Patents

Literature

55results about How to "Little flow fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

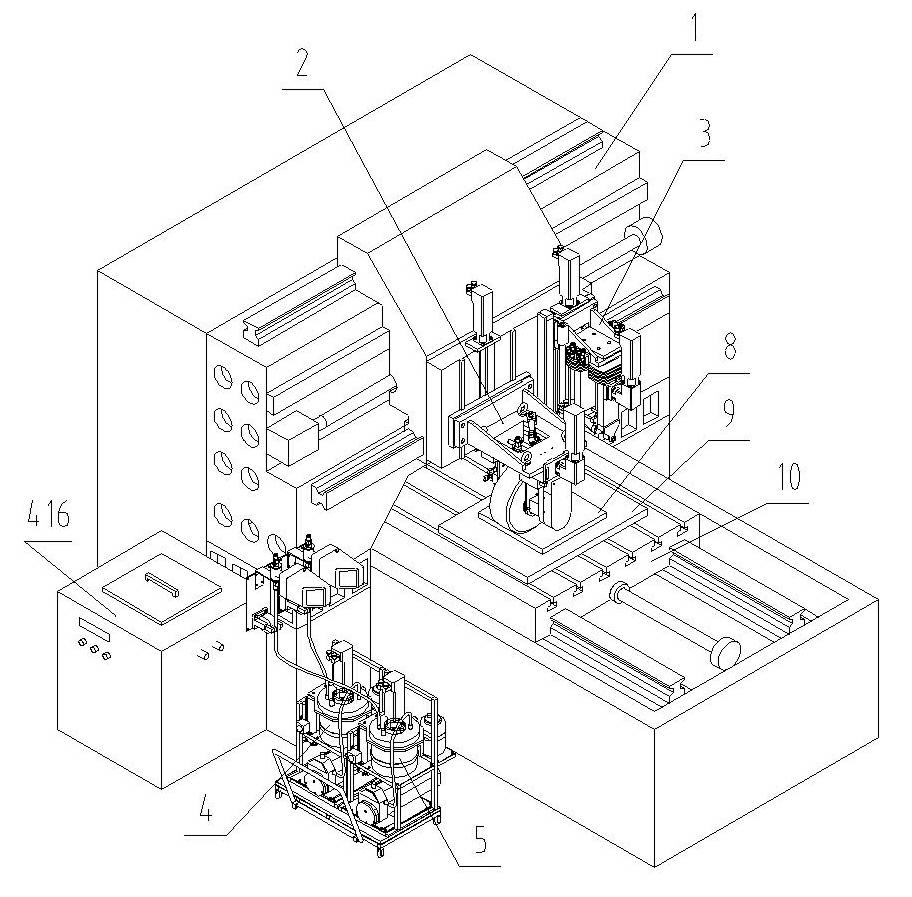

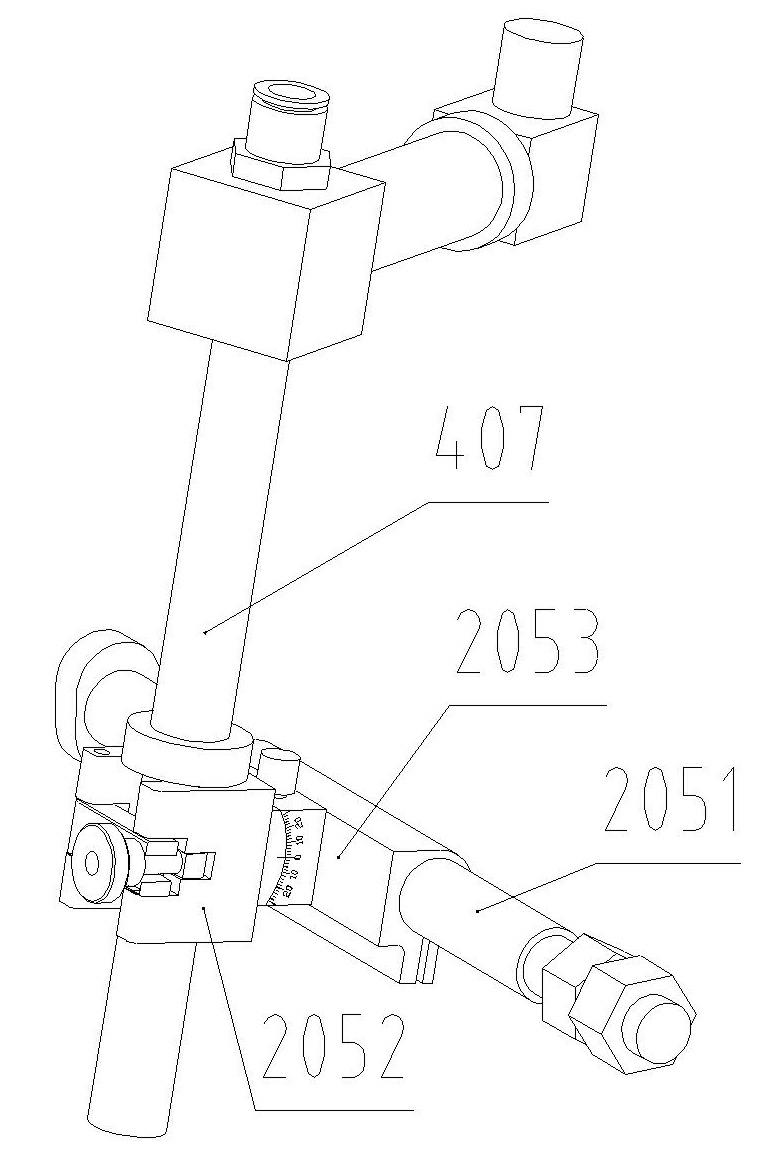

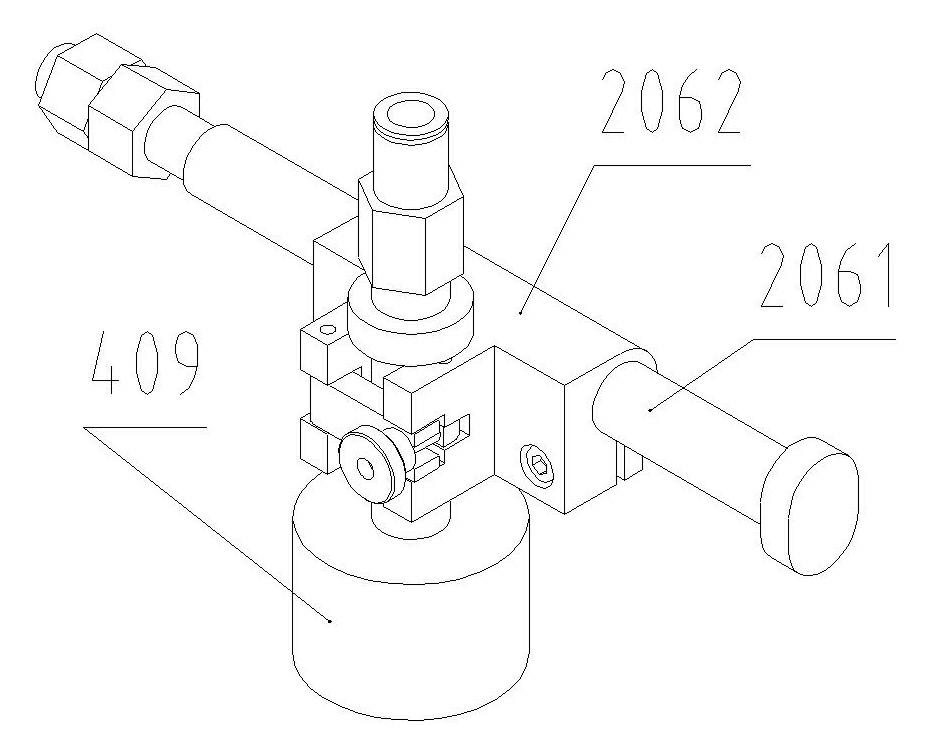

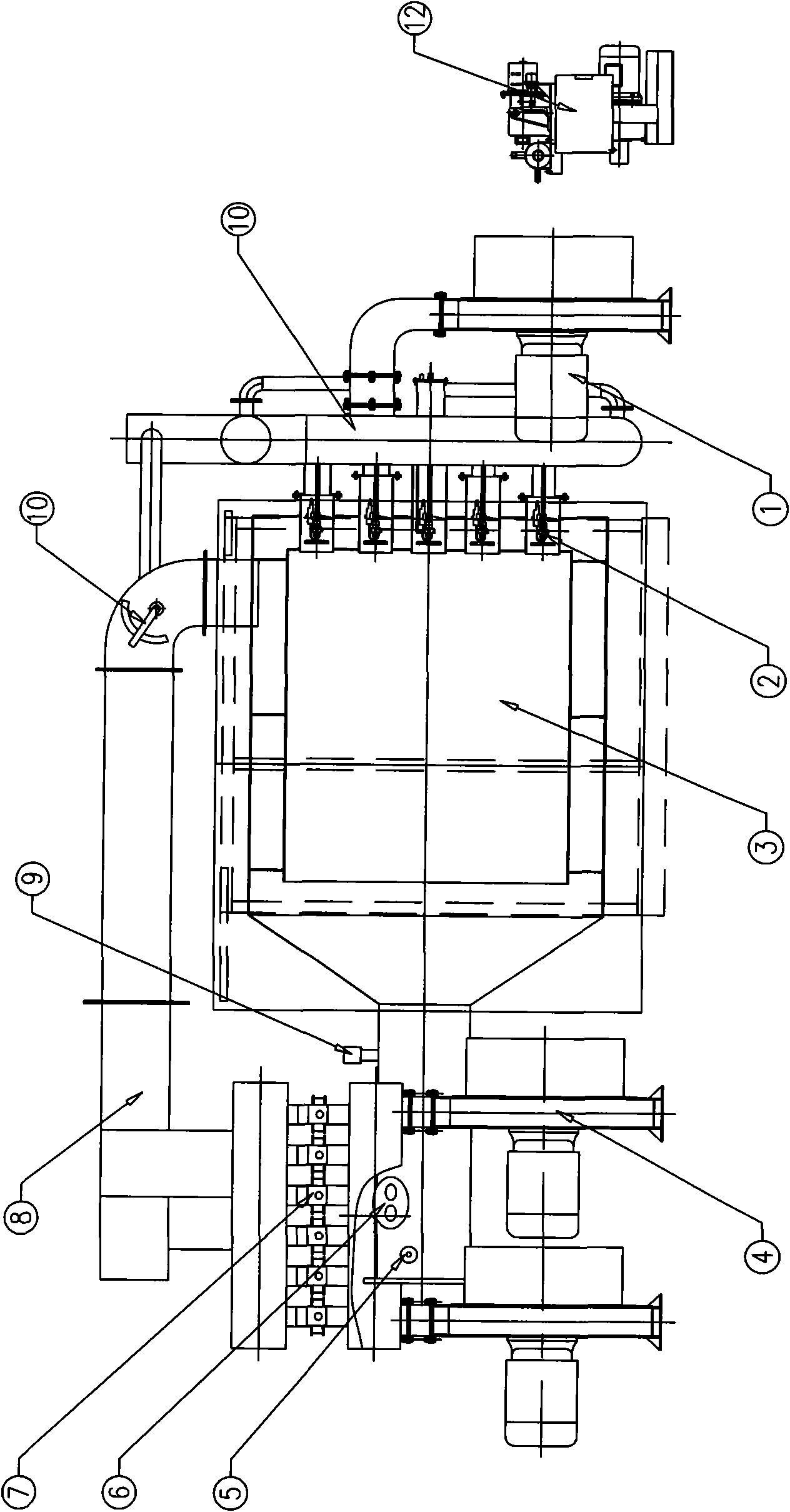

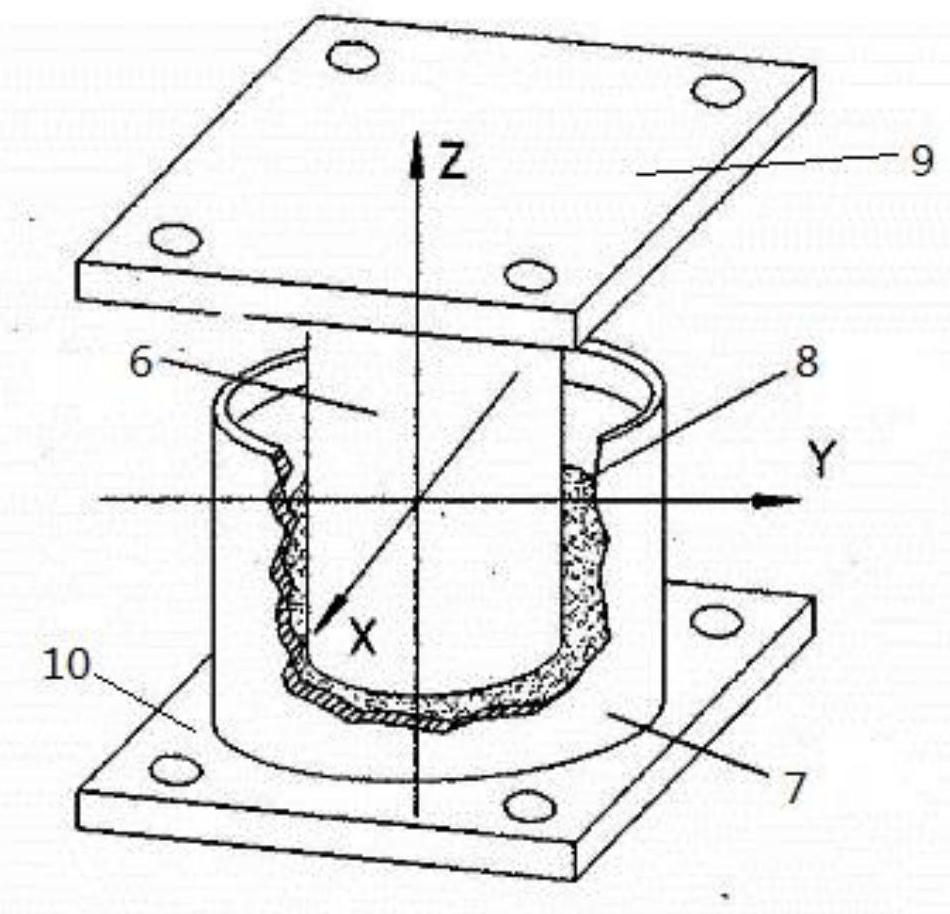

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

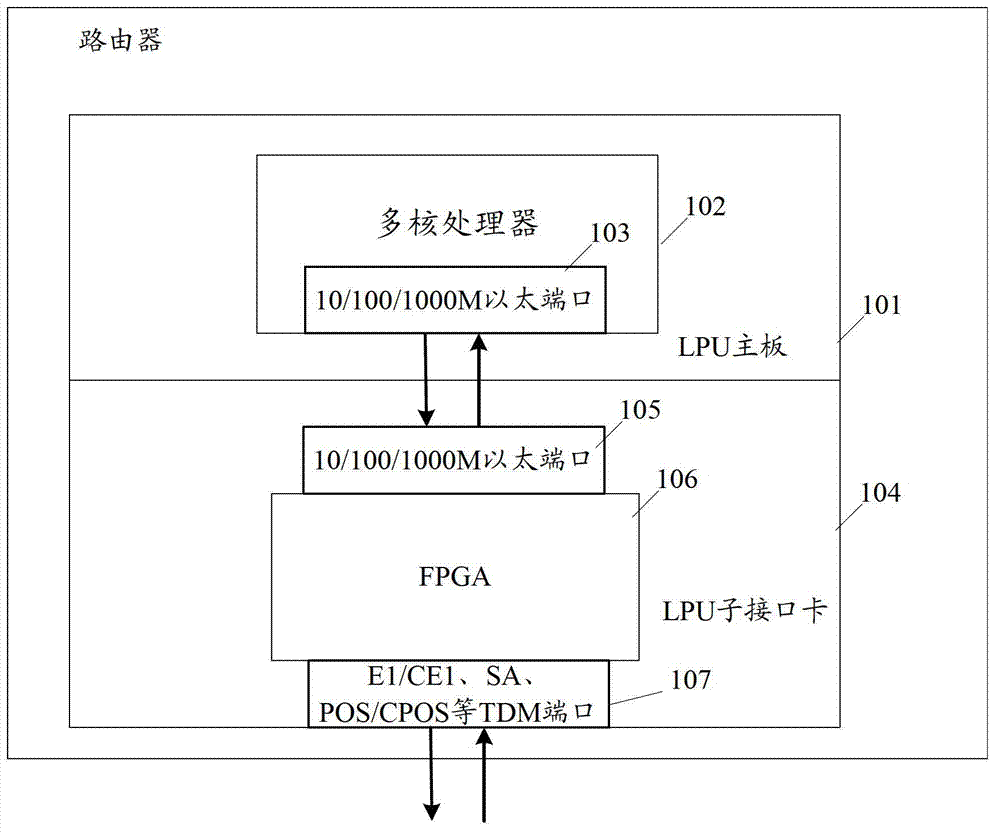

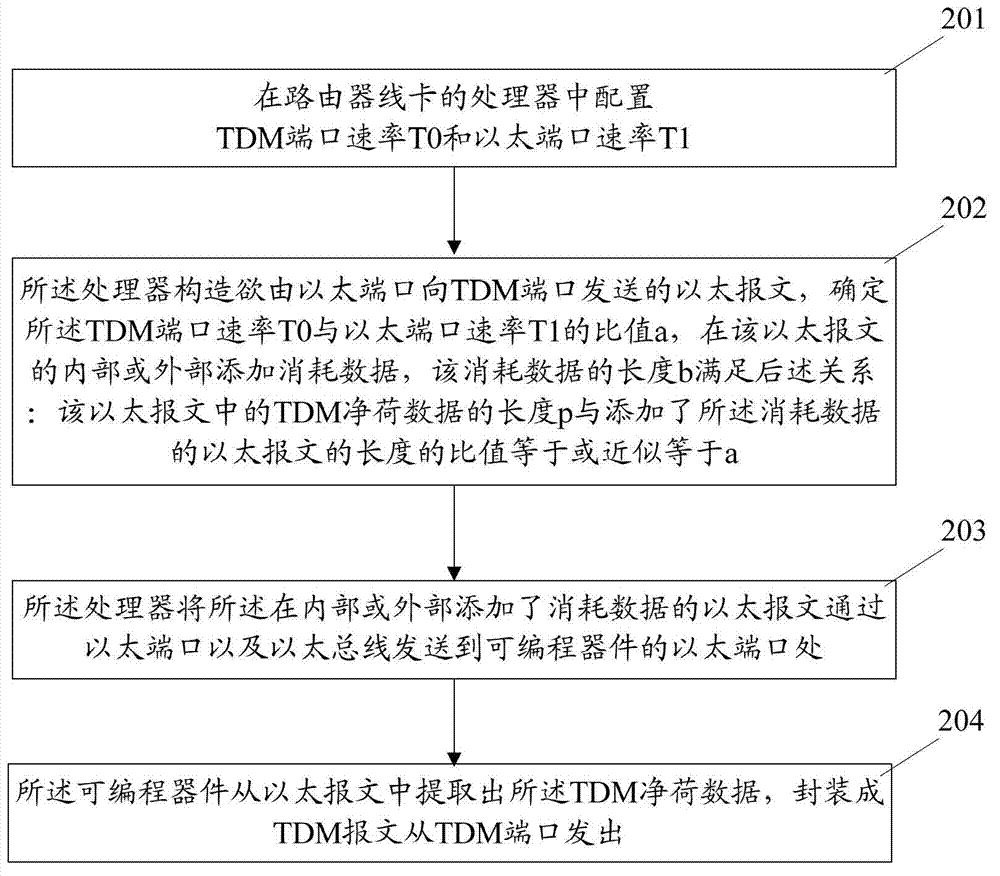

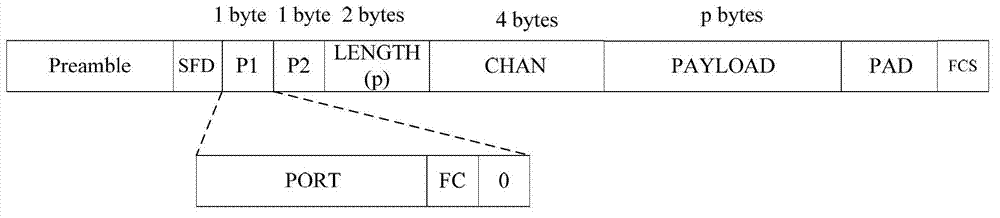

Router wire card and data processing method

ActiveCN102780639AImprove bandwidth stabilityLow costData switching networksTraffic capacityLine card

The application discloses a router wire card and a data processing method thereof. The data processing method comprises the steps that TDM (time division multiplexing) port rate T0 and ether port rate T1 are allocated in a processor of a router wire card mainboard; the processor structure sends an ether message to a TDM port from an ether port to determine the ratio a of T0 to T1, consumption data is added to the inside or outside of the ether message, and the length b of the consumption data meets the relation that the ratio of the length p of TDM payload data in the ether message to the length of the ether message added with the consumption data is equal or approximate to a; the processor sends the ether message added with the consumption data inside or outside to a programmable device arranged at the TDM port through the ether port and an ether bus; and the programmable device extracts the TDM payload data from the ether message, encapsulates to obtain a TDM message and sends the TDM message from the TDM port. According to the invention, the flow fluctuation from the ether port to the TDM port can be reduced with lower cost and processing expense.

