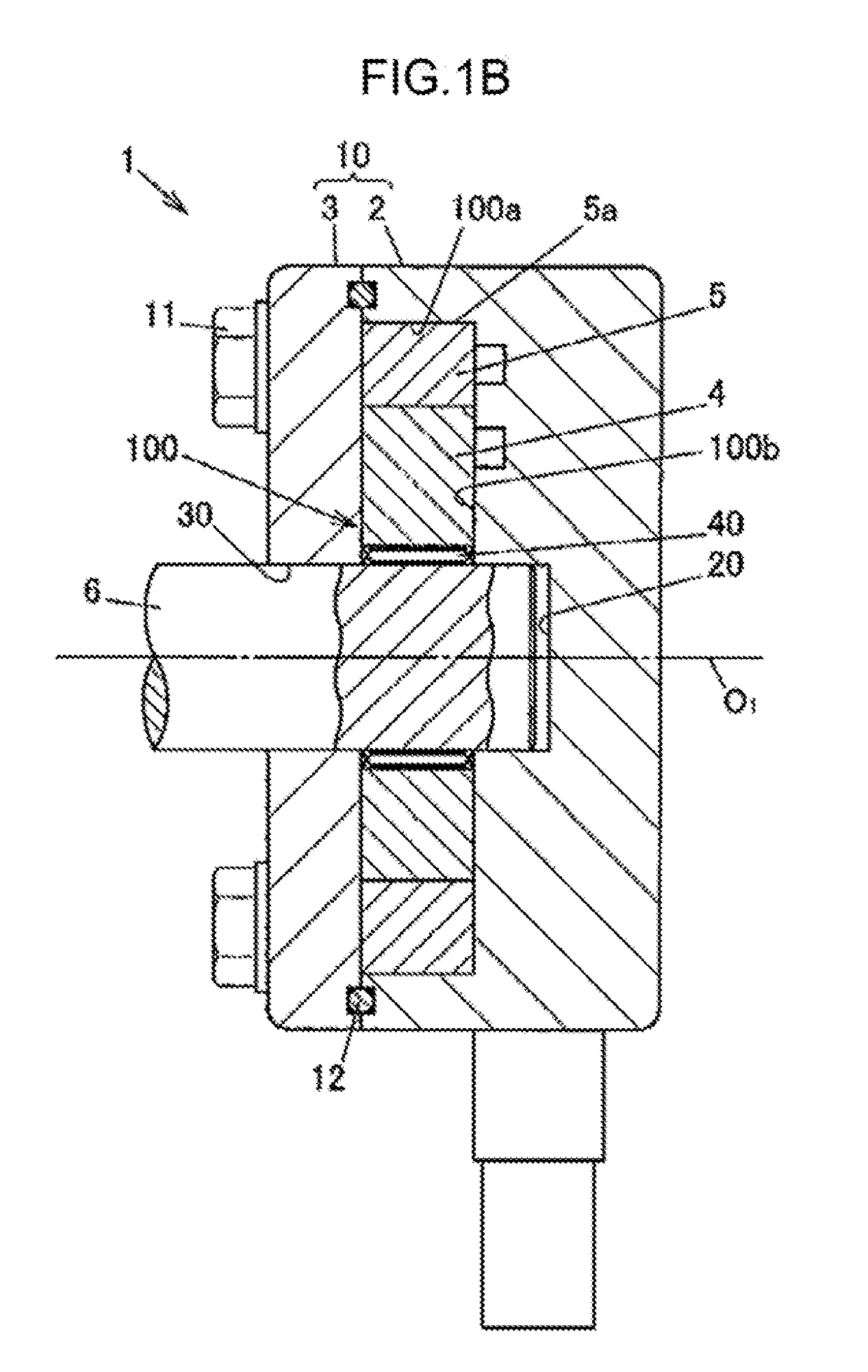

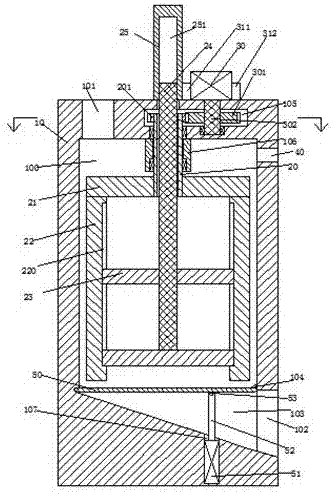

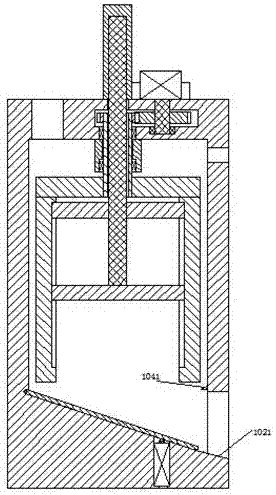

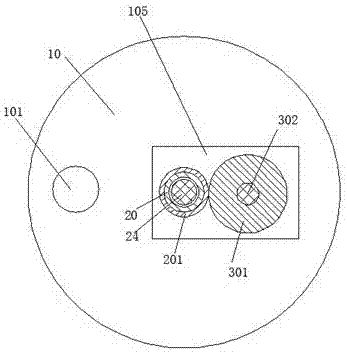

Hydrostatic rotary cylinder engine

InactiveUS7832996B2Eliminate deficienciesIncrease frictionEngine of arcuate-engagement typeOscillating piston enginesWorking fluidRotary valve

The invention relates to a hydrostatic, slow-speed rotary cylinder engine comprising a power part (1) which acts as an output, said power part comprising a central, stationary stator (4), a rotary cylinder (6) which is used as a rotor and a shaft (2) which is mounted in a central manner on both sides of the roller bearings (10, 11) which are arranged directly adjacent to the power part (1). Supply and discharge of tooth chambers comprising the working fluid is controlled by means of a disk-shaped rotational valve (3) which is mounted in a continuously centered manner in relation to the shaft (2) and the stator (4). A toothed wheel drive is arranged between a shaft external toothing (14) and an internal toothing (17) of a stationary internal toothed ring (28; 92) as a synchronous drive for the rotational valve (3). The toothed wheel drive is subsequently arranged in the leakage oil region of the engine and is formed by a planetary gear (80) or, preferably, by an eccentric gear (30).

Owner:WILLIBALD ARTUR

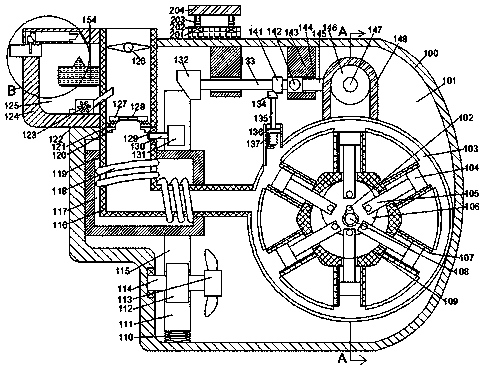

Environment-friendly engine

InactiveCN109057960AEnsure safetyExtended service lifeFloat-controlled apparatusMachines/enginesCircular discSprocket

The invention discloses an environment-friendly engine, comprising an engine body and a first cavity arranged in the engine body. A circular cylinder is fixedly connected with the inner wall of the right end of the first cavity. Piston cavities distributed equally are circumferentially arranged in the circular cylinder. Pistons are connected with the piston cavities in a sliding fit mode. Piston push rods are fixedly connected with the proximal ends of the circle centers of the pistons. An internal tooth chamber located at the circle center is arranged in the circular cylinder. An output shaftextending back and forth is connected with the internal tooth chamber in a rotating fit mode. A first chain wheel located at the rear end of the circular cylinder is arranged on the output shaft. A disc is sleeved on the output shaft. A first fixing pin located at the circle center is fixedly connected with the disc. A hinge is arranged between the first fixing pin and the output shaft for connection. The environment-friendly engine is high in linkage, and an optimal oil-gas ratio is achieved by driving a valve to open and close through the output shaft, and the occupied area is reduced by the arrangement mode of the annular cylinder.

