Pore-pin type cycloid rotor motor

A hole-pin type and rotor technology, which is applied in the direction of rotary piston pumps, rotary piston machines, rotary piston engines, etc., can solve the problem of complex spline connection processing and manufacturing, cycloidal rotor speed can not be high, cycloidal rotor eccentricity Small problems, to achieve the effect of improving mechanical efficiency and service life, increasing output torque, and small flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

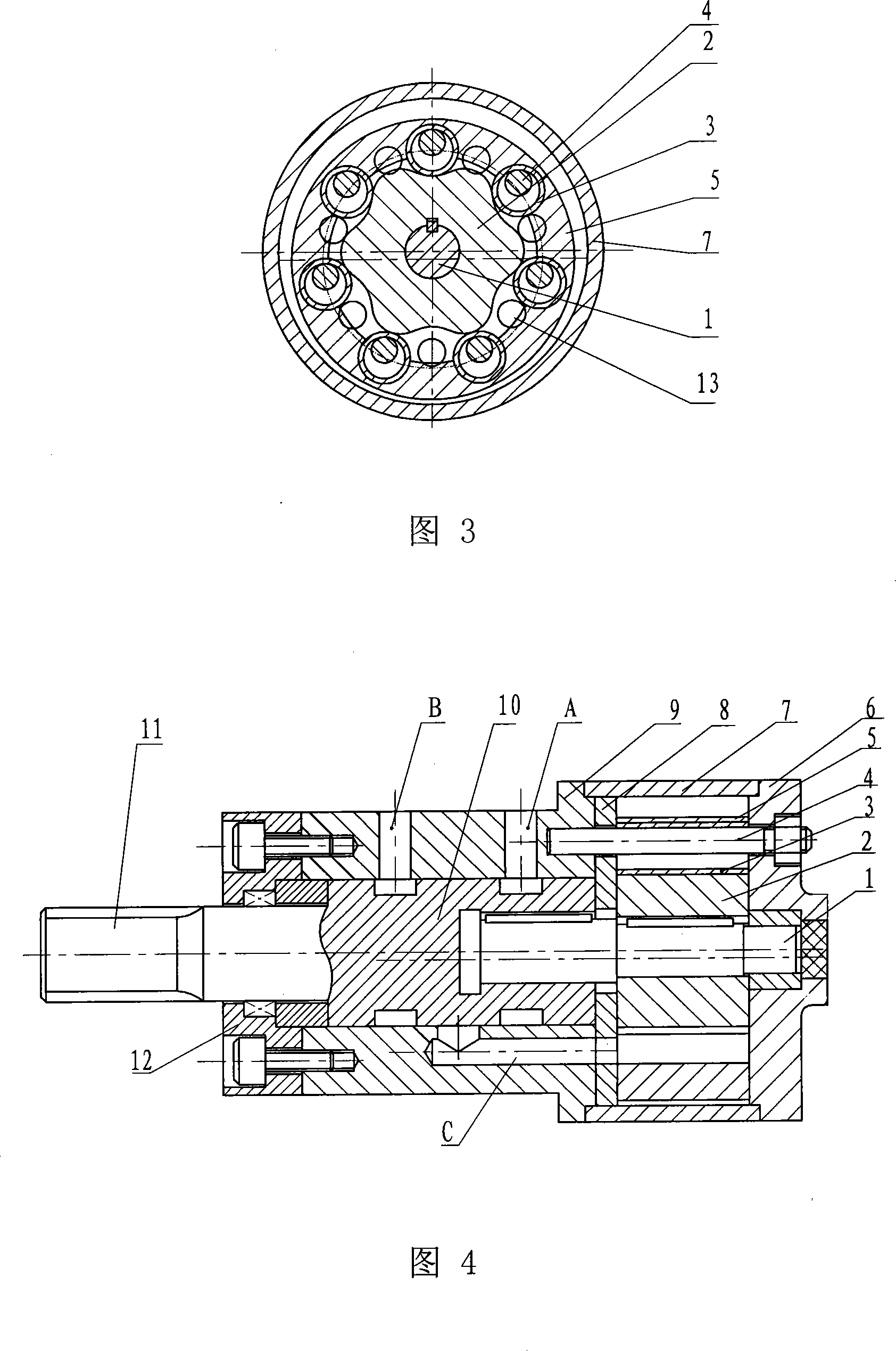

[0045] As shown in Figures 3 and 4, it is mainly composed of the core shaft 1, the inner rotor 2, the sleeve 3, the pin 4, the translation plate 5, the front end cover 6, the housing 7, the backing plate 8, the base 9, and the distribution shaft 10. , The output shaft 11, the rear end cover 12 and other parts. One end of the core shaft 1 is connected with the inner rotor 2 with a coaxial flat key, and the other end is connected with the distribution shaft with a coaxial flat key. The center of the translation disc 5 is a cavity, and seven sleeves 3 are embedded in the inner cavity of the translation disc 5 and form a pin wheel together with the translation disc 5. Seven pins 4 pass through the sleeve 3 and the backing plate 8 and are fixed on the base 9. The diameter of the pin 4 is smaller than that of the sleeve 3. The distribution positions of the sleeve 3 and the pin 4 on the base 9 are the same. The output shaft 11 is coaxially connected with the distribution shaft 10 and the...