Owner:MAIPU COMM TECH CO LTD

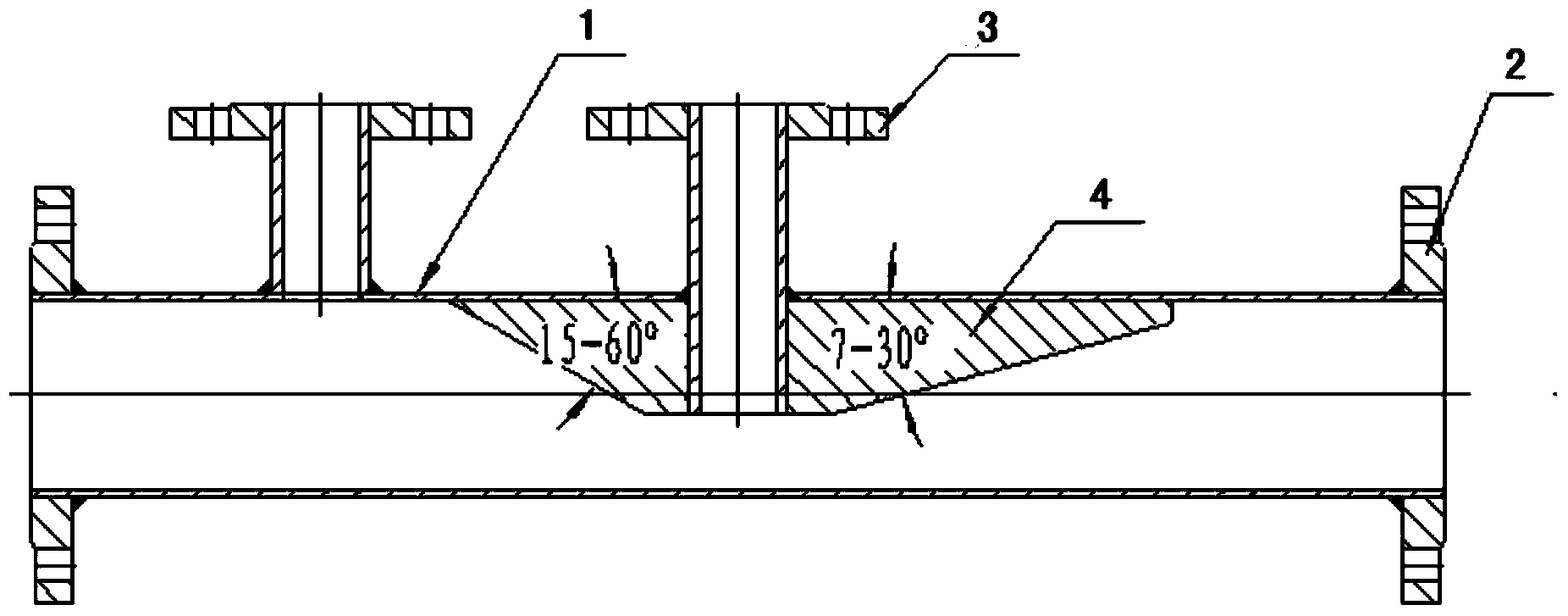

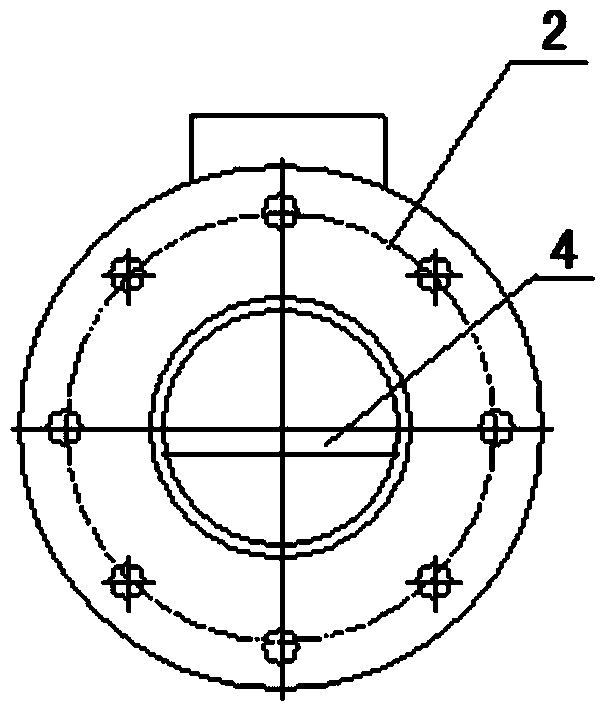

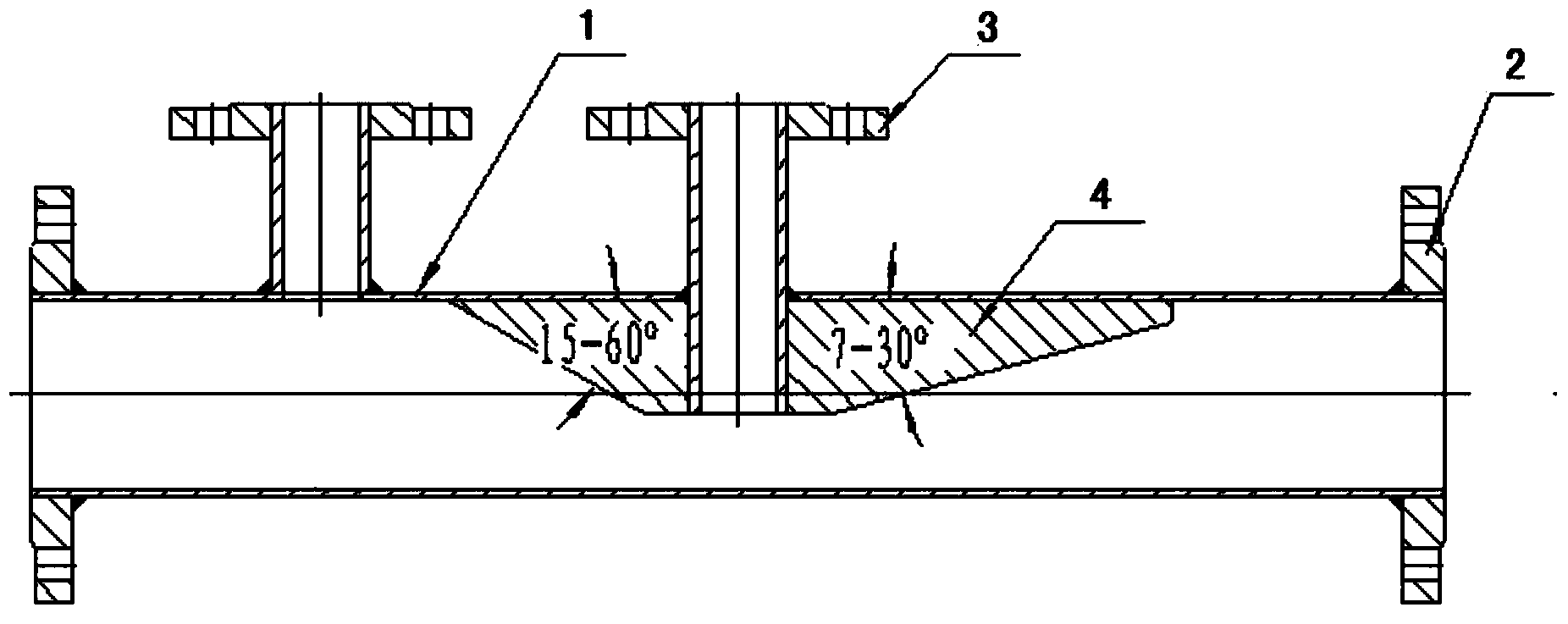

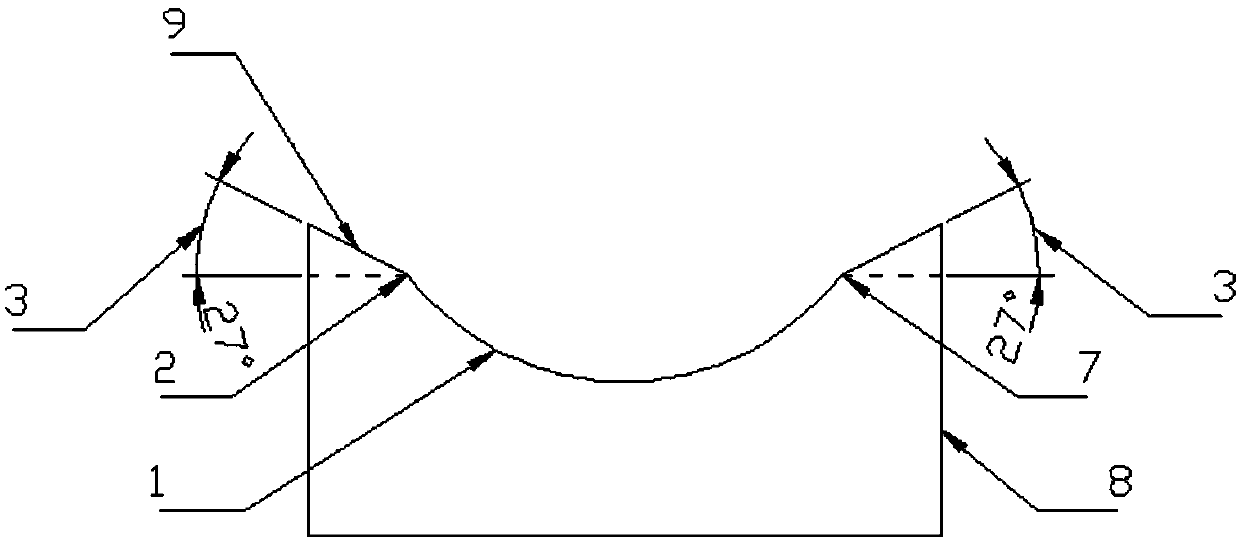

Diffusion tube type rectangular flow meter

InactiveCN104019853AUnique structureHigh precisionVolume/mass flow by differential pressureAcute angleEngineering

The invention relates to a flow meter, in particular to a diffusion tube type rectangular flow meter. The diffusion tube type rectangular flow meter comprises a measurement tube and body flanges welded to the two ends of the measurement tube, and a pair of pressure tapping flanges are welded to the measurement tube in the axial direction. The diffusion tube type rectangular flow meter is characterized in that a trapezoid throttling element is arranged at the position, below the pressure tapping flanges, in the measurement tube; the cross section of the trapezoid throttling element is in a circular notch shape, the front projection is in the inverted trapezoidal shape with the big upper portion and the small lower portion, two acute angles of the trapezoid are 15-60 degrees and 7-30 degrees respectively, and a negative pressure sampling hole is formed in the center of the throat. The diffusion tube type rectangular flow meter is unique in structure, high in accuracy, good in linearity, high in long-term working stability and reliability, long in service life, high in pressure recovery and small in perpetual pressure loss.

Owner:唐力南

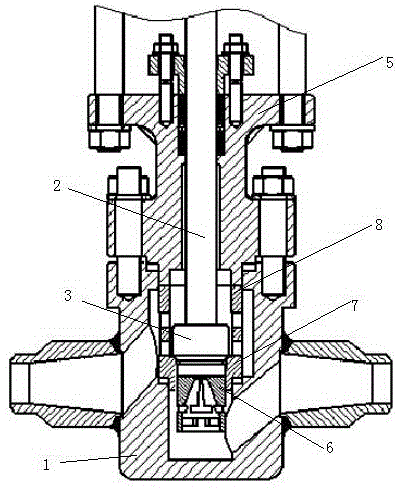

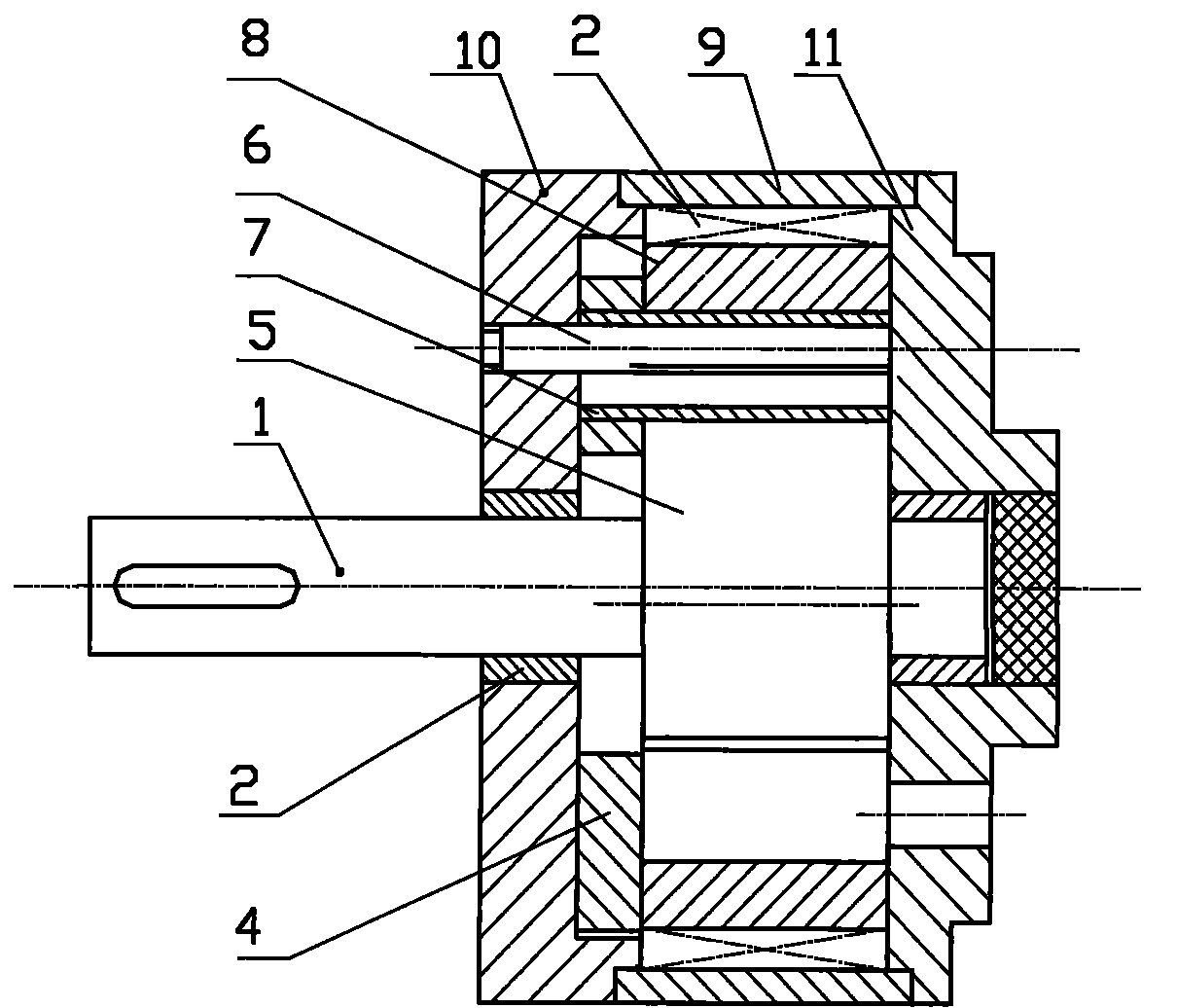

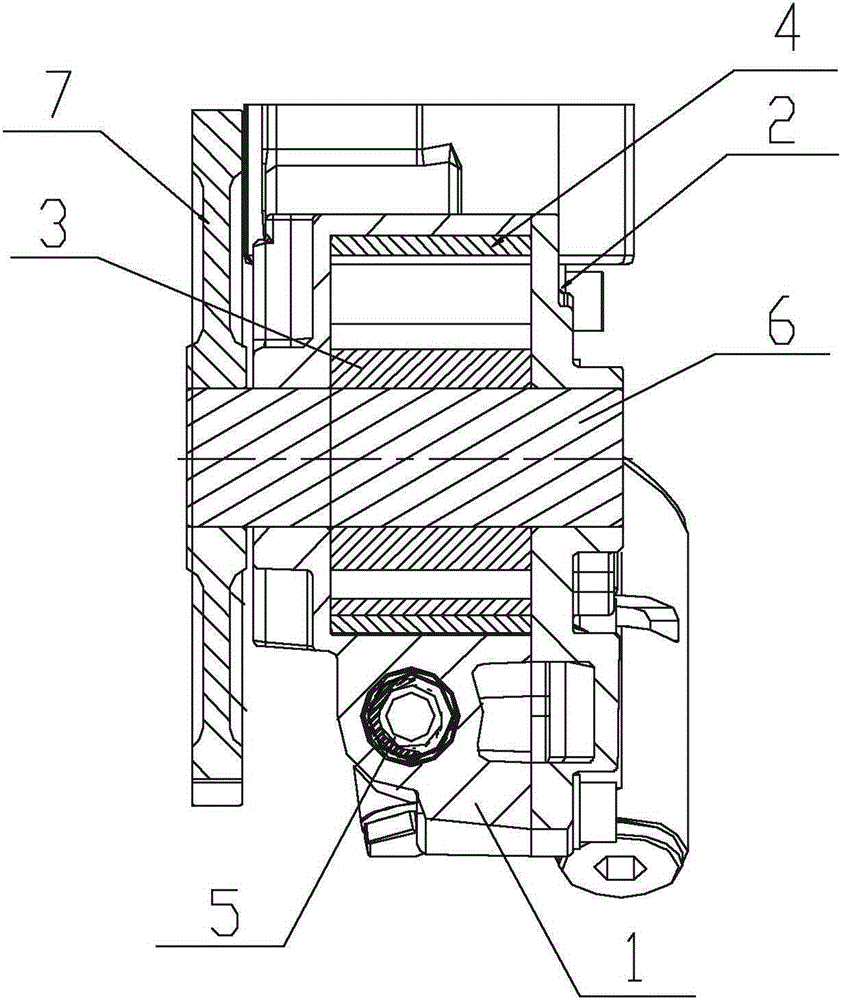

Flow regulating valve

ActiveCN104930197AExtended service lifeAccurate adjustmentValve members for absorbing fluid energyLift valveBarrel ShapedEngineering

The invention discloses a flow regulating valve which is characterized in that a barrel-shaped guide sleeve is arranged at the lower end of a valve core; flow adjusting windows are formed in the barrel-shaped guide sleeve and composed of a triangular window and a rectangular window; the upper layer is the triangular window with an upward vertex angle; a barrel-shaped valve seat is composed of a valve seat and a valve barrel; the inner diameter of the valve seat is smaller than that of the valve barrel; an assembly boss is arranged in the middle of the outer wall of the valve seat; an assembly groove matched with the lower end part of the assembly boss of the valve seat is formed at a liquid outlet in a valve body; the valve seat is connected with the valve body through the assembly boss and the assembly groove; an assembly groove matched with the upper end part of the assembly boss of the valve seat is formed in the inner wall of the lower end of the valve barrel; the valve barrel is connected with the valve seat through the assembly groove and the assembly boss; and the valve barrel and the valve seat are fixed in the valve body through a valve cover and bolts. According to the flow regulating valve, cut-off sealing surfaces of the valve core and the valve seat are separated from a flow adjusting surface, so that the phenomenon that the valve is damaged due to washing when being opened slightly is avoided, therefore, the service life of the valve is prolonged greatly; and the flow regulating valve has the advantages of accurate flow adjustment, small flow fluctuation during starting, low noise and the like.

Owner:SHANDONG BOAO POWER EQUIP CO LTD

Displacement adjusting method for positive-flow hydraulic pump of excavator

InactiveCN102937085AReduce traffic lossReduce feverPump controlPositive-displacement liquid enginesHydraulic pumpEngineering

The invention discloses a displacement adjusting method for a positive-flow hydraulic pump of an excavator. A throttle opening is arranged on an oil return passage in a multiple directional control valve in a hydraulic system, and a plurality of pilot valves are installed outside a variable pump; largest pilot pressure is selected through a shuttle valve group to control the displacement of the hydraulic pump, and a displacement value of the hydraulic pump is controlled according to opening degrees of a way of valves with largest pilot pressure; an electric control unit of the hydraulic pump is reserved on one of main valves, and the pilot pressure of the main valves is converted into electrical signals through a pressure sensor; main hydraulic pump outlet pressure is detected to calculate another displacement value of the main pump according to a curve, the displacement of the main pump is adjusted according to the two values; and the pressure sensor, a tilt angle sensor and a displacement sensor are arranged at corresponding positions of the excavator. The displacement adjusting method for the positive-flow hydraulic pump of the excavator has the advantages that the output flow of the hydraulic pump is in accordance with the operation of operators, the response time is short, the flow fluctuation is small, the operability is good, and the working efficiency can be improved.