Owner:宁波鄞州康圣机械科技有限公司

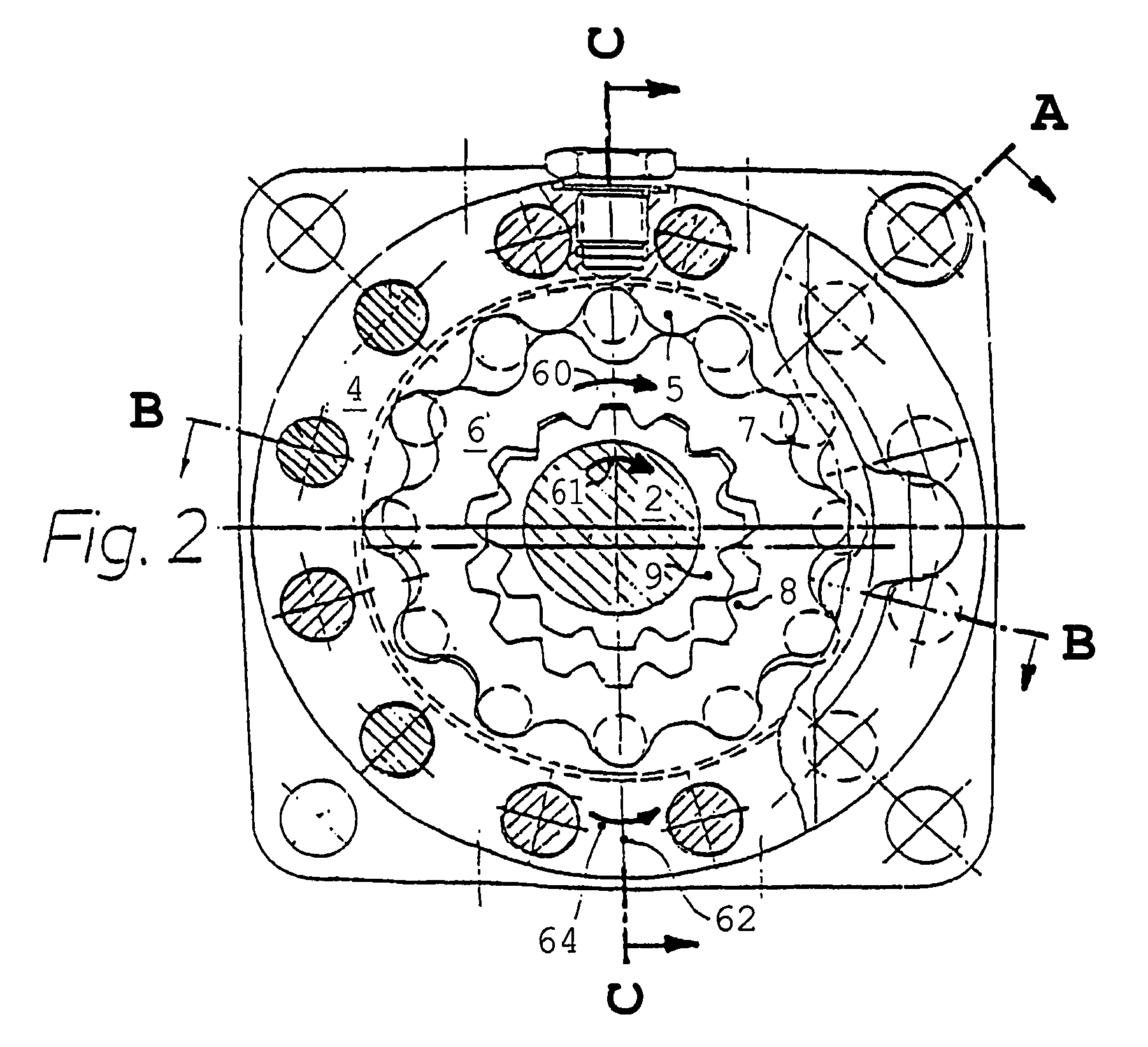

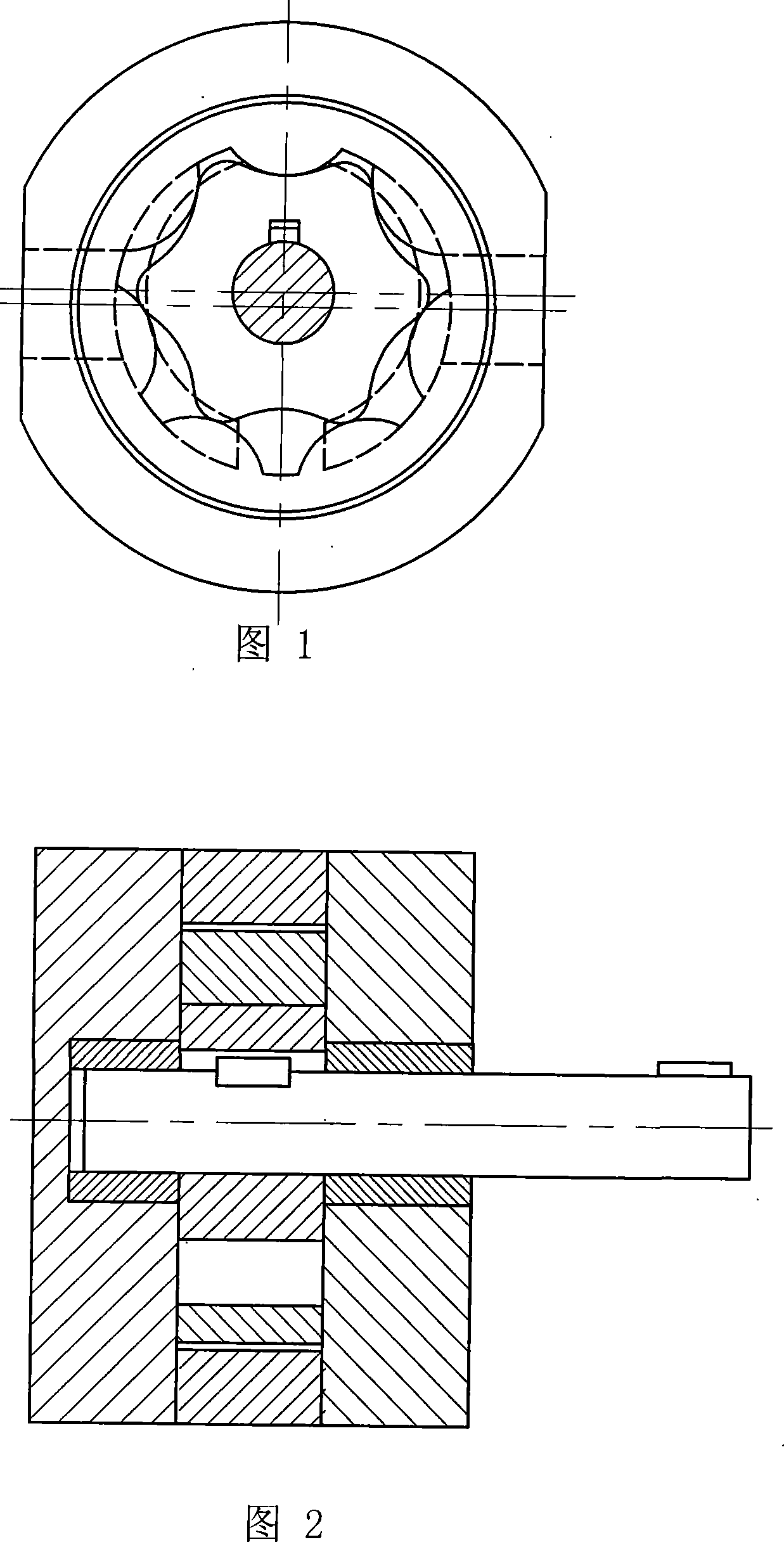

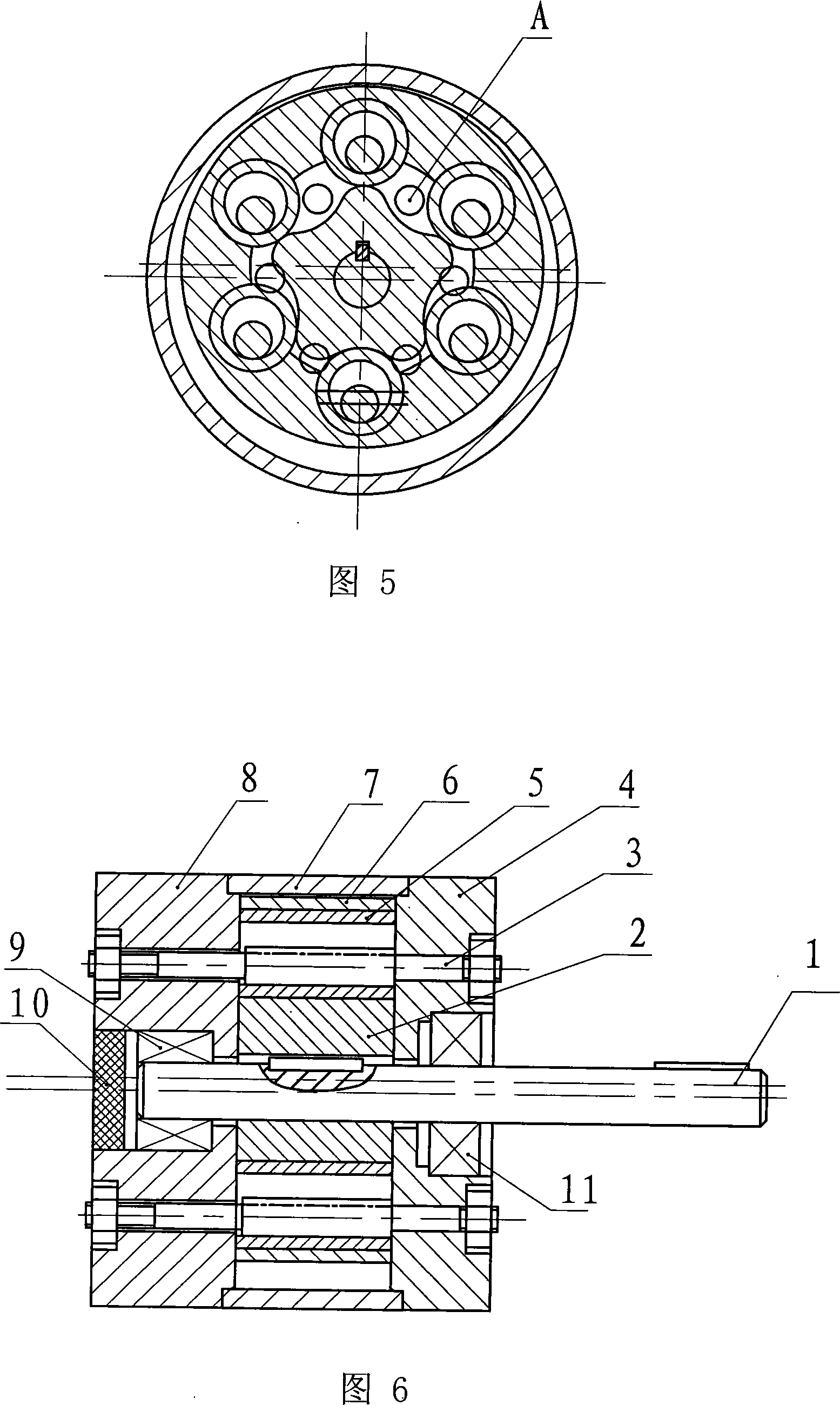

Pin-hole type cycloid rotor pump

InactiveCN101139988ALittle flow fluctuationSmall pressure fluctuationsRotary piston pumpsRotary piston liquid enginesHydraulic pumpEngineering

The invention is a rotor pump structure. A hole-pin type cycloidal rotor pump comprises a pump body, two pump covers respectively in the front and rear of the pump body, and a rotary shaft in the pump body center and through the pump covers; the rotary shaft is fixed to connect with an internal rotor, and an internal rotor is sleeved with a needle wheel; the internal rotor is a short-web external cycloidal gear; the center of the translational disk is a chamber, and around the cavity, at least three sleeves are embedded to form the needle wheel; the pump covers are positioned with dowel pins in the same fixing and connecting quantity of the sleeve, and with the same arrangement position as where the sleeves are embedded on the translational disk; the dowel pins are plugged into the corresponding sleeves; outside diameter of the dowel pin is smaller than inside diameter of the sleeves; the short-web outside cycloidal gears on the internal rotor, the chamber inner-wall in the center of the needle wheel, and sleeves can form a plurality of tooth chambers; and meanwhile, oil inlet and outlet ports are opened. The invention provides a rotor pump structure that can reduce flow rate fluctuation and pressure fluctuation, increase oil pressure, improve hydraulic pump stability, improve and increase comprehensive performances of hydraulic pumps.

