Process overload control method for ship unloader and belt conveyor

A belt conveyor, overload control technology, applied in the direction of loading/unloading, transportation and packaging, etc., can solve the problems of slow response speed, large belt flow fluctuation, etc., to reduce equipment damage, avoid production accidents, and reduce flow fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

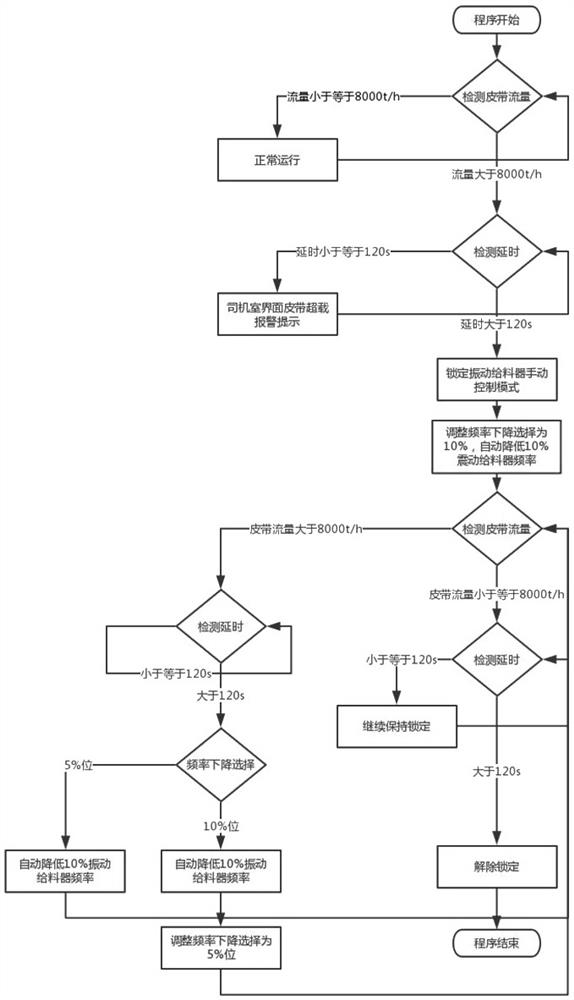

Image

Examples

Embodiment Construction

[0010] A process overload control device for a ship unloader and a belt conveyor, comprising a control code unit, a frequency converter for a vibrating feeder, a programmable controller for a belt conveyor, a programmable controller for a ship unloader, an optical fiber and a switch. The programmable controller of the belt conveyor communicates with the programmable controller of the ship unloader in the form of optical fiber through the switch, and the programmable controller of the ship unloader controls the output of the frequency converter of the vibrating feeder through the control program. The data used include: belt conveyor instantaneous flow signal (real number type), normal mode detection delay time (time type), vibration feeder manual control mode lock switch (Boolean type), driver's cab operation interface alarm prompt (Boolean type), Lock mode overload detection delay time (time type), lock mode normal detection delay time (time type), frequency drop detection dela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com