Owner:无锡汇虹机械制造有限公司

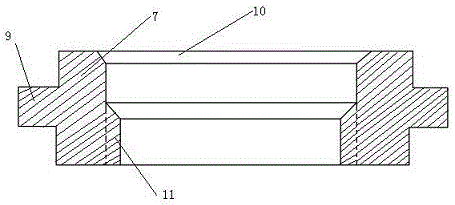

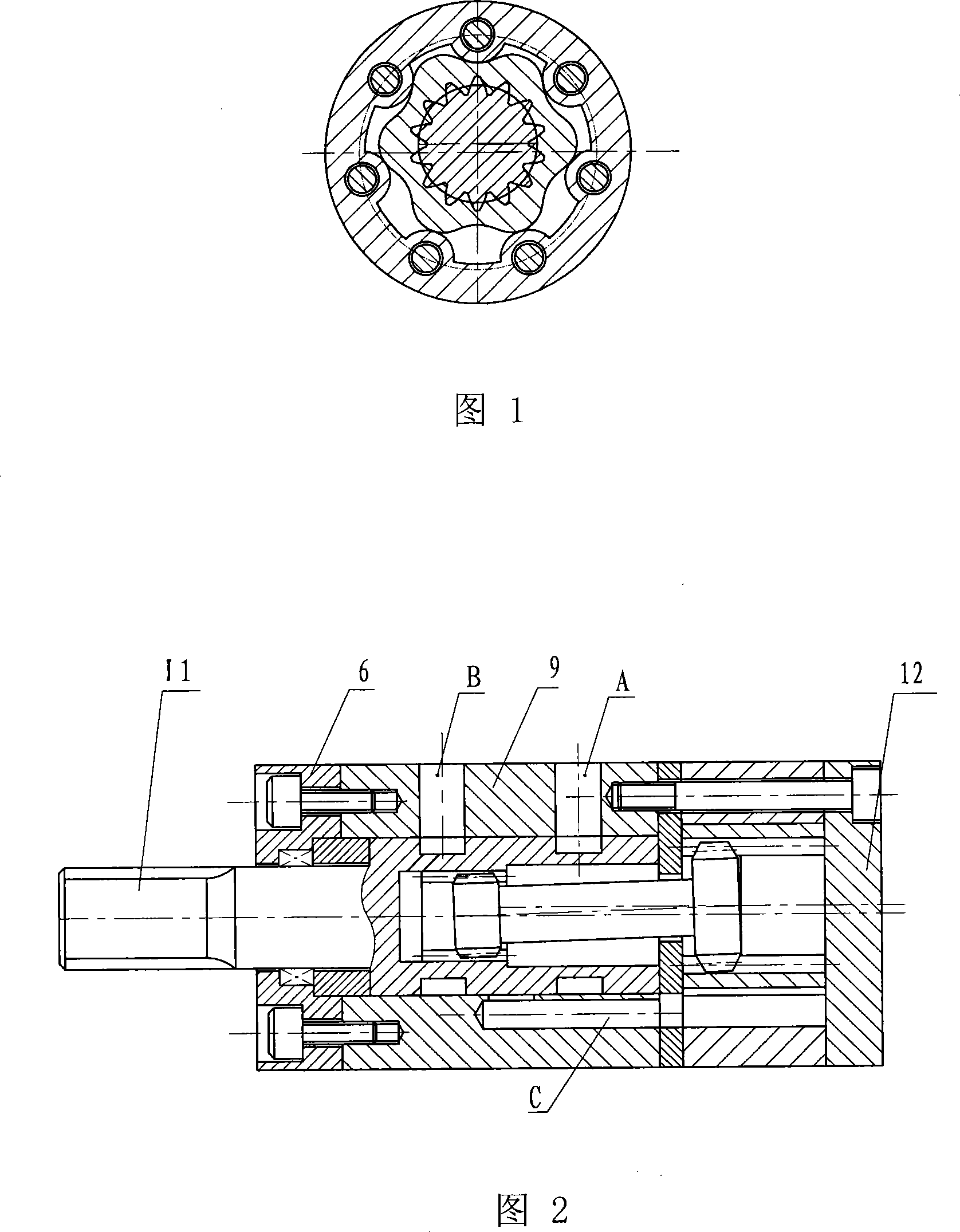

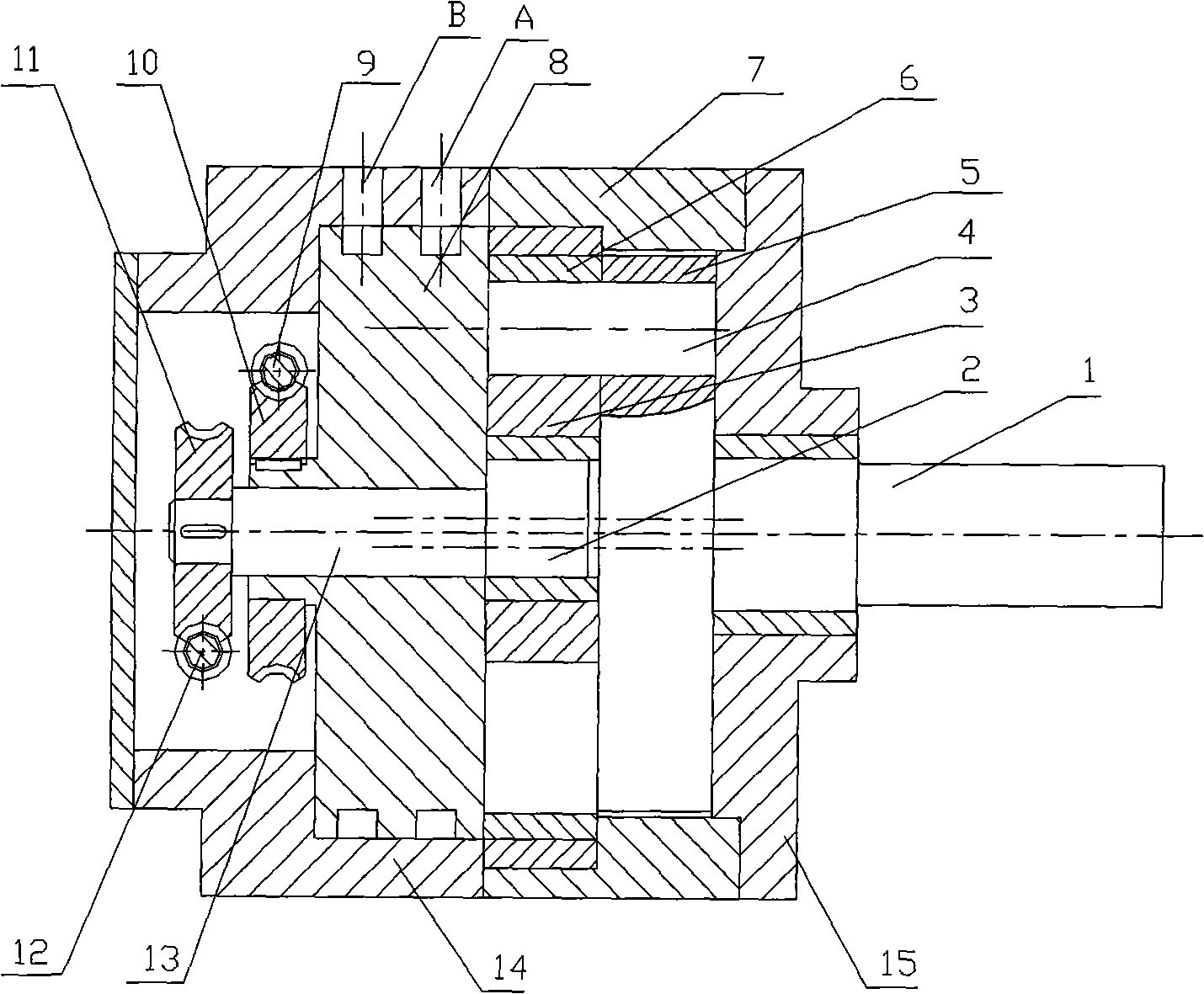

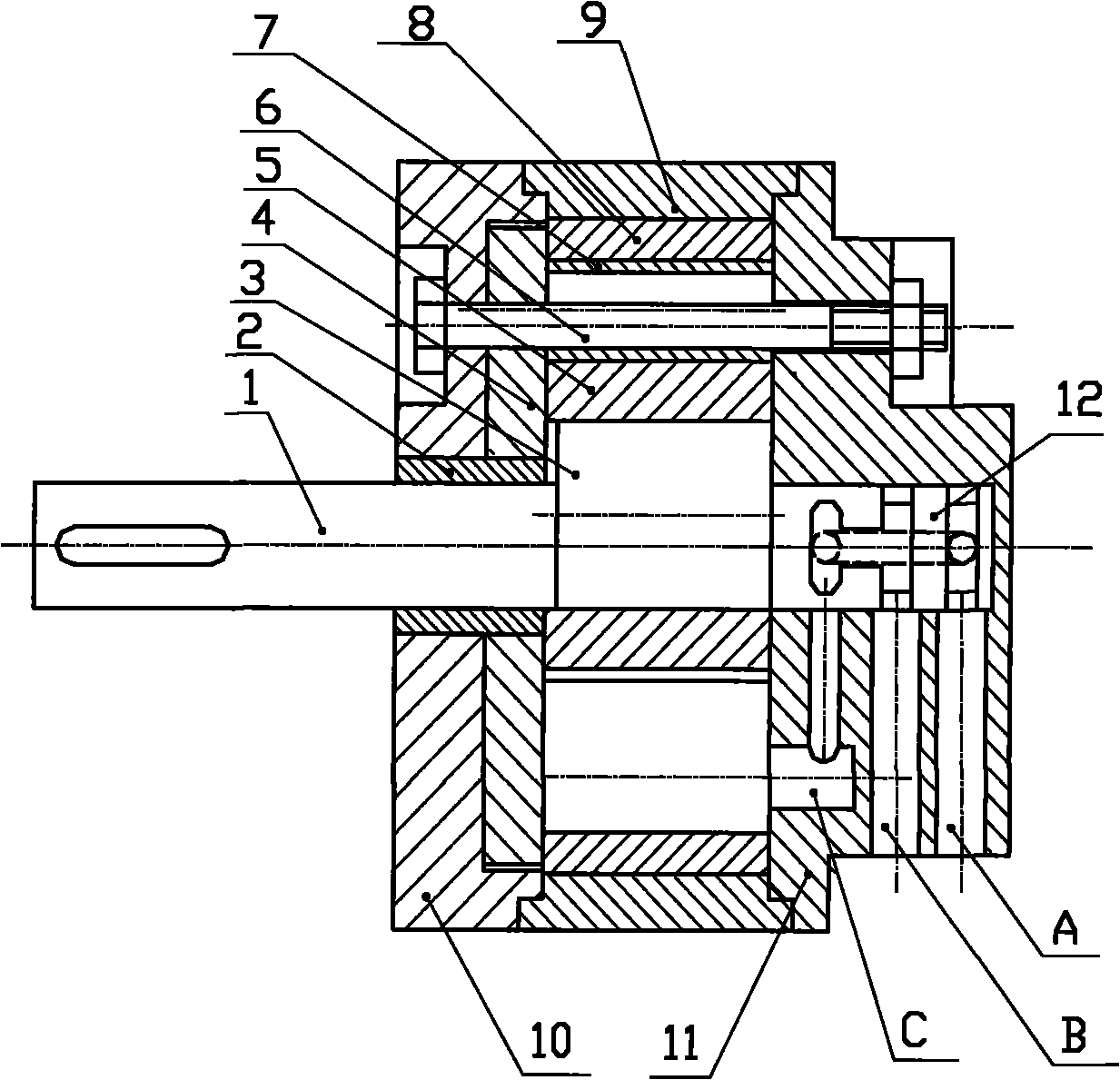

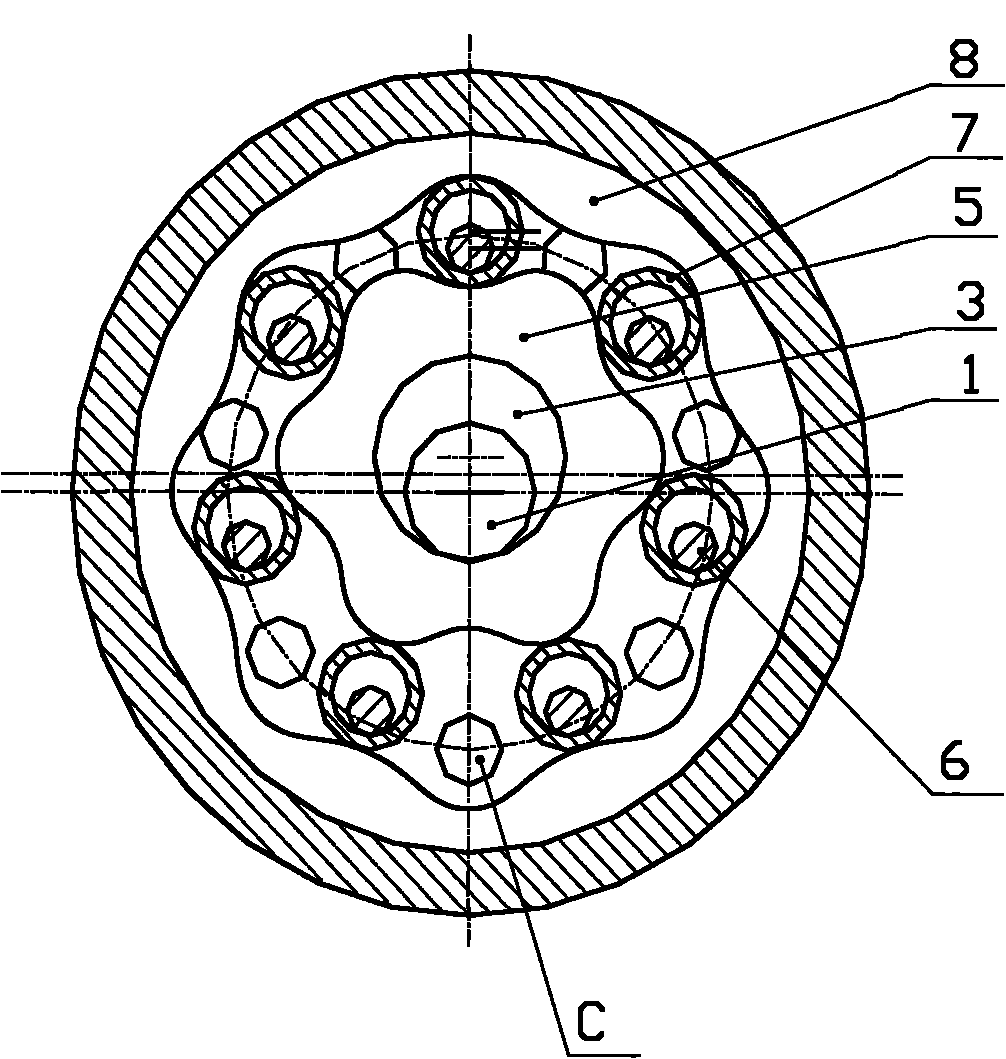

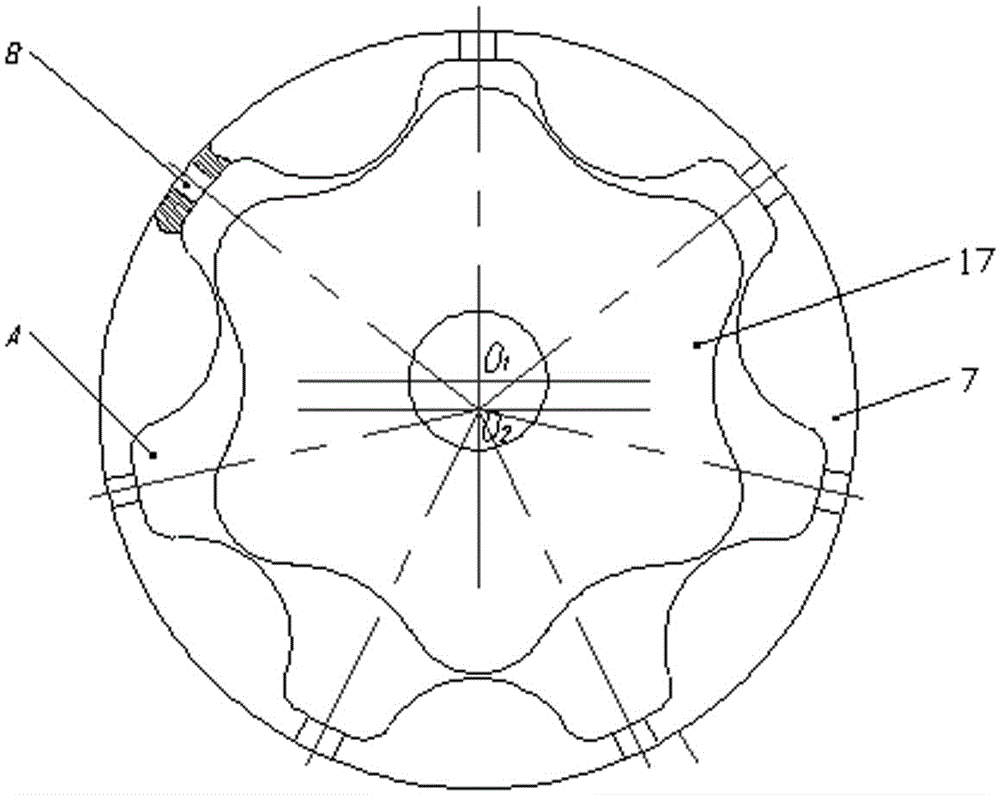

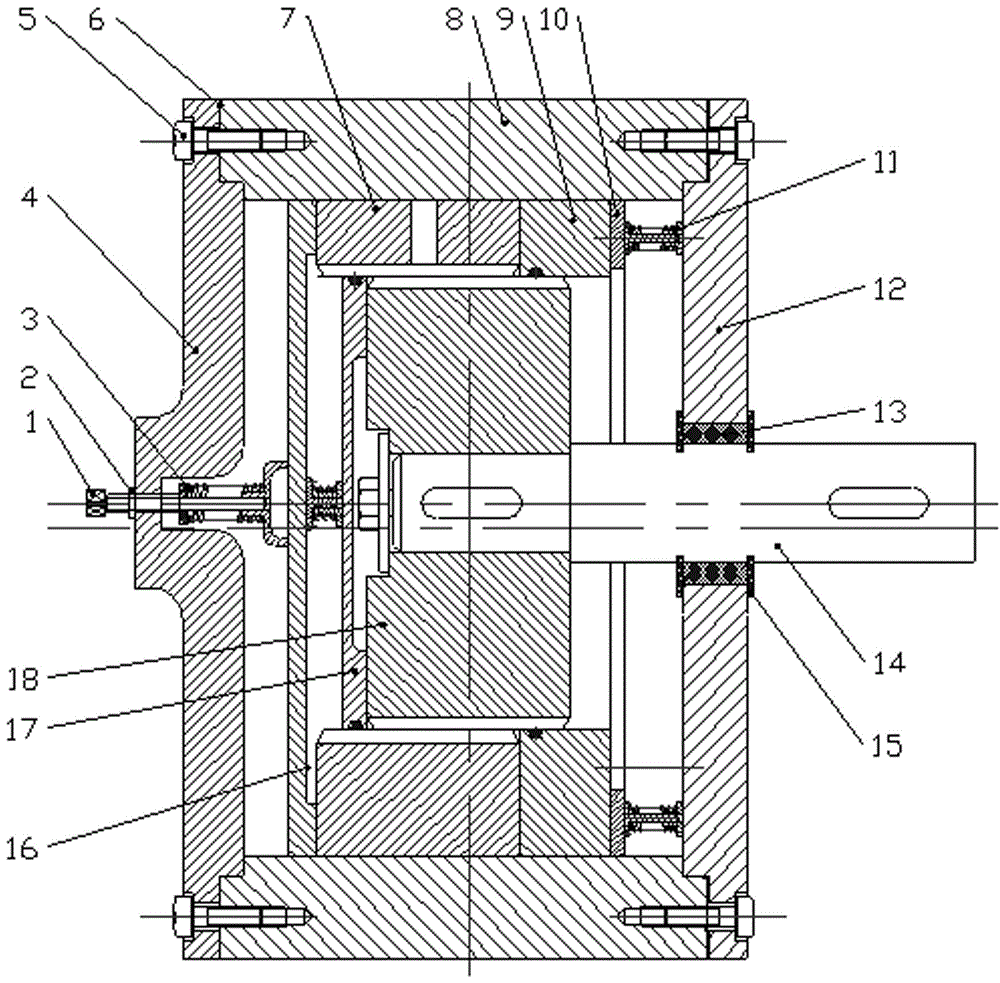

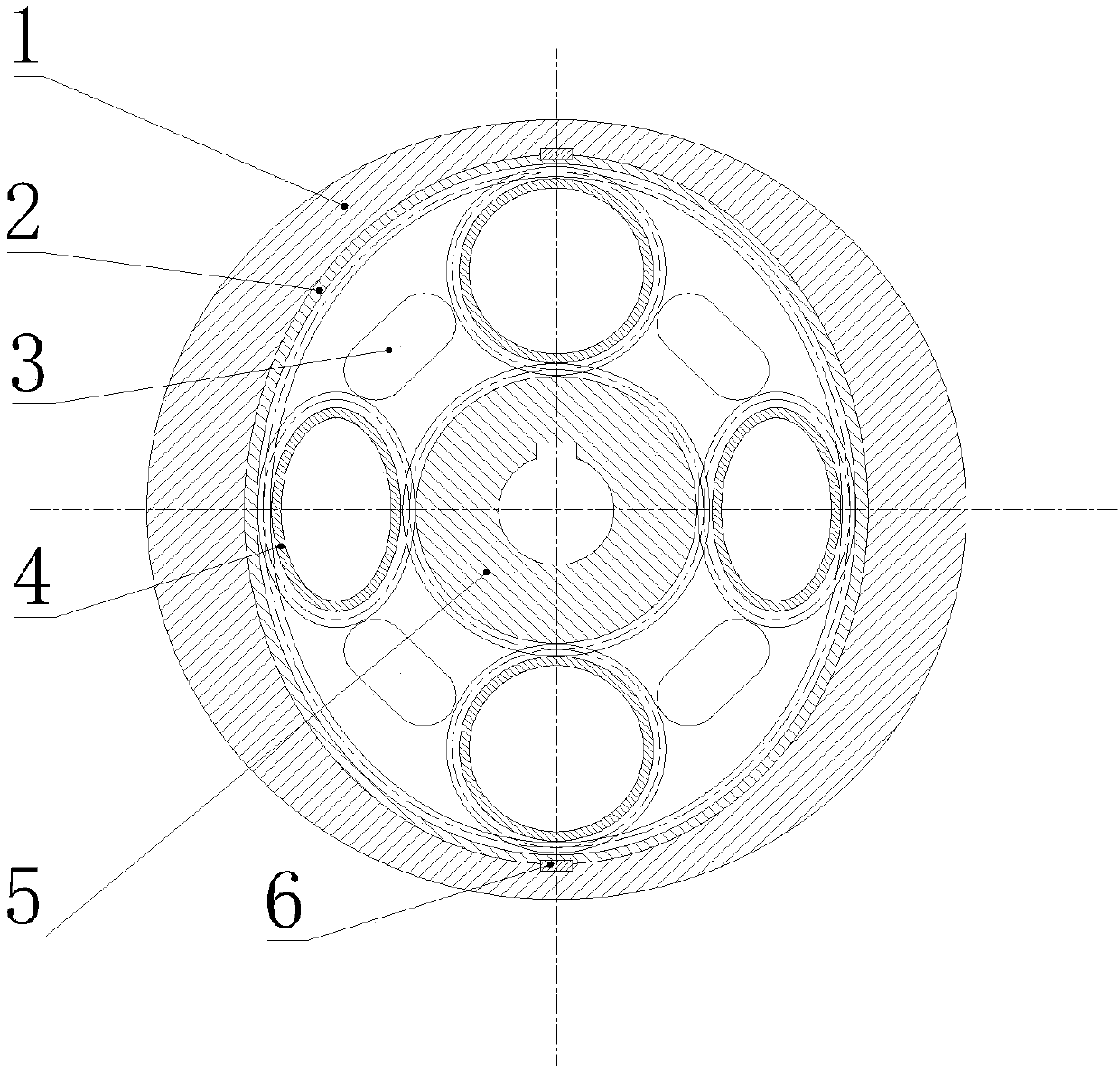

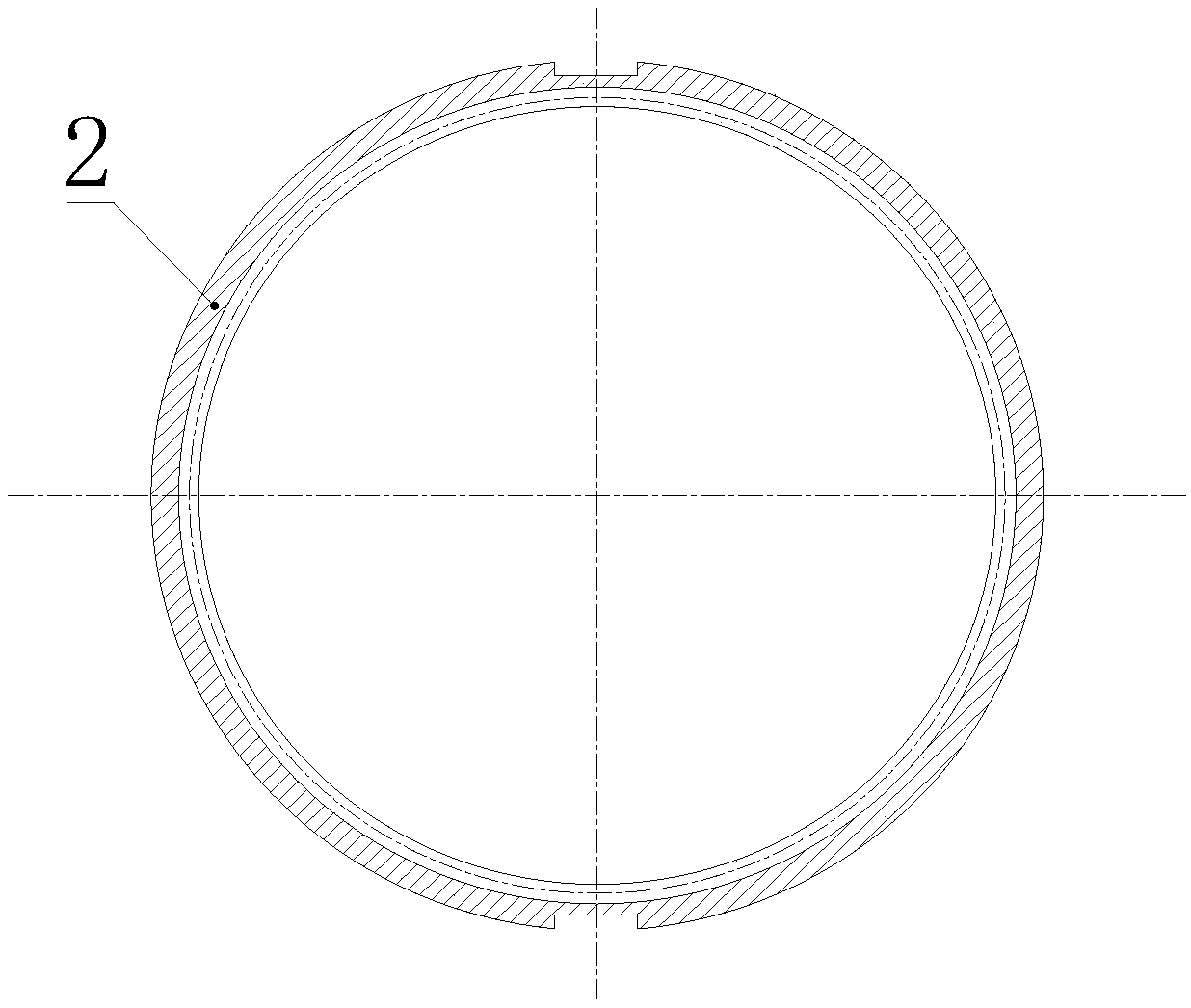

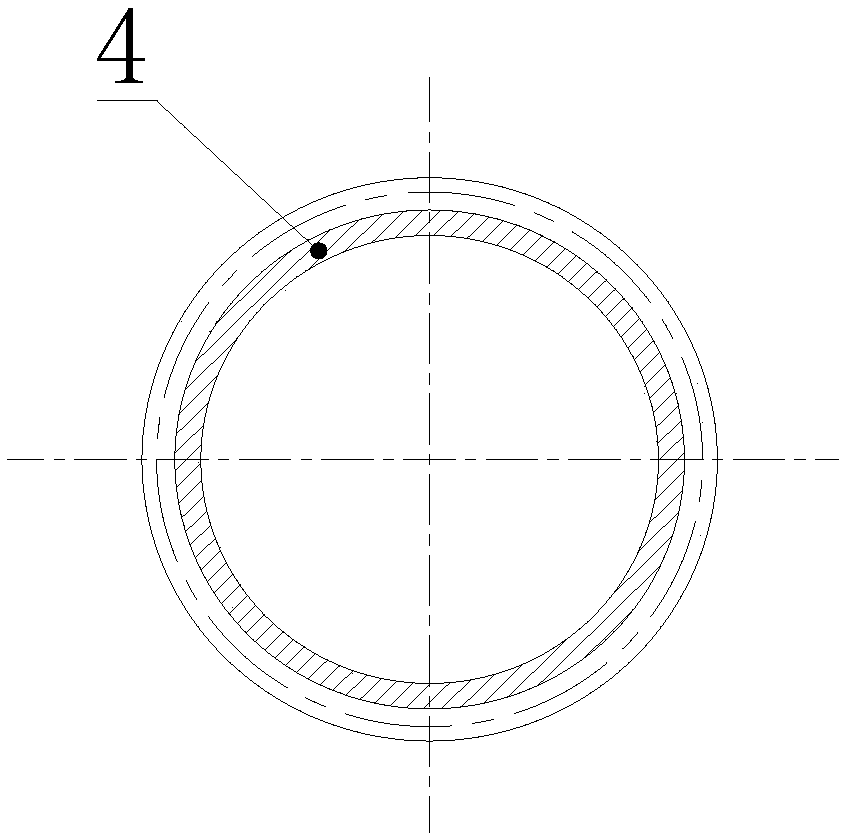

Pore-pin type cycloid rotor motor

InactiveCN101144461AReduce connectionsImprove eccentricityRotary piston pumpsRotary piston liquid enginesHydraulic motorHydraulic pressure

The invention relates to a hydraulic pressure cycloid rotor type motor structure. A hole pin type cycloid rotor motor, and comprises a front end cover (6), a machine seat (9), a rear end cover (12) and a flow distribution axle (10) positioned at the axle center of the machine seat (9), the invention is characterized in that the flow distribution axle (10) is extended into the casing body (7), and an inner rotator (2) is connected coaxially and fixedly; a short amplitude outer cycloid gear is arranged in the inner rotator (2); a plurality of sleeves (3) are embedded on the inner wall of the central cavity along the parallel operating plate (5); column pins (4) with the same number of the sleeves (3) are respectively penetrated into the sleeves (3), the diameter of the column pin (4) is smaller than the sleeve (3), the column pins (4) are vertically fixed on the machine seat (9) or the end covers (6) and (7), the distribution position on the plane of each column pin is the same as the sleeve (3), and the distance between the parallel operating plate (5) and the casing body (7) is larger than or equals to the diameter difference of the sleeve (3) and the column pin (4). The invention increases the displacement of the hydraulic motor; the torque and the speed are enhanced. The structure is simplified, the manufacturing process is improved, the cost is reduced, and the mechanical efficiency and the service life of the motor are enhanced.

Owner:SHANGHAI NORMAL UNIVERSITY

A continuous decoking method for a thermal plasma reactor

The invention discloses a continuous decoking method for a thermal plasma reactor. The continuous decoking method is characterized in that in the cleavage reaction process, decoking gas is continuously introduced to react with a coking material so as to finish coke cleaning; the decoking gas is carbon dioxide or a gas mixture of carbon dioxide and hydrogen. According to the invention, the pyrolysis gas flow and composition can't be influenced, the decoking can be conducted continuously, the continuous decoking method has the characteristics of short decoking time and high decoking efficiency, more safety and lower energy consumption; the continuous decoking method is suitable for different thermal plasma reactors and has an obvious cleaning effect for coking materials with different properties and content.

Owner:ZHEJIANG UNIV

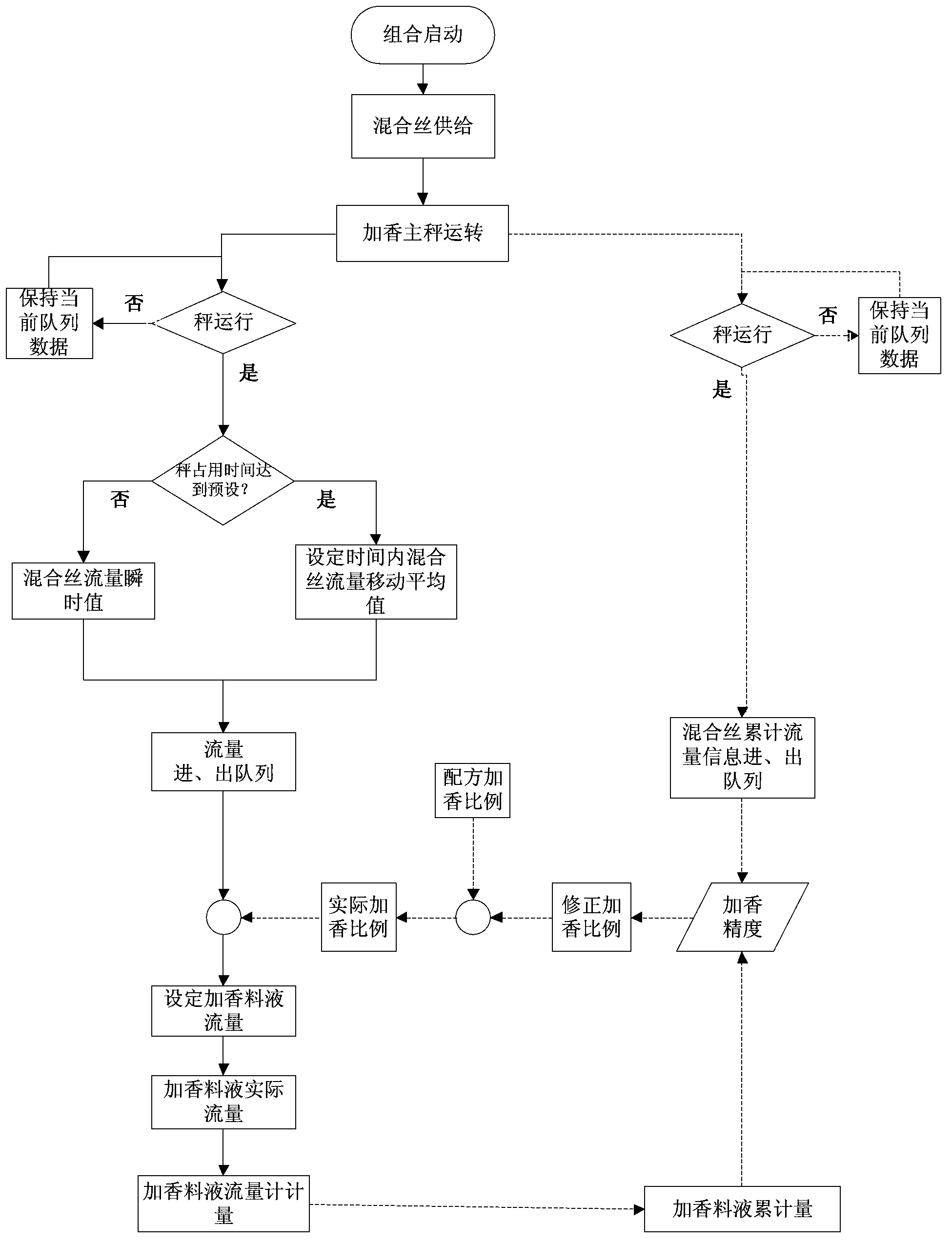

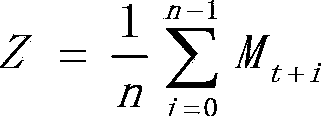

Flow control method and system for adding spice liquid in tobacco processing technology

InactiveCN103892432AReduce the flow fluctuation of flavoring liquidImprove stabilityTobacco preparationMoving averageStreamflow

The invention discloses a flow control method for adding spice liquid in the tobacco processing technology. The method comprises the steps that first, instantaneous flow information of mixed filaments is measured and collected in a fixed collecting cycle within a preset time period; second, a programmable controller is used for processing the instantaneous flow information obtained in the step one to obtain moving average information of the mixed filaments and feeding the moving average information back to a spice-liquid-adding flow controller; third, the spice-liquid-adding flow controller is used for controlling flow of added spice liquid according to the moving average information and a preset spice liquid adding formula proportion in the processing technology. The method can effectively lower fluctuation of flow of the added spice liquid caused by too large fluctuation of the instantaneous flow of the mixed filaments, achieve accurate control over flow of the added spice liquid, and improve stability of inner quality of products.

