Light large-flow oil pump

A high-flow, oil pump technology, used in lubrication pumps, mechanical equipment, engine components, etc., can solve problems such as affecting the fuel economy of the engine, the structure is not compact, and the service life of the oil pump is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

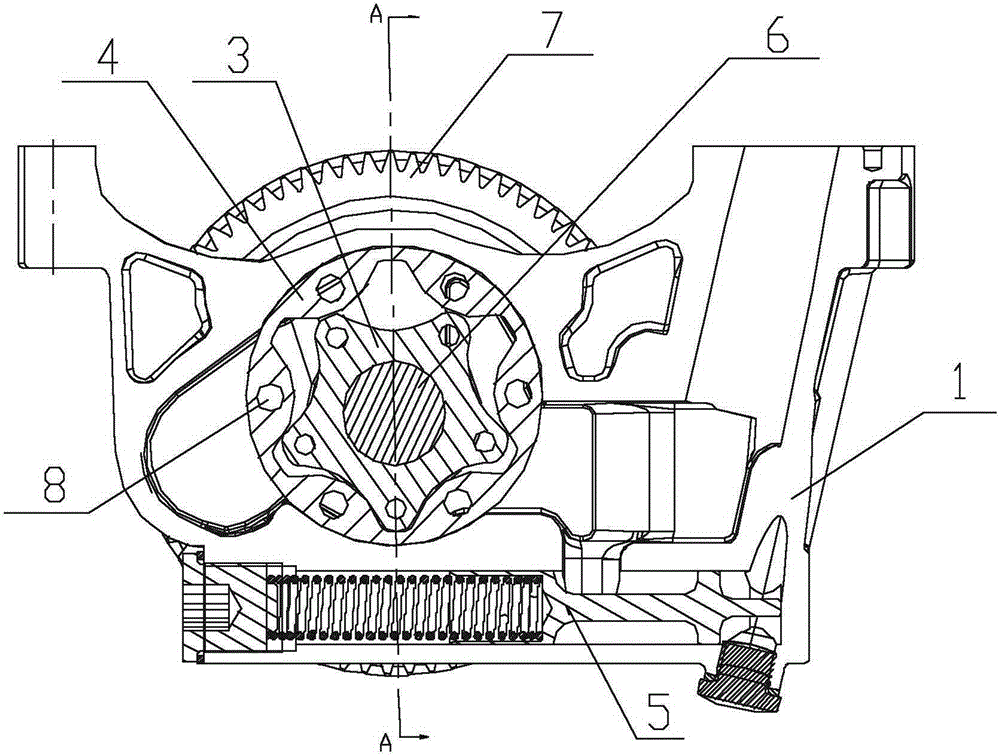

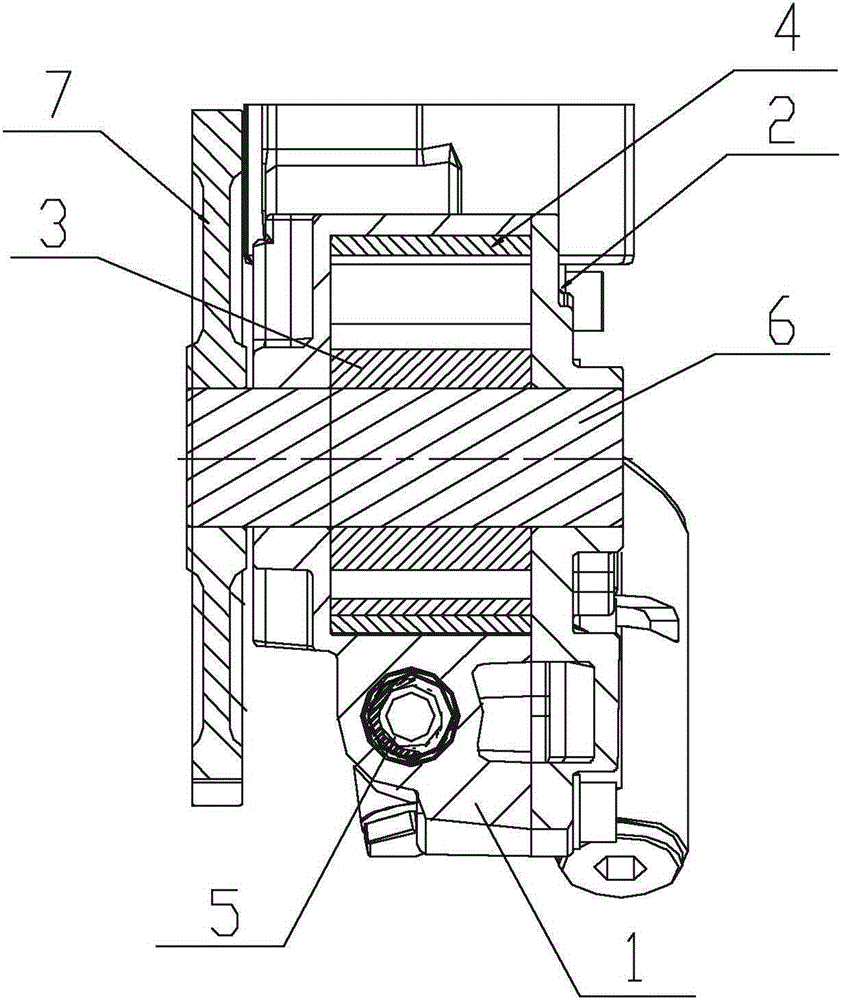

[0009] like figure 1 , 2 A light-duty large-flow oil pump is shown, which includes a pump body 1, a pump cover 2, an inner rotor 3, an outer rotor 4, a pressure limiting valve 5, a driving shaft 6, and a transmission gear 7; the inner rotor 3 and the outer rotor 4 is located in the rotor cavity of the pump body 1, the inner rotor 3 and the outer rotor 4 are made of powder metallurgy, the end faces of the inner rotor 3 and the outer rotor 4 are provided with weight-reducing holes, and the drive shaft 6 One end is installed on the transmission gear 7, the other end of the drive shaft 6 is installed on the inner rotor 3 through the shaft hole of the pump body 1, the pressure limiting valve 5 is an internal discharge pressure limiting valve, and the pump body 1 And the pump cover 2 is an aluminum die casting, and the pump cover 2 is installed on the pump body 1 by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com