Owner:SHANGHAI NORMAL UNIVERSITY

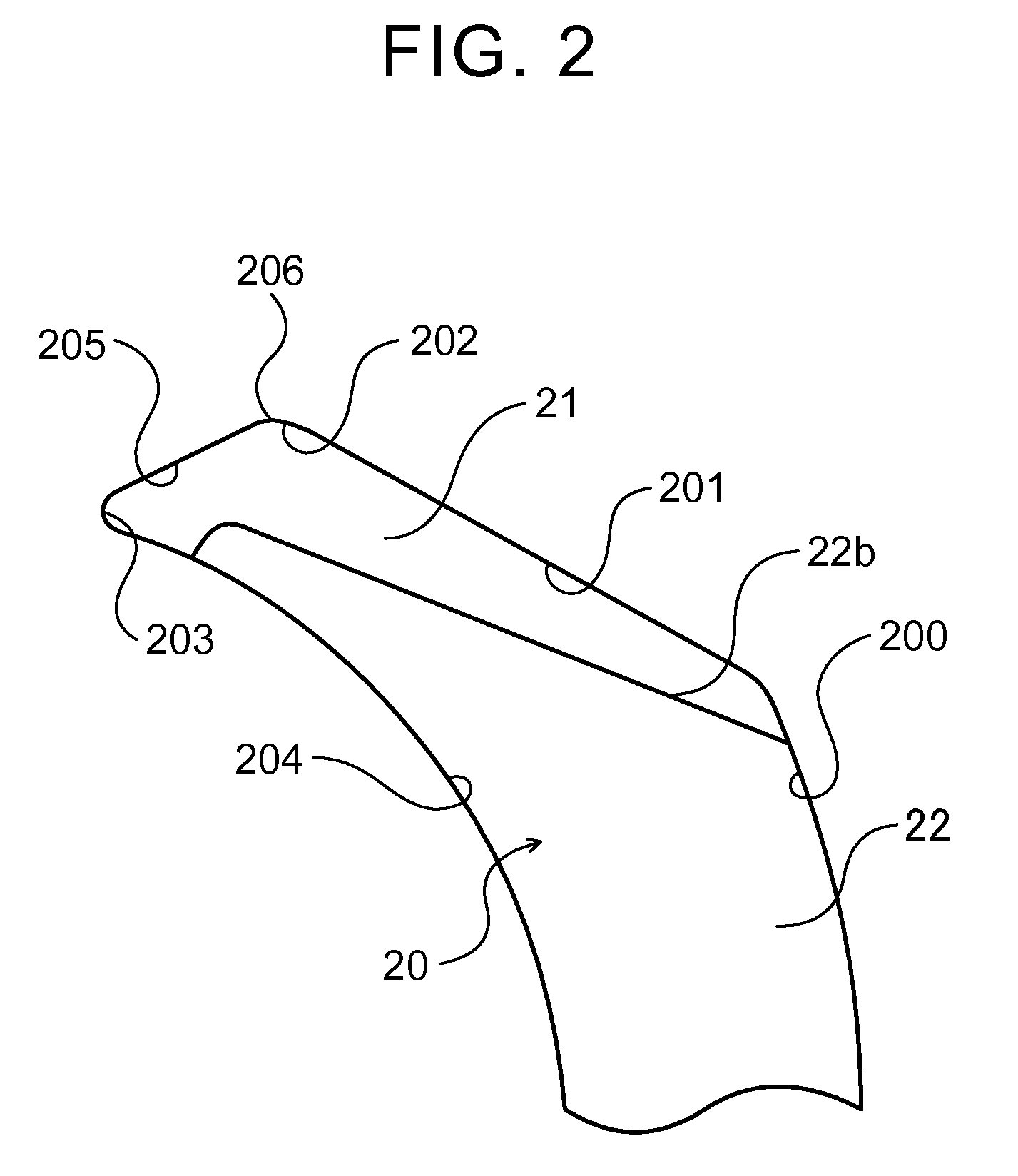

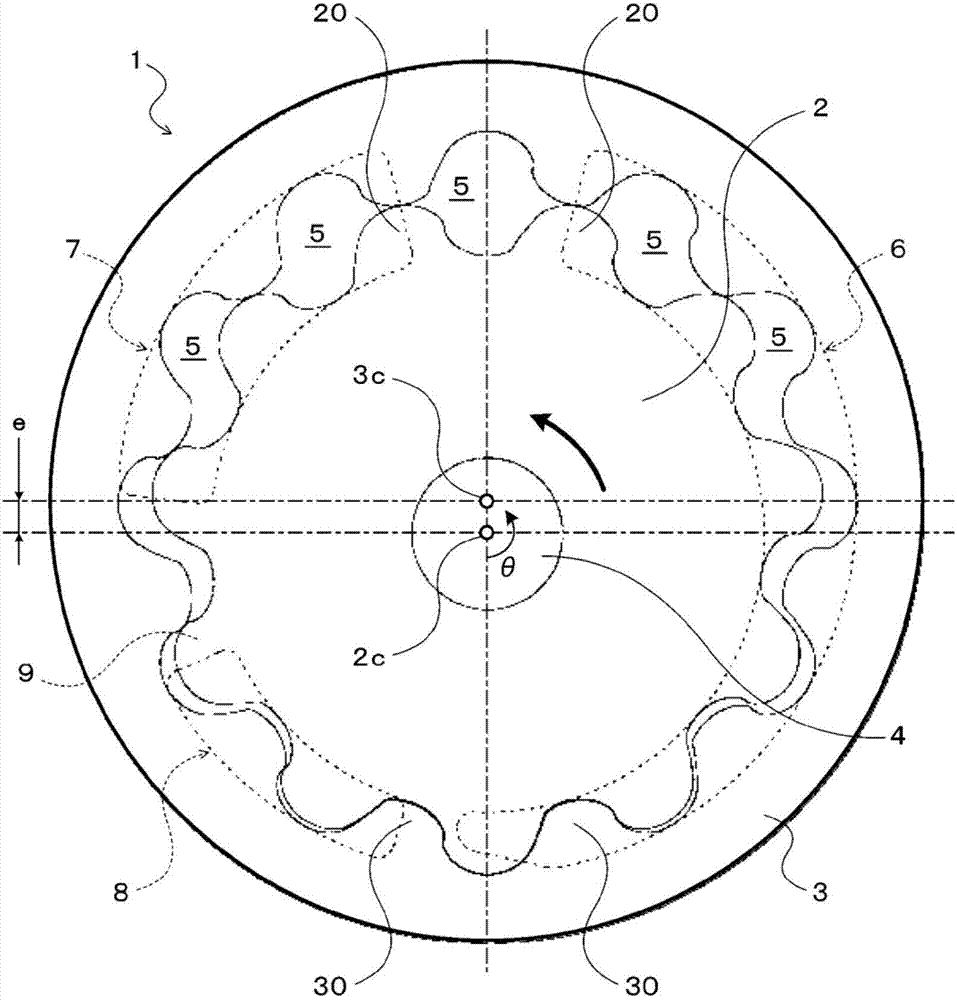

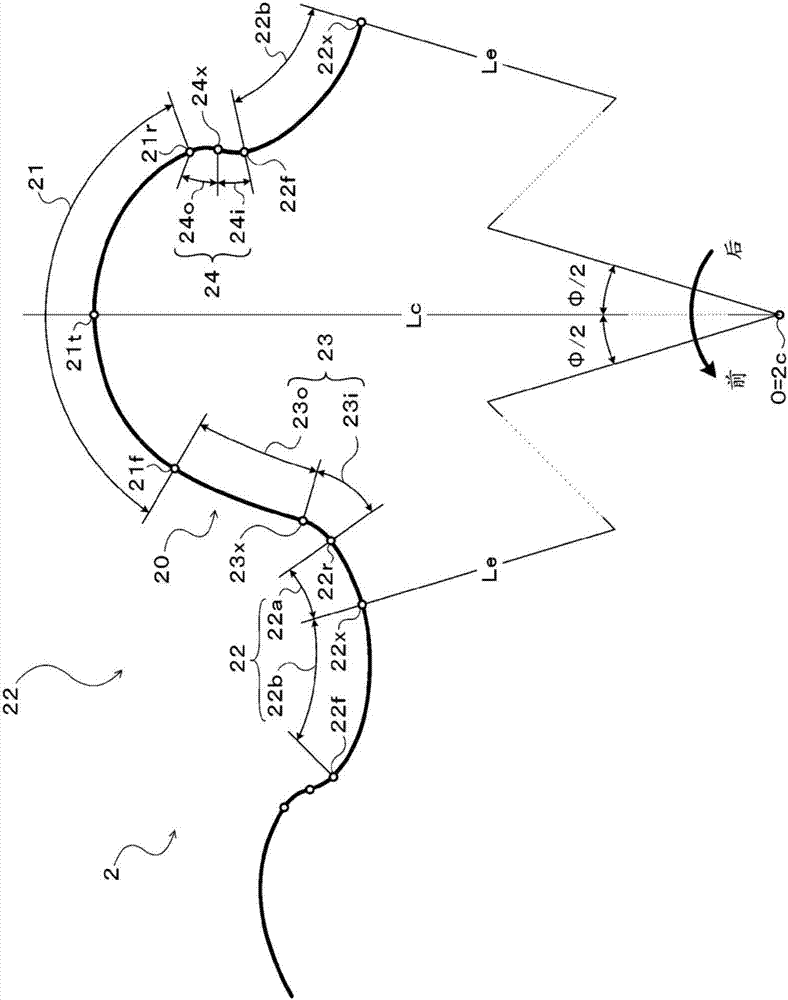

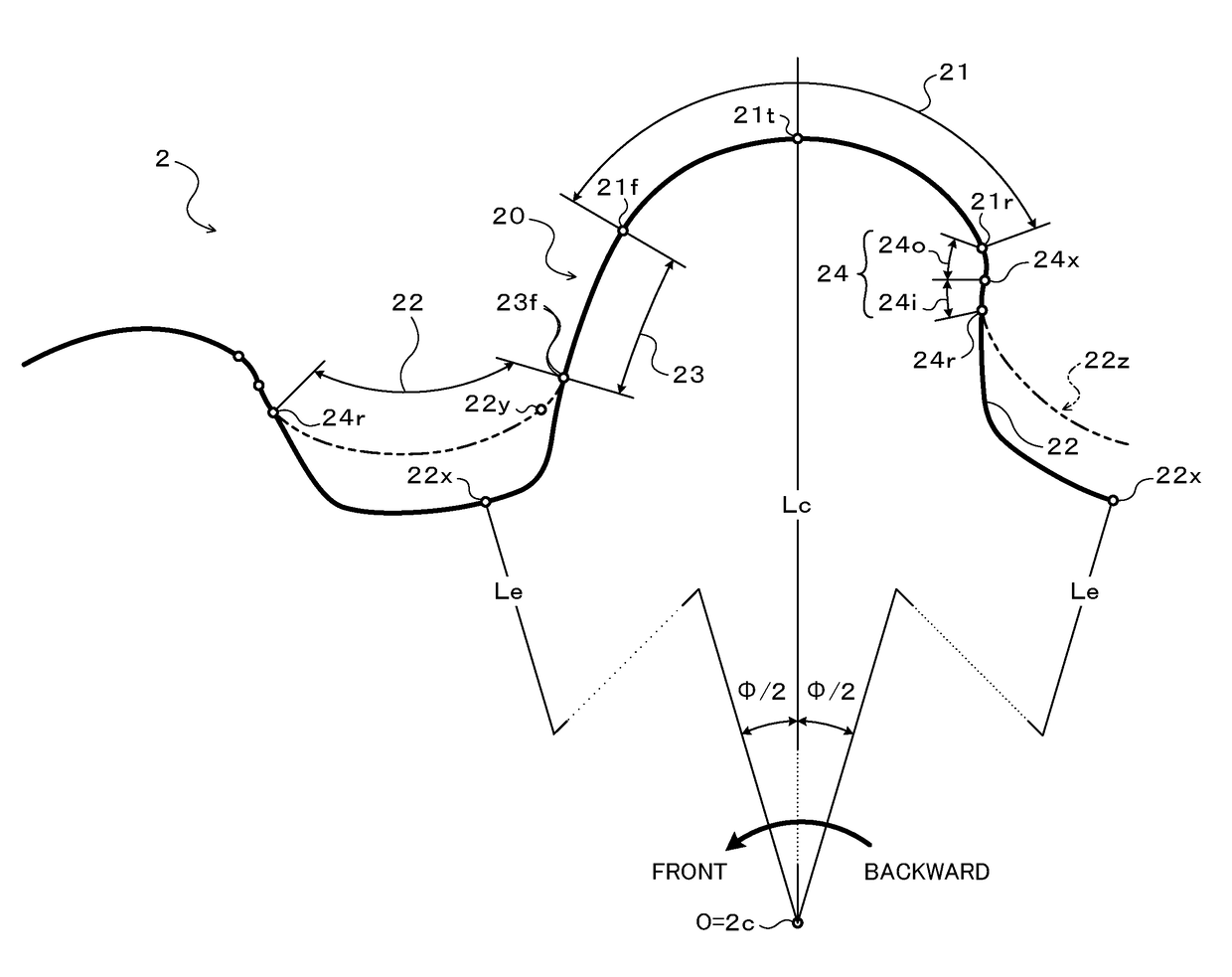

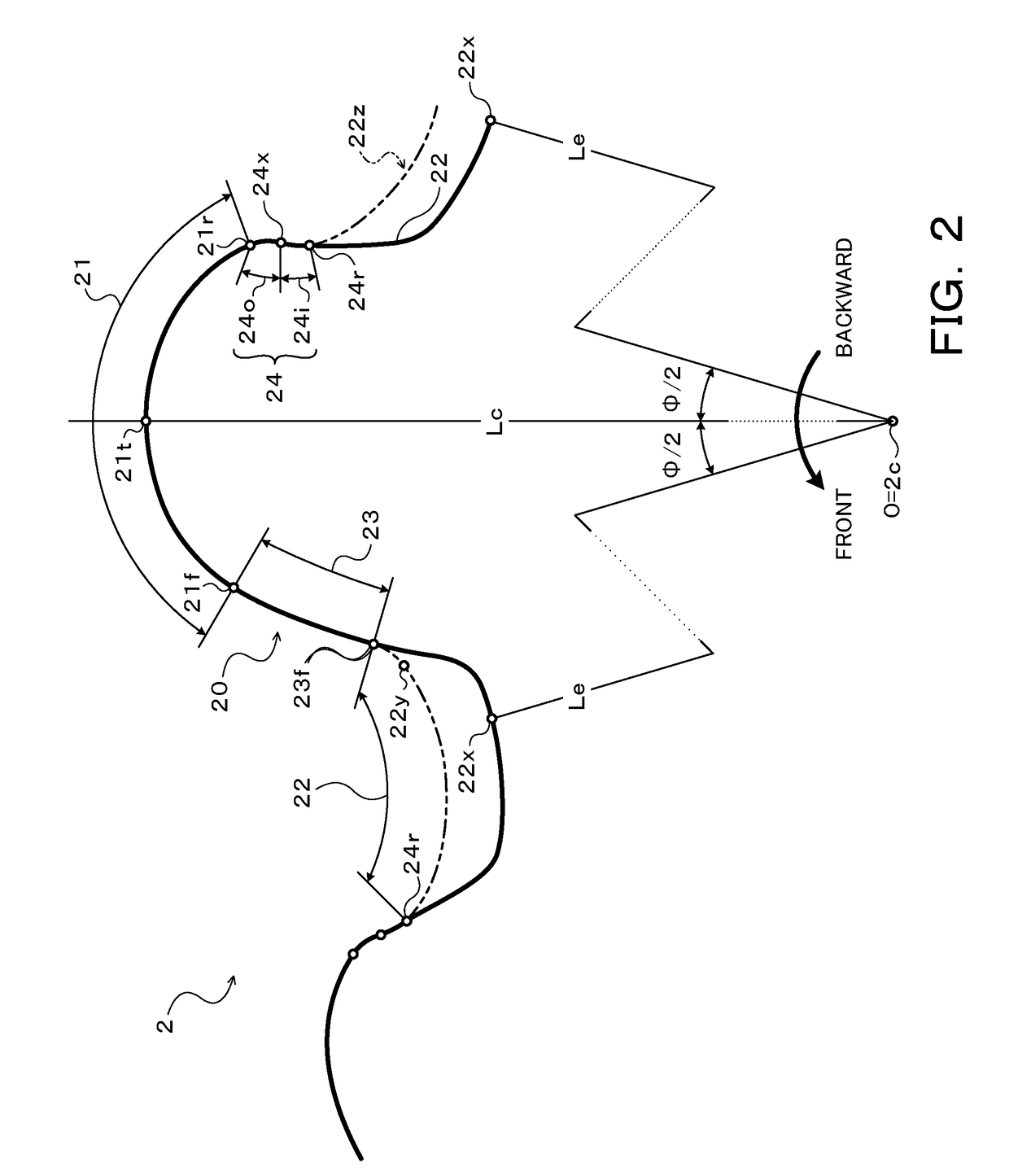

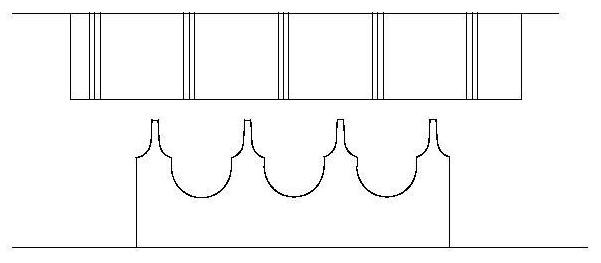

Gear pump and method for manufacturing same

InactiveCN107208627AAvoid cavitationRestricted circulationRotary piston pumpsRotary piston liquid enginesGear pumpBiomedical engineering

A plurality of external teeth 20 of an inner rotor 2 are formed such that the intake-side clearance CLi is greater than the discharge-side clearance CLd, where the intake-side clearance is the minimum value of clearance CLi between external teeth 20i and internal teeth 30i delineating an inter-tooth chamber 5 that is in communication with an intake port 6 and will demonstrate the largest change in volume when the inner rotor 2 rotates by a unit angle, and the discharge-side clearance CLd is the minimum value of clearance CLd between external teeth 20d and internal teeth 30d delineating an inter-tooth chamber 5 at least partially overlapping a partition wall 9 between first and second discharge ports 7, 8 when the change in volume per unit angle is largest.

Owner:AISIN KIKO CO LTD +1

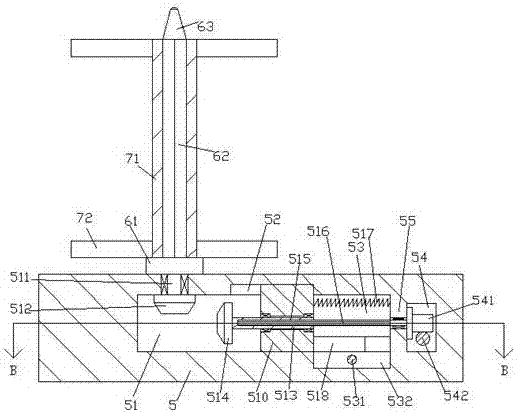

Multifunctional chuck clamp

InactiveCN111331406AAvoid damageEasy to operateLarge fixed membersPositioning apparatusEngineeringTooth cavity

The invention discloses a multifunctional chuck clamp. The multifunctional chuck clamp comprises a base, wherein a supporting plate is arranged on the upper side of the base, and a moving mechanism used for moving the supporting plate front and back is arranged inside the base; baffles are fixedly arranged at the two ends of the upper surface of the supporting plate, and a square block and a firstsquare barrel fixedly arranged on the front side of the square block are arranged between the baffles; and a tooth cavity is formed in each of the opposite side walls of the baffles, and racks whichare fixedly arranged on the left surface and the right surface of the square block and are symmetrical left and right in position are arranged in the tooth cavities. A part can be clamped only by controlling the electrifying condition of an electromagnet, compared with a conventional clamp, actual operation is more convenient, and the pressure between a squeezing plate and the part is controlled to be kept at a proper value through a sensor so that the part can be prevented from being damaged by excessive pressure of the squeezing plate.

