Series connected type double-acting injection-production pump for high-water-cut oil-producing well

A double-acting, series-type technology, which is applied to components of pumping devices for elastic fluids, variable displacement pump components, pumps with flexible working elements, etc., can solve the problem of insufficient oil-water separation efficiency and reduce flow Fluctuation, effect of increasing separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

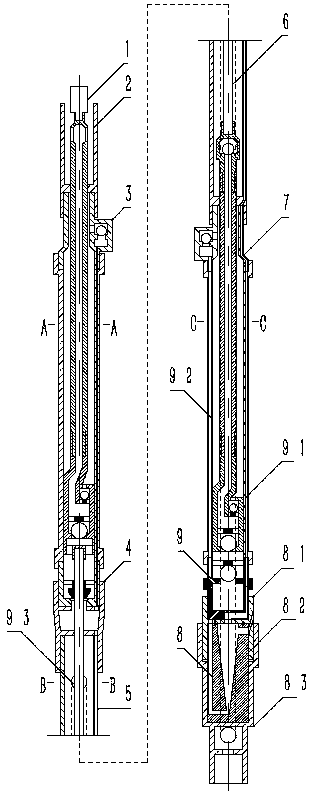

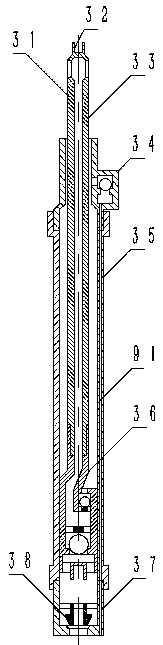

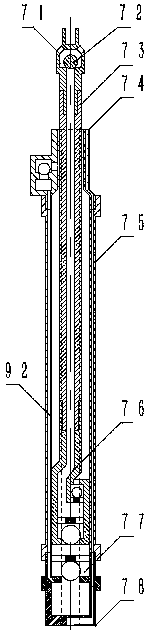

[0021] See attached figure 1 , a tandem double-acting pump for injection and production in the same well provided by this embodiment includes a disconnector 1, an upper tubing collar 2, a double-acting oil well pump assembly 3, an intermediate collar 4, an intermediate pump barrel 5, a core Rod 6, double-acting water injection pump assembly 7, cyclone assembly 8, flow channel 9. The upper end of the double-acting oil well pump assembly 3 is connected to the upper oil pipe coupling 2, and the upper plunger 31 is arranged inside the double-acting oil well pump assembly 3, and the disconnector 1 is installed on the upper end of the disconnector joint 32 of the upper plunger 31. The lower end of the oil well pump assembly 3 is connected to the middle coupling 4 and the middle pump barrel 5 sequentially from top to bottom, and the lower end of the middle pump barrel 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com