Owner:CHINA TOBACCO SHANDONG IND

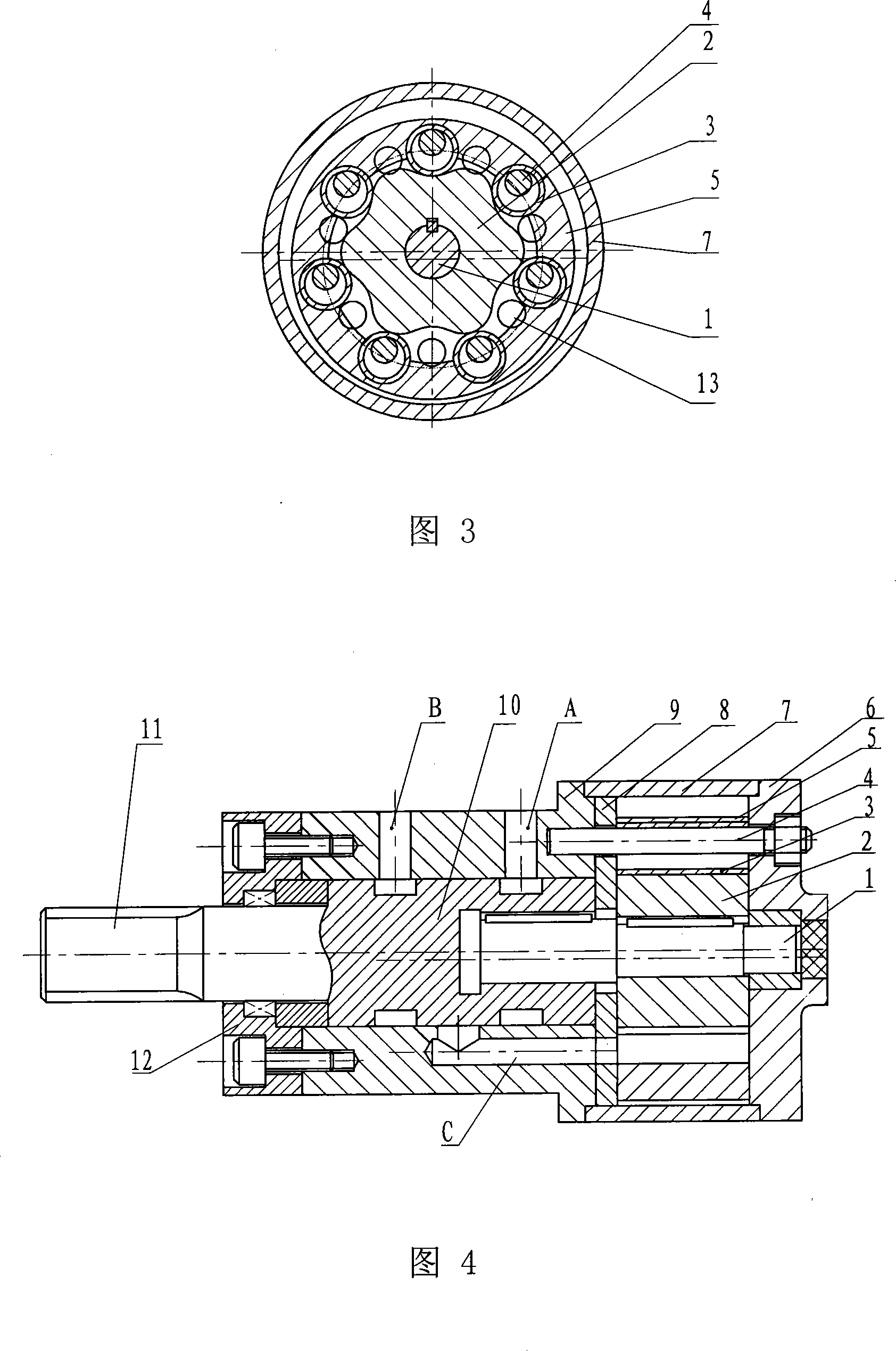

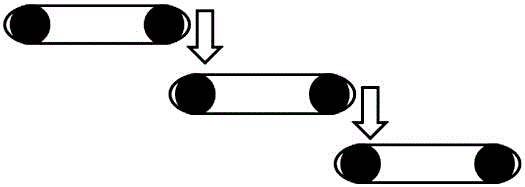

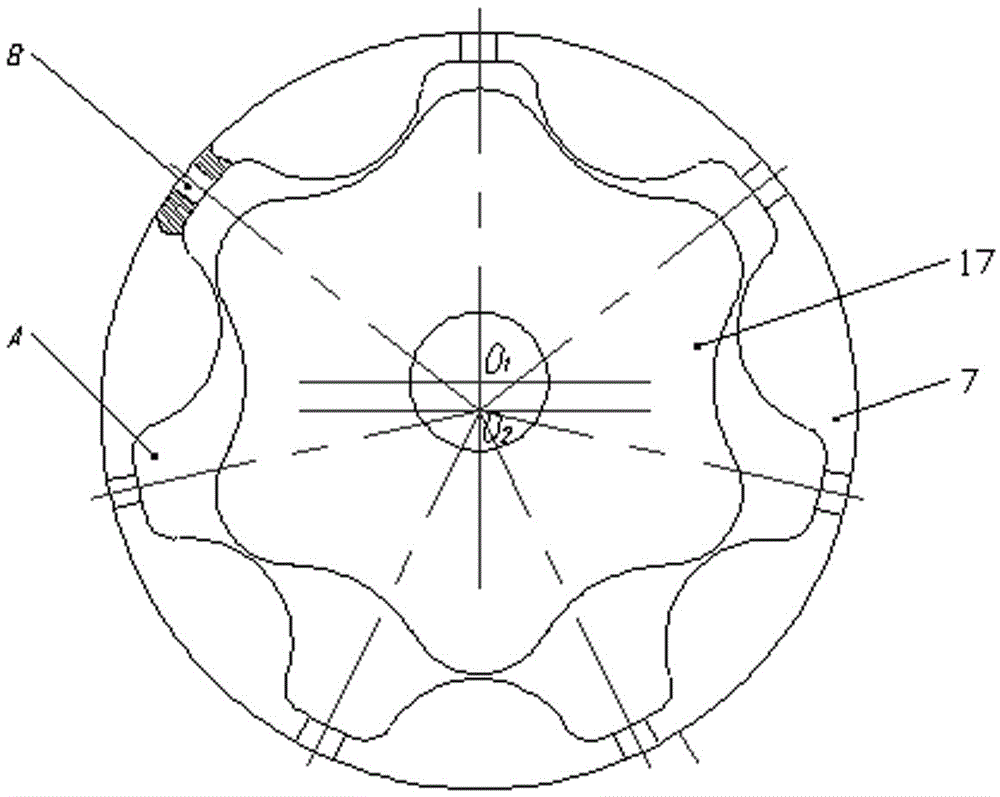

Double-cycloid rotor variable pump

InactiveCN101560973AEasy to adjustSimple structureRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention relates to a rotor pump structure which can change flow rate, in particular to a double-cycloid rotor variable pump; a rear end cover (14) is internally provided with a valve plate (8) which is provided with an oil inlet (A) and an oil outlet (B); a variable shaft (13) is inserted into the center of the valve plate (8); a variable mechanism is configured on the variable shaft (13); the right end of the variable shaft (13) is fixedly connected with an eccentric shaft (2) with the mutual axis position being deviated; a transmission shaft (1) is inserted into the center of a front end cover (15) and is fixedly connected with a rotating disc (5); a ring of cylindrical pin teeth (4) are arranged on the rotating disc (5) by a cantilever; the pin teeth exposed outside of the cantilever are inserted in a ring groove formed by matching of an outer rotor (6) and an inner rotor (3); and the axis of the front end cover (15) and the center of the circular inner wall of a shell (7) have eccentricity. The flow rate can be changed by rotating the eccentric shaft (2); the adjustment of the flow rate is simple, convenient and easy; and the continuity of absorbing and discharging oil is strong and the requirement to hydraulic oil is not high.

Owner:SHANGHAI NORMAL UNIVERSITY

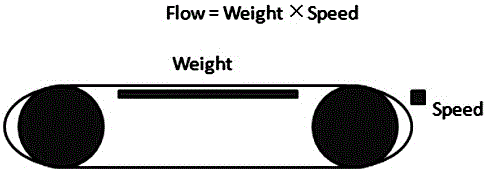

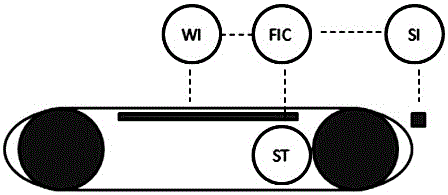

Linkage control method for multi-stage solid conveying equipment

ActiveCN105836421ALittle flow fluctuationAvoid consumptionControl devices for conveyorsCement factoryControl engineering

The invention discloses a linkage control method for multi-stage solid conveying equipment. The loading signal of lower-stage conveying equipment is adopted as the controlled variable for controlling the rotation speed of upper-stage conveying equipment, and PID control or model prediction control over the relation between the loading signal of the lower-stage conveying equipment and the rotation speed of the upper-stage conveying equipment is adopted. The method is easy to implement and high in control accuracy. According to the control effect of applying the linkage control method to a cement plant, the flow fluctuation of conveying equipment is obviously reduced, the control accuracy is obviously improved, the emptiness condition and the fullness condition are completely eradicated, and material consumption and energy waste are obviously reduced.

Owner:依泰可(诸暨)智能装备有限公司

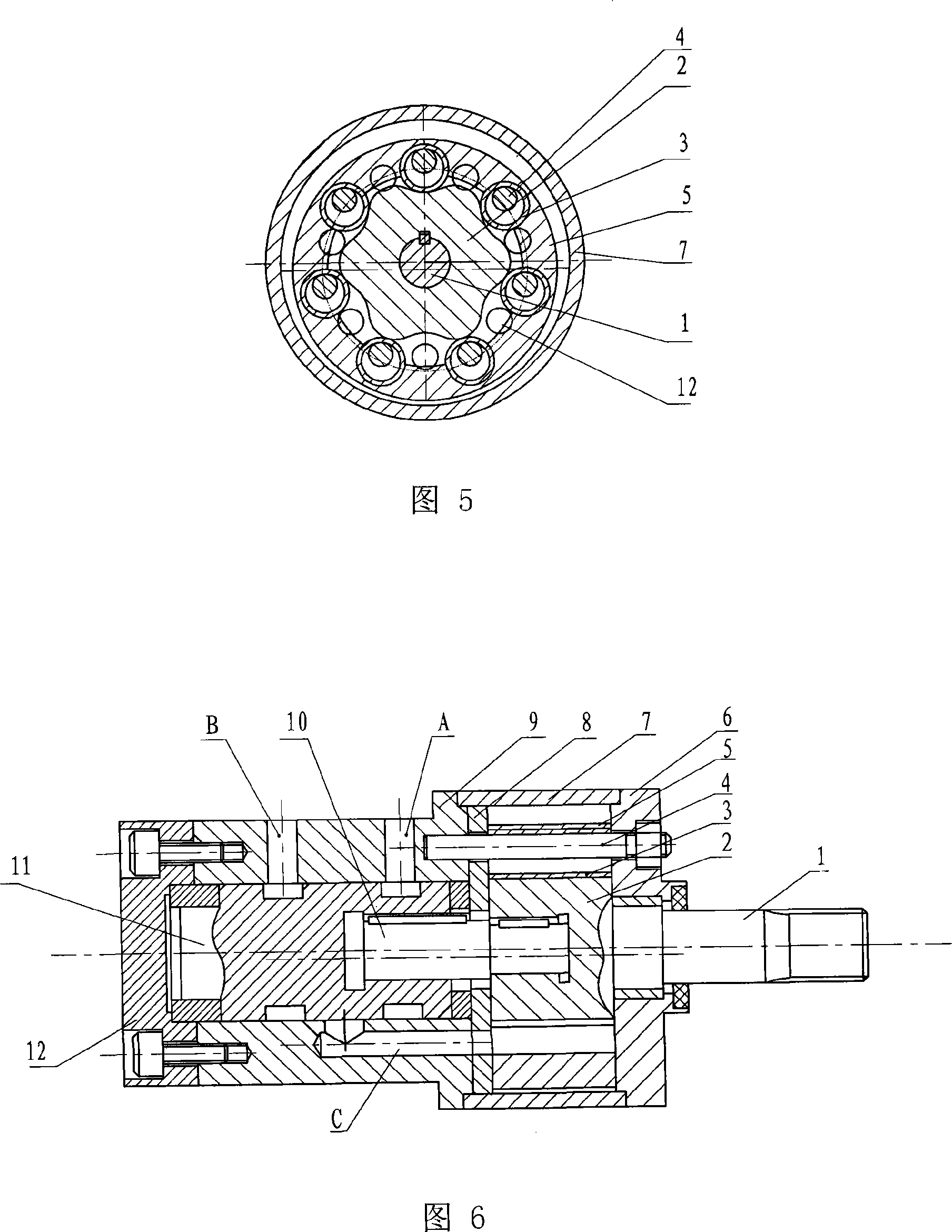

Eccentric double-cycloid rotor pump

InactiveCN101900110AHigh trafficOvercoming conventional thinkingRotary piston pumpsRotary piston liquid enginesDrive shaftHydraulic pump

The invention relates to a hydraulic transmission device, in particular to a hydraulic pump with the cycloid rotor structure. The eccentric double-cycloid rotor pump comprises a front cover (10), a shell (9), a rear cover (11) and a transmission shaft (9) which is arranged at the centre of a circle and extends in the shell (9), wherein the corresponding number of pins (6) are distributed on the concentric circumferences of the front cover (10) or rear cover (11); a sleeve (7) of which internal diameter is more than the external diameter of the pins (6) is sleeved on each pin (6); and the annular outer rotor (8) of a curtate hypocycloidal gear is sleeved on the outside of the circumference of the sleeve (7). The invention is characterized in that the inner rotor (5) of a curtate epicycloidal gear is sleeved on an eccentric shaft (3) which deviates form the connecting shaft of a transmission shaft (1). By adopting the eccentric shaft structure, the rotor pump has new characteristics on the original basis while the original advantages are maintained; and the axes of the inner and outer rotor have a certain eccentric distance, and the larger the centric distance is, the higher the flow is, thus higher flow can be obtained.

Owner:SHANGHAI NORMAL UNIVERSITY

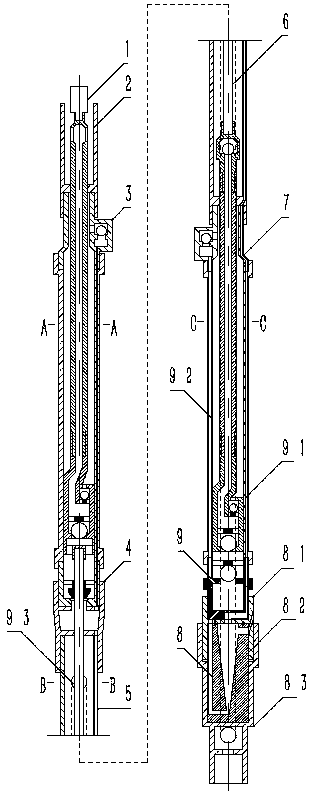

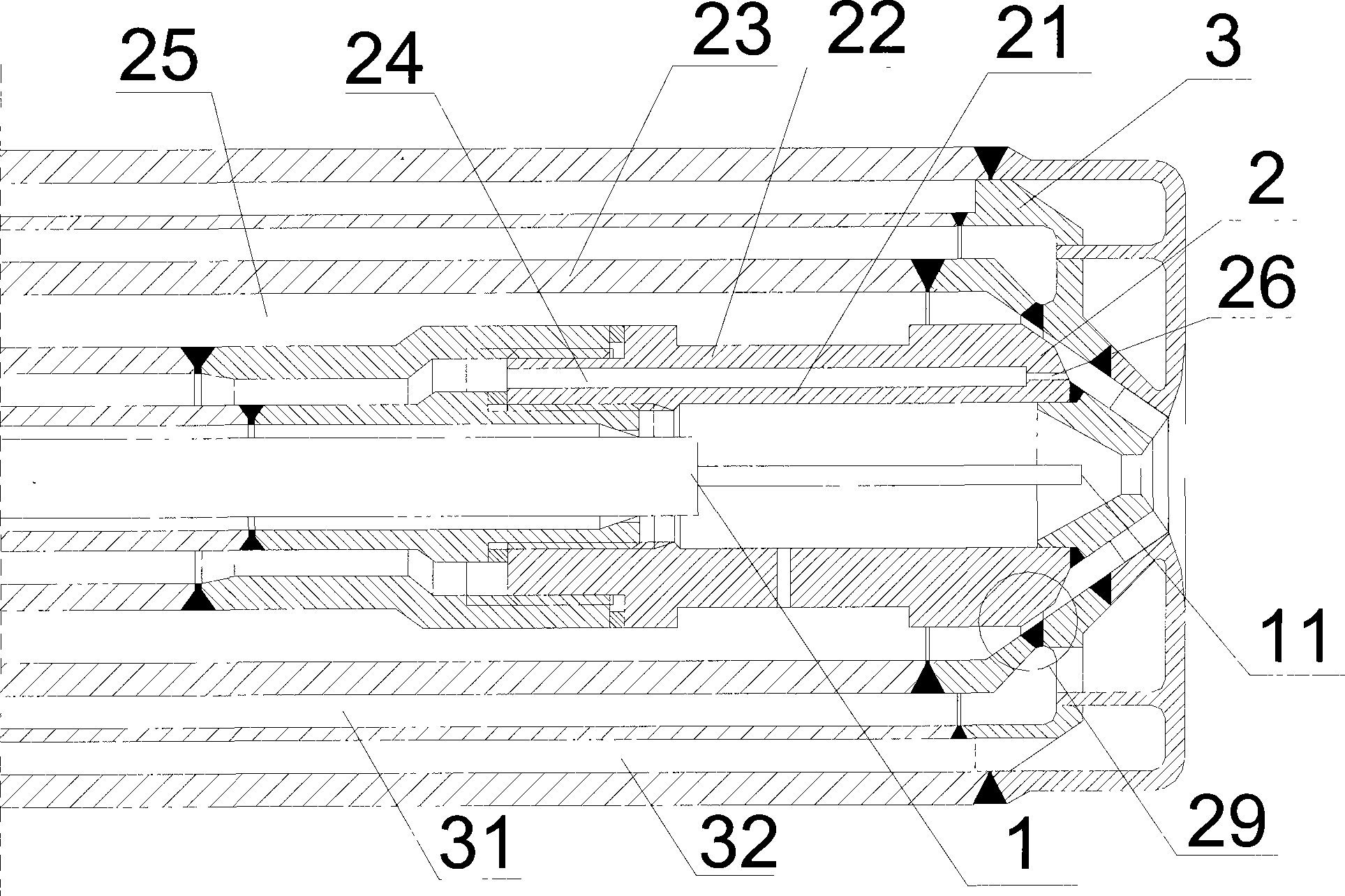

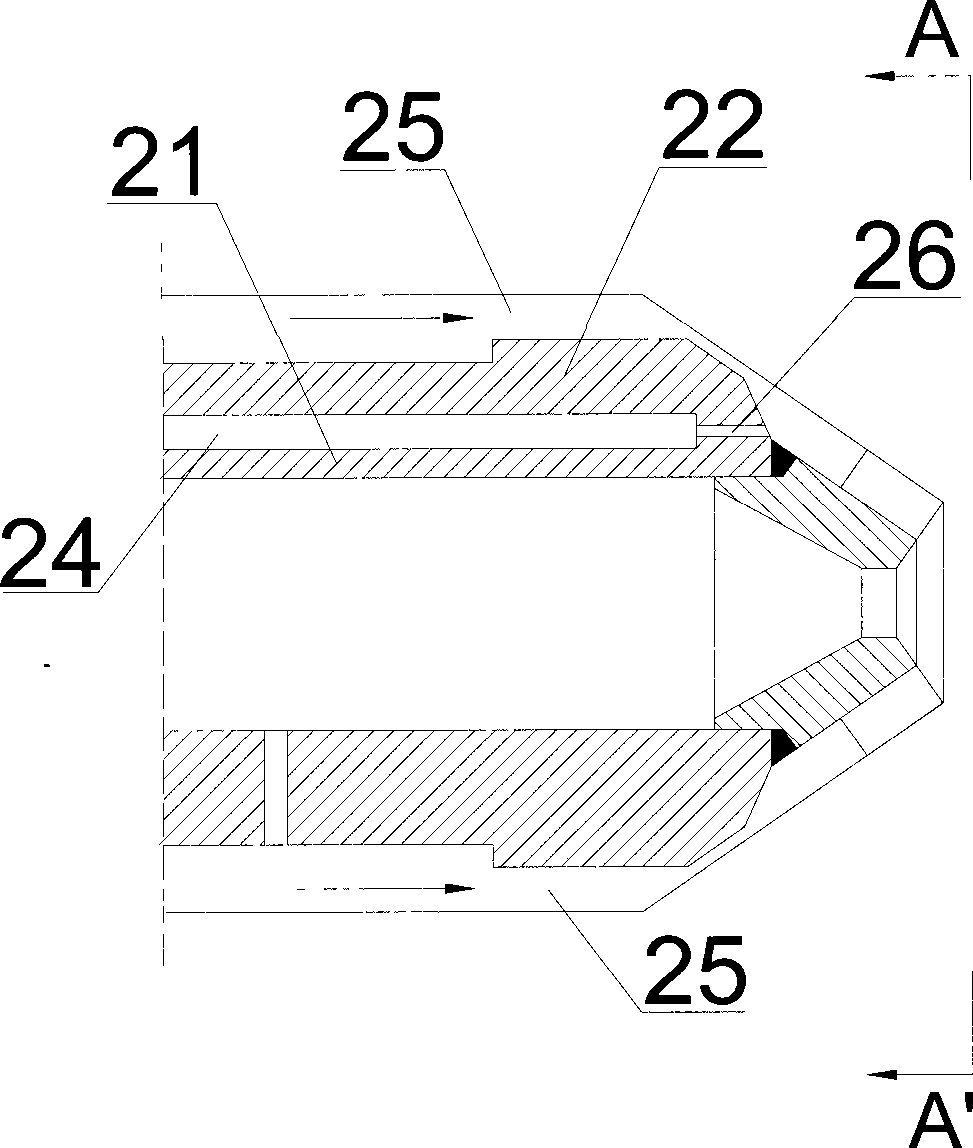

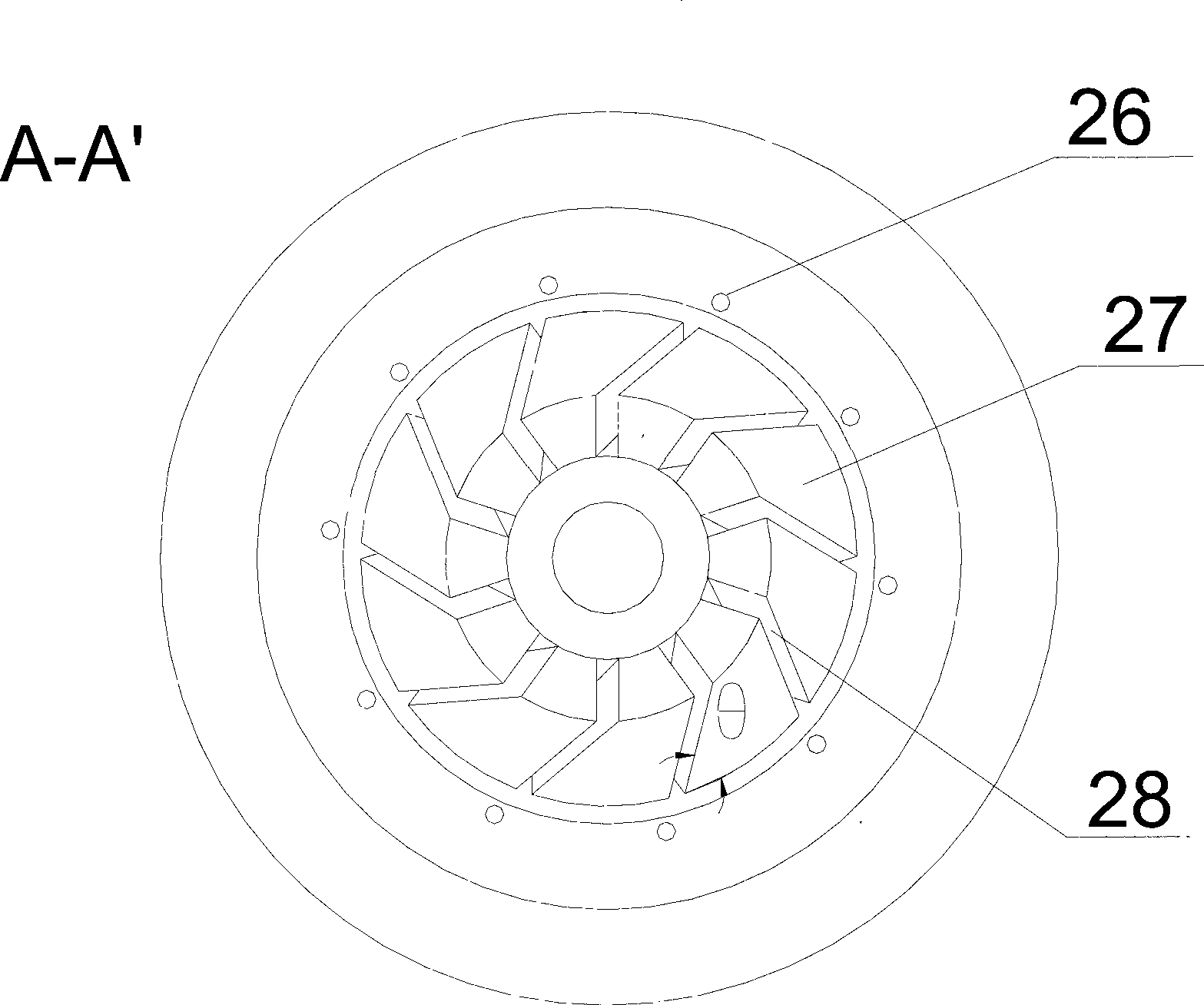

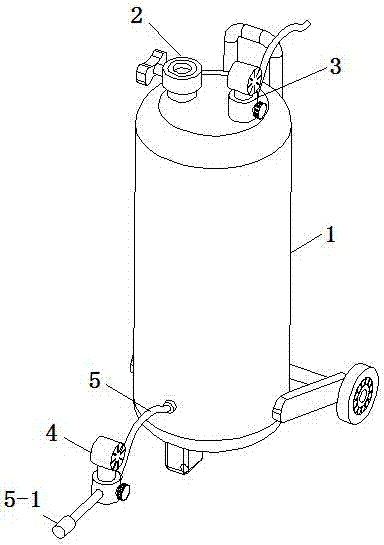

Series connected type double-acting injection-production pump for high-water-cut oil-producing well

PendingCN109973371ALittle flow fluctuationImprove separation efficiencyDrilling rodsPositive displacement pump componentsCouplingReciprocating motion

The invention relates to a series connected type double-acting injection-production pump for a high-water-cut oil-producing well. The series connected type double-acting injection-production pump mainly consists of a connecting-tripping device, an upper part tubing coupling, a double-acting oil pumping pump assembly, a middle coupling, a middle pump cylinder, a core rod, a double-acting water injection pump assembly, a swirler assembly and a flow channel, wherein the upper end of the double-acting oil pumping pump assembly is connected with the upper part tubing coupling; an upper plunger is arranged in the double-acting oil pumping pump assembly; the connecting-tripping device is mounted at the upper end of a connector of the connecting-tripping device of the upper plunger; the lower endof the double-acting oil pumping pump assembly is sequentially connected with the middle coupling and the middle pump cylinder; the lower end of the middle pump cylinder is connected with the double-acting water injection pump assembly; a lower plunger is arranged in the double-acting water injection pump assembly, and is connected with the upper plunger through the core rod; the swirler assemblyis mounted at the lower end of the double-acting water injection pump assembly; and when the oil pumping rod is in reciprocating motion once, the series connected type double-acting injection-production pump completes oil recovery twice and waterflooding twice, so that the flow fluctuation of liquid entering a downhole swirler can be reduced, and the separation efficiency of the downhole swirler is improved.