Owner:福州约春向科技有限公司

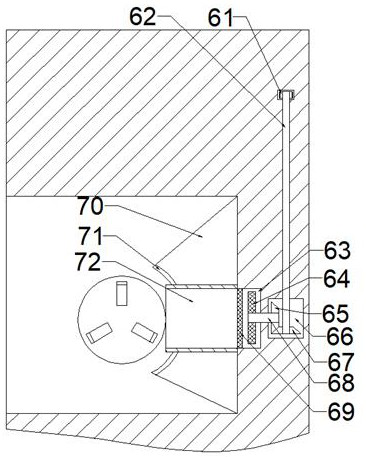

Shade tree protective paint spraying device

InactiveCN111822195ASpray evenlyShorten the timeSpraying apparatusPlant protectionTree trunkClassical mechanics

The invention discloses a shade tree protective paint spraying device. The device comprises a main box body, wherein the main box body is internally provided with an up-down sliding cavity with a leftward opening, a front gear is internally in sliding fit connection to a working sliding block, an up-down through sliding rod cavity is arranged in the working sliding block, the left side of the sliding rod cavity is in communication with a pushing rod cavity with a leftward opening, the upper portion of the up-down sliding cavity is in communication with a semi-open cavity, a conical tooth cavity is provided in the upper portion of the semi-open cavity, the left side of the conical tooth cavity is provided with a belt pulley cavity, an openable and closable annular device may be used for surrounding trunks of different thicknesses, internal nozzles continuously perform annular motion during lowering of the annular device, so that the nozzles finally realize spiral motion relative to thetrunks during a working process, spraying on the trunks is more uniform under such motion, and compared with a traditional mode, a spraying liquid can be saved while time is saved.

Owner:FUZHOU ZHIBUQU TECH CO LTD

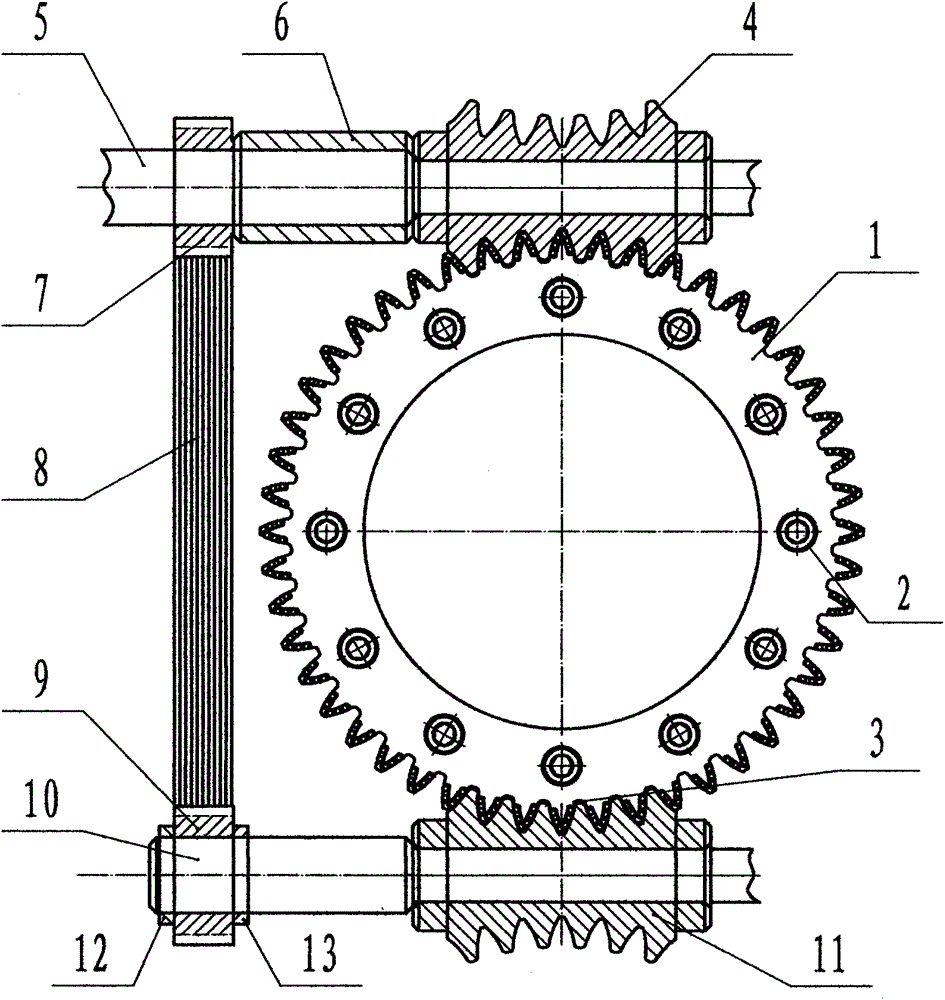

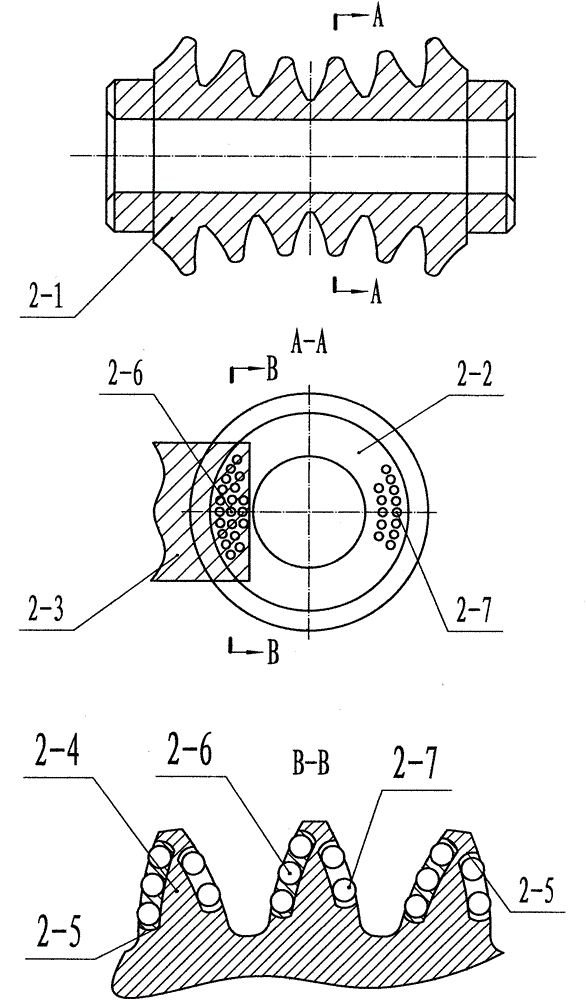

Bearing type precise ball cambered surface envelope worm wheel spoke

The invention provides a bearing type precise ball cambered surface envelope worm wheel spoke. For meeting the requirements of industrial equipment and machine tool building at present, the manufacturing of a wear-resisting worm wheel spoke which has a high requirement for precision and is large in the number of teeth in engagement and stable in rotation is badly needs to be realized; the bearing type precise ball cambered surface envelope worm wheel spoke utilizes a spiral cambered surface envelope worm wheel poke as a standard component, and adopts the mode that a spiral cambered surface block is cut out precisely in the face of worm wheel teeth, precision drilling is conducted to produce the ballistic curves evenly distributed around the cambered surface and exceeding the teeth face by a certain distance, installation ball steel balls are embedded on the face of the worm wheel teeth of a spiral cambered surface and meshed with a worm rod chambered surface of a spiral cambered surface envelope and rotate. Three to six teeth can be designed as required by the design, a multi-teeth chambered surface can be meshed with an envelope worm rod which can be single or double, and the transmission is stable.

Owner:陈安模

Gear pump including an inner rotor having a plurality of teeth

ActiveUS9581156B2Suppress cavitationImprove suction efficiencyOscillating piston enginesRotary piston pumpsTooth chamberEngineering

In a gear pump, an outer inner wall surface of a suction port which is located on a downstream side in a rotor rotation direction, that is, a first inner wall surface, is located inward of a bottom land between internal teeth of an outer rotor, and the suction port has a shallow portion extended inward from the first inner wall surface on the downstream side in the rotor rotation direction, and a deep portion that is formed so as to be continuous with the shallow portion and that is deeper than the shallow portion. Communication between an inter-tooth chamber and the suction port is cut off with the inter-tooth chamber facing only the shallow portion.

Owner:AISIN AW CO LTD

Labor-saving cup device

ActiveCN107175979AImproves front and rear movement stabilityRealize automatic reset workOther artistic work equipmentsModel makingEngineeringTooth cavity

The invention discloses a labor-saving cup device. The labor-saving cup device comprises a frame body and rotary elements which are distributed on the top end face of the frame body at equal intervals. Internal screw holes are formed in the bottom of the frame body, and studs are mounted in the internal screw holes in a matched mode. A tooth cavity which expands forwards is arranged in the potion, below each rotary element, of the frame body. A first groove body which expands left and right is formed behind each tooth cavity in a communicating mode. A second groove body is formed in the portion, in front of each first groove body, of the frame body. An isolation plate is arranged between each first groove body and the corresponding second groove body. A guide groove is formed in the inner top of the front side of each first groove body, and a first sliding frame expanding downwards is arranged in each guide groove. The labor-saving cup device is simple in structure, a plurality of rotary cylinders can be mounted, replacement of one rotary cylinder after winding is not needed, time and labor are saved, and the efficiency is improved; and in addition, an extra driving device is not needed, manufacturing cost is reduced, and meanwhile, purchase cost is reduced for enterprises.

