screw pump

A technology for screw pumps and pump casings, applied to pumps, rotary piston pumps, rotary piston machines, etc., to achieve the effects of avoiding internal leakage, smooth changes, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

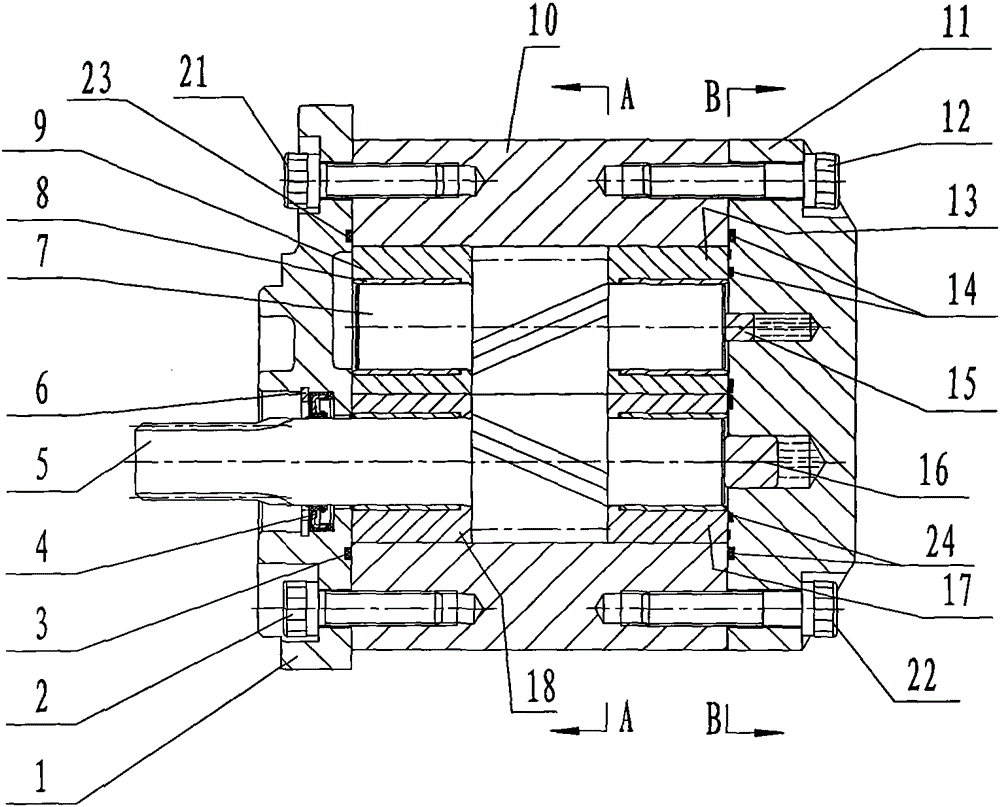

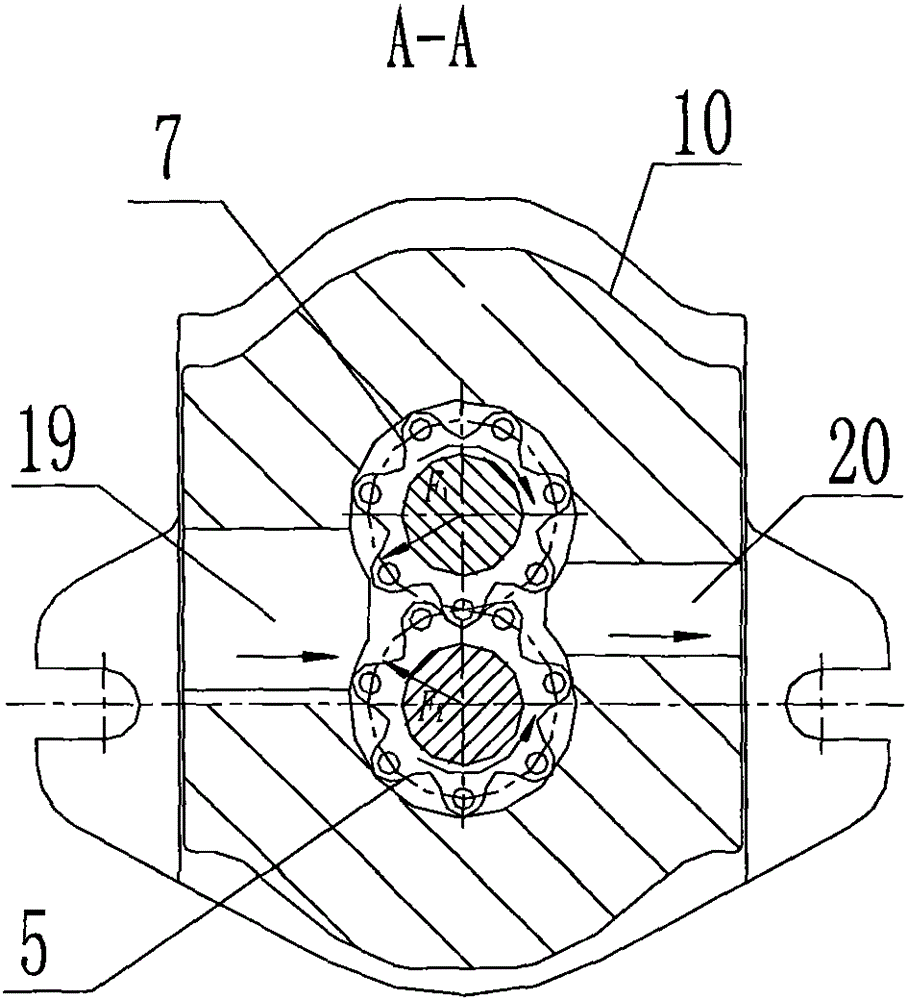

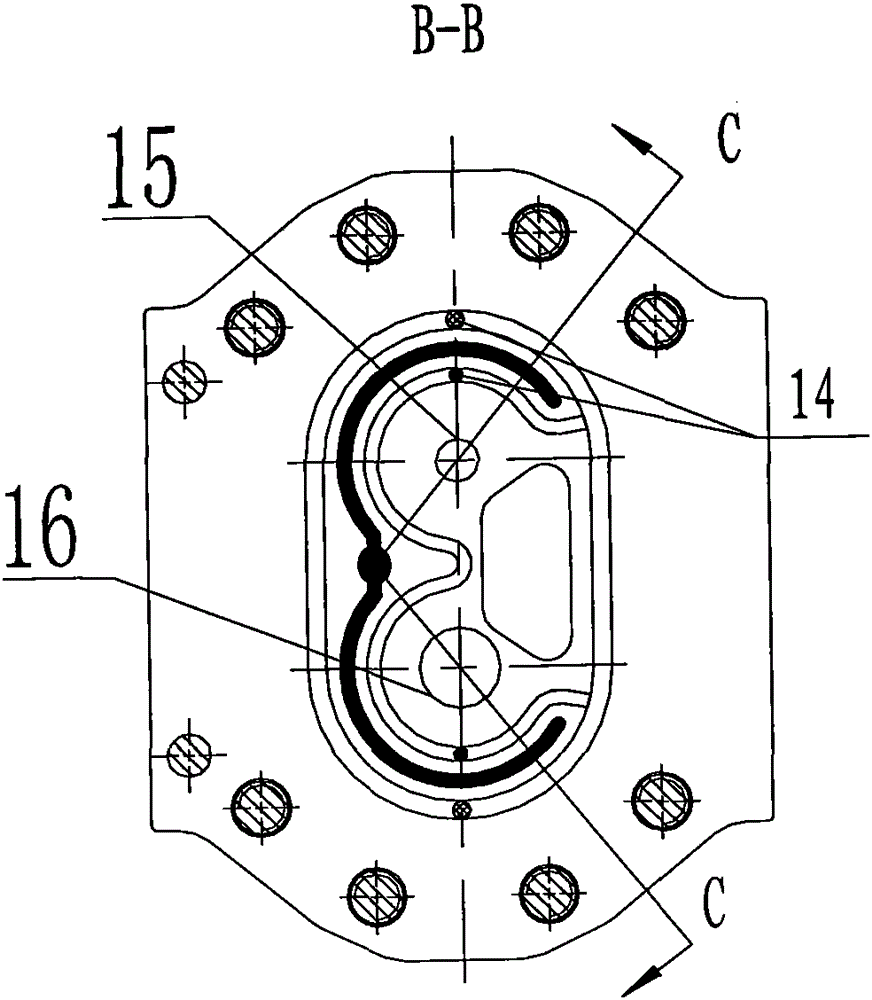

[0030] see figure 1 , figure 2 and image 3 , a screw pump, including a pump casing 10, an end cover 1 and an end cover 11 encapsulated on both sides of the pump casing 10, and a bearing 8 fixedly connected to the bearing housing 9, the bearing housing 13, the bearing housing 17 and the bearing housing 18, The driving helical gear 5 and the driven helical gear 7 that can be meshed in the bearing 8, the driving helical gear shaft ejector pin 16 arranged on the right end surface of the driving helical gear 5 and the driven helical gear arranged on the right end surface of the driven helical gear 7 Helical gear shaft jacking pin 15.

[0031] Such as figure 2 As shown, the left side of the driving helical gear 5 and the driven helical gear 7 is the oil suction port 19, and the right side is the oil pressure port 20, the oil suction port 19 is the low-pressure area, the oil pressure port 20 is the high-pressure area, and the low-pressure oil comes 19 enters, flows into the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com