Owner:SOUTHWEST PETROLEUM UNIV

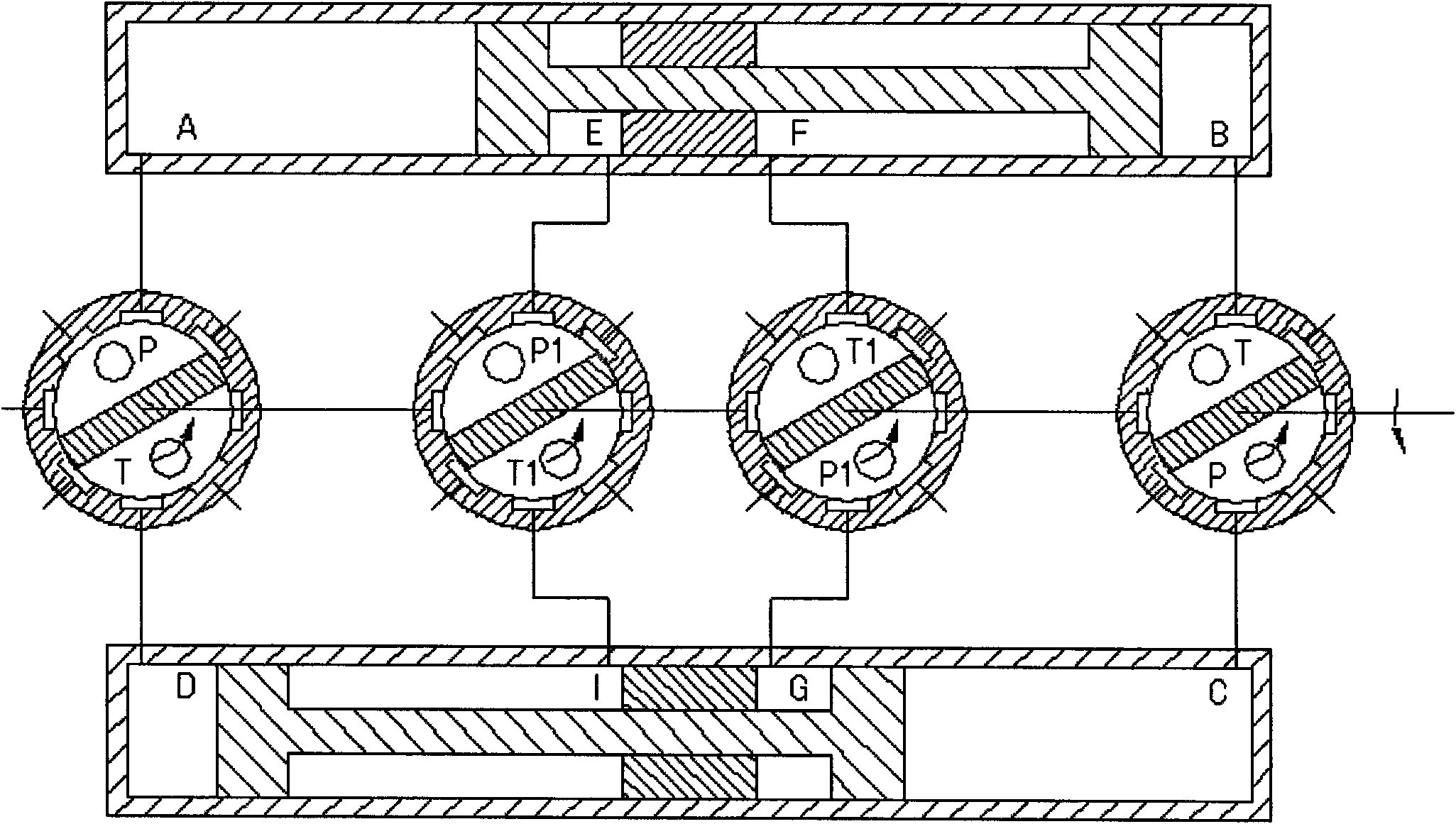

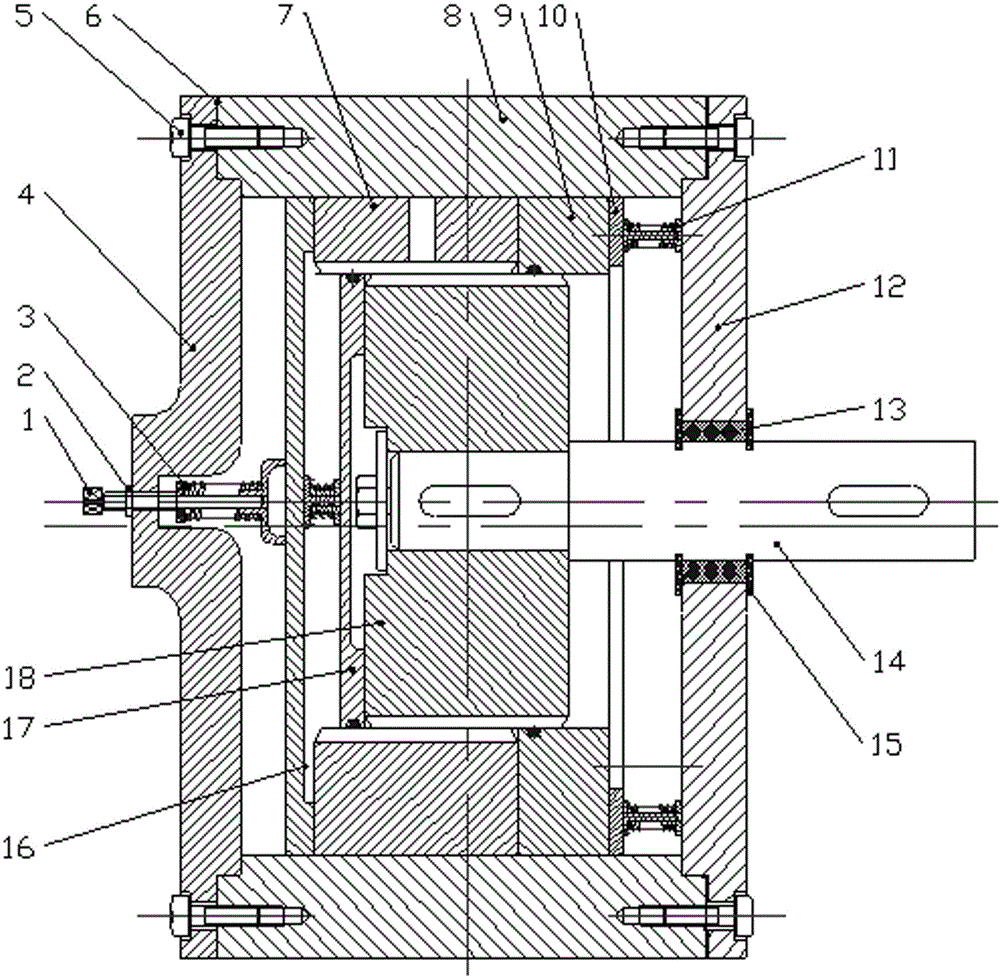

Positive displacement liquid pressure energy recovery device

InactiveCN102128188AImprove capacity utilizationReduce volumeFluid-pressure actuator componentsEnergy recoveryEngineering

The invention belongs to the field of liquid pressure technical equipment, and in particular relates to a positive displacement liquid pressure energy recovery device by which liquid with excessive pressure is required to be used or discharged under reduced pressure in the industrial production process. The device comprises end covers, a pump body, a double-acting pressurization tank piston, a double-acting pressurization tank body, a bearing, a flow distribution shaft and a speed regulation motor, wherein the bearing is arranged on the pump body and is used for supporting the flow distribution shaft; the flow distribution shaft is arranged in the central hole of the pump body in a movable fit way; the two end covers are used for fixing the flow distribution shaft and limiting the movement of the flow distribution shaft in the axial direction; the speed regulation motor is fixed on one end cover at one end through a screw; and an output shaft of the speed regulation motor is connected with the flow distribution shaft through a key. By the device, energy emitted by the liquid with the excessive pressure in the industrial production process can be effectively used and recycled, and production cost can be reduced; and the device has a wide application range.

Owner:丁春生

Fuel gas generator

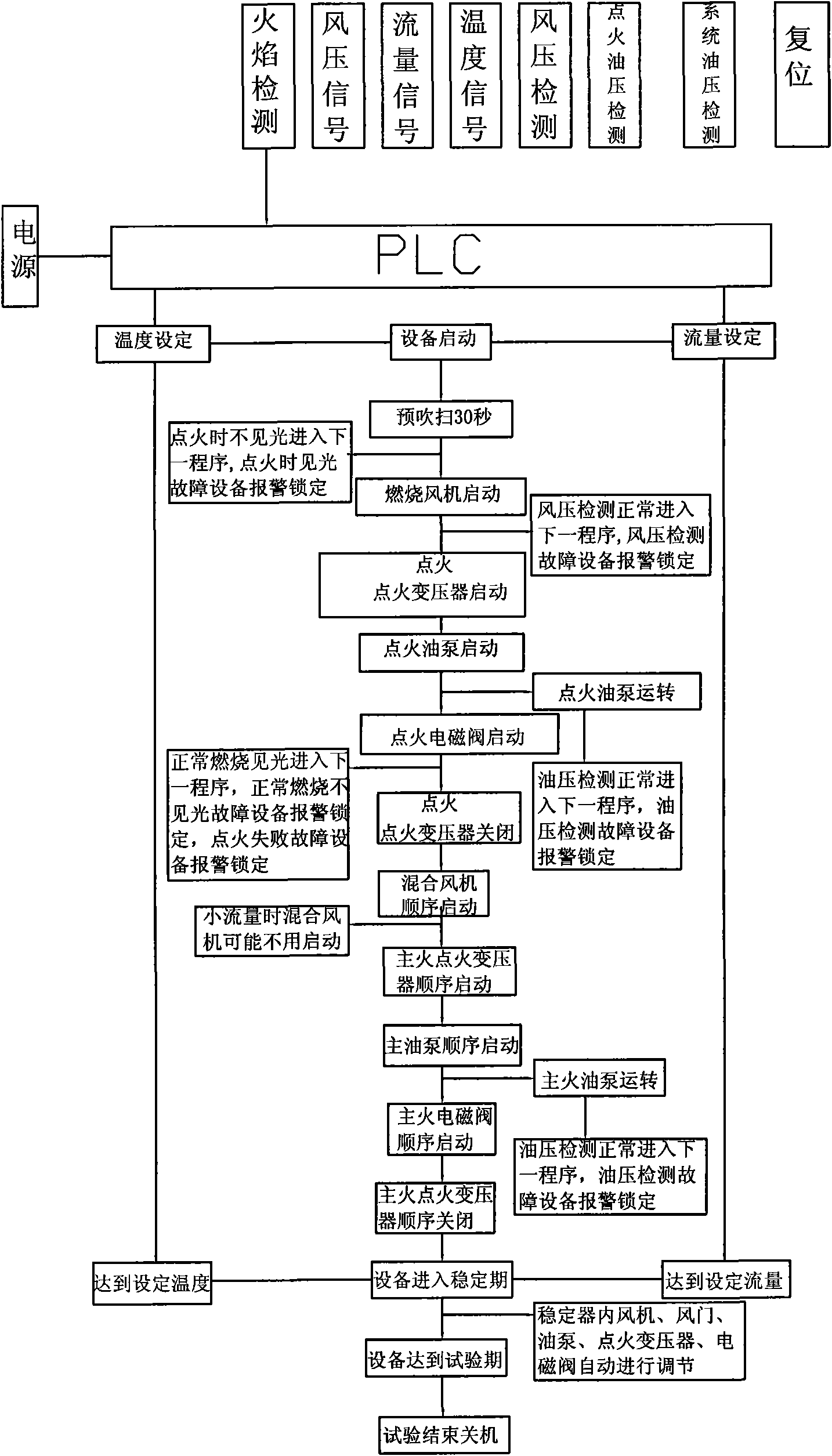

InactiveCN101608978ASave electricityExtended service lifeStructural/machines measurementProgramme control in sequence/logic controllersProcess engineeringGas generator

The invention discloses a device capable of generating high-temperature high-pressure smoke gas, in particular to a fuel gas generator which can muffle under test states, save energies and have high burning efficiency. The technical proposal is as follows: the fuel gas generator is characterized by consisting of a fuel gas generator body, an air supply system, a burning system, a detecting system, a PLC control system, an oil supply system, and a balancing air adjusting system, wherein the air supply system consists of a burning fan and a mixed fan; the burning system consists of a burning blow gun; the burning blow gun is arranged on the side wall of the fuel gas generator body; the detecting system consists of a flowmeter, a pressure sensor and a thermoelectric couple; the flowmeter, the pressure sensor and the thermoelectric couple are respectively connected with the PLC control system; the PLC control system receives a signal transmitted from the detecting system and implements control on the air supply system and the burning system; the air supply system consists of an oil supply pump set; the oil supply pump set is connected with the oil path of the fuel gas generator body; and the balancing air adjusting system consists of a balancing air valve.

Owner:刘洪斌

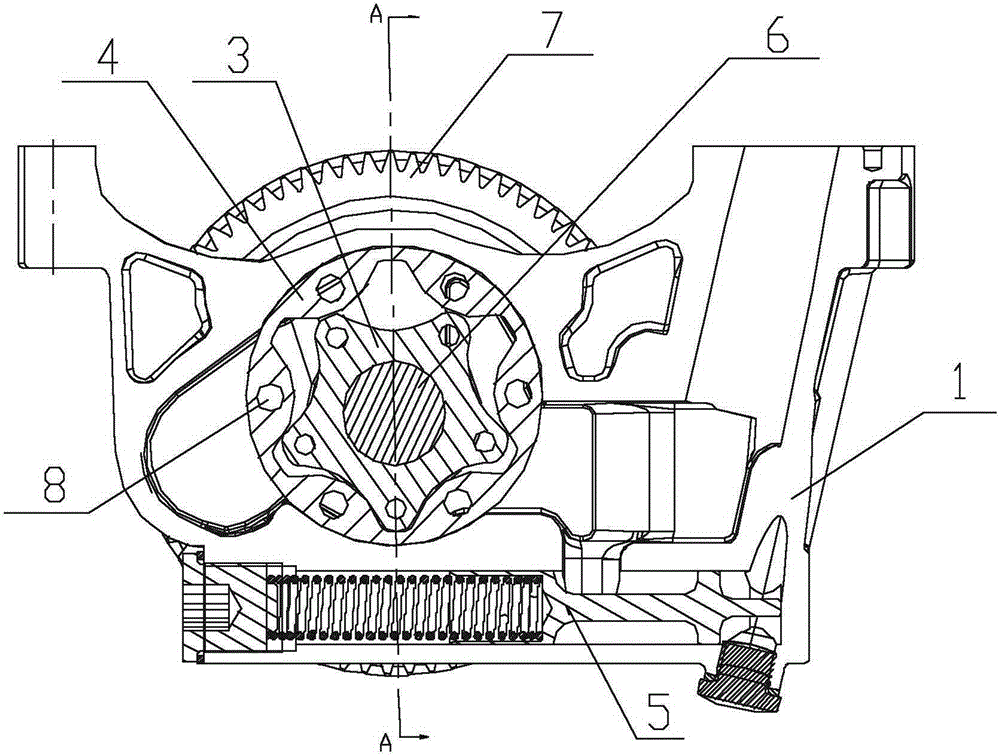

Light large-flow oil pump

The invention provides a light large-flow oil pump which comprises a pump body, a pump cover, an inner rotor, an outer rotor, a pressure-limiting valve, a drive shaft and a transmission gear, wherein the inner rotor and the outer rotor are positioned in a rotor cavity of the pump body; end surfaces of the inner rotor and the outer rotor are provided with weight-reducing holes; one end of the drive shaft is mounted on the transmission gear; the other end of the drive shaft penetrates through a shaft hole of the pump body for being mounted on the inner rotor; the pressure-limiting valve is an inner relief type pressure-limiting valve; the pump body and the pump cover are aluminum die-casting fittings; and the pump cover is mounted on the pump body through a bolt. According to the technical scheme, the inner and outer rotor type structures and the inner relief type pressure-limiting valve are adopted, so that the structure of the whole oil pump is relatively compact; the pump body and the pump cover are aluminum die-casting fittings, and the end surfaces of the inner rotor and the outer rotor are provided with weight-reducing holes, so that weight is reduced; and oil in the inner relief type pressure-limiting valve can be returned into an oil inlet of the oil pump to supplement oil inlet amount, so that flow fluctuation of the oil outlet is reduced.

Owner:HUNAN OIL PUMP

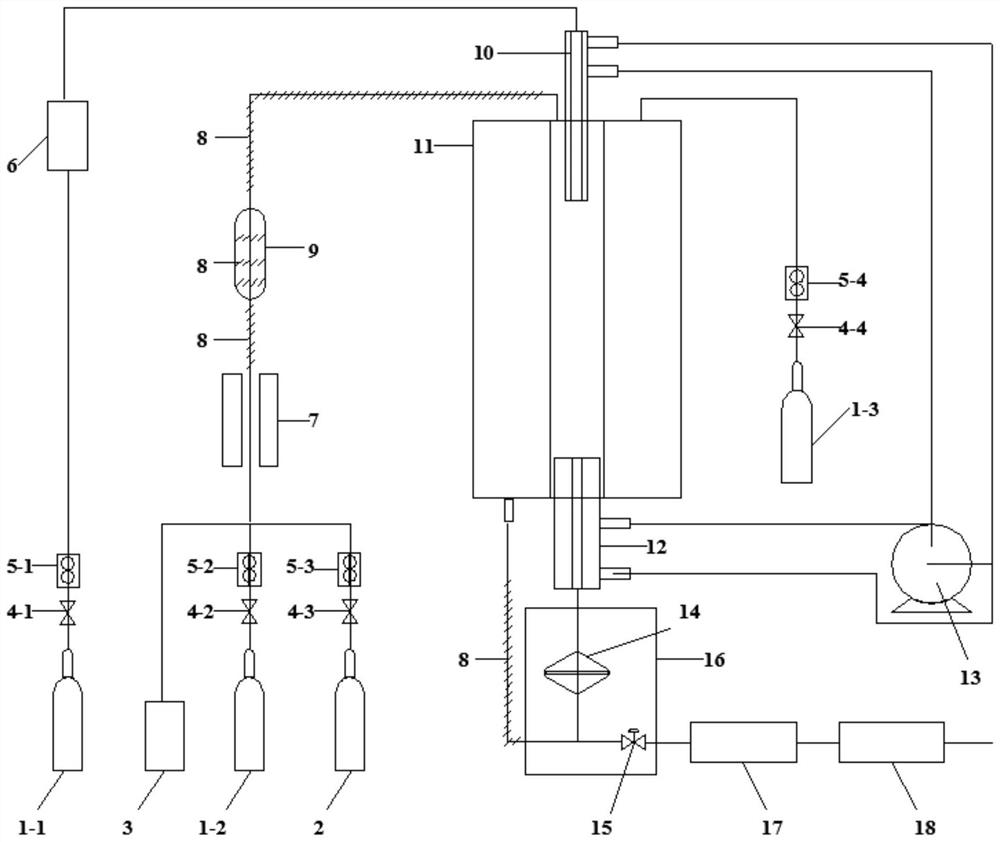

Gasification/combustion performance testing device for solid fuel under pressurized oxygen-water vapor condition and use method of gasification/combustion performance testing device

ActiveCN113406297AImprove combustion efficiencyStable pressure controlFuel testingOxygen tankFlue gas

The invention relates to a gasification / combustion performance testing device and a use method thereof, in particular to a gasification / combustion performance testing device for solid fuel under a pressurized oxygen-water vapor condition and a use method of the gasification / combustion performance testing device, aims to solve the problem that an experimental research system and method for pressurized oxygen-water vapor combustion mode performance evaluation are unavailable at present. The device consists of an inert gas tank, an oxygen tank, a high-pressure constant-flow water injection pump, a powder feeder, a preheating furnace, a heating belt, a premixing tank, a sample injection gun, a one-dimensional furnace, a sampling gun, a gas-solid separator, a high-temperature-resistant back pressure valve, a constant-temperature box, a water-vapor separator and a flue gas analyzer. The method comprises the steps that: solid fuel particles are placed in the powder feeder, the inert gas tank is opened, the one-dimensional furnace is heated, the inert gas tank and the oxygen tank are opened, the high-pressure constant-flow water injection pump is started,the high-temperature-resistant back pressure valve is adjusted,the powder feeder is started for thermochemical conversion, and meanwhile gas phase detection is conducted; and the water injection pump, the inert gas tank and the oxygen tank are closed, the high-temperature-resistant back pressure valve is adjusted, heating and residual particle sample and condensate water detection are turned off, and operation is repeated.

Owner:HARBIN INST OF TECH

Composite startup burner for powder coal gasification furnace

ActiveCN101665725BLittle flow fluctuationLittle change in speedCombined combustion mitigationGranular/pulverulent flues gasificationFront neckHigh pressure

The invention discloses a composite startup burner for a powder coal gasification furnace. The composite startup burner comprises an inner burner and an outer burner which are provided with a front necking end respectively and are coaxially sleeved from the inside to the outside, wherein a cooling water jacket adopting a single-spin mode is arranged on the periphery of the outer wall of the outerburner; the front end of the inner burner is provided with an ignition electrode; and the nozzle of the burner is provided with a supersonic atomization device. The composite startup burner adopts supersonic atomization to ensure that the burner has small fluctuations in fuel and atomization airflow rate, and a little change in outlet speed in a process that the back pressure rises continuously so as to ensure the atomization effect and high-temperature flame far from the head of the burner; the composite startup burner adopts a center ignition mode to save an ignition burner to realize the two-in-one function, and adopts a single-spin cooling mode to ensure that the head of the burner is protected from damage under the condition of high temperature and high pressure to prolong the service life of the burner.

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD

Device used for measuring water flow of drip irrigation products and use method

The invention relates to a device and a using method for measuring the water flow of drip irrigation products. Connect the tap water pipe to the water injection valve, connect the air pressure adjustment valve to the air pump, and connect the drip irrigation belt to the PVC hose outlet; open the handle of the water injection valve, and close the water injection valve when the water volume is 3 / 4 of the volume of the pressure vessel barrel Handle; start the air pump, open the air pressure regulating valve handle to inject compressed air; open the water pressure regulating valve to pass water, immediately start timing with a stopwatch, then convert the flow rate per hour, and close the water pressure regulating valve, record the water in each measuring cup Whether the liters of water conform to the rated value of drip irrigation products, such as 1L, 2L, 3L, the range of liters generally fluctuates within 0.1L is a qualified product; in this way, the precise measurement of drip irrigation belt products can be realized in a simple and fast way. This technology only needs to invest in equipment once, without other additional costs, and saves nearly 200,000 yuan in product measurement costs a year.

