Composite startup burner for powder coal gasification furnace

A technology for start-up burners and gasifiers, which is applied in the field of compound start-up burners for pulverized coal gasifiers, which can solve the problems of complex start-up process and burnout of the start-up burner head, so as to ensure the atomization effect and prolong the use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

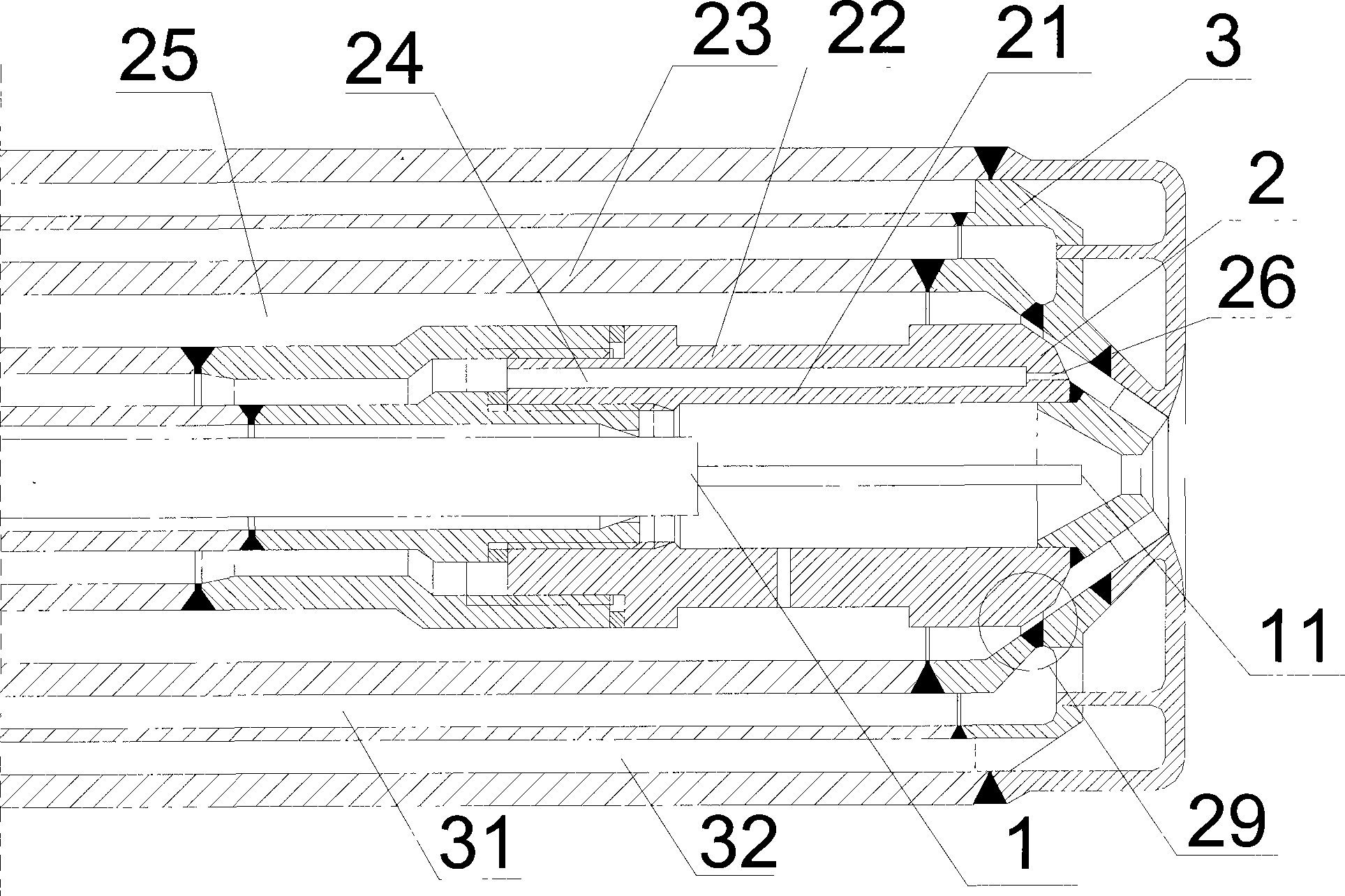

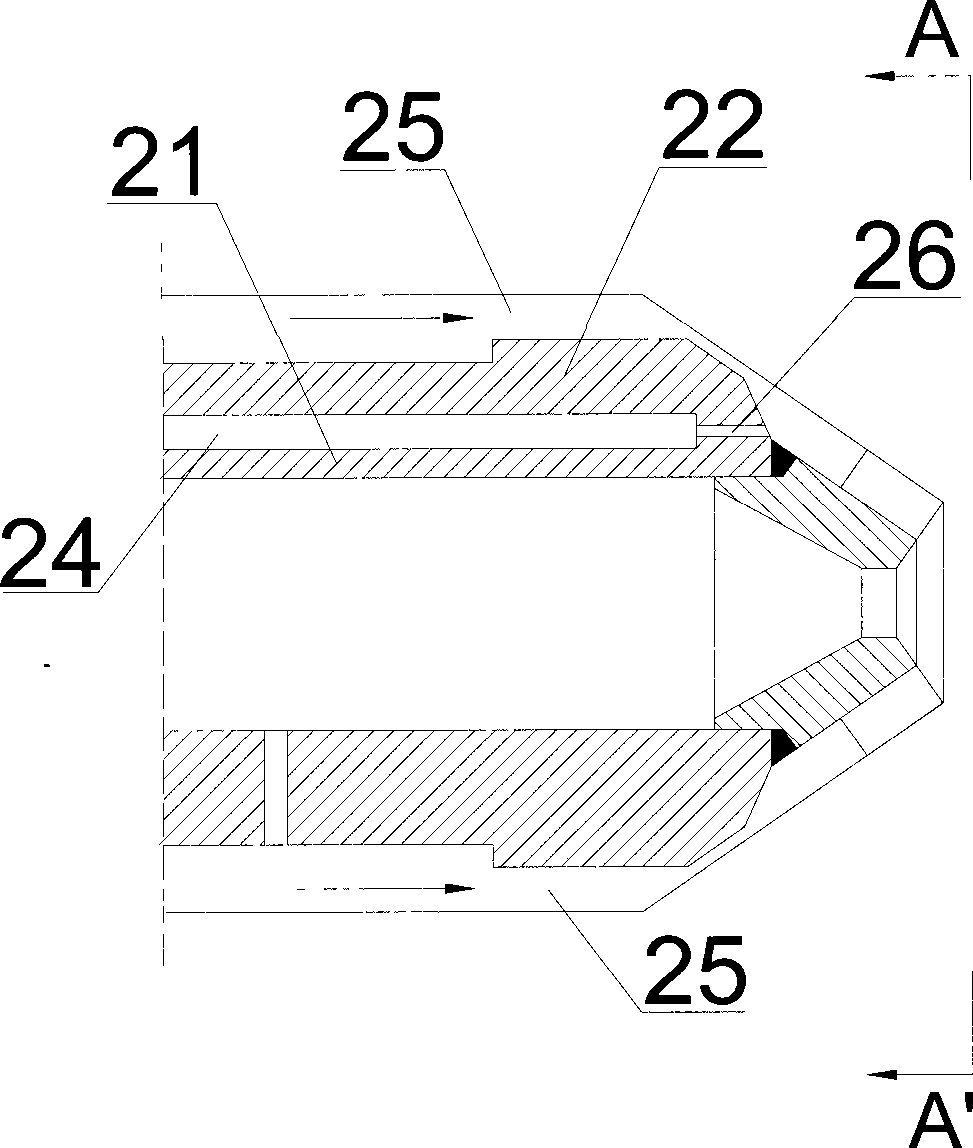

