A shaft distribution type double-row radial piston hydraulic pump

A radial column and axial flow distribution technology, applied in the direction of piston pumps, pumps, multi-cylinder pumps, etc., can solve the problems of complex transmission links and low efficiency, and achieve the effects of large output flow, high volumetric efficiency, and easy assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

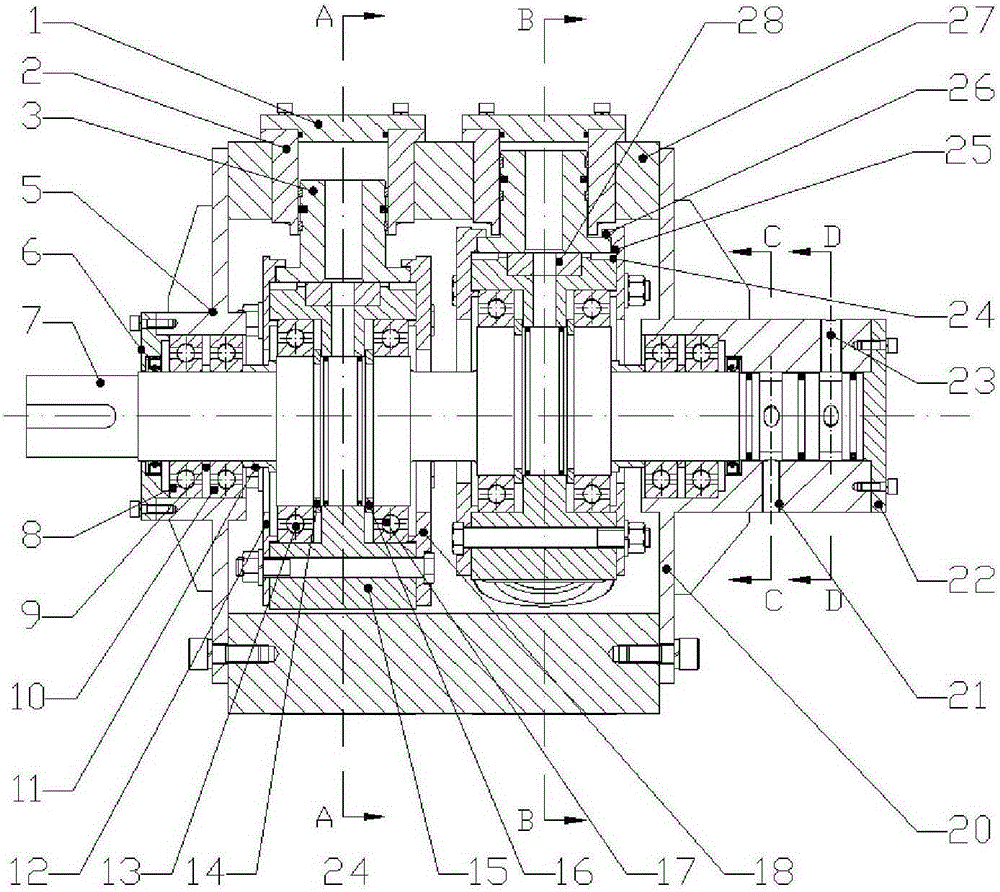

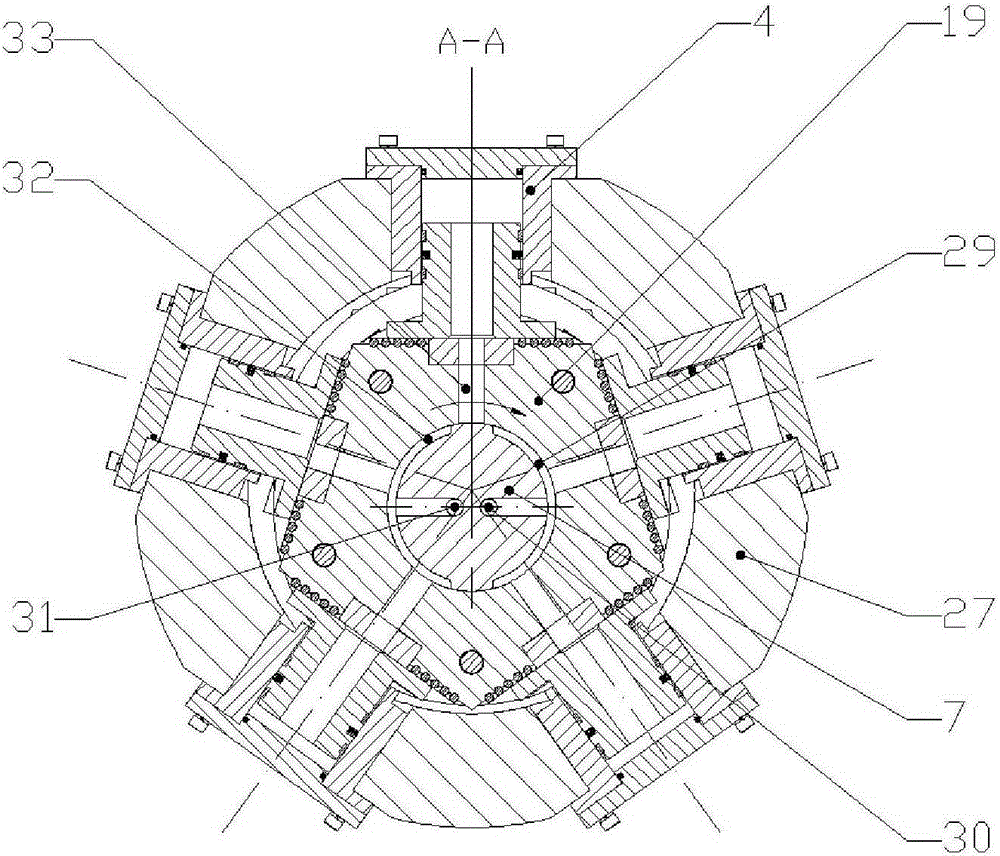

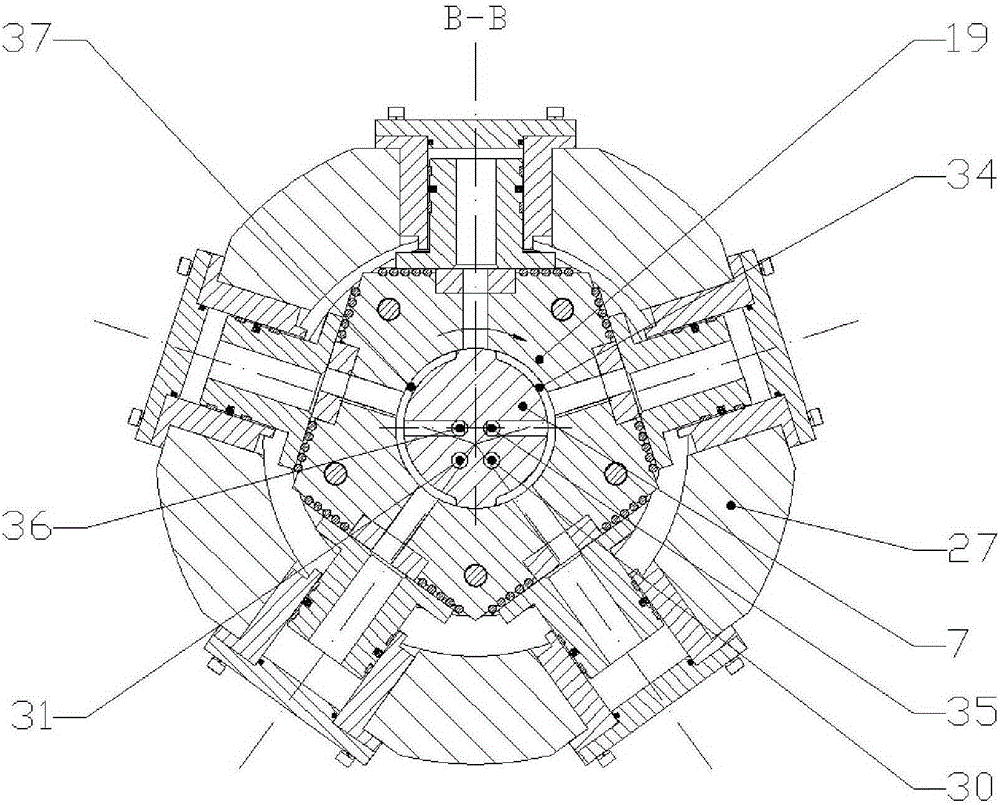

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] refer to figure 1 and figure 2 , a shaft-distribution type double-row radial plunger hydraulic pump, including a pump body 27, ten groups of plunger groups 4 are installed on the pump body 27, and the ten groups of plunger groups 4 are arranged in parallel in double rows, and each row The plunger groups 4 are evenly arranged radially, and each group of plunger groups 4 includes a plunger cylinder gland 1, a plunger cylinder barrel 2 and a plunger 3, and the plunger cylinder gland 1 is installed at the bottom of the plunger cylinder barrel 2, and the plunger cylinder 3 Insert from the top of the plunger cylinder 2 and move linearly in the plunger cylinder 2, the screw passes through the plunger cylinder gland 1 and the flange on the plunger cylinder 2 and screws into the threaded hole on the pump body 27 to realize fixed connection;

[0026] The five-star g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com