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

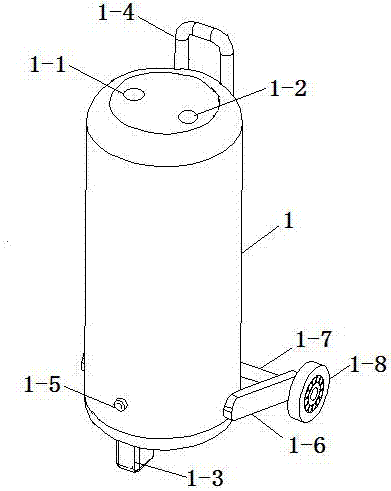

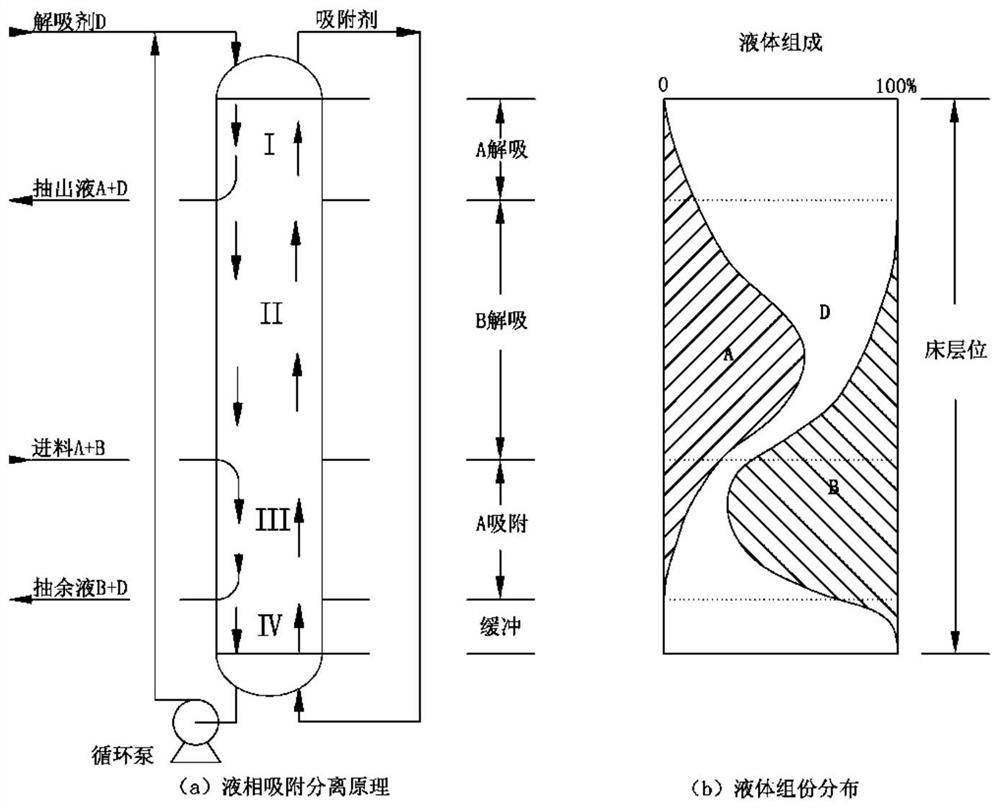

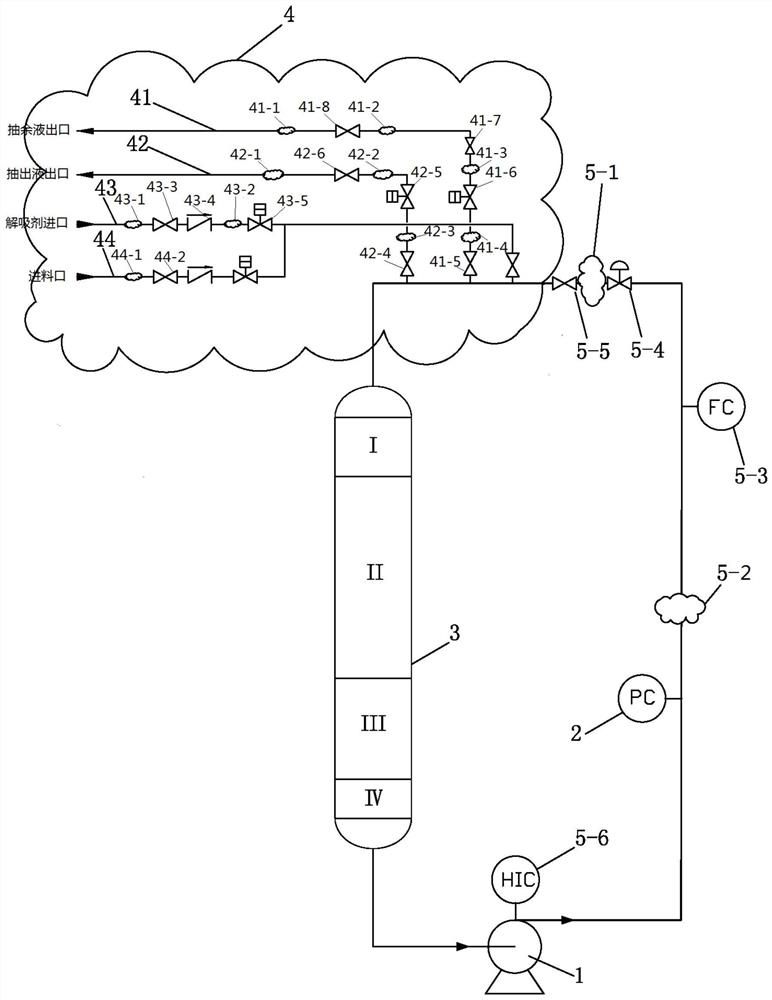

Liquid-phase adsorption separation system

PendingCN112245971AGuaranteed unchangedReduce outlet pressureSolid sorbent liquid separationFluid phaseSeparation technology

The invention discloses a liquid phase adsorption separation system, and belongs to the technical field of adsorption separation. The liquid phase adsorption separation system comprises a liquid phaseadsorption separation circulating tower, liquid phase adsorption separation circulating bed layer pipelines, a pumping circulating pipeline, variable frequency circulating pumps and a pressure controller, wherein the bottom end of the liquid phase adsorption separation circulating tower is connected with one end of the variable frequency circulating pump through a pipeline, the other end of the variable frequency circulating pump is connected with the top end of the liquid phase adsorption separation circulating tower through the pumping circulating pipeline, a pumping circulating pipeline damper is arranged on the pumping circulating pipeline, the liquid phase adsorption separation circulating tower bed layer pipeline is arranged between each bed layer of the liquid phase adsorption separation circulating tower and the pumping circulating pipeline, and a viscous damper is arranged on the liquid phase adsorption separation circulating tower bed layer pipeline. The system can reduce the energy consumption of liquid phase adsorption separation system equipment, reduce pipeline vibration, eliminate pipeline stress, reduce the pressure difference between the front portion and the rearportion of a regulating valve, increase the flexibility of load regulation and the like.