Embodiment 2

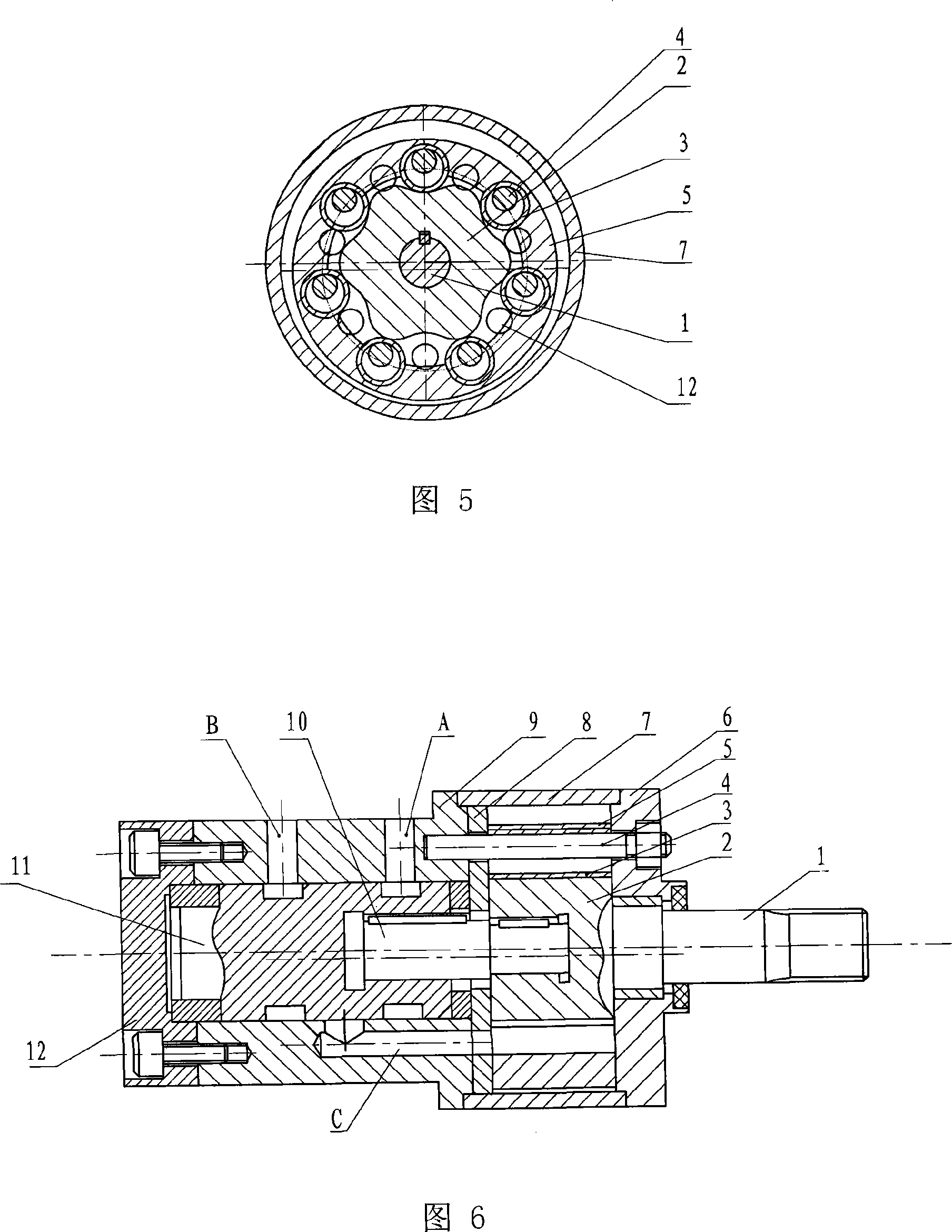

[0049] Its structure is shown in Figures 5 and 6. The output shaft 1 and the inner rotor 2 are coaxially and fixedly connected, and the output shaft 1 directly outputs power from the rotation of the inner rotor 2. This structure generates less torque on the distribution shaft 11 and has less impact on the device and equipment, which is beneficial to the present invention. Maintenance of the life and accuracy of linear rotor motors. The other components and structures are the same as those of the first embodiment, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com