Owner:盐城泓文广告传媒有限公司

Oil pump

InactiveUS20170227003A1Increase oil pressureReduce adverse effectsRotary piston pumpsLubricating pumpsEngineeringTooth chamber

In an oil pump, an inner rotor and an outer rotor rotate to discharge the oil through a discharge port. The discharge port has an outer extension portion located on a radially inner side with respect to a root circle of the outer rotor and on a radially outer side of a tip circle of the outer rotor and an inner extension portion located on the radially inner side with respect to the tip circle of the outer rotor and on the radially outer side with respect to a root circle of the inner rotor. An inter-tooth chamber facing a partitioning portion that partitions the suction port from the discharge port comes into communication with the outer extension portion and the inner extension portion. Then, a tip seal portion defining the inter-tooth chamber intersects an outer edge of an opening of the discharge port.

Owner:JTEKT CORP

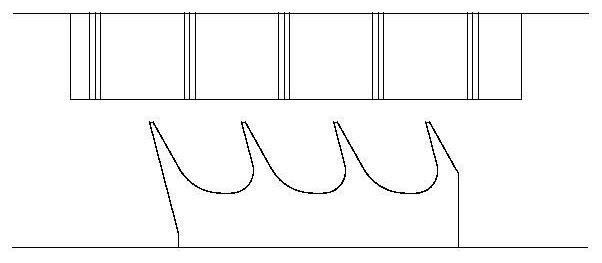

Gear pump

InactiveUS20180172000A1Lower the volumeVolume andPump componentsRotary piston pumpsGear pumpTooth chamber

A gear pump having a suction port, first and second discharge ports, an inner rotor having external teeth, an outer rotor having internal teeth such that the number of the internal teeth is larger than that of the external teeth of the inner rotor, and inter-tooth chambers defined by the external teeth and the internal teeth. The first and second discharge ports are in communication with the inter-tooth chamber whose volume is decreased along with rotation of the inner rotor etc. An inter-tooth chamber which has been brought out of communication with the second discharge port is brought into communication with the suction port while the volume is decreasing. The volume of the inter-tooth chamber which has been brought out of communication with the second discharge port is increased after at least a part of the inter-tooth chamber has been brought into communication with the suction port.

Owner:AISIN AW CO LTD

Valve well capable of automatically removing water and conveniently opening and closing novel valve

InactiveCN111877403AEasy to detectAchieve dischargeArtificial islandsOperating means/releasing devices for valvesWater leakageEngineering

The invention discloses a valve well capable of automatically removing water and conveniently opening and closing a novel valve. The valve well comprises a box body, wherein a valve well cavity with an upward opening is formed in a main box body, a telescopic cavity is formed in the right side of the valve well cavity in a communicating mode, a rack cavity extending rightwards is formed in the right side of the telescopic cavity in a communicating mode, a rack plate is connected to the lower end wall of the rack cavity in a sliding fit mode, a rack is fixedly connected to the upper end surfaceof the rack plate, and a wide tooth cavity located in the lower side of the rack cavity is formed in the right side of the telescopic cavity; a screw rotates to drain accumulated water in the valve well cavity through a water leakage cavity, a screw cavity and a drainage cavity, the accumulated water detection and drainage are achieved, the working intensity for manual detection is reduced, a novel valve in the valve well is prevented from being soaked and corroded, a rotary disc and a rotary disc block rotate, and a switch ring is rotated to open the novel valve. The operators are help to open the novel valve difficult to rotate, and the rotary disc and the rotary disc block are moved to be close to the right end wall of the valve well cavity, so that the working space used by the operators is enlarged.

Owner:福州经济技术开发区易通元智能科技有限公司

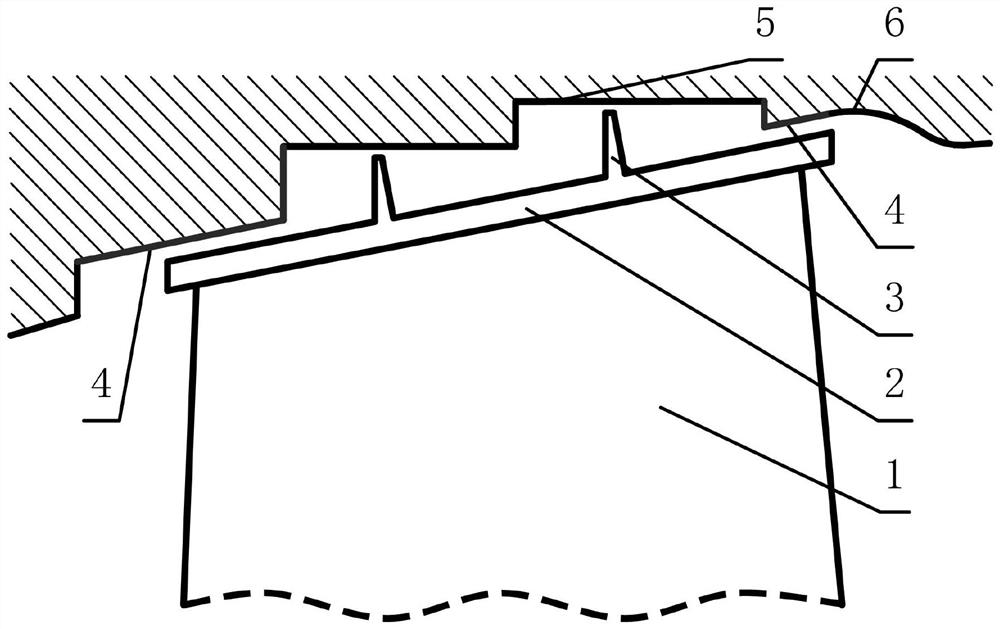

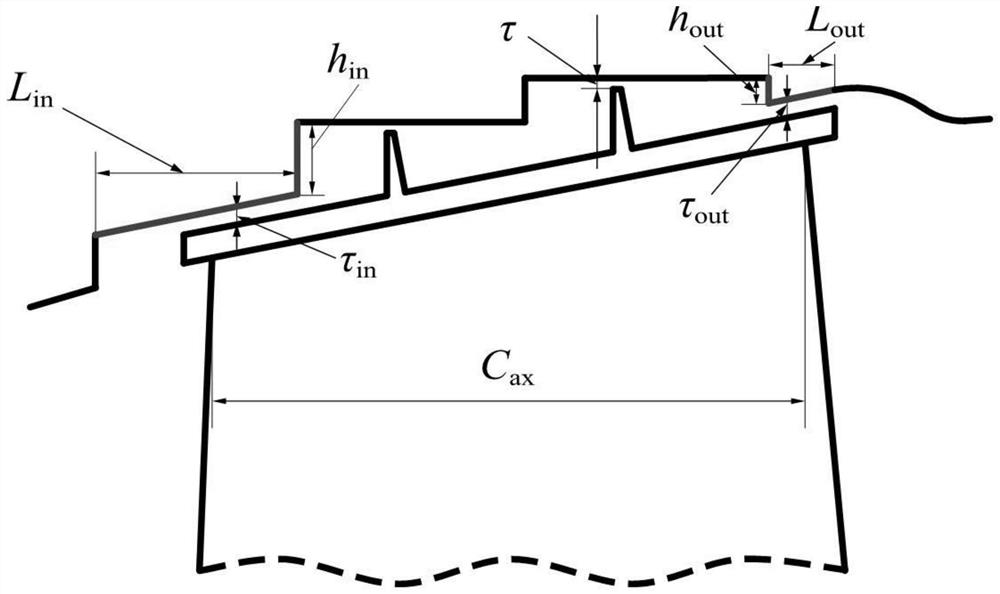

Crown turbine with margin plate step casing

PendingCN114776389AIncrease flow resistanceReduce leakageBlade accessoriesLeakage preventionClassical mechanicsStructural engineering

The shrouded turbine with the margin plate step casing comprises the casing and a hub, blades are evenly installed on the hub along the circumference, the hub and the blades are both installed in the casing, a blade crown is installed on the circumference of the end of each blade, labyrinth teeth are installed on the outer wall of each blade crown, and the labyrinth teeth are installed on the periphery of the end of each blade. Gaps are formed among the blade crown, the comb teeth and the wall surface of the casing at the top of the blade crown, the comb teeth divide the blade crown accommodating cavity into an inlet cavity, a comb tooth cavity and an outlet cavity, margin plate steps are arranged on the wall surfaces of the casing at the tops of the inlet cavity and the outlet cavity, and a smooth curve is connected behind the margin plate step at the top of the outlet cavity for transition.