Owner:恒力石化(大连)炼化有限公司

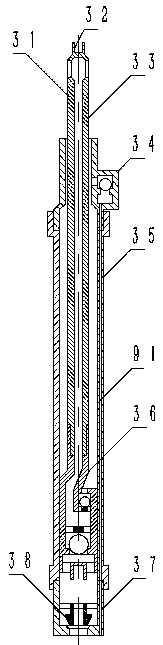

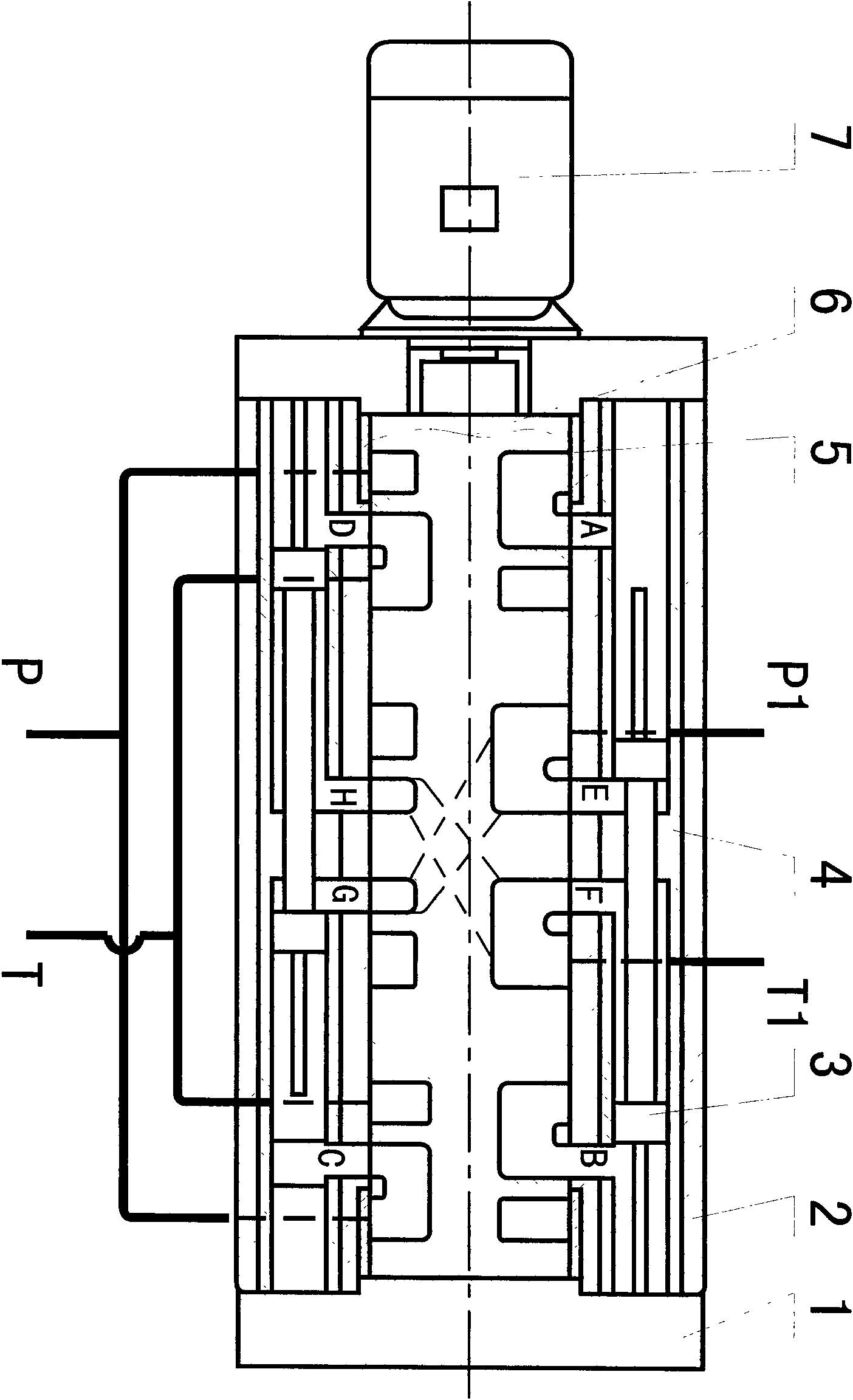

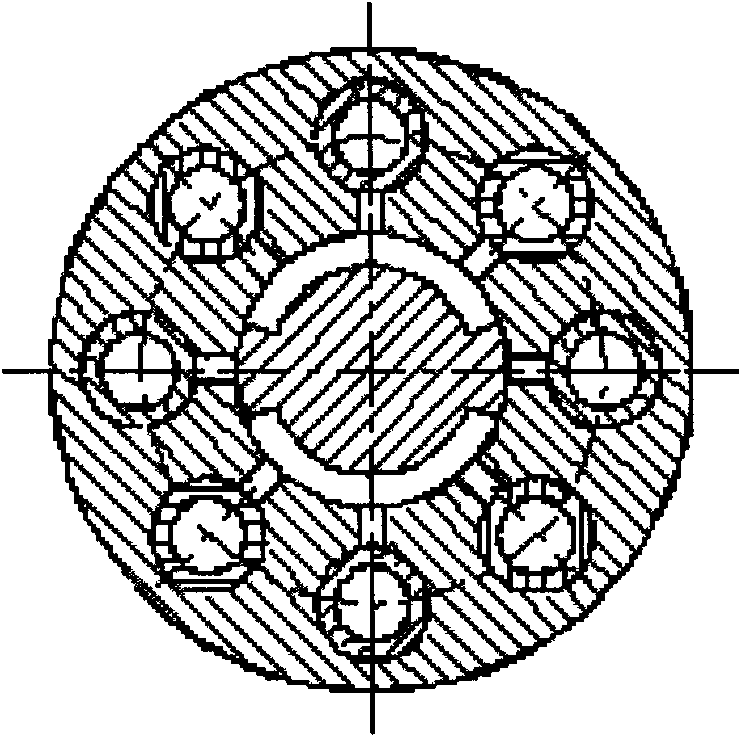

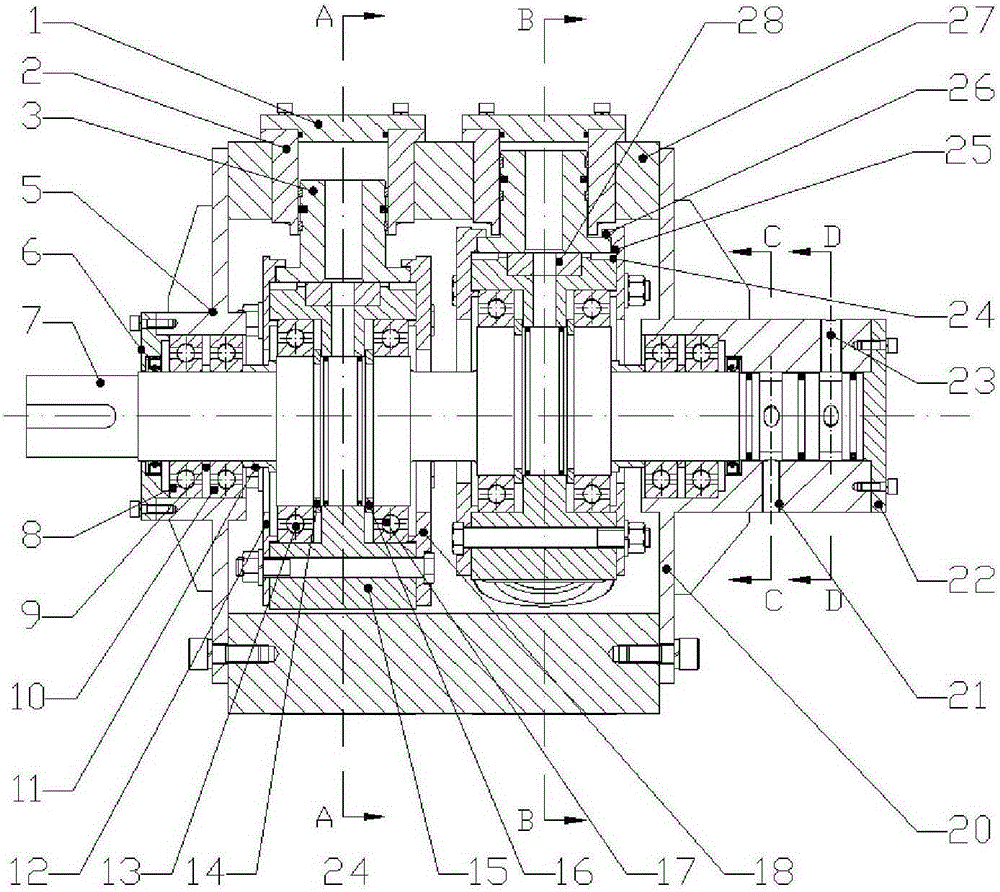

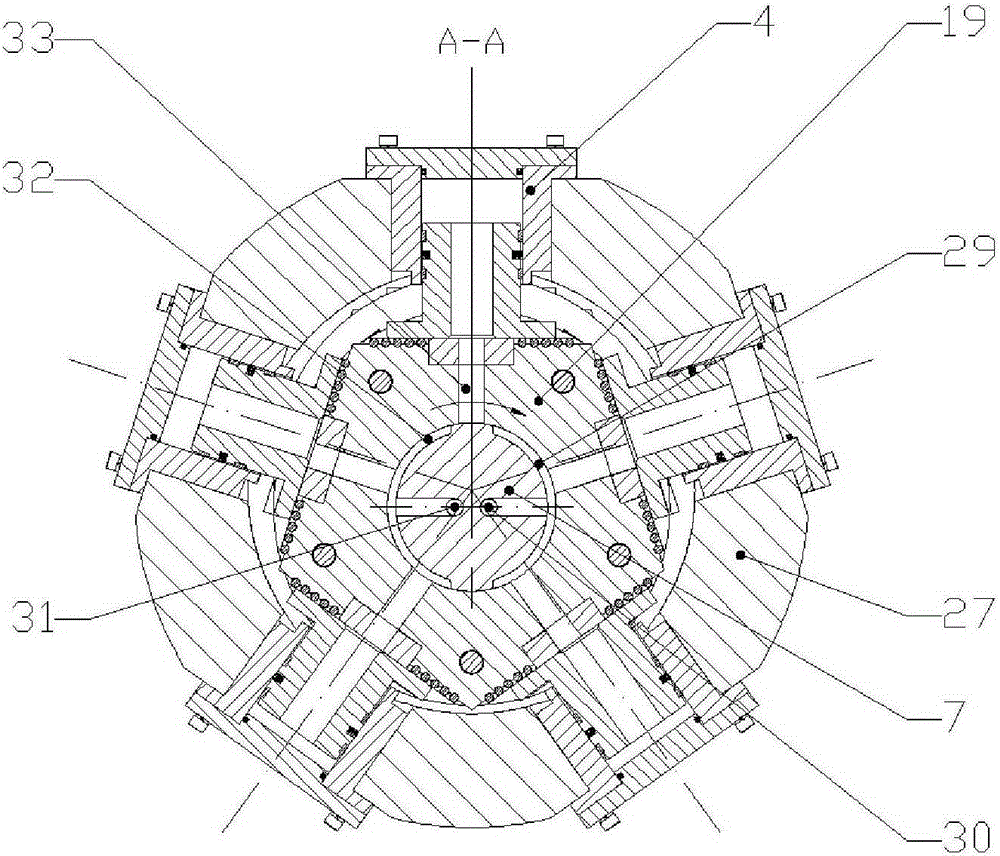

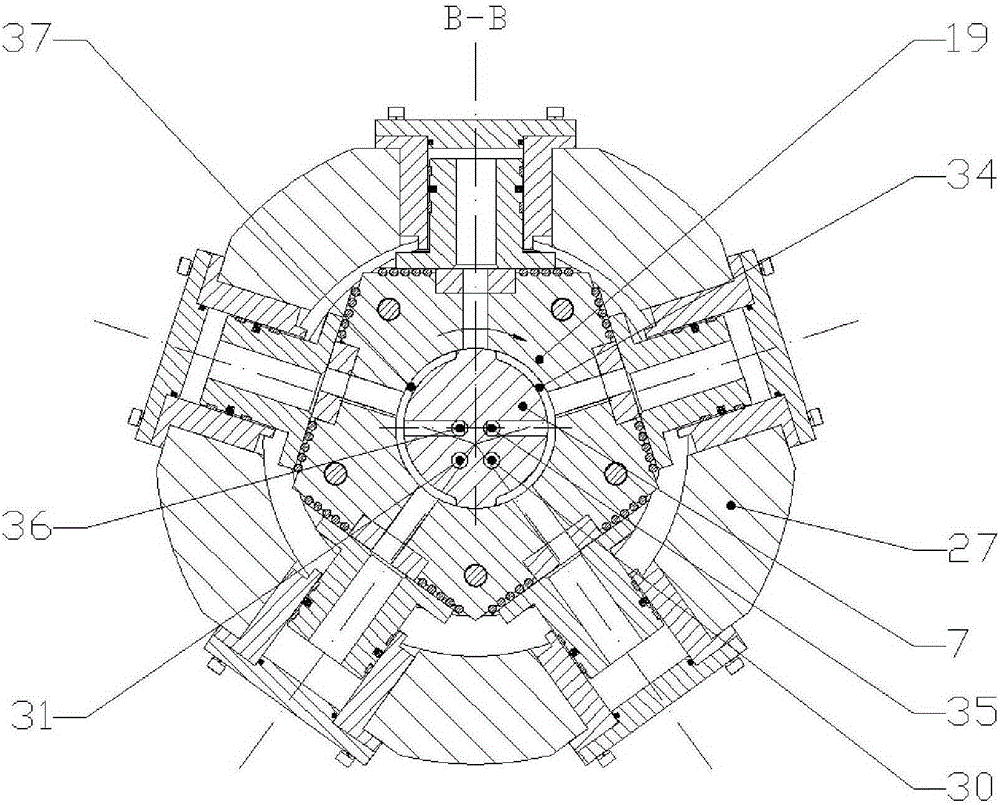

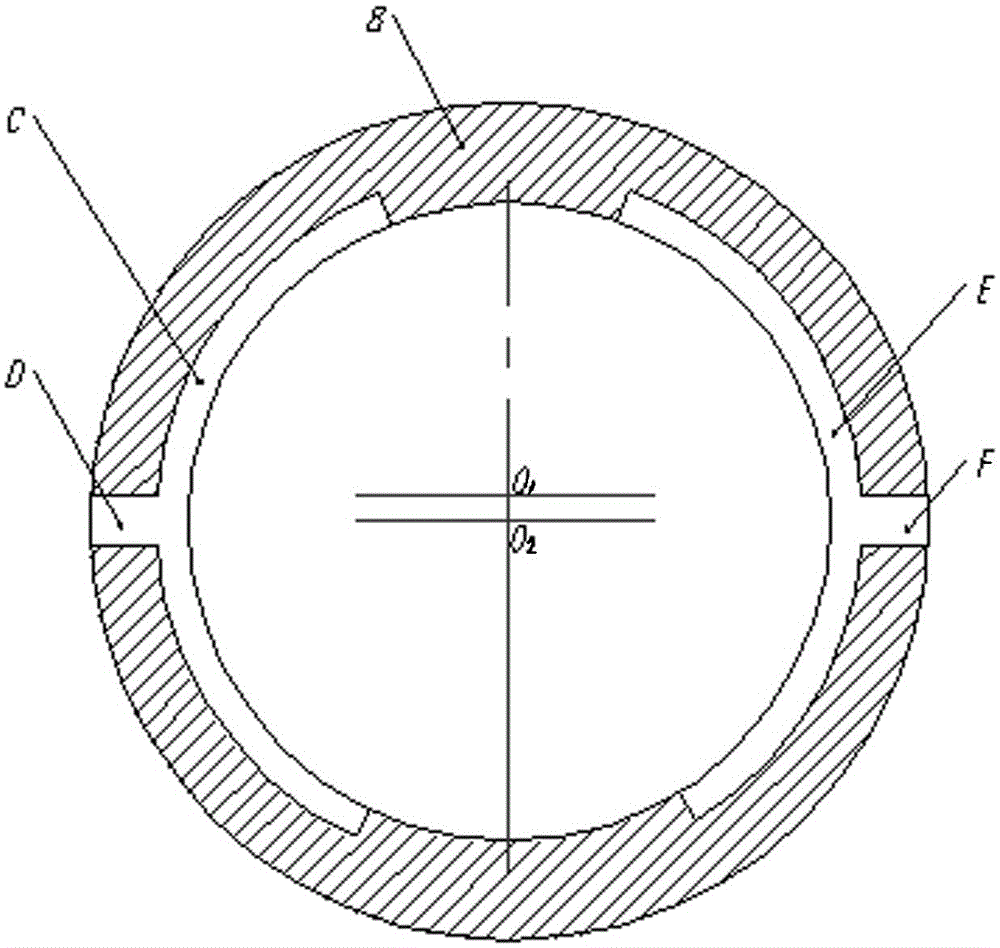

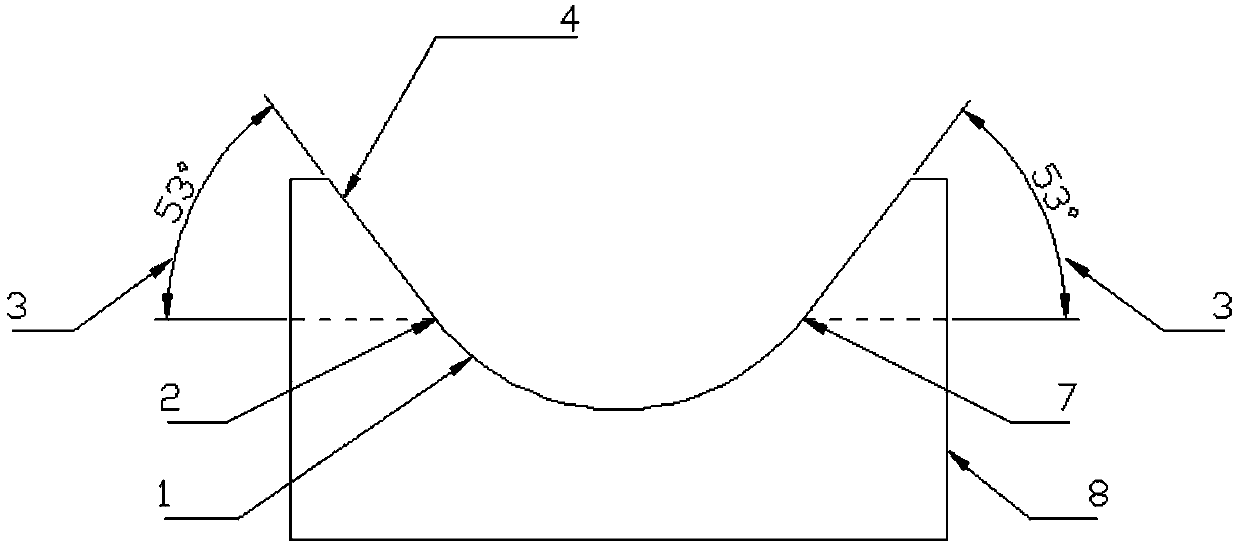

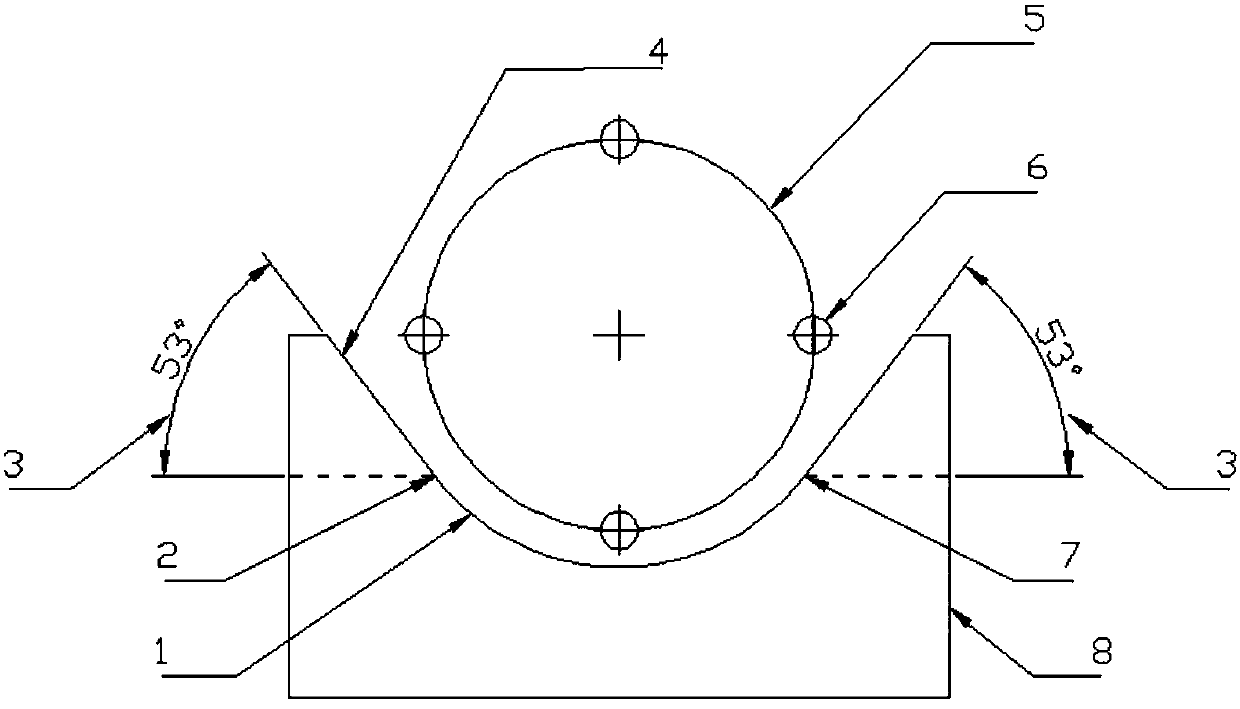

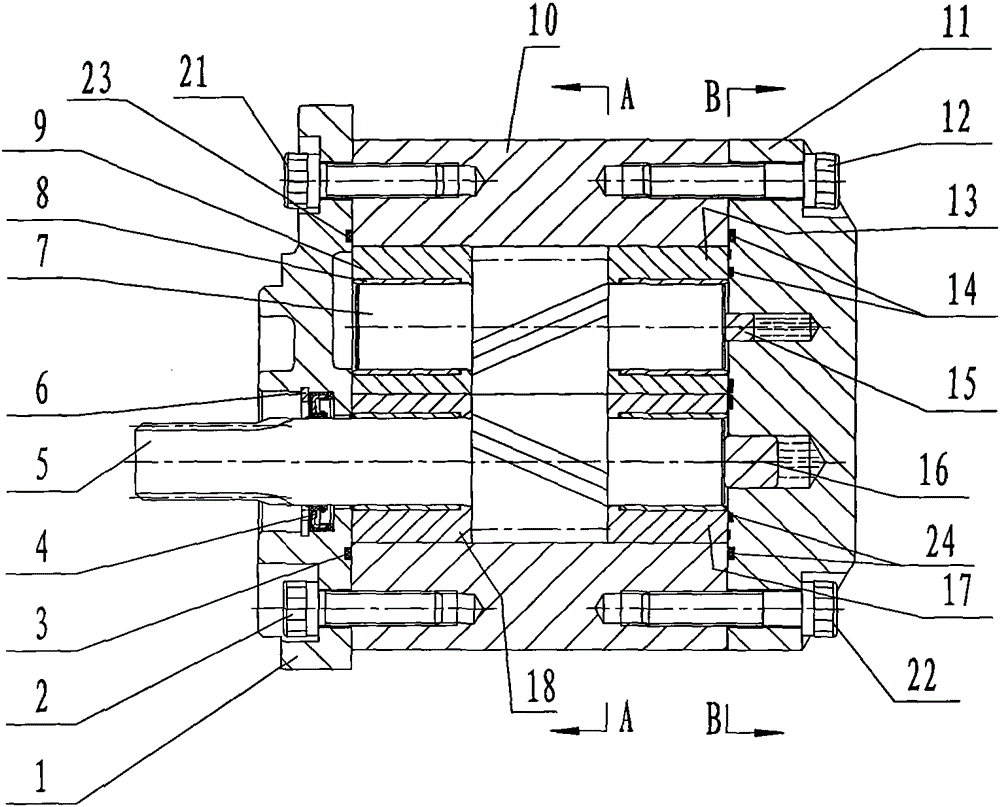

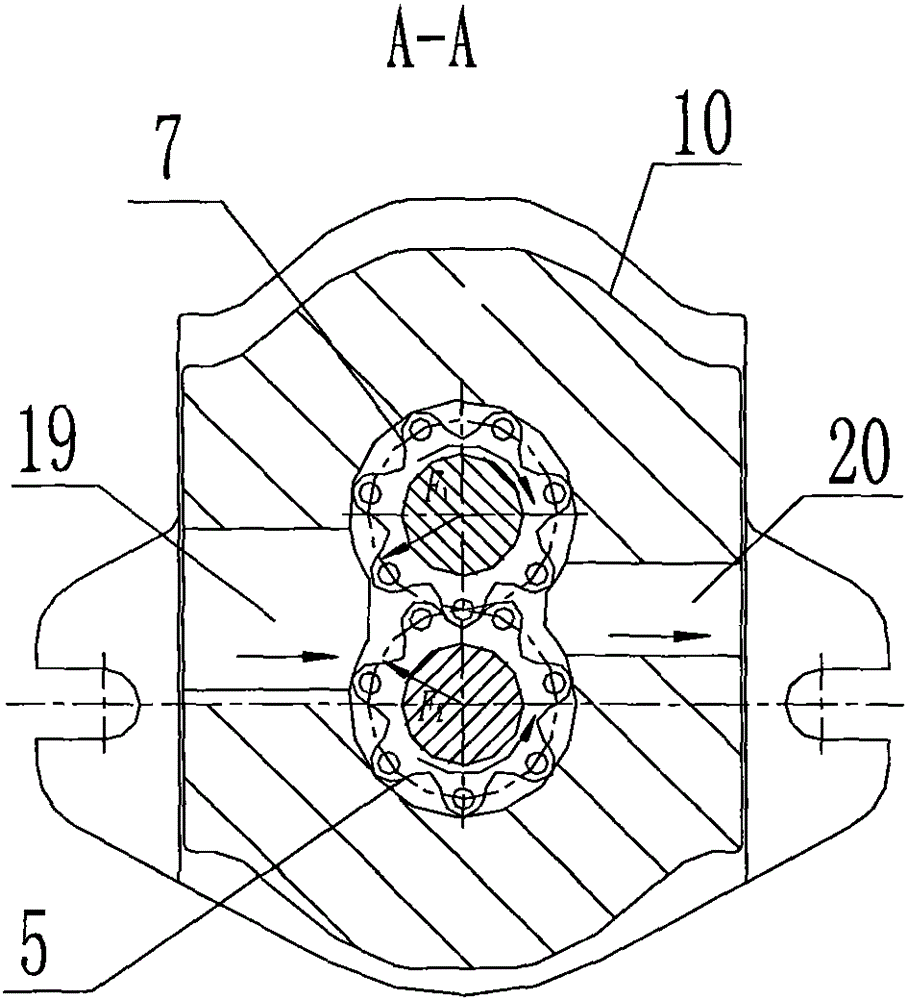

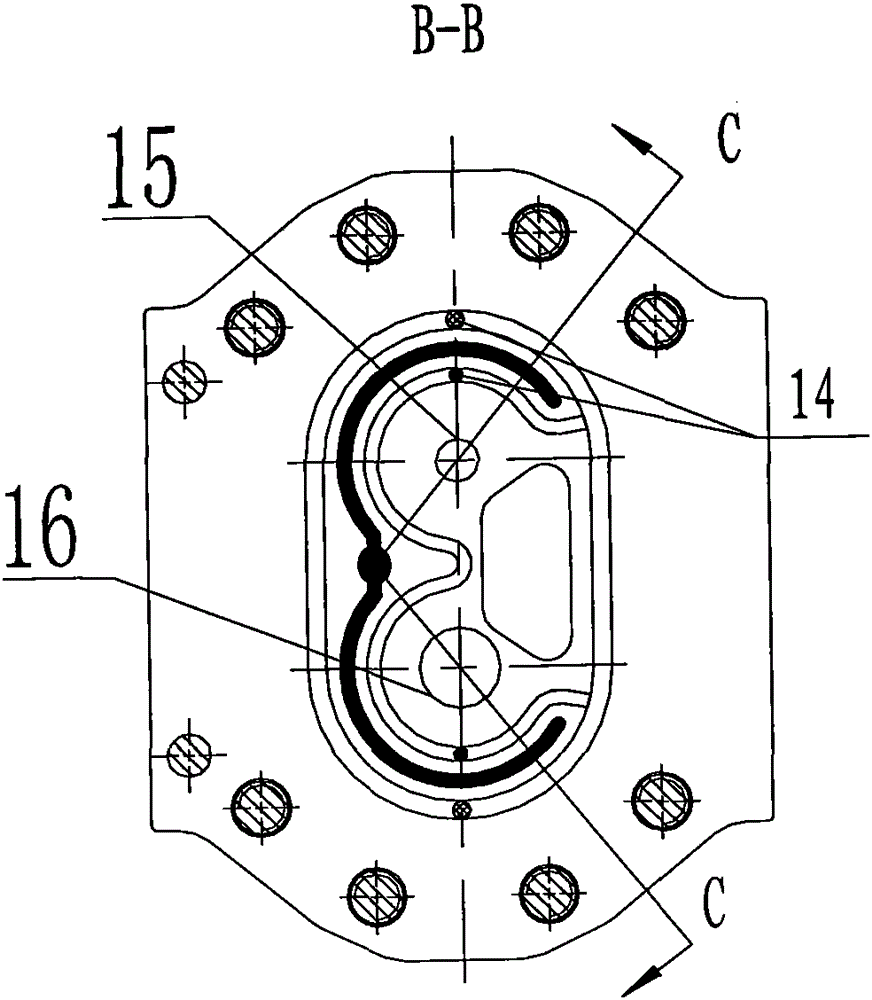

A shaft distribution type double-row radial piston hydraulic pump

ActiveCN103758721BCompact structureSimple drivePiston pumpsPositive-displacement liquid enginesRolling resistanceRadial piston pump

The invention discloses an axial-flow type hydraulic pump with double rows of radial plungers, wherein two rows of plunger groups are arrayed in the pump in parallel, the movements of the plunger groups are not affected by each other, and the space in the pump body is used in the maximum degree. According to the axial-flow type hydraulic pump with double rows of radial plungers, an eccentric shaft drives a star wheel to push the plungers to move, the transmission is realized through rolling friction, so that the axial-flow type hydraulic pump with double rows of radial plungers is simple and reliable; the total output of the pump is the sum of the output abilities of all the plunger groups, so that the delivery capacity is high; a plurality of cylinders work together, so that the output peak values of the cylinders are complementary, and the total flow fluctuation can be lowered obviously; the plungers and the plunger cylinder barrels are independent from the pump body, so that the axial-flow type hydraulic pump with double rows of radial plungers is simple to process, is low in cost, is convenient to assemble and maintain, and can be mounted and demounted quickly; the pump uses axial flow mode, the parts among the plungers, the star wheel, the eccentric shaft, an oil inlet and an oil outlet are sealed, so that the capacity utilization ratio is high.

Owner:XI AN JIAOTONG UNIV

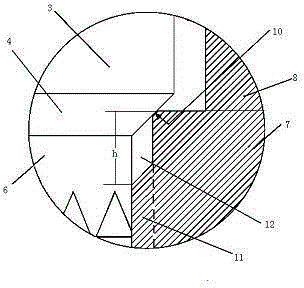

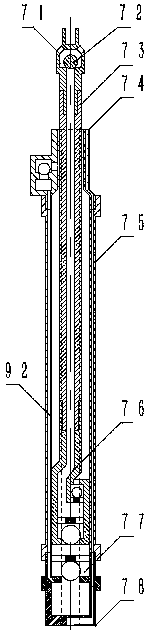

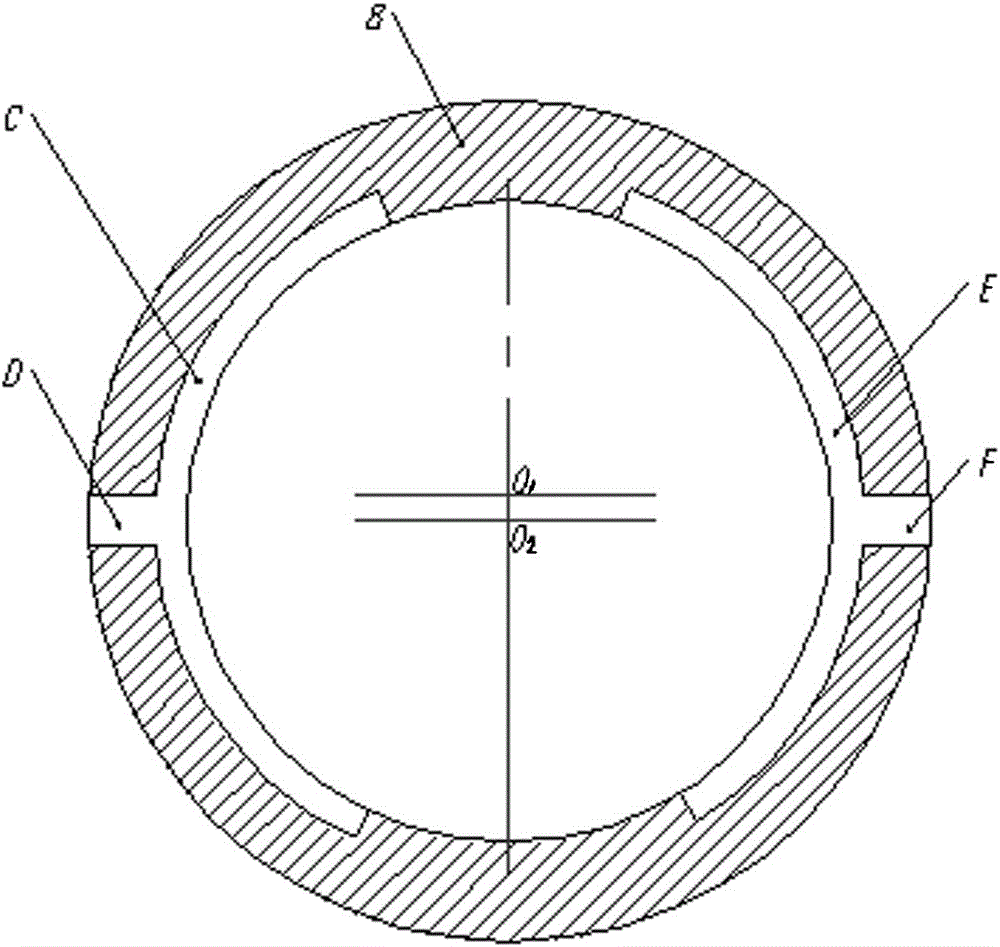

Variable-displacement cycloid rotor pump

ActiveCN105041637ASimple structureGuaranteed continuityRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention provides a variable-displacement cycloid rotor pump. The variable-displacement cycloid rotor pump comprises a front cover, a rear cover, a pump shell, an outer rotor, an inner rotor, a sealed outer rotor, a sealed inner rotor, a variable disk and a transmission shaft. The front cover and the rear cover are installed at the two ends of the pump shell respectively. The outer rotor and the sealed outer rotor are installed in the pump shell. The opposite end faces of the outer rotor and the sealed outer rotor are tightly attached to each other. The outer rotor is axially located through the variable disk. The sealed outer rotor is axially located through a friction plate. The inner rotor and the sealed inner rotor are installed in the outer rotor. The opposite end faces of the inner rotor and the sealed inner rotor are rightly attached to each other. The inner rotor is fixedly installed at the shaft end of the transmission shaft. The bottoms of toothed sockets of the outer rotor are provided with outer rotor oil channels. According to the variable-displacement cycloid rotor pump, the axial meshing width of multiple tooth space sealing volume is changed by adjusting the axial position of the variable disk through an adjusting bolt, and then the purpose of adjusting flow is achieved; and flow adjustment is convenient and easy. The variable-displacement cycloid rotor pump further has the beneficial effects of being small in size, low in cost and small in flow fluctuation.

Owner:XIANGTAN UNIV

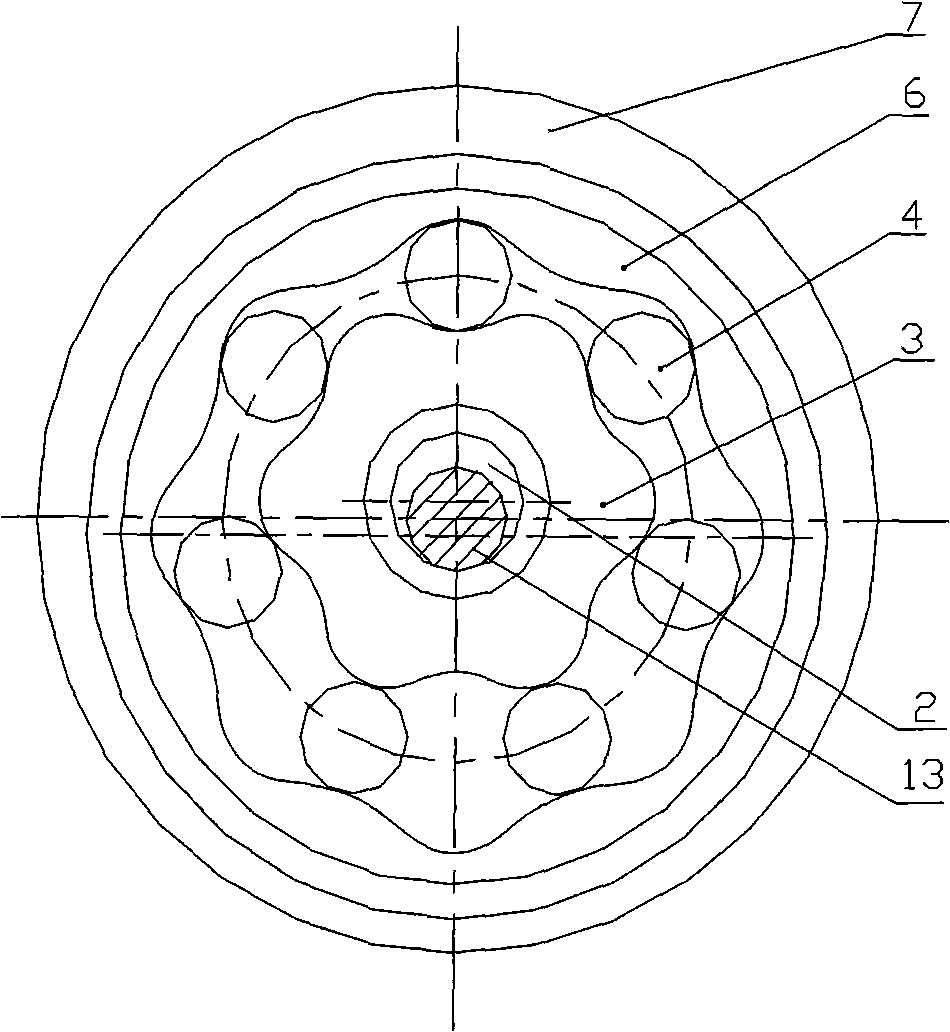

Concave pressing block with slow release areas for peristaltic pump

InactiveCN109519358AEven by forceExtended service lifeFlexible member pumpsPositive-displacement liquid enginesRefluxPeristaltic pump

The invention relates to a concave pressing block with slow release areas for a peristaltic pump. The concave pressing block with the slow release areas for the peristaltic pump comprises a pressing block body, one side of the pressing block body is an arc surface, and areas near the apex of at least one end of the arc surface are the slow release areas; and the slow release areas are involute oblique surfaces and / or large angle oblique surfaces and / or involute irregular surfaces. When the slow release areas are arranged at an outlet end, a roller wheel leaves a departure point, the longer slow release areas enable the roller wheel to gradually release the compression on a hose, and the hose gradually returns to an original state; the liquid reflux speed at the outlet end is slower, and the liquid flow rate at the outlet end fluctuates less; when the slow release areas are arranged at an inlet end, the longer slow release areas enable the roller wheel gradually tighten the hose, and the hose narrows slowly; the liquid reflux speed at the inlet end is slower, and the liquid flow rate at the inlet end fluctuates less; and when the slow release areas are arranged at both ends of the arc surface of the concave pressing block, the force of the hose is more balanced, and prolonging the service life of the hose is facilitated.

Owner:郑州玄一机器人有限公司

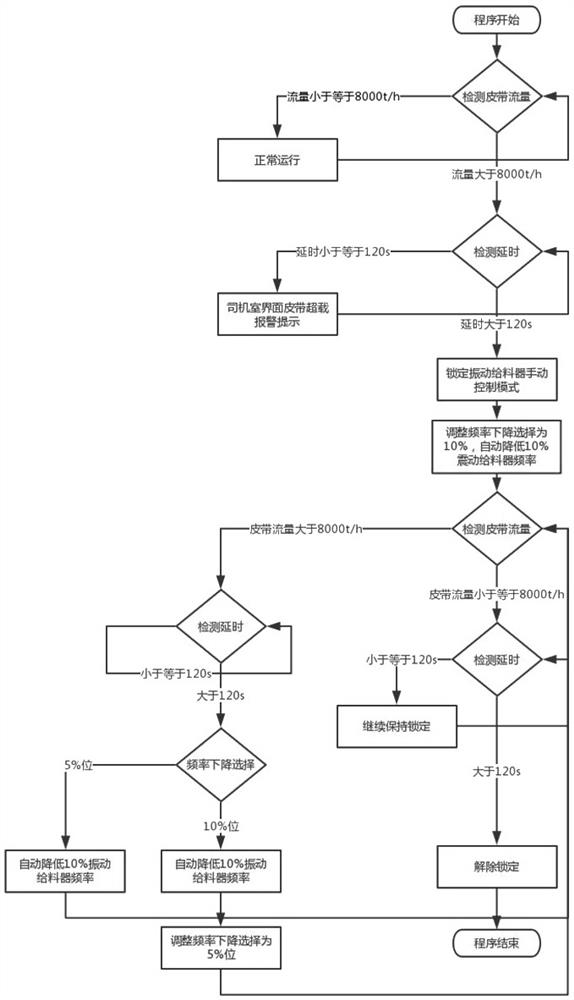

Process overload control method for ship unloader and belt conveyor

ActiveCN108609408BAvoid production accidentsImprove overload response efficiencyLoading/unloadingControl engineeringElectrical control

The invention relates to a ship unloader and belt conveyor process overload control method and belongs to the technical field of ship unloader and belt conveyor electrical control methods. According to the technical scheme, the control method includes the steps that firstly, signal collection is conducted, wherein a belt conveyor instantaneous flow rate signal is input into a ship unloader programmable controller by a belt conveyor programmable controller via an opc communication mode; secondly, signal processing is conducted, wherein the belt conveyor instantaneous flow rate signal is led into a vibration feeder motor control program of the unloader programmable controller; and thirdly, the programmable controller conducts logical judgment, and output includes adjusting of the manual modelocking on-off state of a vibration feeder motor, alarm prompting of an operation interface of a cab, automatic lowering of a frequency set value and lowering of the running frequency of the vibration feeder motor. By means of the ship unloader and belt conveyor process overload control method, flow overload of the belt conveyor is prevented, the phenomenon that the belt conveyor is overloaded for a long time, and consequently production accidents are probably caused is avoided, equipment damage and losses caused by long-time overload of the belt conveyor are reduced, the overload respondingefficiency of the belt conveyor is improved, flow fluctuation of the belt conveyor is reduced, and the production efficiency is improved.

Owner:PORT OF CAOFEIDIAN ORE TERMINAL CO LTD

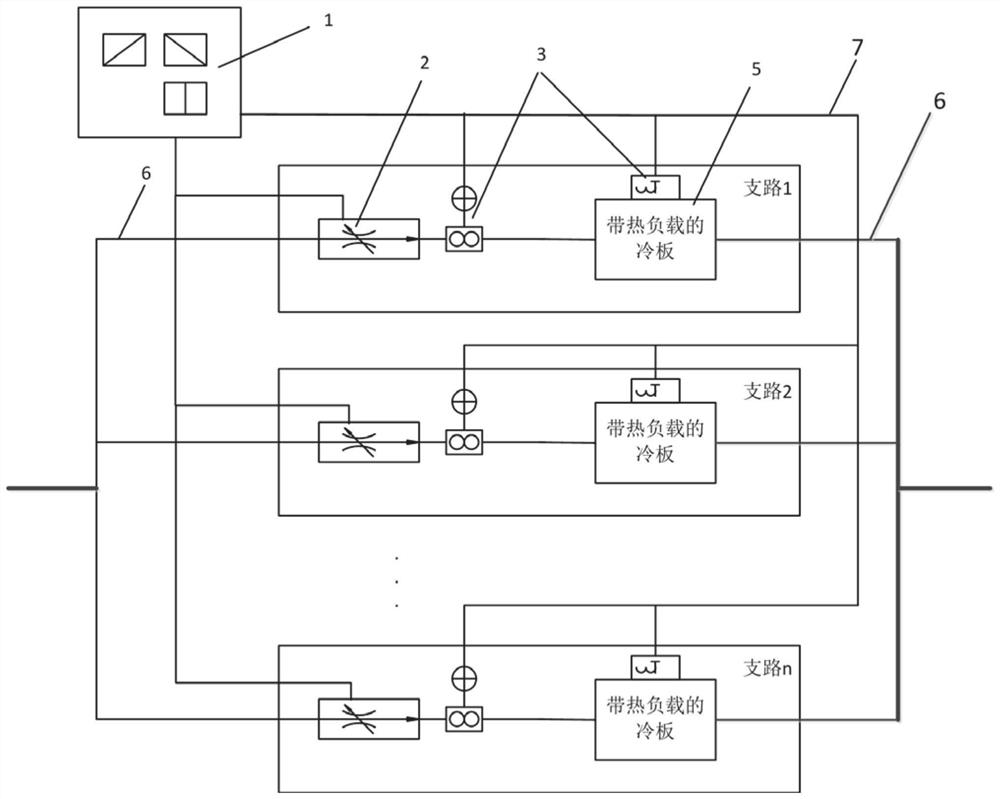

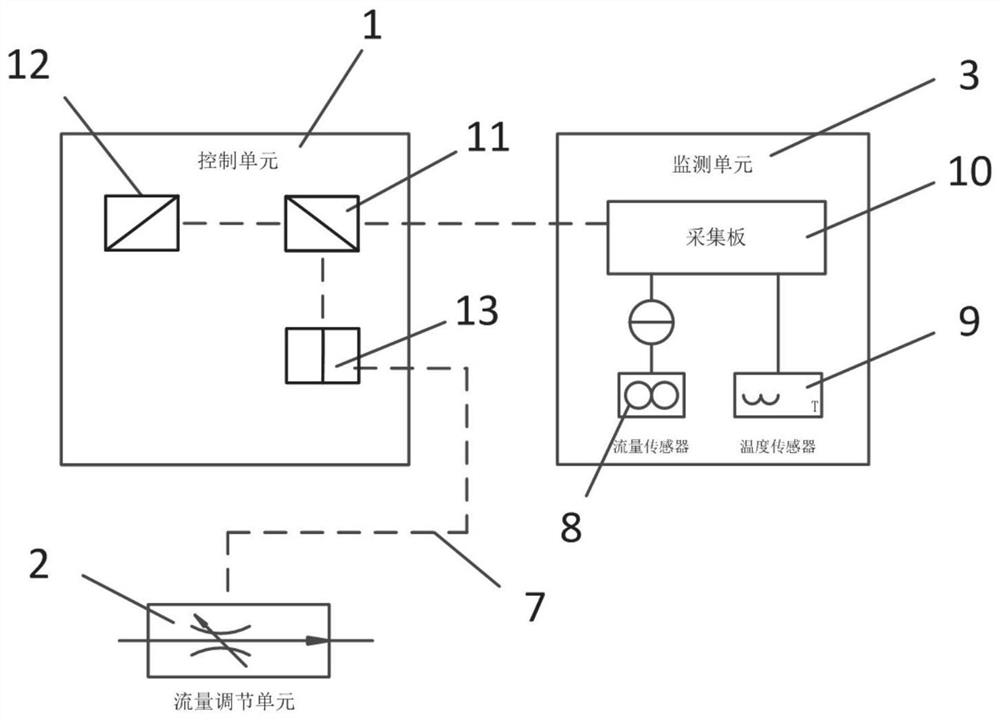

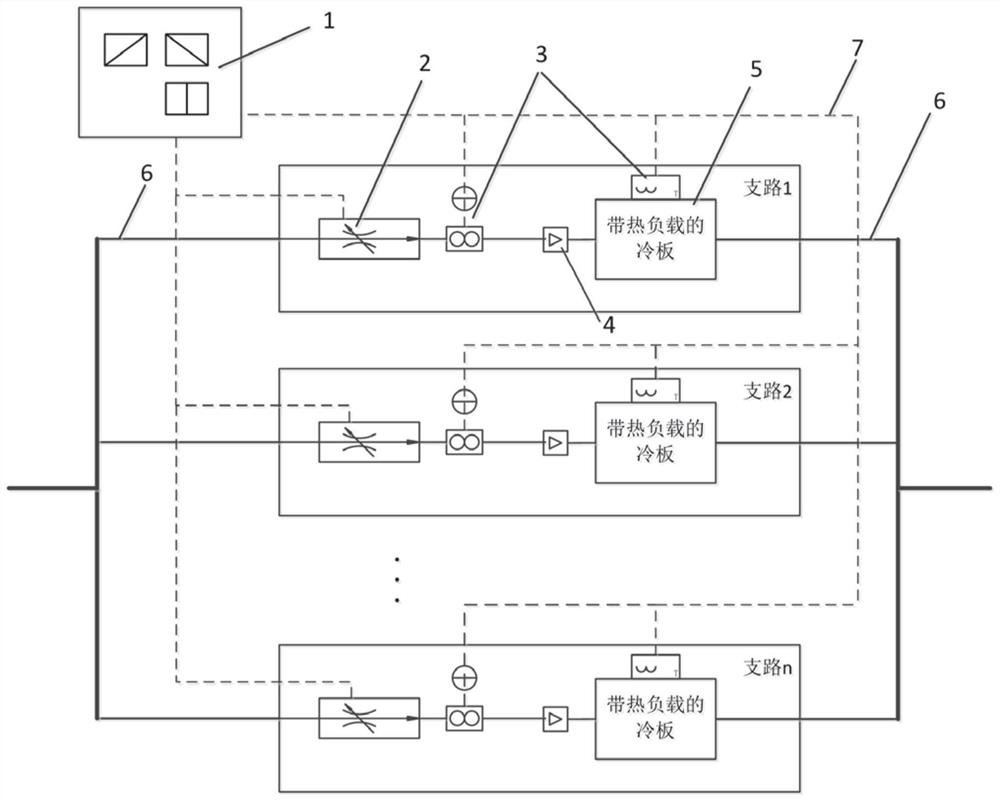

Two-phase cooling system multi-parallel branch stabilization device and method

ActiveCN111998707BImprove robustnessDoes not affect normal workSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsControl signal