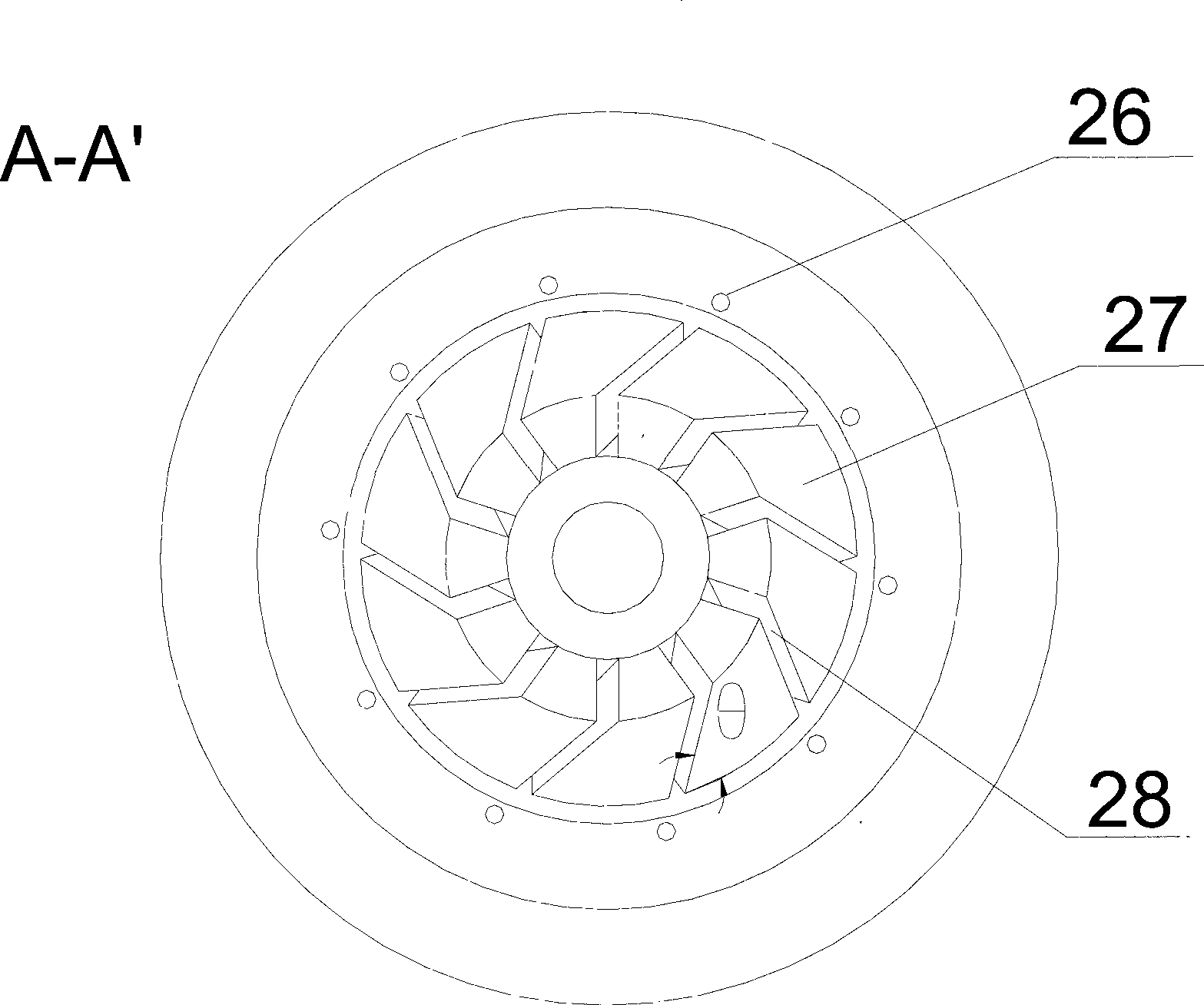

[0019] see Figure 1 to Figure 5 , the compound start-up burner for pulverized coal gasification furnace of the present invention is composed of an inner burner 1 and an outer burner 2 coaxially sleeved from inside to outside with a front closing end, and the outer burner includes an inner wall 21, a middle layer 22. The outer wall 23, the passage 24 between the inner wall 21 and the middle layer 22, and the passage 25 between the middle layer 22 and the outer wall 23. A cooling water jacket 3 with a front end sealing is also provided around the outer wall 23 of the outer burner.

[0020] The inner burner 1 is provided with a channel, which is a natural gas channel, and an ignition electrode 11 is provided at the front end of the inner burner 1 .

[0021] The passage 24 between the inner wall of the outer burner and the middle layer is a fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com