Owner:BEIHANG UNIV

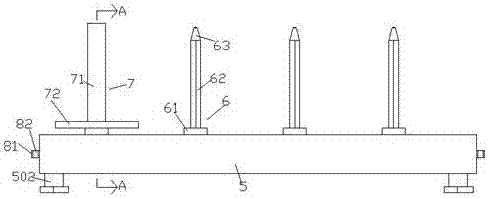

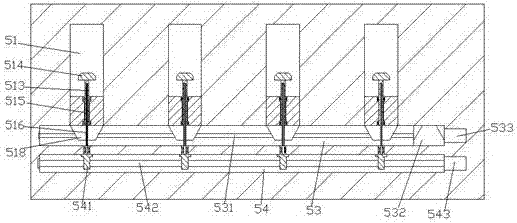

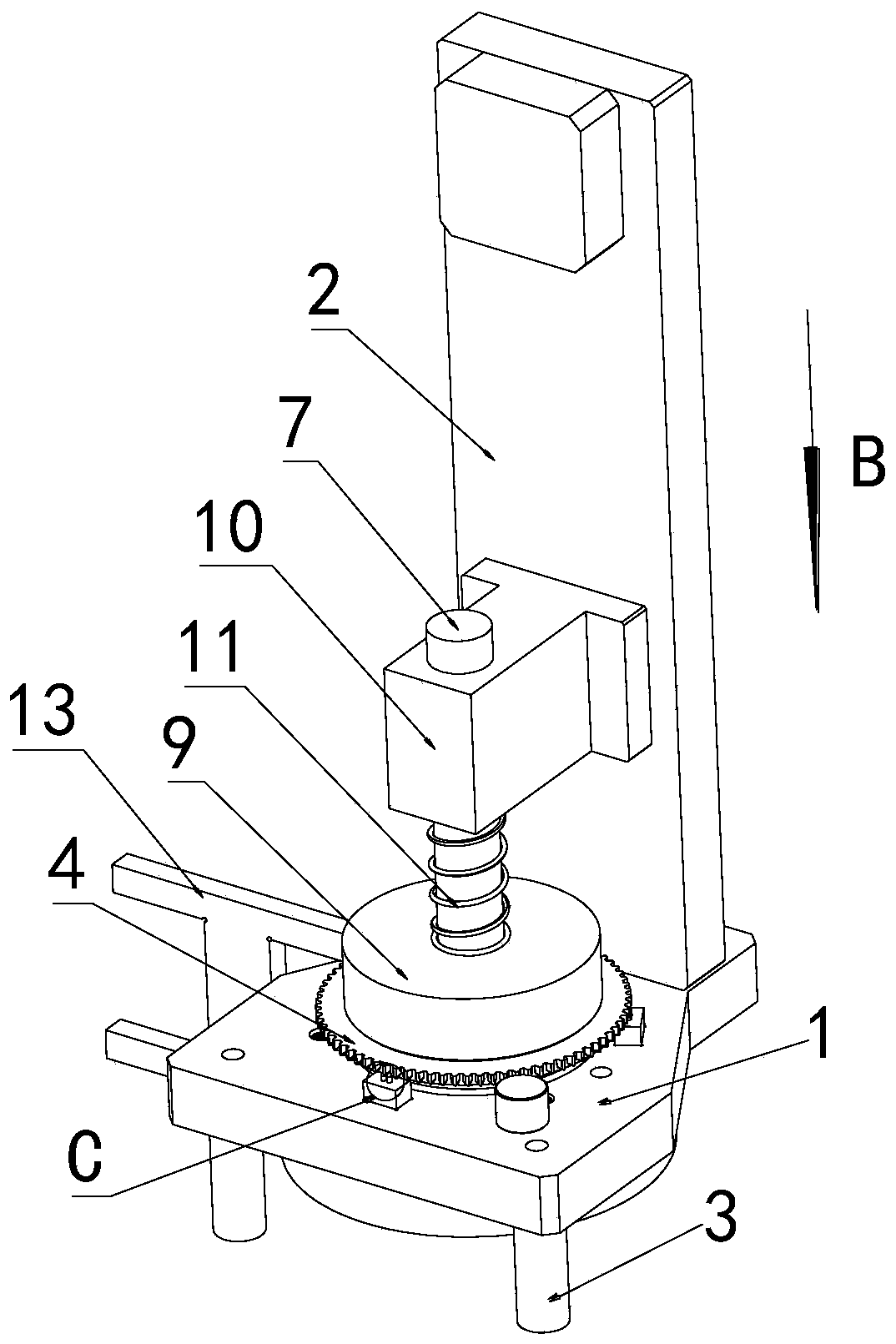

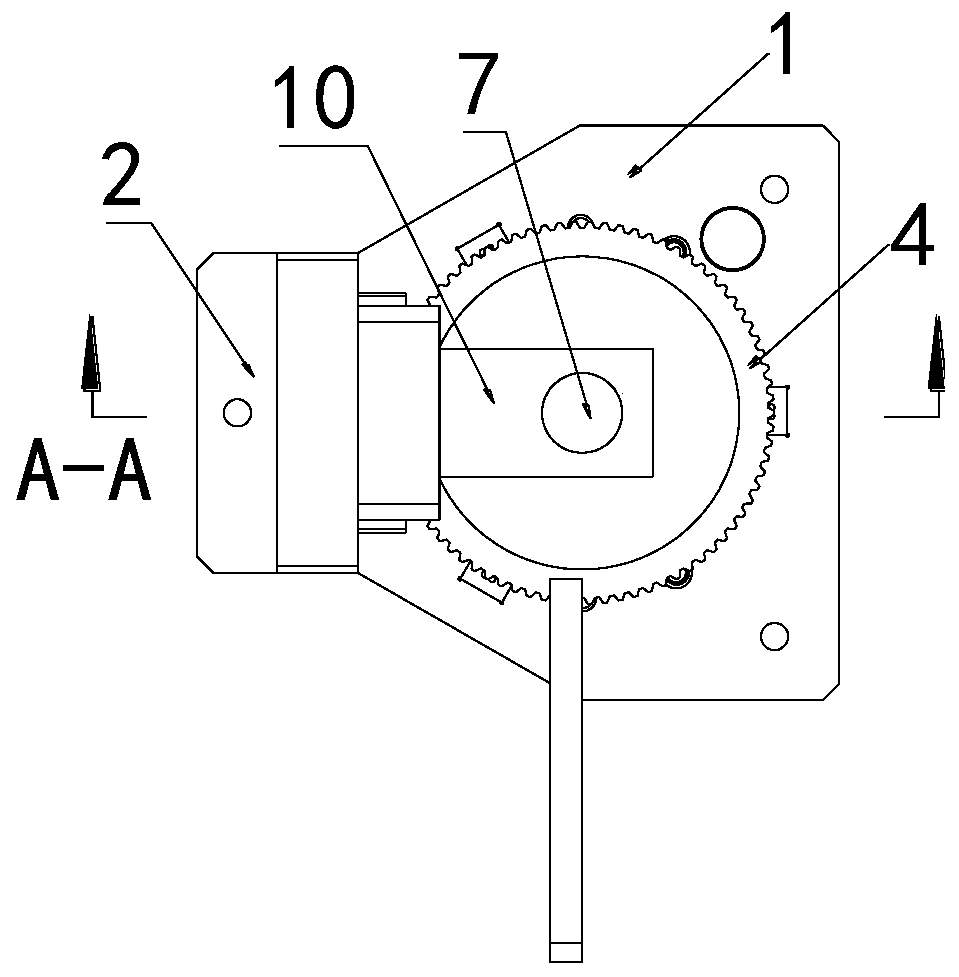

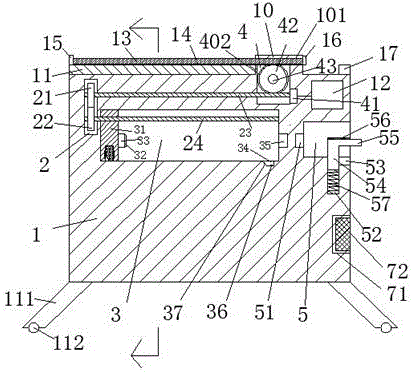

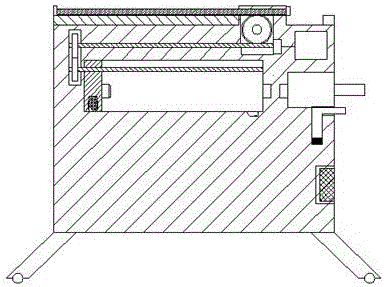

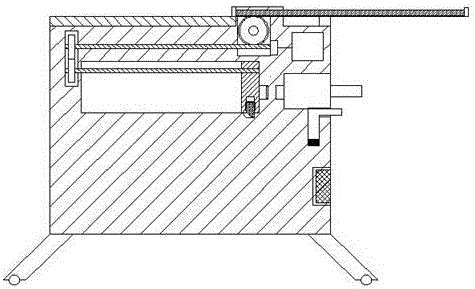

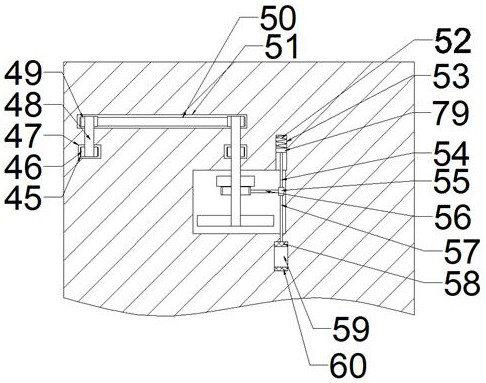

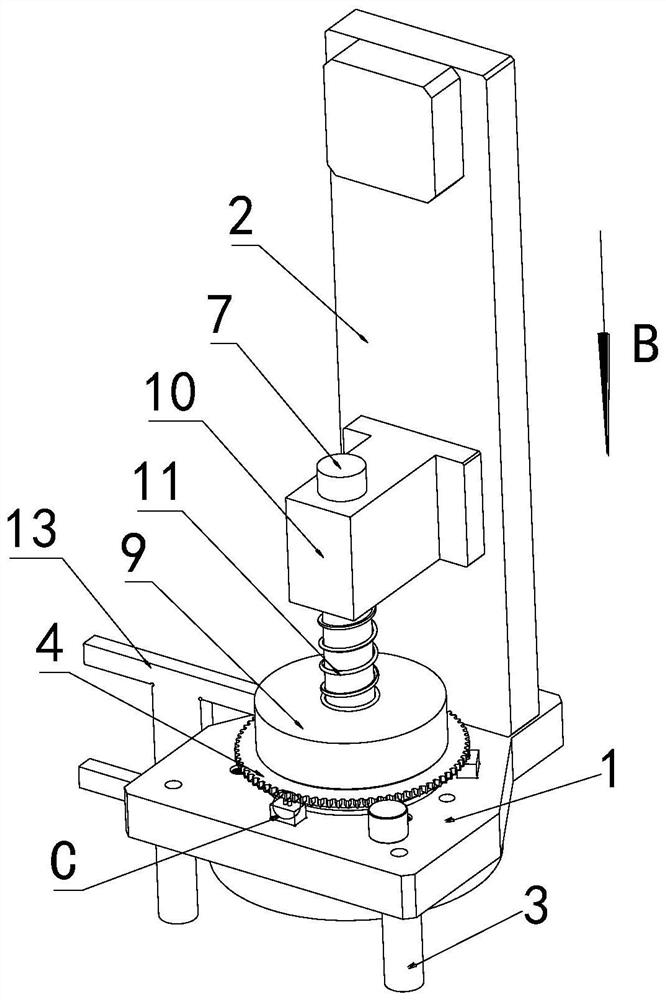

Tooth chamfer tester of tooth ring

ActiveCN110411306AGuaranteed deflectionShorten the timeMechanical clearance measurementsOrthodonticsTooth chamber

The invention relates to a tooth chamfer tester of a tooth ring, and belongs to the technical field of tooth rings. The tester comprises a column arranged on a pedestal, the pedestal is supported by supporting legs, the pedestal is provided with a through hole for placing the tooth ring and at least three groups of spherical supporters, each group of spherical supporters supports the two side surfaces of a chamfer of the same tooth in the tooth ring, a positioning mandrel is further included, one end of the positioning mandrel is provided with a positioning cylinder matching the inner ring ofthe tooth ring, and the positioning mandrel and the positioning cylinder are arranged on the column in an up-down sliding way. Thus, detection time for the tooth chamber is shortened, the detection efficiency is improved, and the cost is reduced.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY

Teeth cleaning device with sight glass

The invention provides a teeth cleaning device with a sight glass. The teeth cleaning device comprises a connection section, a sight glass part and a sighting tube, wherein a high-pressure water pump is arranged in the connection section; the sight glass part is connected with the connection section; a camera lens is arranged on the sight glass part; the sighting tube is connected with the connection section, and is arranged at one side opposite to the sight glass part; the sighting tube is communicated with the high-pressure water pump in the connection section; and a water outlet is formed in the tail end of the sighting tube. Compared with the prior art, the teeth cleaning device has the beneficial technical effects that through the sight glass part and the telescopic sighting tube, a physician can conveniently see the condition in a dental cavity clearly in the teeth cleaning process; positioning on foreign matters in a slit between the teeth is relatively accurate; the high-pressure water pump can be directly started through a switch after the positioning is finished; and trickle jet water jets towards the foreign matter part without secondary positioning, so that the teeth cleaning effect is effectively improved.