The invention belongs to the technical field of cooling equipment, and discloses a multi-parallel branch stabilization device and method for a two-phase cooling system. The device includes a control unit, a monitoring unit for each branch, a flow adjustment unit, and a cold plate with heat load , and the pipeline: the control unit determines the corresponding driving control signal for adjusting the flow regulating unit according to the temperature on the branch; the monitoring unit collects the flow and temperature on the branch, and feeds back to the control unit; The flow rate of the two-phase cooling working medium of the circuit; the cold plate is provided with a two-phase cooling flow channel; the pipeline connects the flow regulating unit, the monitoring unit, and the cold plate with heat load in each branch to form a parallel two-phase working medium passage. Adopting the present invention can solve the uneven flow distribution and flow instability caused by the unbalanced heat load of multiple parallel branches of the two-phase cooling system through functions such as inlet throttling and flow adjustment, and ensure that each branch is not blocked due to excessive temperature. burn out.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

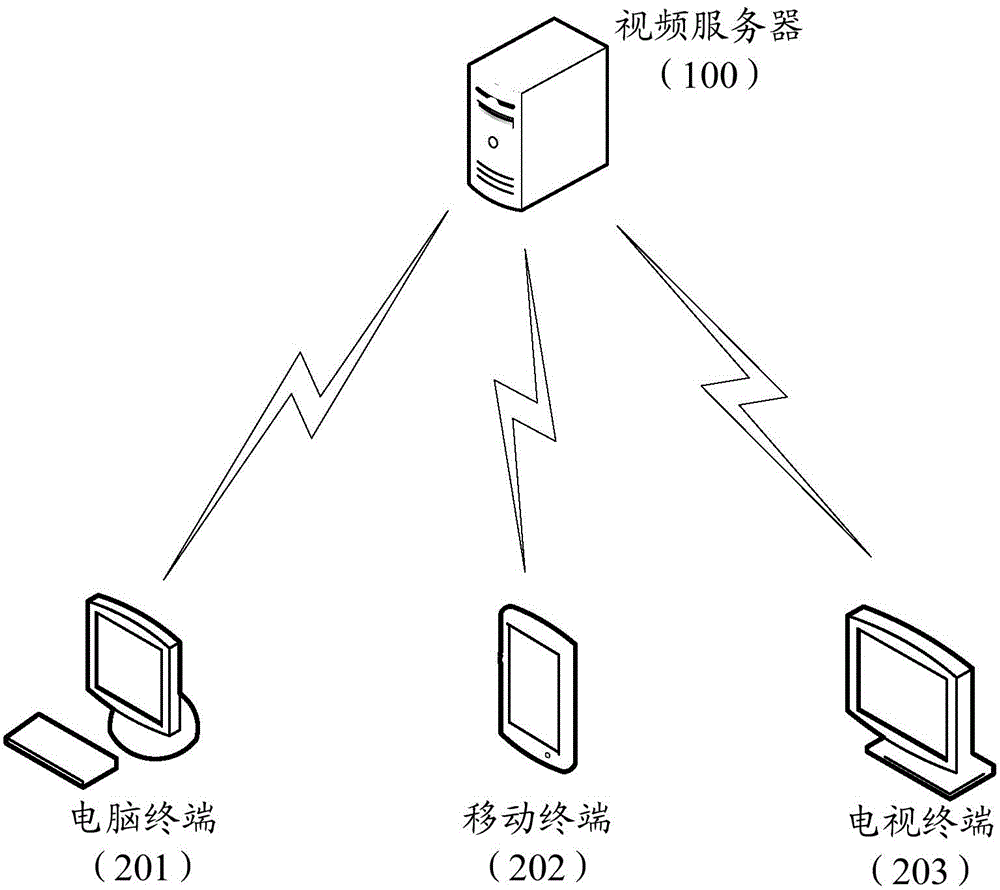

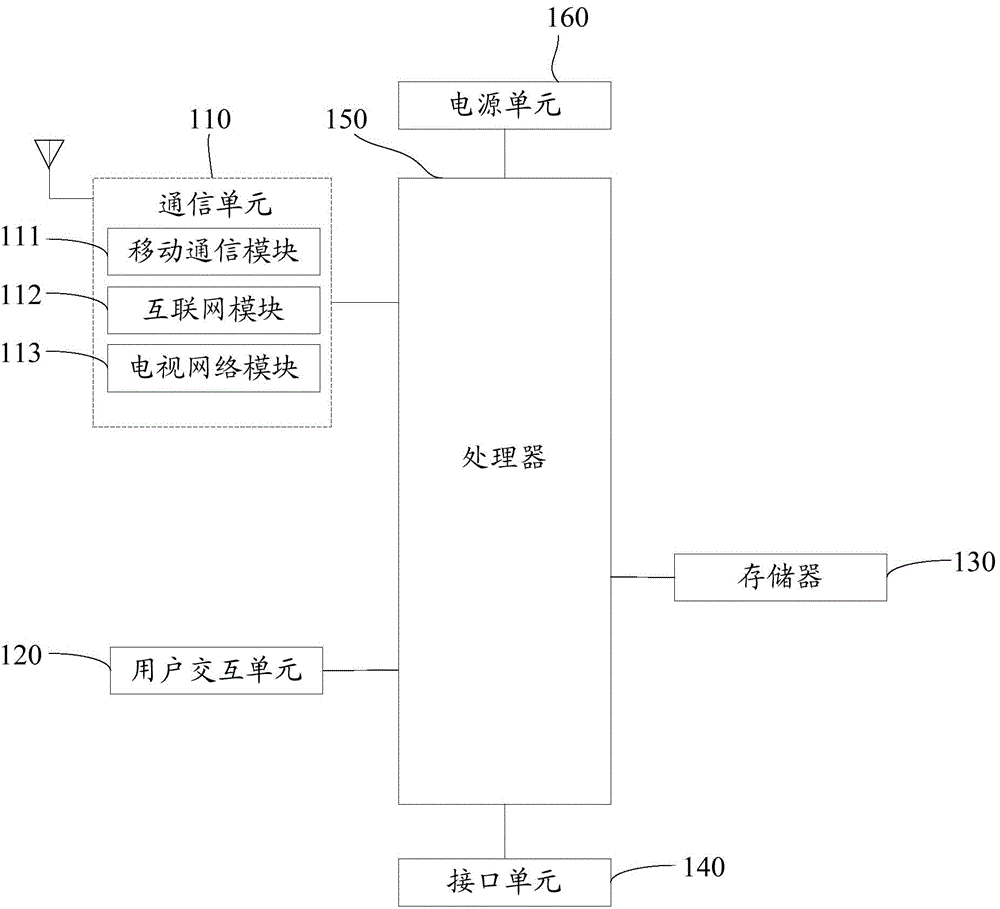

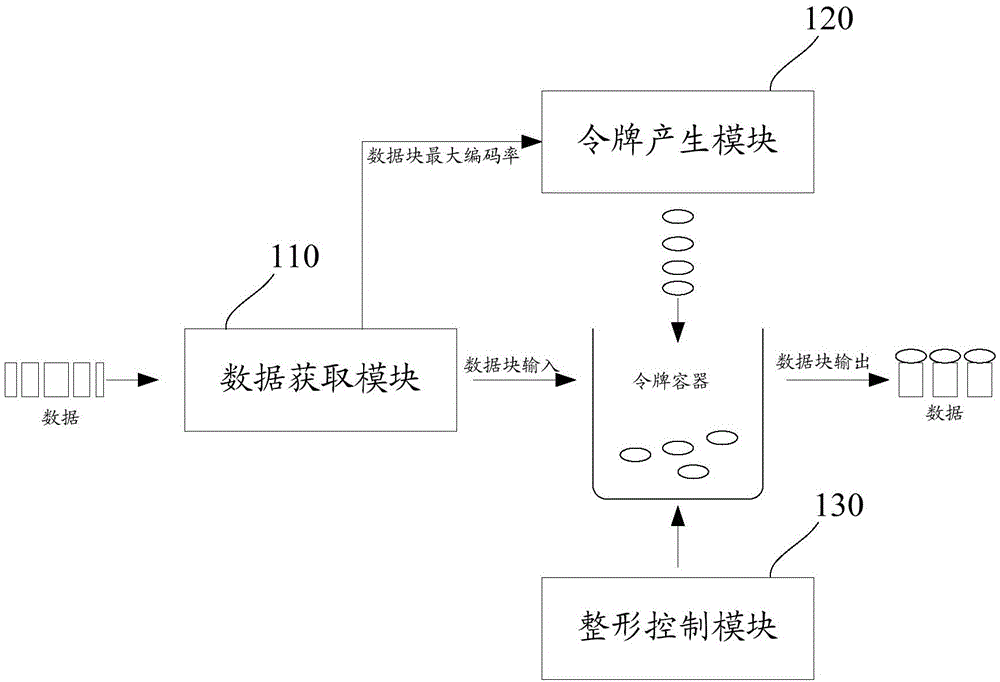

Transmission control method and device of video data

ActiveCN104980779ALittle flow fluctuationReduce risk of data lossSelective content distributionTraffic volumeData transmission

The invention discloses a transmission control method of video data. The method comprises the steps as follows: obtaining the video data to be transmitted and code rate of the video data; generating a token with a preset rate and placing the token in a token container, wherein the token capacity in the token controller is adaptively adjusted according to the maximum code rate of the video data to be transmitted; controlling the transmission of the video data to be transmitted according to the token in the token container. The invention further discloses a transmission control device of the video data. The method and the device of the invention improve the flow shaping efficiency in the transmission process of the video data.

Owner:TENCENT TECH CHENGDU

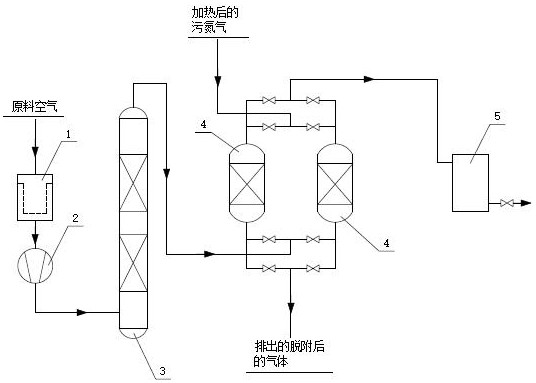

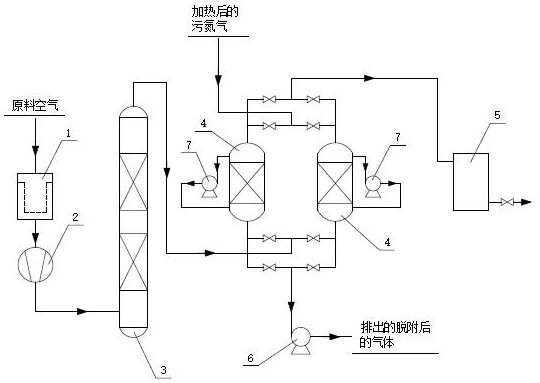

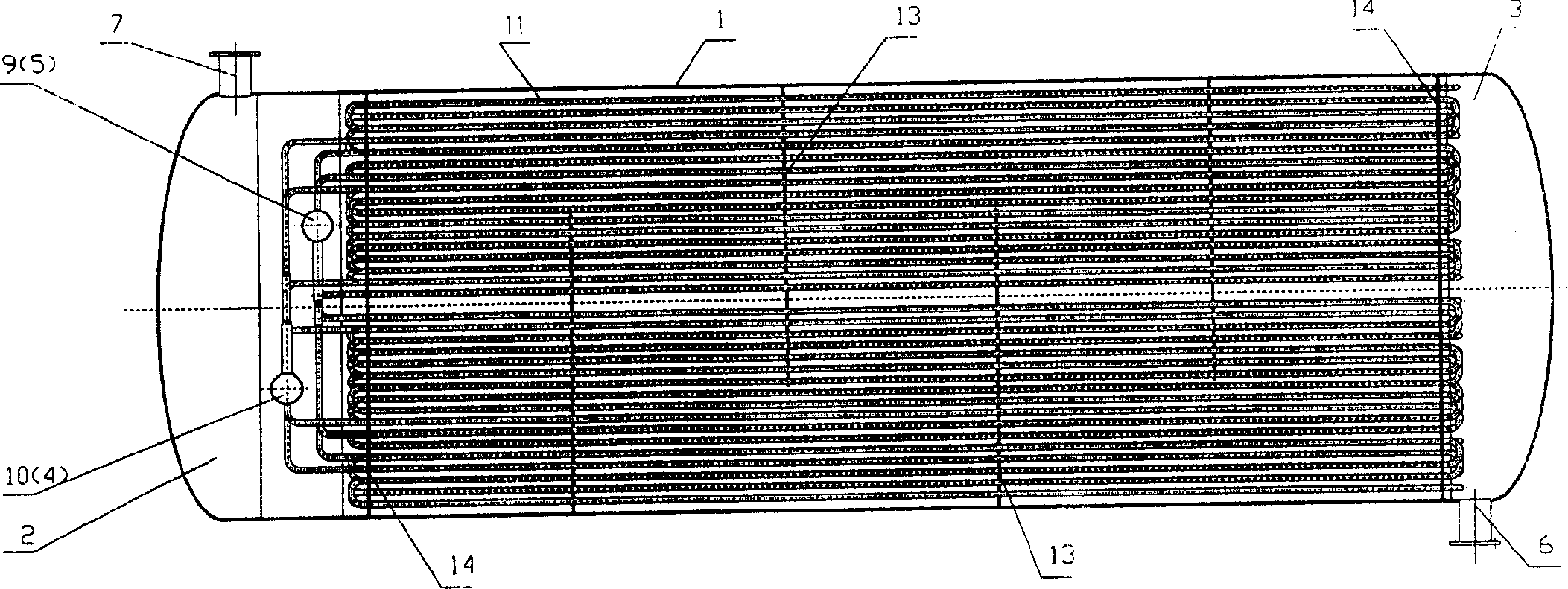

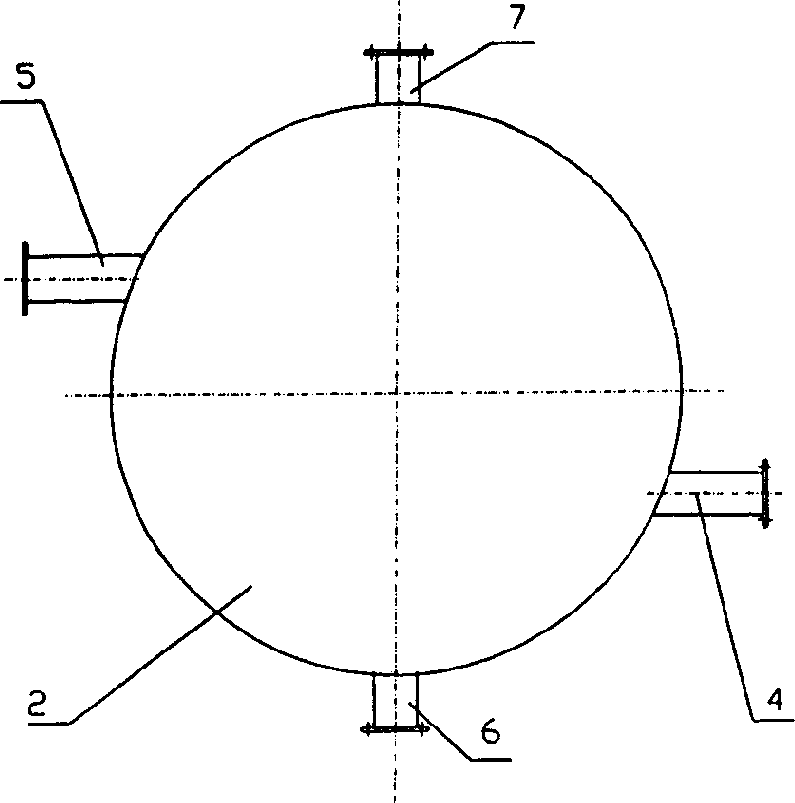

Method for improving compressed air quality of air compression station

PendingCN114483546AImprove product qualityReduce energy consumptionPositive displacement pump componentsDispersed particle filtrationCooling towerPressure stabilization

The invention provides a method for improving the quality of compressed air of an air compression station, which comprises the following steps of: filtering air by an air filter, removing dust and mechanical impurities in the air, compressing the air by an air compressor, and pre-washing and cooling the air in an air cooling tower in an air pre-cooling system; then the air is adsorbed and purified by a molecular sieve in the molecular sieve adsorber, and then enters a buffer tank for pressure stabilization and storage; the air pre-cooling system is used for washing and cooling, a molecular sieve adsorber in the purification system is used for adsorbing and removing moisture, carbon dioxide and hydrocarbon in air, the quality of a compressed air product reaches the first-grade standard, the air cooling tower is used for replacing an original freezing dryer, and the energy consumption is reduced. The molecular sieve and the activated aluminum oxide are activated and regenerated by using the waste nitrogen produced by the oxygen production system, so that the energy consumption is obviously reduced, the production cost is reduced, the production efficiency and the economic benefit are improved, and the environmental protection is facilitated.

Owner:SHANDONG IRON & STEEL GRP YONGFENG LINGANG CO LTD

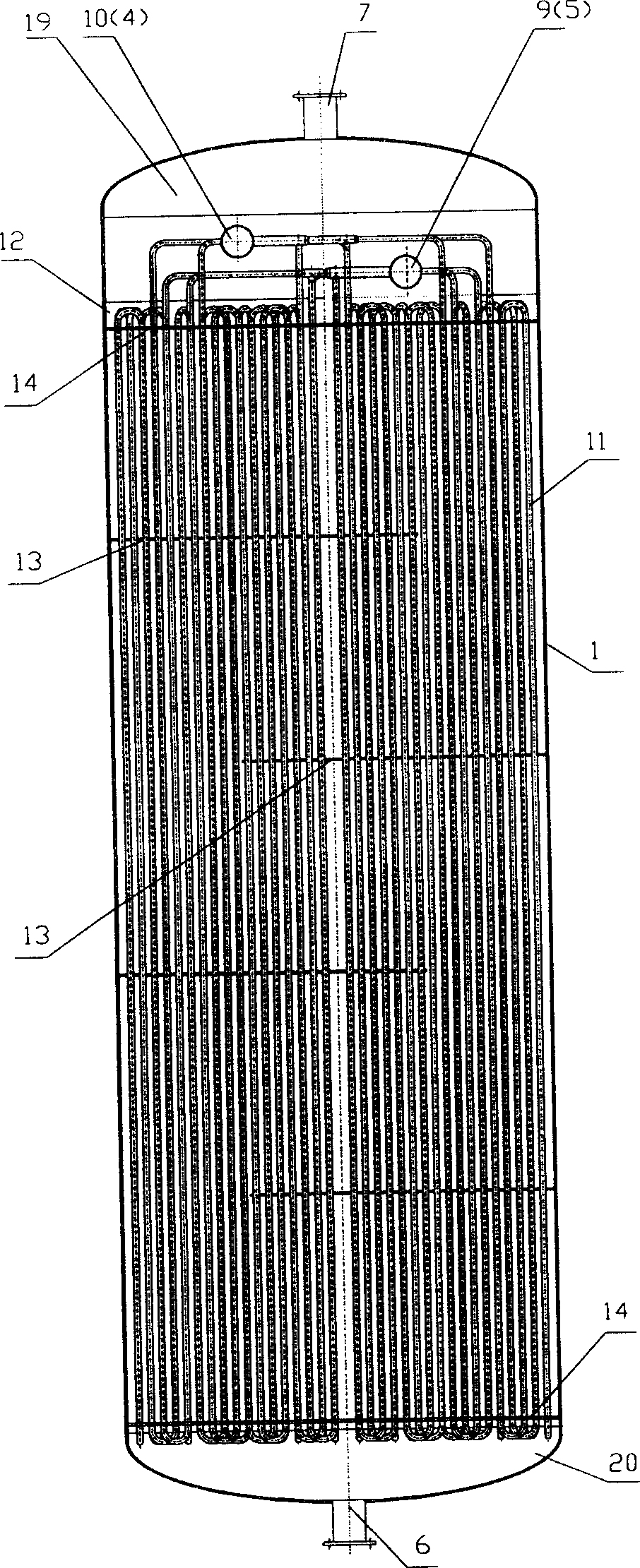

A closed-type external ice thawing ice-accumulating chamber

InactiveCN1464281ALittle flow fluctuationImprove efficiencyEnergy recovery in ventilation and heatingHeat storage plantsMagnetic valveWater flow

The closed outer ice-thawing ice accumulating tank includes casing, ice coil pipe, secondary refrigerant liquid separating pipe and secondary refrigerant liquid collecting pipe. Structurally, the present invention features that inside the casing with closed ends, the ice coil pipe is the secondary refrigerant passage formed by bent pipes and straight pipes and is closed inside the casing by the pipe sheets with water flow passage. The space between the ice coil pipe and the casing form the air conditioner water passage, inside which there are several crossed radial water flow deflecting boards. The ice coil pipe assembly inlet is connected to the secondary refrigerant liquid separating pipe, while the ice coil pipe assembly outlet is connected to the secondary refrigerant liquid collecting pipe. All the pipe channels are led out the ends separately. The air conditioning system of the present invention has high reliability, low system cost.

Owner:TSINGHUA TONGFANG CO LTD +1

A Variable Displacement Cycloidal Rotor Pump

ActiveCN105041637BSimple structureGuaranteed continuityRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention provides a variable-displacement cycloid rotor pump. The variable-displacement cycloid rotor pump comprises a front cover, a rear cover, a pump shell, an outer rotor, an inner rotor, a sealed outer rotor, a sealed inner rotor, a variable disk and a transmission shaft. The front cover and the rear cover are installed at the two ends of the pump shell respectively. The outer rotor and the sealed outer rotor are installed in the pump shell. The opposite end faces of the outer rotor and the sealed outer rotor are tightly attached to each other. The outer rotor is axially located through the variable disk. The sealed outer rotor is axially located through a friction plate. The inner rotor and the sealed inner rotor are installed in the outer rotor. The opposite end faces of the inner rotor and the sealed inner rotor are rightly attached to each other. The inner rotor is fixedly installed at the shaft end of the transmission shaft. The bottoms of toothed sockets of the outer rotor are provided with outer rotor oil channels. According to the variable-displacement cycloid rotor pump, the axial meshing width of multiple tooth space sealing volume is changed by adjusting the axial position of the variable disk through an adjusting bolt, and then the purpose of adjusting flow is achieved; and flow adjustment is convenient and easy. The variable-displacement cycloid rotor pump further has the beneficial effects of being small in size, low in cost and small in flow fluctuation.

Owner:XIANGTAN UNIV

Flexible gear pump

PendingCN107842495AEasy to install and maintainSimple structureRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention provides a technical scheme for a flexible gear pump. According to the scheme, the flexible gear pump comprises a pump shell, a flexible inner gear body, a flexible planet gear, a centergear, a connection key and a flow allocating hole. The technical problems that common pumps are divided into blade pumps, plunger pumps and gear pumps, the blade pumps and the plunger pumps are complicated in structure and high in price, the gear pumps are simple and compact in structure, and low in price, and thus are widely popularized, but the defects that gear pumps in the prior art are largein noise, large in flow pulsation, large in leakage amount and the like limit the application range of the gear pumps are solved. The technical scheme for the flexible gear pump has the beneficial effects that the structure is simple, machining is easy, the separated type structure facilitates installing and maintaining, cost is low, self pressure sealing between teeth can be achieved, leakage isreduced, symmetrical distribution is achieved, and the lateral force is reduced. In the running process, the flexible planet gear is in continuous and uniform deformation, flow fluctuation is reduced, and the beneficial effects that the blade pumps are large in displacement, high in pressure level and the like are achieved.

Owner:ANHUI UNIV OF SCI & TECH

screw pump

ActiveCN102322419BAvoid oil trappingExtended service lifeRotary piston pumpsRotary piston liquid enginesLow noiseGear pump

The invention discloses a screw pump. The screw pump comprises a pump shell, an end cover packaged on the two ends of the pump shell, a bearing base arranged in the pump shell, a bearing fixedly connected to the bearing base, a driving screw gear arranged at the interior of the bearing and a driven screw gear. The screw pump is characterized in that the driving screw gear and the driven screw gear adopt spiral screw gear mechanisms, and a subsection circular arc which is tangential with the gear side is reserved at the tooth crest of the screw gear; the tooth crest and dedendum of the screw gear are in a circular arc, the tooth crest circular arc and the dedendum circular arc are mutually coincided and seamless, no bottom clearance exists, and the entrap phenomenon is not generated; and the sides of the driving screw gear and the driven screw gear are provided with oil storage tanks. The screw pump provided by the invention has the advantages of low noise, low vibration and low energy consumption, and can be used for completely avoiding the entrap phenomenon of a traditional gear wheel pump, reducing the friction of a gear and bearing, and prolonging the service life of a gear wheel pump.

Owner:ZHEJIANG AOVITE HYDRAULIC MECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com