Owner:TIANJIN JINGUI YONGSHENG MEDICAL EQUIP DEV

Convenient bridge construction equipment

InactiveCN107181123AEfficient power generationSo as not to damageCoupling device detailsElectricityEngineering

The invention discloses convenient bridge construction equipment which comprises a frame and an electricity inlet head which is connected with electric equipment, supports are fixed to the bottom of the frame, the supports are arranged in an inclined way, rollers are fixed to the bottoms of the supports, a convex portion is arranged on the top end of the frame, a first sliding groove extending to left and right is arranged in the frame, a tooth chamber is arranged on the left end of the first sliding groove in the frame, a turbine groove extending upwards in the convex portion is arranged in the frame, and a through hole communicated from left to right and communicated with the turbine groove is arranged in the convex portion. According to the invention, the overall structure of the device is simple, power supply is safe and reliable, the operation is simple and convenient, electric shock accident caused by inserting and extracting the electricity inlet head is effectively reduced, human life safety is ensured, sudden disconnection of the electric equipment caused by error kicking can be avoided, the service life of the electric equipment can be effectively improved, and the equipment provided by the invention saves energy, protects the environment and is suitable for popularization.

Owner:何志达

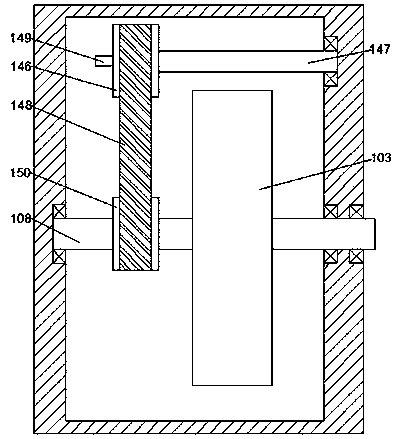

Quick expansion and quick contraction auxiliary clamping device

The invention discloses a quick expansion and quick contraction auxiliary clamping device. The device comprises a lathe body, wherein a cutting cavity provided with a forward opening is formed in thelathe body, a three-jaw chuck cavity is arranged at the left side of the cutting cavity in a communicating mode, a wide tooth cavity is arranged at the upper side of the cutting cavity, a clamping block moving cavity extending upwards is arranged at the upper side of the wide tooth cavity, a clamping block limiting cavity is arranged at the upper side of the clamping block moving cavity in a communicating mode, a clamping block cavity is arranged at the upper side of the clamping block limiting cavity in a communicating mode, and a speed-changing cavity is arranged at the left side of the widetooth cavity. According to the device, a motor big gear drives a driven shaft to rotate through a driven small gear, finally high-speed rotation of a clamping shaft with low torque is realized, therefore, quick clamping is realized, and machining efficiency is improved; after clamping jaws make contact with a workpiece, gear shifting is performed through a torque detector, a motor small gear drives the driven shaft to rotate through a driven big gear after gear shifting, finally low-speed rotation of the clamping shaft with high torque is realized, and therefore low-speed clamping is realized; and during clamping, a fan works to clean cuttings, so that the locating precision of clamping is improved.

Owner:福州鼓楼卓穆尼奥科技有限公司

Grate tooth sealing structure

PendingCN114738119AIncrease energy dissipationAvoid vibrationInternal combustion piston enginesLeakage preventionTooth cavityPhysics

The invention provides a labyrinth sealing structure which comprises a lining and a rotor, the rotor is provided with at least two labyrinth teeth, so that a tooth cavity is formed between the two labyrinth teeth, at least one set of impact holes are formed in the middle position, matched with the tooth cavity, of the lining, and the impact holes are formed in the middle position, matched with the tooth cavity, of the lining. And the turbulent flow introduced from the impact hole forms an air curtain in the tooth cavity, and the air curtain can prevent leakage of gas in the sealed air guide flow path and destroy vortex systems in the tooth cavity at the same time, so that a larger vortex system is impacted into two smaller vortex systems. According to the labyrinth sealing structure provided by the invention, for an original labyrinth sealing air path, turbulent airflow is increased to form an air screen, when a labyrinth gap is greatly changed, a strong blocking effect is formed on the original sealing air path, leakage increase caused by gap increase is relieved to a certain extent, energy dissipation in a tooth cavity is increased, and the sealing effect of the labyrinth sealing structure is improved. Therefore, fluid leakage of an original gas circuit is reduced.

Owner:AECC SHENYANG ENGINE RES INST

Novel sewage treatment equipment

InactiveCN108002463AWell mixedStirring speed is fastWater/sewage treatment apparatusEngineeringSewage treatment

The invention discloses a novel sewage treatment equipment. The novel sewage treatment equipment comprises a support body; a groove is arranged in the support body; a loading groove is arranged in thetop wall of the support body, and is communicated with the groove; an opening groove is arranged on the right upper part of the groove in the support body; a slope groove is arranged in the bottom wall of the groove; the upper end of the slope groove is rotatablely provided with a blocking plate through an articulated shaft; a driving device is arranged in the support body, and is used for driving the blocking plate to rotate; a tooth chamber is arranged in the top wall of the groove; a shaft rod is rotatablely arranged in the tooth chamber; a first tooth wheel is fixedly arranged on the shaft rod; the upper end of the shaft rod is connected with a motor which is fixedly arranged on the support body; a holding shell sleeve is fixedly arranged at the center of the top wall of the groove; atorsion shell sleeve is rotatablely arranged in the holding shell sleeve; the top end of the torsion shell sleeve is pressed into the tooth chamber, and is fixedly provided with a second tooth wheelmatching the first tooth wheel; the lower end of the torsion shell sleeve is fixedly provided with a connection rod; and first stirring blades are fixedly arranged on the left side and the right sideof the lower end of the connection rod. The novel sewage treatment equipment is excellent in stirring effect, and high in stirring efficiency.

Owner:广州念泽环保科技有限公司

A tooth chamfering inspection tool for a ring gear

ActiveCN110411306BGuaranteed deflectionShorten the timeMechanical clearance measurementsEngineeringPhysics

The invention relates to a tooth chamfer tester of a tooth ring, and belongs to the technical field of tooth rings. The tester comprises a column arranged on a pedestal, the pedestal is supported by supporting legs, the pedestal is provided with a through hole for placing the tooth ring and at least three groups of spherical supporters, each group of spherical supporters supports the two side surfaces of a chamfer of the same tooth in the tooth ring, a positioning mandrel is further included, one end of the positioning mandrel is provided with a positioning cylinder matching the inner ring ofthe tooth ring, and the positioning mandrel and the positioning cylinder are arranged on the column in an up-down sliding way. Thus, detection time for the tooth chamber is shortened, the detection efficiency is improved, and the cost is reduced.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY

Anti-deformation and efficient automatic material cleaning and taking-out device for long and thin steel plate

InactiveCN112091053AReduce work intensityEasy to take outStripping-off devicesMetal working apparatusSheet steelMetallic materials

The invention relates to the related field of metal materials, and discloses an anti-deformation and efficient automatic material cleaning and taking-out device for a long and thin steel plate. The anti-deformation and efficient automatic material cleaning and taking-out device comprises a main box body, wherein a blanking machine is fixedly connected to the left end face of the main box body, a left-right through blanking cavity is formed in the blanking machine, a taking-out belt cavity is formed in the main box body, and a conical tooth cavity for taking out is formed in the front side of the taking-out belt cavity; an upward belt cavity which is located at the right side of the taking-out conical tooth cavity and extends downwards is formed in the front side of the taking-out belt cavity, and a rotary disc protruding block and a connecting rod drive a push-out sliding block to slide back and forth in a reciprocating manner, so that blanking edge materials are automatically pushed into a waste cavity, and the working intensity of workers is reduced; a taking-out connecting block and a taking-out electromagnet drive the long and thin steel plate to move rightwards, so that it isrealized that under the the condition that a blanking upper die is slightly improved, the blanked long and thin steel plate is automatically taken out, the working efficiency is improved, the bendingdeformation of the long and thin steel plate is prevented under the support of a workbench, and therefore the product quality is improved.

Owner:XIANGSHAN XUWEN STEEL TECH CO LTD

Oil pump having extension portions that reduce the effect of #the collapse of bubbles in the oil

InactiveUS10174757B2Reduce adverse effectsIncrease oil pressureOscillating piston enginesRotary piston pumpsEngineeringTooth chamber

In an oil pump, an inner rotor and an outer rotor rotate to discharge the oil through a discharge port. The discharge port has an outer extension portion located on a radially inner side with respect to a root circle of the outer rotor and on a radially outer side of a tip circle of the outer rotor and an inner extension portion located on the radially inner side with respect to the tip circle of the outer rotor and on the radially outer side with respect to a root circle of the inner rotor. An inter-tooth chamber facing a partitioning portion that partitions the suction port from the discharge port comes into communication with the outer extension portion and the inner extension portion. Then, a tip seal portion defining the inter-tooth chamber intersects an outer edge of an opening of the discharge port.

Owner:JTEKT CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com